-

Posts

113 -

Joined

-

Last visited

-

Days Won

2

bartenderfloyd last won the day on March 21 2022

bartenderfloyd had the most liked content!

Reputation

62 ExcellentProfile Information

-

My Project Cars

1950 Plymouth Special Deluxe

Converted

-

Location

New York

-

Interests

Cars

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I was going to say the same thing Eneto and Los Control said. The thread Eneto linked was the one I used to get an idea on how the rockers were supposed to look and connect. I have a 1950 though so I had to improvise a bit. I also used Fitzee to learn how to weld sheetmetal and get rid of rust. https://www.youtube.com/@fitzeesfabrications. The smallest steel I was used to welding was 1/4 inch thick. Fitzee showed me how to weld 18 gauge. I had to practice for a few days but it wasn't that bad as I didn't want the car perfect, just to look good. I had the same issue as you with the rusted body mounts. My frame was in great shape but the rockers disintegrated. Check out my thread. I welded a 2inch by 3 inch square stock pipe from the front to the back on each side of the car. Attached it with steel plates. I used that as the base to weld the floors and rockers.

-

Wow. It's beautiful. Great job!

-

I had never heard of this. I've been doing this all weekend and not 1 grind. It has been eliminated. Thank you for suggesting it!!

-

Can't wait to see it in action!

-

ANSWERED Sad ending to first outing...

bartenderfloyd replied to SwannySwanson's topic in P15-D24 Forum

Same thing happened to me last year. Seemed starves for fuel a few times but I thought it was low gas in the tank. One outing it died and it was the pin in the fuel pump that worked its way out. 10 minute fix with some jb weld to make sure it never wiggles its way out again. -

Setting timing 1949 Special Deluxe. (Pointer MIA)

bartenderfloyd replied to Oliver Klozoff's topic in P15-D24 Forum

-

I've been using the Fram with no issues. https://www.amazon.com/gp/product/B000C31J4G/ref=ppx_yo_dt_b_search_asin_image?ie=UTF8&psc=1

-

I used strips of cardboard to measure. Like the first pic. Then laid it flat and cut the rug. It is by no means perfect but it is light years better than it was.

-

I had a lot of pics in my rebuild thread here. I have lots more pics I didn't post so let me know if you need more.

-

I spray glued those pieces in my 50 Special Deluxe. Like you I was looking to learn. That was how my old headliner was attached.

-

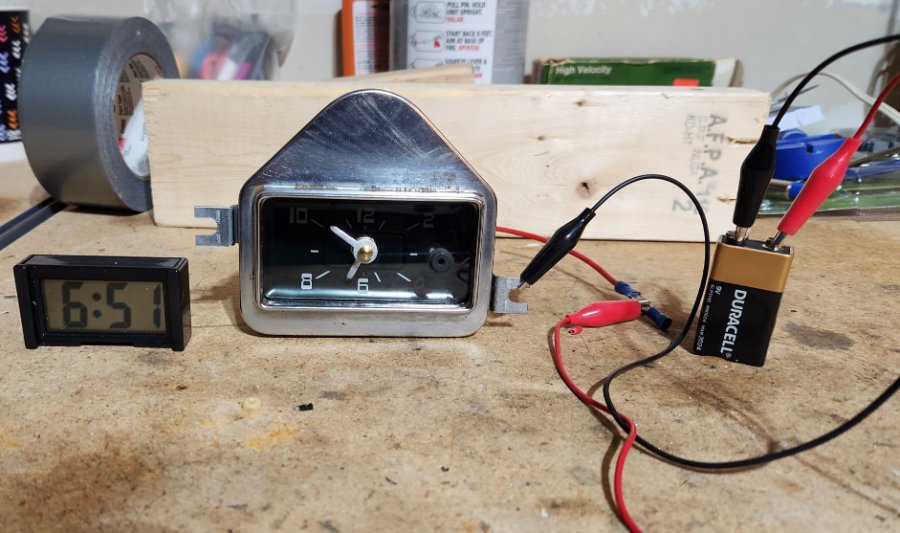

Update on the clock. I cleaned it up but it must have had a bad electromagnet so I figured I'd take it to the local clock repair to get it replaced. Naive me thought they were going to actually get a replacement electro magnet, clean up the old clock and get it to work. No luck. I discovered that all they do is wait for an old clock movement to come in to their "supplier" and they just replace the guts with a working one. I could have done the same thing buying a used one off ebay. So I moved on to plan B. As I've stated in previous posts, I'm ok with things not being original. I replaced the movement with this https://www.amazon.com/Torque-Movement-Mechanism-Different-Length/dp/B07KZRVVWP/?_encoding=UTF8&pd_rd_w=R2GH6&content-id=amzn1.sym.b4f172f0-a2ab-4ffa-ac9d-22e96231ca8e&pf_rd_p=b4f172f0-a2ab-4ffa-ac9d-22e96231ca8e&pf_rd_r=EK8VZPNEZTZKA5DX03D5&pd_rd_wg=V496a&pd_rd_r=19950c76-a48f-4eba-b424-1c6ff8cb0318&ref_=pd_gw_ci_mcx_mr_hp_atf_m. But not wanting to have to change the batteries, I wired in a buck converter to step down the 6v power to 1.5v and now I can just wire it in the car. I also got those on amazon here https://www.amazon.com/LM2596-Converter-3-0-40V-1-5-35V-Supply/dp/B08NV3JCBC/ref=sr_1_1?crid=17Z4GZCQWUZHI&keywords=buck+converter&qid=1675642909&sprefix=buck+converter%2Caps%2C98&sr=8-1. It's not perfect but it now tells the time more than twice per day. Here's the finished product.

-

Has anyone tried the one at Bernbaum? https://www.oldmoparts.com/parts/g_service_brakes/front-disc-brake-converstion-kit-for-1949-1954-plymouth-dodge-wayfarer-10-brakes-and-standard-transmission/

-

Awesome car! Welcome!

-

I went to Michael's for everything. Batting and fabric.

-

I ordered floor pans from him last year. The quality is excellent and he is really nice. He does have issues though getting parts. Also, if you are looking for floor pans, I would do them myself. While the quality was great, they were nothing I anyone with the skill to install them could not make themself.