-

Posts

1,647 -

Joined

-

Last visited

-

Days Won

19

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by John-T-53

-

Is the cutout relay on the regulator stuck closed? It should open when the IGN is OFF or otherwise low charging condition (to prevent the battery from draining. Also, if the ammeter moves when you rap on the gage face that might signal loose connections at the back side like others suggested. How old is the battery? It might be part of the problem. take it down to NAPA and have them test for a bad cell. Was the generator polarized if it, the regulator, or battery was disconnected? I recently went through all this with my regulator, let me find pics when I was using my current and volt meter/tester and remember what I did... In short, you need some instruments to find out what's going on here.

-

I never thought about comparing the flathead six to a "lawn mower engine". I can't think of one thing they would have in common other than gasoline and four strokes. Regardless, the old hemi in this C-series is totally cool. A Briggs & Stratton V-twin in a Pilot House pedal truck would be the cat's a**!

- 371 replies

-

- 3

-

-

-

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Thin ice, boys....thin ice....haha -

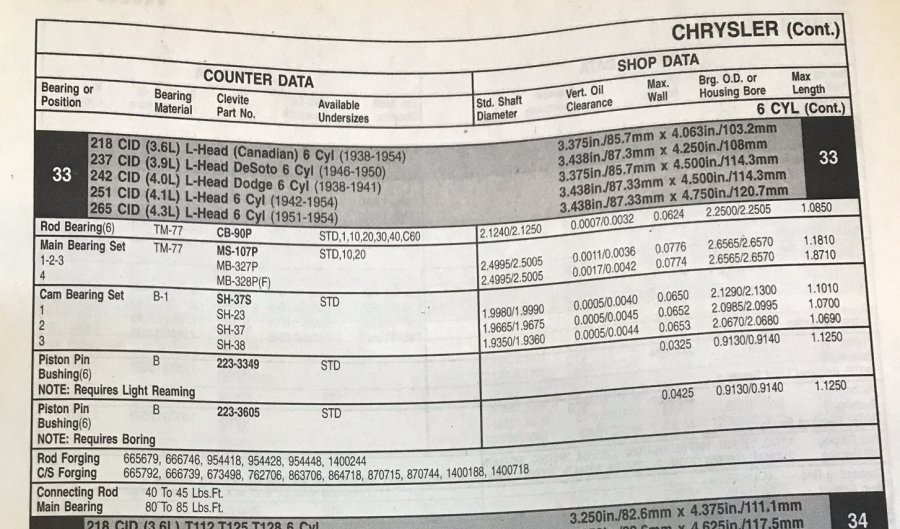

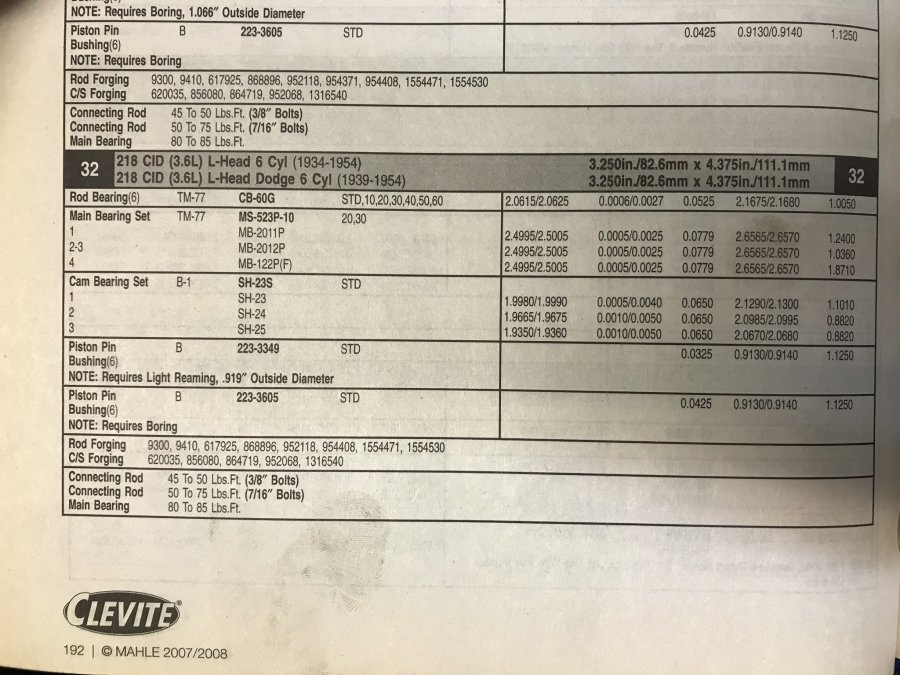

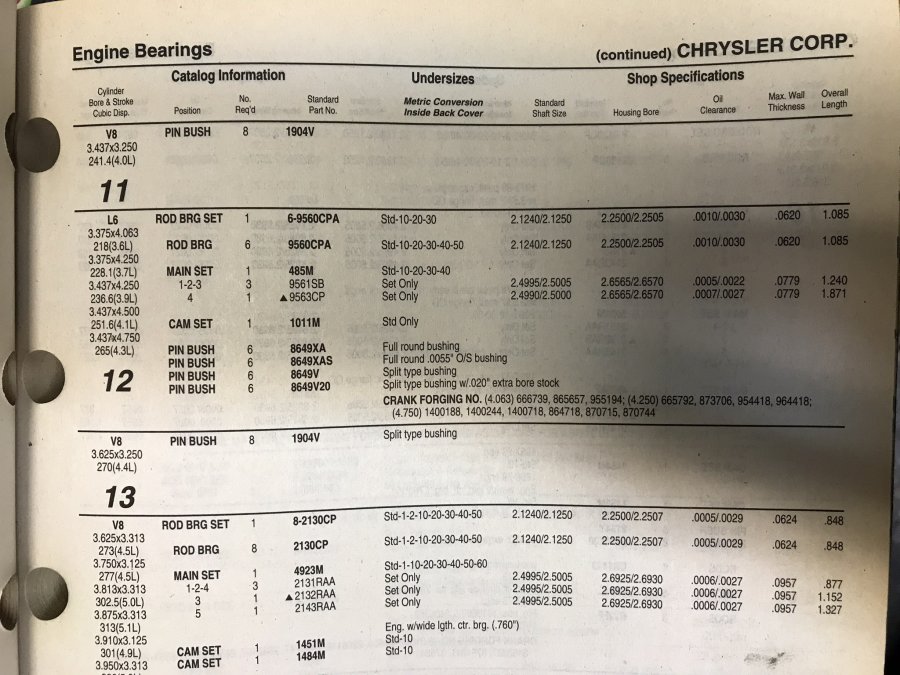

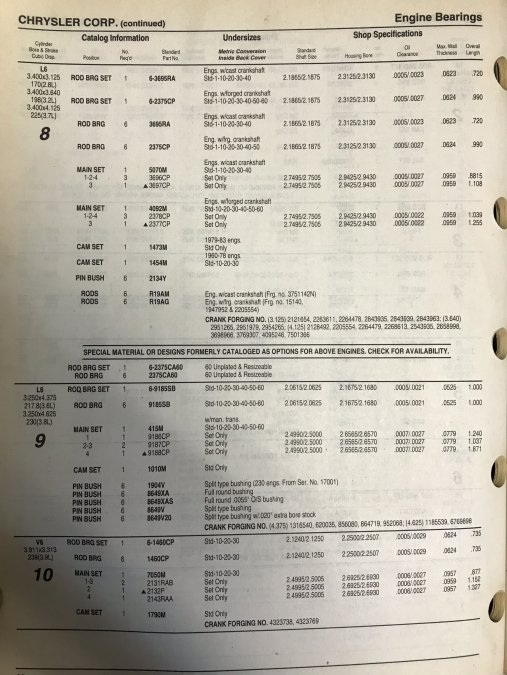

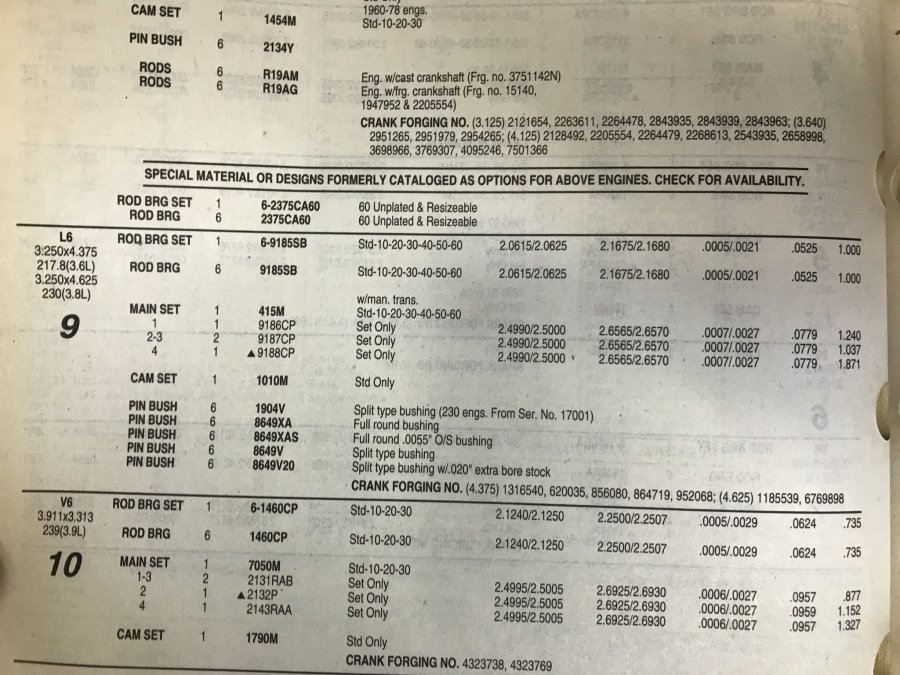

As for the .001" incremental bearings, I think that's the point of view from which Tim was making in his first posts. These were used at the factory and with new cranks purchased as replacement parts, because, factory-ground cranks weren't exactly perfect. Thus you had the availability of these bearings for "saving an engine" or crank as-is instead of having to regrind it (or discard it). And in these instances, the bearings were "sized" to the (already finished) crank journals. This made sense back in the 1950s when the market for these engines was huge and you could easily get these special bearings. Nowadays, building such engines is an entirely custom job and you wouldn't normally approach setting up your crank like this. If you're building a modern racing engine, that's a different story.

