-

Posts

9,400 -

Joined

-

Last visited

-

Days Won

87

Everything posted by Merle Coggins

-

Your B3C and B4C should have the same size bed, but the bed board layout in the B4 will be a bit different. More boards, and narrower each. The B3B would have the narrower, and shorter, bed than the 3/4 ton versions.

-

For start up you can set the ignition timing to 0, or TDC. Also, double check that you don’t have the distributor installed 180 degrees off. It’s happened to me more often that I’d like to admit.

-

Both switches are robust enough to handle the current for stock wattage headlights, since that's how they were designed to work, as long as the contacts are clean and the wiring isn't adding more resistance (load).

-

Pickup identification challenge

Merle Coggins replied to Vet Doc's topic in Mopar Flathead Truck Forum

I don't know that any trucks left the factory without grill bars, but many got removed over the years for whatever reason. And I was just clarifying your statement, "1950 had painted grille bars as an option" to say that Stainless was the option in '50 and painted steal was standard. -

Pickup identification challenge

Merle Coggins replied to Vet Doc's topic in Mopar Flathead Truck Forum

Actually, the stainless grill bars were standard on all light trucks in the B-1 series. Medium and Large trucks got the painted steel grill bars, with stainless as an option. The change in 1950 to the B-2 series made the painted steel grill bars standard on all trucks, with stainless as an option. -

Pickup identification challenge

Merle Coggins replied to Vet Doc's topic in Mopar Flathead Truck Forum

First one appears to be a '50 B-2, based on the steel grill bars. It's hard to tell from the picture angle, but possibly a 3/4 ton, C model. This one would be the best match up to the body panels on your B-1-B. The second one is a '51-'52 B-3-C. Most of the body panels of this truck will be slightly different than your truck. Hood, nose, and doors are certainly different. Front fenders may be slightly different too. -

Yes, the Vaseline trick works great. I've also used white assembly grease. It helps seal up the clearances in the pump and create a suction to draw up oil, as well as keeping it lubricated when things start to spin.

-

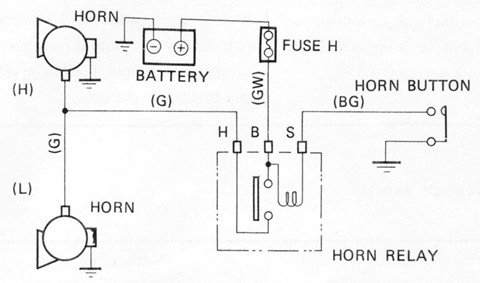

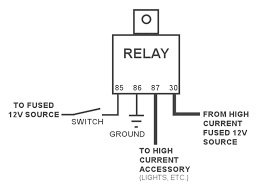

The first picture certainly looks like a horn relay, and you would be correct on the markings. H=Horn, B=Battery, and S=Switch. I don't know how it would hold up to a continuous use, but it may be fine. The other relay looks like a typical 4 terminal relay, but with only 3 wires? Did you say is for your fog lights? I can't see it, but I would assume that the other end of the fuse connects to another terminal input to supply fused voltage? That would make your B and C the 85 and 86 terminals possibly. If the fuse is connected to a second terminal that would indicate, to me, that the 30 and 85 are connected together and the relay is controlled by switching the ground for the coil (86). Pretty much the same function as the 3 terminal relay for the horn. The third relay also looks like a 3 terminal relay, like a horn relay. It's possible that someone wired it up to the high beams to take some amp load off the headlight switch.

-

Yes, the top of the bell housing wraps down in front of the flywheel. Pull the clutch and flywheel, then remove the bell housing. I've never seen a housing brake like that? What would cause that? Top trans bolts come out and put all the stress on the bottom ones?

-

Couldn’t add these photos yesterday, from my phone. Here is the Napa switch I opened up. Notice the black coating on the contacts. I don’t believe the type of brake fluid would have any affect on this part. It could have an affect on the diaphragm under the contact plate, depending on it’s fluid compatibility. A quick rub with Emory cloth cleaned it up pretty quick, but they shouldn’t corrode like that. This is the Standard P/N I am using now. This one is the spare I carry and haven’t needed since making the switch. The box has a “Made in Mexico” label.

