-

Posts

1,695 -

Joined

-

Last visited

-

Days Won

21

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by John-T-53

-

Hubcap Red Lettering Touchup Paint

John-T-53 replied to FlashBuddy's topic in Mopar Flathead Truck Forum

I got a pint of one-shot red for this purpose. it's more orange than the original paint, but works for me. It flows really well and lays out really niiiiice. First time using One-Shot, already a huge fan.- 21 replies

-

Very nice! You should move that into the living room for display 'til you put it in. And put xmas lights on it.

- 371 replies

-

- 2

-

-

11th Annual Clements Tailgate BBQ, in Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Glad to see this continuing for another round! Count me in as usual, my truck is already in the 'hood. I met a Volvo mechanic in San Mateo that is restoring a power wagon and he is already talking about coming (with wagon). There are also supposedly a couple other hard core Mopar guys that will be coming from the local area out there...I think they live somewhere down Jack Tone....or maybe Linden....Will have to check with farmer Steve again. -

That element looks like it could be made from one of them mineral blocks you put in a parrot cage.

-

The iron duke is a Pontiac engine.

-

The iron duke's still power the USPS delivery vehicles. There are thousands still roaming the streets daily. When the USPS replaces these vehicles with the next generation, there might be a surplus of used and abused 'dukes available, if you're into that sort of thing....

-

-

Except for.....protecting YOU from THEM... Which is part of the plan.

-

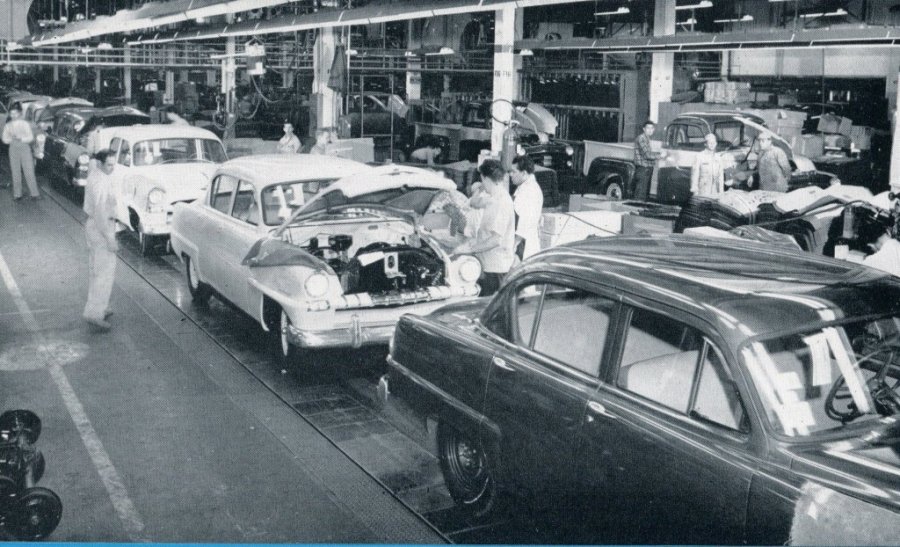

California Assembly Plants: Where, What & When?

John-T-53 replied to 49D-24BusCpe's topic in P15-D24 Forum

I wouldn't want to be stuck in that neighborhood after dark... -

Maybe he'll post some when not under fire...

-

California Assembly Plants: Where, What & When?

John-T-53 replied to 49D-24BusCpe's topic in P15-D24 Forum

San Leandro...The buildings still stand. I visited here a few years ago on a tour of Olsen Steel (non knowing the building's significance at the time). In the back of the taller building is Drake's Brewing. -

Me too.... I hope that someday you will find peace in your life.

-

These engines had a highly advance oiling system for their day. Speaking from real world experience, the most important thing that one can do, if undertaking a rebuild, is to maintain specified tolerances throughout, and have quality machine work done. Good crank grinders are getting more scarce these days. It's imperative to have a crank grinder, with a good crank grinding machine, that knows how to size journals appropriately to the correct limit range based on the bearings that he should already have in hand, which will ensure even oil supply across all journals. If I were to attempt any improvements in the oil system of one of these motors, I would examine the pan baffling and perhaps look at adding full-flow filtration.