-

-

-

-

-

Build Thread : Volare front end Experiment...

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Daily driver status....I like the sound of that...talk about domestication and what-have-ya....Drive the Brick out to Cupertino for MOPAR ALLEY in June. -

You must be 'Phelan high' being behind the wheel of that jewel once again!

- 371 replies

-

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

The goal was to create the illusion of work being done...water was being moved more vertical than horizontal by that rake. I made a note to bring tools and implements with me for next year, haha..... -

Oh I thought we were just talking about rods? LOL From my experience I would think this is a rare practice...usually done in .010 increments from my experience. I'm actually heading down to the machine shop this afternoon and I will get their input.

-

I more or less agree; just the quoting and terminology is getting skewed a bit here. I didn't say that a machine would size a bearing...I don't know what that means. Can we still be friends?

-

"a machine ship will grind the journal to stock if built up and returned to standard....." I was referring to grinding to the next step undersize. Cranks are readily available for our flatheads so I would not recommend welding all the journals on a crank to bring it back to STD. It's easier to get a less worn one if your crank is garbage. Besides, by the time it gets up there towards the wear limits you are usually dealing with cracking and other flaws. If it just has one bad journal, though, that's a different story. Or if you have a rare crank... "they will go in exact increment undersize from there....the bearings are made for the journal as per the specification of the BLUEPRINT from the original builder....." Correct as stated previously. .010" under, .020" under, up to .050"...and the bearings are harder to find as you increase thickness. "IF however you micro polishing a journal that may be a bit work..." Nobody would attempt using a polishing machine for removing that amount of material. If attempted, the journal would be out of round and the side radii not right. Polishing is just the final step after grinding. It might remove a few tenths (.0001) at the most, but you have to use the right belts. "you can get special bearings to take into account this usually in .001; .002 ; or .00 and then for under size of .010 and appreciative wear from there....012." I have not heard of undersize bearings (for our engines) available in increments of one thousandth of an inch, just increments of ten thousandths. "I would not want/pay a machine shop to just polish journal to a random mixture of measurements...." Why would you want that anyway? I'm sure that most shops are not dumb enough to do this and would educate any customer requesting it. Cranks are ground so that all journals are the exact size. Rods are honed in the same manner.

-

It's a mutual relationship... I'm not sure how you'd size a bearing other than selecting a particular size from a parts dealer. They are not modified in thickness. Sometimes shimmed, sometimes trimmed at the edges (custom applications mainly). By sizing a journal I'm talking about grinding and polishing (on a crank grinding machine).

-

There was factory clearance at the rod journals. There needs to be clearance otherwise it wouldn't spin. Per the manual the clearance should be .0005" - .0015" Therefore, for a STD journal size would be 2.062 to 2.061" If it's been ground .010" under, then 2.052 to 2.051". You can keep subtracting for every .010" thereafter... Journals are sized provide the correct clearance for the bearings that will be used.

