-

Posts

9,999 -

Joined

-

Last visited

-

Days Won

180

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

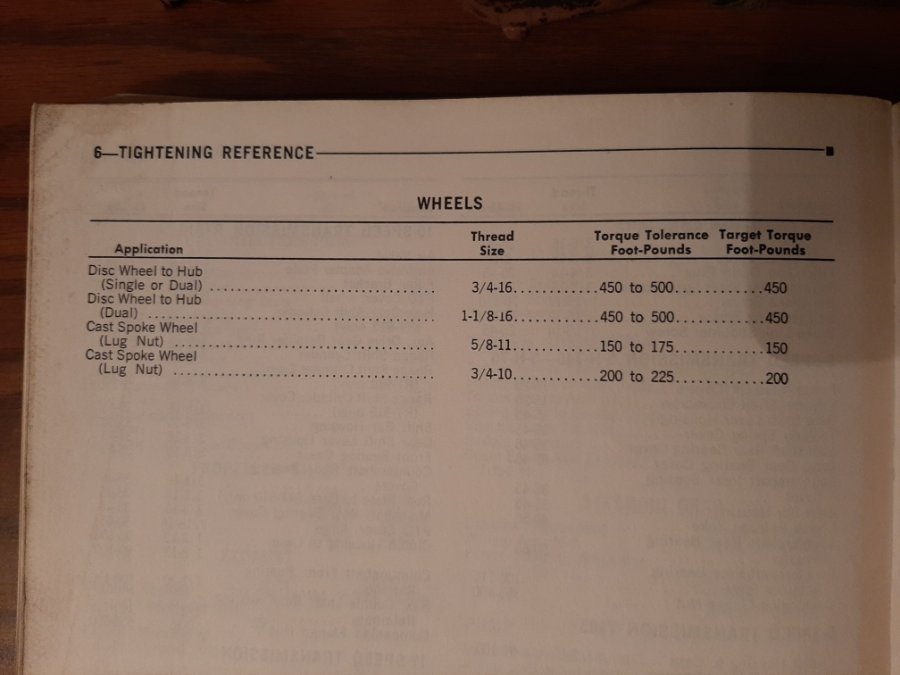

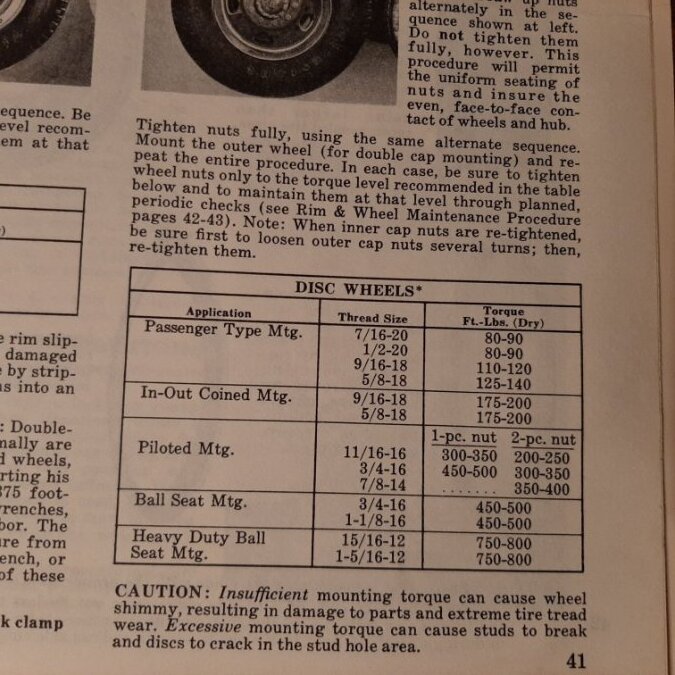

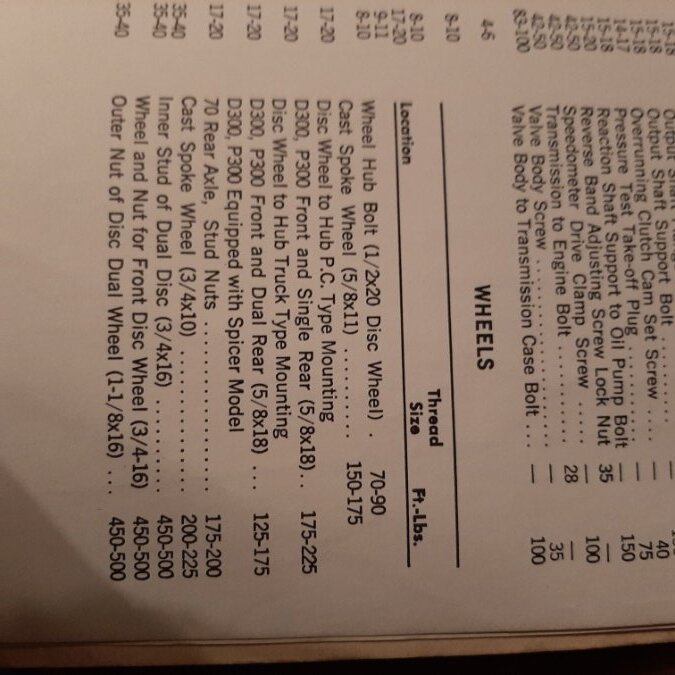

Here are more pics of early 60's Dodge shop manuals lug nut torque specs and lug nut specs out of my Firestone Wheel tech book.... They all come up with the same torque spec on the radius ball seat style nut/wheels like used on all old Dodge medium duty truck wheels. The torque is much higher than the 3/4" X 16 axle shaft nut. That nut tightens up against a nice smooth washer. The 1-1/2" lug nuts tighten against a 1/4" wide radius bevel. This nut bevel is located at the outer edge of that 1-1/2" lug nut hex. Requiring a much higher torque value. Kinda a DOT standard .....especially for a 15-18,000lb truck.

-

Yes that is a typical torque for that size lug nut and stud. That # is off a 1959 Dodge D 600 2 ton front wheel.....same size studs and nuts as yours... Be sure they are tight!

-

How do you install the clutch overcenter spring in 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

If you have the tool or good cardboard copy you use the tool to properly adjust the over center spring turn buckle. -

450-500 lbs. .....1-1/2" lug nuts... 3/4" X 16 tpi hub/drum studs.

-

How do you install the clutch overcenter spring in 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

You have to unscrew (lenghten) the turn buckle to be able to rehook it from the torque shaft to the frame "L" hook bracket. But first...... ...accurately measure the turn buckle original as is length so you can put it exactly as it was from the factory if you have not already changed it. Rotate pic 90 degree's to the left. -

Found my camshaft! - Pulling motor on 1948 Dodge.

Dodgeb4ya replied to Bryan's topic in P15-D24 Forum

That "KD" style valve spring compressor is made specifically for the car/truck flathead engines. A good tool. Of course if the screw is not lubed it will sieze up. Operator error. I have used the exact same KD style one hundreds of times since I bought it when I was 18. ? My favorite go to flathead valve spring compressor. I also have my old "Bluepoint" C-clamp one too. I mainly used it for out of engine work and more modern OHV jobs. -