-

1950 Dodge B-2-B bell housing and transmission

Merle Coggins replied to Jay's topic in Mopar Flathead Truck Forum

This thread already IS on the truck forum. I’m not sure what Andy was thinking... -

I went through 5 or 6 Echilin brake switches from Napa before I gave up on them and purchased a Standard switch from Rock Auto. Napa switched would last a few months. They kept replacing them under warranty, but it was getting old. I had to keep a spare in the glove box so I could replace it on the road when I’d notice the brake lights not working again. The Standard switch has lasted several years now, and still going strong. The last Echilin one I took out I cut open. The switch contacts were corroded black and wouldn’t pass electricity.

-

If you want to ensure it won't run hot, keep a garden hose connected to the water pump inlet and connect another hose to the thermostat outlet and direct it out the door, or to a drain. This will ensure water flow through the engine to eliminate a heat issue. If you want to get some heat in the block put a shut off valve on the outlet hose and partially close it to restrict/control the water flow through the engine. When I fired my engine up for the first time, on a test stand, I filled the block with water and connected the water pump inlet and thermostat outlet together in a loop. That created a lot of pressure as it warmed up and it started pushing coolant out my rebuilt water pump shaft seal. I quickly ditched that setup and replaced the water pump with a new unit.

-

1950 Dodge B-2-B bell housing and transmission

Merle Coggins replied to Jay's topic in Mopar Flathead Truck Forum

'51 - '53 bell housing should work just fine. '54 and '55 would be considerably different. Also watch the trans bolt pattern. Some are drilled for 4 speeds, some for 3 speeds, and if you're lucky you find one drilled for both. 3 speeds and 4 speeds have different mount bolt patterns. -

How would a set screw allow more adjustment? In my experience, set screws do a good job of damaging threads. And when it does come time to remove the item it ends up damaging the internal threads when threading it out. I would stick with the jam nuts.

-

Visors

Merle Coggins replied to 53 Pilot's topic in DPETCA - Dodge Pilothouse Era Truck Club of America

I'm guessing you are missing the visor board and upholstery? You may just need more leverage to pivot the visor strip around the arm. There are springs, or something, in there to keep it from falling down and without the visor board you may not have enough leverage to overcome them. -

Yeah... what he said...

-

Remove that clutch cover from the bottom of the bell housing. This will give you the room you need for reassembly. After the oil pan is back on you can reinstall the clutch cover.

-

Mine (the short one) is from DCM. It's next to useless, except to balance the look of the truck. Unless I have those larger mirrors on it I can't see anything in the right side mirror. Even with the larger mirror I can't see much in it. As for Kris' long arm mirrors, he'll have to fill you in on them. I think they have been with the truck for some time, but I also remember something about a replacement arm.

-

Big Hemi Express Truck Now that I look at it closer, it is really a ‘57

-

While roaming around the Appleton Old Car Show today I spotted this COE and decided I had to have it... Best $6.00 I spent all day... ?

-

I was struggling to upload photos from my phone while at the show. Now that I’m home, I’ll try again. Here they are, side by side. Got several comments about having them together. We talked to one guy that say’s he’s had a Pilot House truck for many years. It was a daily driver for several years back in the 70’s or 80’s. I don’t recall all the details. He still uses it from time to time, but didn’t feel it was worthy to bring to a show like this. I talked with another fellow that had come across a ‘50 that he was considering buying. He asked a few questions about parts availability. He also noticed my dash plaque from pilot-house.com. I encouraged him to check us out for more information. At the end I think he was ready to pull the trigger on the purchase. The only other Pilot House trucks there today was the ‘51 “Little Red Express” truck that I saw last year. We also spoke with the owner for a bit. And the Cool Bus... (too bad it has a Chevy engine/trans in it) I also liked this Power Wagon bus... Snow days? We don’t need no stinkin’ snow days... We have Power Wagons. We’ll still pick up the kids... LOL!!

-

The heat wave finally broke here, after some nasty storms yesterday. Today is the Appleton Old Car Show and Kris Bolstad and I met up and parked together at the show. It’s a beautiful day today. Nice and sunny, but not too hot. I’ll get pics posted later...

-

I was 2, so I don’t remember it. But I certainly learned much about it in the years to follow.