-

Is it a radiator, or a wall hanger?

John-T-53 replied to Los_Control's topic in Mopar Flathead Truck Forum

It appears that the fan blades impacted the core...if that's the case I'd bet that the tubes have been compromised too. I am generally not a fan of aluminum parts in cooling systems because it is more susceptible to corrosion from electrolysis, and can't be fixed like copper/brass radiators. -

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

I think this year it would have been John, with Kevin coming in at a close second. There has also been an Estrada family member whose beard has been likened to "Mohammed style", in the past... Yeah...BEST BEARD should be a category for next year. -

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Does this mean that the one ton is coming again? -

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Add me in on that too! Will trade for drive in mine... -

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Keeping an eye on the rain....the weather keeps going back and forth about rain or clouds or both on Saturday. As of now it says rain on Friday and overcast on Saturday. A rainy Friday will get in the way of our cleanup and mowing day... -

- 29 replies

-

- 1

-

-

- heater valve bypassing

- heater valve refurbishing

- (and 11 more)

-

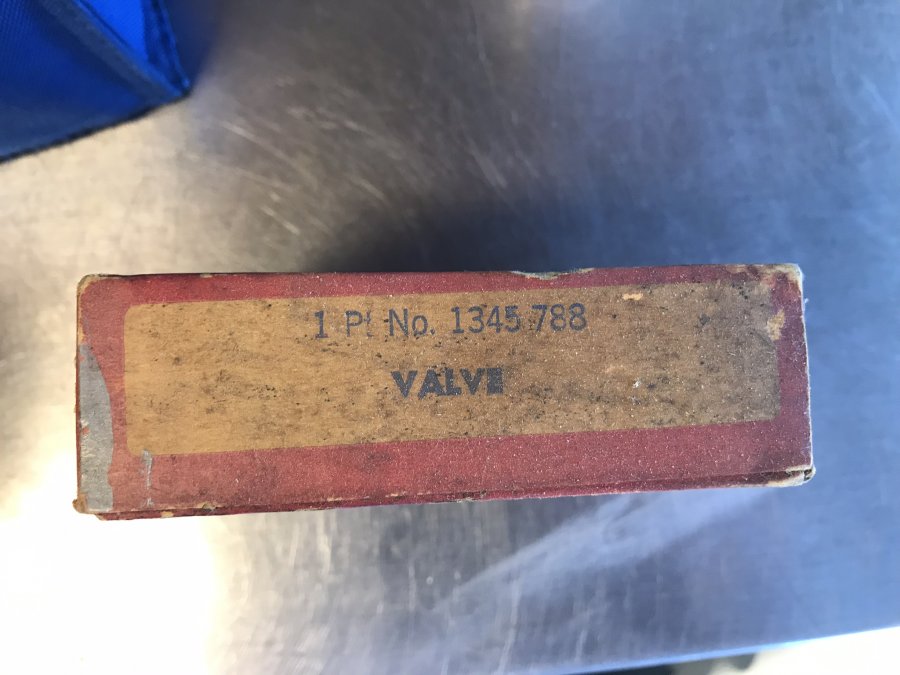

Sticking valve in a rebuilt motor

John-T-53 replied to 41/53dodges's topic in Mopar Flathead Truck Forum

Were the tappet covers removed? If so, any corrosion or varnish may be evident on the valve stems in the closed position. If considerable corrosion is evident, it should also be present on the other interior surfaces of the motor. Take some photos of the tappet chamber and post them here. -

Sticking valve in a rebuilt motor

John-T-53 replied to 41/53dodges's topic in Mopar Flathead Truck Forum

What are the guide to stem clearances that were set? I believe that the spec calls for a pretty tight clearance (.001 - .002" or so if I remember correctly - just guessin') and the exhaust is a tad looser than the intake. This leaves little room for slippage if any foreign material, gum, or varnish gets in there. I'd try applying some extra lubricant as others have said. If it still gives you trouble you might have to remove the head and valve and 'kiss it' with a guide hone. I too had a sticking valve after doing a valve job a few years ago - on the way to the BBQ actually. it happened on the side of the freeway. Luckily it popped back with a screwdriver and didn't stick again, and I was back on my way shortly. The culprit was a speck of metal or something - it scratched the stem. -

12th ANNUAL CLEMENTS TAILGATE BBQ, Clements California

John-T-53 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Beer is handled, so bring PUMA. Given today's standards, you could have her as your emotional support animal on the plane!