All 1949-52 Plymouths use the armored cable style ignition switch. The armored cable with the wire lead coming out of it feeds the "-" negative side of the coil.. This armored cable is the "IGN" terminal on the ignition switch. Accessory electrical items like the heater/radio are connected to the "ACC" terminal.

-

Thin Copper Head gaskets for 230 flat head motor

Dodgeb4ya replied to grady hawkins's topic in P15-D24 Forum

Have never seen or heard of one either. -

How can I release clutch from fluid driving plate on 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Well lets see.... Normal non FD stuck clutches are typically easy to break loose. A clutch disc stuck hard to the clutch cover or flywheel on a FD coupling can be really tough to break loose because it is a fluid coupling. If you cannot break it loose dumping the clutch, starting in gear etc.... you will have to remove the large lower cast iron bell housing cover for access to the stuck disc? ...not too easy like on a Plymouth Dodge or DeSoto. You need to double nut the two lower 7/16" transmission studs and back them out of the lower cast pan housing threaded holes as far as you can. Studs remain in the trans. Then there are two 1/2" hex bolts tucked tight right above the cross member...jack up the trans and bell housing just enough for access to unscrew both. Leave them loose in the cover as they will not drop out...space too tight. The other ten or so bolts are easy. The exhaust pipe shield needs to be shoved off to the side. Drop the lower cover. Two ways to unstick a stuck rusty disc... First one is easy and fast if lucky..other way is longer and requires loosening all six pressure plate bolts.. ***Push the clutch pedal to the floor and hold it it place with a stick or what ever..carefully use a putty knife or thin wide screw driver to wedge the stuck disc loose from either the flywheel or the clutch pressure plate. *** If the disc is still really stuck loosen all the PP bolts just about all the way... (make sure the clutch pedal is released)...then attempt to wedge the disc loose. If it's still difficult to get the disc to break free you are in a little bit of trouble as if you remove all the PP bolts the PP will drop down 2-3 inches... it can be some what difficult to get the PP back up and centered to the throw out bearing...and yes now you should be able to break that disc free...? I've been down this road on a few cars including a couple Fluid Drive cars...the last one was a 48 Chrysler T&C 4 dr. Ended up pulling the trans as needed to see how rusty the parts were. Good luck.... -