-

I didn't know these guys were crank experts too? I though George was the expert on carbs, manifolds, and overdrives. And Tim is the new guy taking over George's business...? Agreed that the original poster is right in not feeling the desire to cross drill is crank. These engines are low revving motors...good up to about 3500, they should go up into the 4k - 5k range, even if possible.

-

You're making some nice progress there! That's one hell of a good lookin' motor. I love the simplicity of the block design.

- 371 replies

-

- 1

-

-

Check out this flathead goodie!

John-T-53 replied to 59bisquik's topic in Mopar Flathead Truck Forum

So it's an F-head conversion. Intakes are overhead and exhaust is thru the block. I didn't see any details photos on the linked page of how it works exactly, but I'm curious, especially how they get an OH intake valve to operate given the existing cam and lifter positions... I only recall an F head in some of the Willys engines of the early 50s, notably the Aero. -

Check out this flathead goodie!

John-T-53 replied to 59bisquik's topic in Mopar Flathead Truck Forum

Might you have a link to the page? Looks like Earl Edgerton's FI setup. Is he selling them now? "The price would gag a maggot"....haha. Would it also harelip the Pope? BTW, I sure home Earl and his shop made it through the firestorm ok. Santa Rosa and the surrounding area got hit hard - I think like 5,000 structures burned completely and over 40 people killed. -

Valves, springs and guides... (oh my)

John-T-53 replied to Brent B3B's topic in Mopar Flathead Truck Forum

You have to drive them out from the top with a pilot drift and a BFH. The pilot must be slightly smaller in diameter than the guide so you don't mushroom the end of the guide, and so you can drive it through the bore. You can make a pilot quite easily if you have a lathe. A good piece of stock to start with is a differential cross shaft, or a king pin. Pound away, you can't really hurt anything as long as the pilot doesn't slip and you don't hit anything else. It takes quite a few blows, you'll only moving the guide about .030" - .050" at the most with each blow. You can break the guides in half when they've been driven half way through with a cold chisel and your trusty BFH, or a reciprocating type "saw thing" like Brent used. Only need to do this if the lifters are in place. Good luck!!! -

Replacing rear main seal on 1950 Meadowbrook

John-T-53 replied to frcc16's topic in Mopar Flathead Truck Forum

How bad is the leak? Do you know what type of seal is in there currently? If rubber, perhaps some ATP-205 additive might help. And / or, "high mileage" type of oil. Unfortunately, the rear main seals on these motors like to leak, even when new and with a polished crank. Often, you will see corrosion pits on the crank surface which a new seal won't fix. See photo below, above the thrust collar. Pits. -

Replacing rear main seal on 1950 Meadowbrook

John-T-53 replied to frcc16's topic in Mopar Flathead Truck Forum

-

Replacing rear main seal on 1950 Meadowbrook

John-T-53 replied to frcc16's topic in Mopar Flathead Truck Forum

-

Replacing rear main seal on 1950 Meadowbrook

John-T-53 replied to frcc16's topic in Mopar Flathead Truck Forum

-

Replacing rear main seal on 1950 Meadowbrook

John-T-53 replied to frcc16's topic in Mopar Flathead Truck Forum

Rear main seal replacement is tricky. I'd pull the motor, mainly because I'm sick of laying on the ground. You'd have to unbolt the transmission and remove the bellhousing and flywheel for proper access. You have to remove the timing chain so that the crank can be moved down for clearance. The good news is that you can leave the connecting rods bolted in place, and the pistons will all slide down in their cylinders. Trick is not to move the crank to the point of the rings snapping out! This is at least for a two-piece modern seal. You need to take these steps so that the seal can be properly glued into place. Without sealant, it's a waste of time. Also, I'm Not sure about a rope seal, that's a different animal. See pics below for a recent rear main seal replacement on a 251. -

Yes.

-

That wheel looks like it failed due to a combination improper attachment, or loose lug nuts while being driven. Corrosion may have also played a role if areas were severely weakened to begin with. This wouldn't normally occur on a wheel just because it's stamped steel or stock.