-

Posts

9,999 -

Joined

-

Last visited

-

Days Won

180

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

-

The 1954-56 DT parts book for the 23" and 25" engines show the timing chain and gear sets changed design in 1954. Went from a early type chain and gear style....chain with a center groove guide.... and gears with a center cut groove for the chain guide. The later new replacement chain and gears are made with out the center groove guide chain and no groove in the cam and crank gear. And I believe this later style set is narrower too. This applies to factory Mopar OE parts.... now days replacement cam chain and gears who knows... not me.

-

Those FD couplings are not really that delicate... problems occur with sloppy handling and hanging the trans in the coupling. Dealer mechanics back in the day probably never used wedges when servicing the couplings or doing clutch jobs. I never did either...never had an issue. Now days being how old the couplings are and tough to get repaired properly best to be extra careful with a good one. I think the eight studs on the FD coupling are just that threaded studs....never attempted to remove them but I think tomorrow I will find out as I have a nice Snappy stud removal tool set... see if I can remove them.

-

-

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Marc...Here is what generally the cotter pins and washers if you want look like on the shifter cover.... Here is the steering column end Jesus clip on the adjustable rod end..and the shifter position rod end nut.. -

Pretty amazing some body could break off one or more of the eight 7/16" X 20 FD studs?

-

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

I'm just throwing more out there to confuse Marc more? -

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Oh wait a minute....how many names for these clips can we find... This is what I have officially known them as. -

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Oh Yea...those are the parts you took off and don't remember where they go... Hate it when it happens? -

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Ok..I'm game... I never have.... -

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

This is what a old Mechanic told me was a Jesus clip...when I was a young man.. Removing it ...oh jesus where did it go!? Typical standard cotter pins are used in the linkage rods at the shift cover levers...the rear shift rod pin is pretty thin. You could use those GM linkage clips if you like at the trans shifter cover levers.....not sure if one of those clips will insert into the rear rod. -

Wrist Pin Retainer/Clip - Need Help!

Dodgeb4ya replied to Matt Wilson's topic in Mopar Flathead Truck Forum

You might have to venture 20' in all directions to find it? You might go to a engine machine shop and talk to them... -

Full meal Carter kits are great! Much better than the quick(1/2) kits

-

Does anyone sell the shift rod clips for a 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

What shift rod clips? Cotter pins used at the trans shift cover...one Jesus clip and a 3/8" X 24 nut used at the shift column rod ends. -

-

Tool # 109-195 is used to remove the main vent tube from the underside of the fuel bowl. The "Idle Orifice" tube is removed from the top of the fuel bowl with a slotted screw driver...it also retains the step up piston assembly. As for the main vent tube removal...yes you have to be careful removing and installing it with the tool. I re-use them. never have an issue doing that... Chances of finding new ones...low. Pics of the tool and tube removal...plus idle orifice tube

-

1946 Dodge fluid drive clutch replacement

Dodgeb4ya replied to brooklynbeer's topic in P15-D24 Forum

That alignment tool is not needed. It you are sending the block out just take the clutch, FD and bell housing off. Strip it all down...send the block off to the machine shop. -

1946 Dodge fluid drive clutch replacement

Dodgeb4ya replied to brooklynbeer's topic in P15-D24 Forum

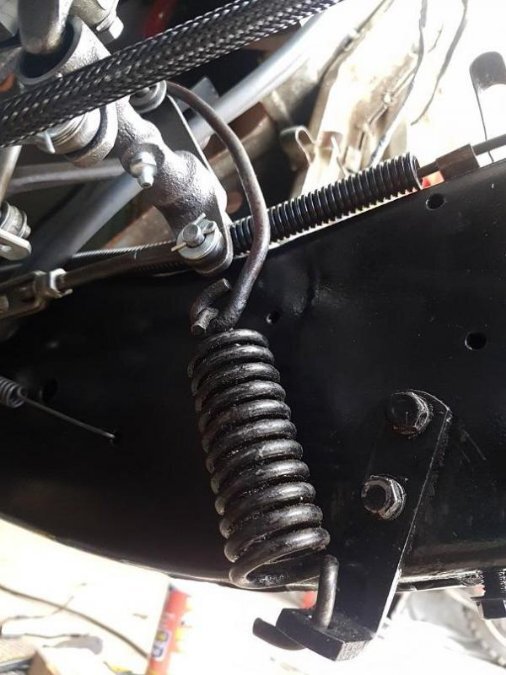

No damage will be done to the FD coupling by turning the crankshaft by hand. This with the FD coupling still attached to the crankshaft and no transmission. To replace the two pilot bushings deep in the FD and replace the clutch disc and clutch pressure plate wedges need to gently but firmly pushed in between the driven plate and coupling housing to prevent "rocking" the clutch driven plate and bellows/graphite seal ring. Excessive rocking movement could crack one or both the graphite seal ring and or the copper bellows seal. If the clutch driven plate on the FD coupling will clean up quickly by hand with say 80 grit sandpaper do that. Otherwise to surface the driven plate it gets complicated very quickly if you don't have the knowledge and special service Miller tools to safely remove this plate. As for the small and large pilot bushing replacement another tool will be needed to pull the bushings out...another to install them properly. The factory bushings fit right and need no sizing after the correct installation. The bushings are deep into the coupling hub. Shown is the Miller Driver tool to install the bushings. A Miller Tool set is used to service these bushings quickly and in a easy fashion. They can be done by a good machine shop with a knowledgeable machinist too. Finding NOS MoPar FD bushings could be difficult. After market might require some machine work .A couple misc pics... -

The gauge has to be tilted carefully one certain way and then it will come out of the cluster... if needed tomorrow I could look and pull one to see which way to tilt it...

-

Some info on the Bakelite KD switch and a carter service bulletin I remembered and found it on hesitation and the check ball info....

-

The master cylinder can be removed from the car without removing the floor board leaving the pedals hanging in the floor board. I have done the 1946-54 cars that way for a long time. A pic showing ready to pull out with pedals and floor board still in car...1946 Chrysler Way too long to take the MC out any other way for me. What's needed is finesse. I realize probably too hard for most.

-

These heavier trucks don't have an abundance of power on hills....especially the 237ci models. Be careful as to how tall of tire you run.

-

I have had that ball come out of a EV1 and a couple other Ball and Ball carbs. Another note ....the original two balls...the small and larger accelerator pump check balls were made of stainless and ...Monel? I think the inlet ball was Monel.... The outlet was stainless. Today all you will get is stainless. It's critical these balls seat and seal properly for full accelerator pump operation.

-

Are you missing the small steel ball swaged into the drilled accelerator pump passage way discharge hole? If the ball is missing fuel will flow out of this hole instead of into the accelerator pump removable jet and venturi discharge hole. Also no ball is placed into the idle vent passage. Maybe the 3rd ball is what should be placed back into the open accelerator drilled passage hole? See pictures....

-

I never use tape on any threaded assembly...hate dealing with stringy threads of it during clean up..it can shred on old corroded block threaded holes. For years I have used Permatex #2 non hardening paste on all threaded assemblies into coolant and oil passages. We all have different solutions...