How can I release clutch from fluid driving plate on 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

It takes a huge amount of force by hand to move the fork enough to release the pressure plate and disc....I couldn't do it. Thats why you need to do it with the linkage hooked up properly. Get it hooked up. It will all work correctly as long as the over center linkage has not been messed with. As for the disc being stuck to either the pressure plate or flywheel...that's a whole different story...you cannot even know if that's a problem unless the engine is running and the trans grinds going into reverse or difficult to shift into low or high range. Maybe need a little more clarification on this clutch problem. Shop is closed now...? -

How can I release clutch from fluid driving plate on 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

You do not need to remove the lower cover to install the clutch fork rod. Just remove the fork push rod ...loosen the lock nut and shorten the rod as much as possible Re-install the rod into the fork recess pocket... then other end onto the torque shaft pin.... The adjust the clutch pedal free play as described in the service manual to 1" -

It would be very difficult to pack the rope seals and trim them properly with the engine in the car. It's tedious even when doing it on a stand. The rope has to be packed/ rolled tight to the diameter of the crank. The ends of the rope need to be cut .010"-.020" above the mating line so the ends crush tight. And a perfectly straight strand free cut too. How ya going to do all this right with the crank in place and on your back ?? I did one recently on a rebuild with the same open difficult back retainer plates. I did what I had to to be sure of no leakage.

-

-

49 plymouth drum brake wheels don't fit disc brakes

Dodgeb4ya replied to 1949 p17's topic in P15-D24 Forum

People today grew up with perfect driving cars and expect the same today. I don't. -

49 plymouth drum brake wheels don't fit disc brakes

Dodgeb4ya replied to 1949 p17's topic in P15-D24 Forum

There were many DeSoto taxi's driven in San Francisco up and down every hill every day...traffic was heavy the too. Today...lining material is wrong and owners don't set them up right...and then drive them everyday to wear and bed them in. -

Buy a 25' roll of copper nickel (Cupra Nickel) 5/16" brake/fuel line. NAPA has it or can order it. Or order online. Get a flaring tool and make a factory like lifetime fuel line. A short approx 10" flex hose is used at the front end of the fuel line to fuel pump. Pictures can be found of this fuel line maybe here and elsewhere online if searching enough or uding the shop manual possibly.

-

There are as I recall four phillip screws holding the latch on the end of the door. Then one more phillips screw under the door panel. The panel of course has to come off. Then remove the inside door handle 23" long link and inner handle pivot shaft. This assembly link and pivot then can be rotated and unhooked from the door latch still mounted in the door. Remove the outside door lock...by using a wide blade screw driver in the narrow oval hole on the end of the door partially hidden under the rubber weatherstrip. There is a retainer clip holding the key outer door lock...use a wide screw driver in the oval door hole and wedge the 1" wide metal clip sideways about 3/8" towards the end of the door ..pull the door lock out. Last step is make sure glass is rolled all the way up.. Then remove the phillips screw at the bottom of the rear glass channel run. Carefully pull channel run torwards the front of door enough so the door latch can be pulled back enough to get it out of the end of door and drop it down while rotating it around the channel run. Remove it from the door.

-

Your door latch is junk. Don't waste your time trying to fix it. The latch star wheel must not be worn or damaged on the front or back sides. Get another "good" door latch and do a proper latch to striker adjustment. The striker plate and spring flipper must not be damaged either. Make sure the door is fit correctly to the body opening. Hopefully the hinges are not bent or completely worn out. A door will close and latch with only a light push...this with good adjustments, plus good latch and striker. Door latches are difficult to properly repair even using the MoPar repair kit.

-

Found my camshaft! - Pulling motor on 1948 Dodge.

Dodgeb4ya replied to Bryan's topic in P15-D24 Forum

3/4" open end wrench shown used for removal of horseshoe clip on rear of the trans internal shoe brake anchor clip .. Use a 13/16" open end on main service brake anchor horseshoe clips. Also shown is the factory Miller tool doing same for removal of main brake anchor clips. -

Found my camshaft! - Pulling motor on 1948 Dodge.

Dodgeb4ya replied to Bryan's topic in P15-D24 Forum

Those horseshoe clips can be easily and quickly removed with a 13/16" open end wrench. -

I think the upper threaded block bolts are 3/8" X 16?

-

Found my camshaft! - Pulling motor on 1948 Dodge.

Dodgeb4ya replied to Bryan's topic in P15-D24 Forum

That pinion nut and flange has been apart before....wonder what they did to the internals?? Probably not much right if the pinion is loose and sloppy. -

That damper (Crankshaft Impulse nuetralizer)is the same part for several years among Dodge, DeSoto and Chrysler cars from 1946-52.