-

Posts

2,058 -

Joined

-

Last visited

-

Days Won

9

Everything posted by Jerry Roberts

-

1947 Dodge WC - Best rear end gear ratio?

Jerry Roberts replied to Forrest's topic in Mopar Flathead Truck Forum

I am using the stock drum e brake on the back of my transmission . On my Dakota rear end I saved the rear cables in case I ever want to change things around . Where the cables entered the backing plates I installed bolts to just plug those holes . 3.55 is good if you have any hills to climb . -

Red for positive .

-

My Auto-Lite book doesn't go back to 1937 but here is the info for 1938 ; Distributor IGS - 4003 B-1 is for 1938 Plymouth P5 or P6 or PT 57 . Individual Auto-Lite part numbers are : cap IGC - 1107S , rotor IGS - 1016B , contact set IGP - 3028A , condenser IG - 3927G , breaker plate assy IGS - 2004 .

-

My son has started our Scarebird conversation

Jerry Roberts replied to medium_jon's topic in P15-D24 Forum

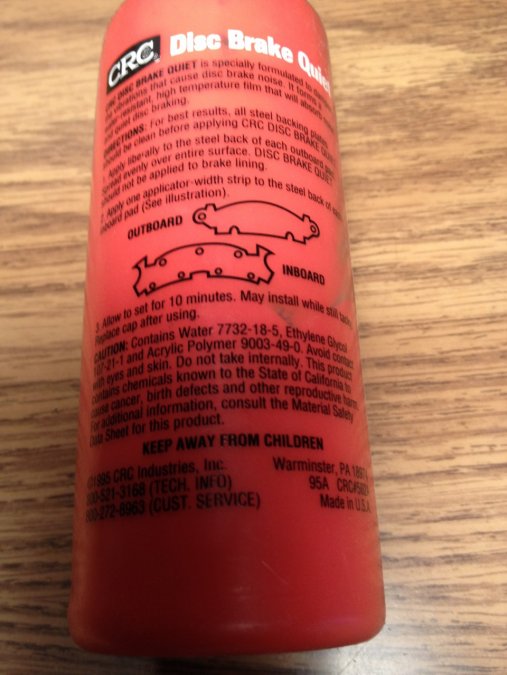

It has been many years since I have made a living installing brakes back when disk brakes were just becoming very popular . Back then I would put the goop on every pad every time . If I didn't use the goop , very often the noise was a very terrible screech , not just a rattle or a click . Perhaps times have changed and parts have improved . Of course all sound is vibration . Does anyone else still use the goop ?- 99 replies

-

- 1

-

-

- conversion

- scarebird

- (and 4 more)

-

My son has started our Scarebird conversation

Jerry Roberts replied to medium_jon's topic in P15-D24 Forum

- 99 replies

-

- conversion

- scarebird

- (and 4 more)

-

One member reported excellent results with Tuff Stuff found in Walmarts Auto Department or O.Reillys .

-

My son has started our Scarebird conversation

Jerry Roberts replied to medium_jon's topic in P15-D24 Forum

Right , He said Chevy CALIPERS and in my minId's eye I was seeing Chevy DISKS . My mistake .- 99 replies

-

- conversion

- scarebird

- (and 4 more)

-

My son has started our Scarebird conversation

Jerry Roberts replied to medium_jon's topic in P15-D24 Forum

" ... The calipers for my Scarebird Disc Brake conversion kit were specified to be Napa 442-2046 and 442-2047 whose application is 1983-92 (Chevrolet) S10 ..." So will you be running Chevrolet rims on the front and Dodge rims on the back ? Carry two spares ? Buy the special rims that will fit both bolt patterns ?- 99 replies

-

- conversion

- scarebird

- (and 4 more)

-

My son has started our Scarebird conversation

Jerry Roberts replied to medium_jon's topic in P15-D24 Forum

Did you put any of the anti - rattle goop on the back of the pads ? You smear it on and let it get semi dry . Better safe than sorry .- 99 replies

-

- conversion

- scarebird

- (and 4 more)

-

From an old post ; George Ash 814-354-2621 Edit make that Asche not Ash .

-

Did you see the aluminum radiator on ebay ? item number 162555758432 at $342 . Located in Michigan . Perhaps you can sell some of your other old parts to help pay for it .

-

Also some members have reported better temps with an adjustment of the timing . Looks like you may have solved the problem anyway .

-

" Maybe I'll go to the dump and pick up an old mattress to lay under the car. When I'm done take it back. " I wouldn't do that , you might pick up some ' cooties ' too .

-

" I was hoping to hear from other vintage Mopar owners with the L6, and their temperatures. " My 218 runs at 160 degrees usually , 165 - 170 if I am stuck in traffic . My thermostat is a 160 . My radiator is aluminum and my hood is vented . You mentioned that some engine work was recently done , if your engine is ' tight ' your temps might come down a little when the engine parts are broken in . Some members have brought their temps down a little with Water Wetter .

-

I have a steering wheel that might have come from a Pilot House truck , It is marked with the mopar logo and part number 1194926 . Can any one verify that it is from a pilot house truck ? 18 inch diameter .

-

See ebay . I don't know if this is what you need or not . eBay item number: 162075671503

-

46 P15 new water pump bypass elbow & tube ?

Jerry Roberts replied to 3046moparcoupe's topic in P15-D24 Forum

The head is marked HEATER at this spot . -

I just had four new tires put on my vehicle . I left my hub caps at home because I spot glue them on . Also when I got home I checked my tire pressure and all of the lug nuts for over tightening . No problems .

-

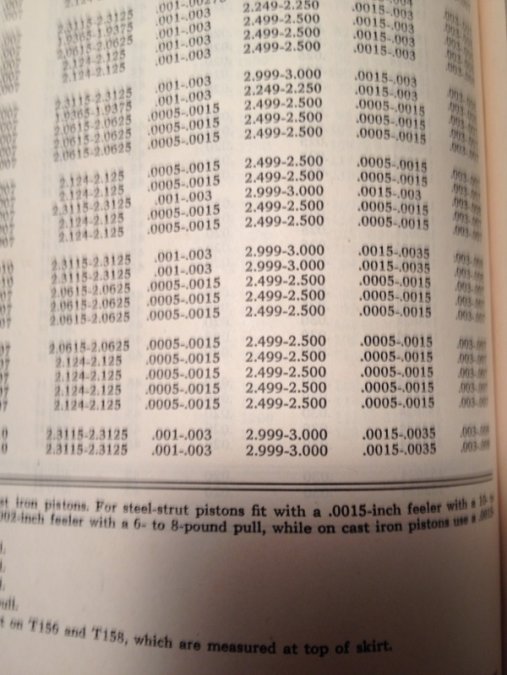

I don't know if there is anything here that will help . This is from a very old Motors Truck & Tractor Repair Manual . I see that for the 1937 1/2 ton truck that the engine model number is T38 . T23 , T25 , T68 , T92 , T105 are 201 engines . T38 is a 218 engine .

-

There has been some discussion on the forum before on having the ball replaced or repaired . Some people have found that the machine shops don't want to do this repair as it is such an important part safety wise . If you can't find one anywhere else try Rare Parts in Stockton , Ca . 1-800-727-8740 . www.rareparts.com EDIT ; The link isn't the correct business , you might have to type the address into your server .

-

-

I am thinking a heli-coil would be best or you would have to enlarge the bolt hole in the head .

-

Does your clutch work ? If not , you can easily remove the clutch cover and look things over while someone else applies the clutch pedal . See what moves and what doesn't move when applying the clutch pedal . Block the tires so that the truck doesn't run over you .

-

Well into Season, but car refusing to cooperate.

Jerry Roberts replied to mlozier76's topic in P15-D24 Forum

The two parts just snap together with the bearing in the middle . I once bought about 20 of these plates that were NOS . Almost all of them had to come apart so that I could lubricate the dried out grease in the bearings . I gently pried the two parts apart with a screwdriver , lubed the bearings , and snaped them back together . Sometimes with just finger pressure and sometimes with pliers .- 13 replies

-

- 1

-

-

- distributor

- starter

-

(and 2 more)

Tagged with:

-

You might try setting your timing with a vacuum gauge . Try for the highest steady reading . And of course you can use the vacuum gauge to adjust the carb too .