-

Posts

3,462 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

Here’s the stripped down simple, quick explanation: The manufacturer has several silos within their corporation. The glue crew is just responsible to make the glue. They are not to concern themselves with what’s going on over in packaging or procurement departments. The packaging team has a different set of KPIs (Key Performance Indicators) to get their annual bonus. They are to package-up the glue as cheap as possible and maintain a higher level of profit than the glue crew. If the glue crew can hammer out 100O liters of glue per day for 365 days per year average, they get their annaul bonus. The fact that they only work 5 days/week is factored-in. Procurement people are to buy the supplies for the glue crew to actually make the glue. They factor-in 85% production machinery uptime and production. They also need the supplies to arrive “just in time” for production so there is no inventory costs. Quite often the supplies arrive late so the glue crew comes on on overtime to meet their weekly production target. The procurement team orders enough supplies to make about 850 or so litres of glue per day. Yet the whole supply chain has never really recovered from covid and a shortage of workers. So the glue crew can’t meet their target and won’t get their annual bonus. The supply chain team blames the packaging people for not getting all of their annual bonus. Packaging costs are too high. The packaging team switches to bulk purchase of UHU glue stix to secure the branding labels. Not only saving money, but the environment too. You see the UHU sticks are water soluble and do not come from a cobalt mine in Uganda. Meanwhile they only get 25% of their annual bonus. Yet they are salary not hourly employees. So no overtime. The accountants withold un-realized losses this quarter to keep stock prices up. Meanwhile the executives are up in the boardroom celebrating massive profits. Each of them getting 200% of their target bonus for the year. Perhaps a 3rd recreational lot is in the cards later this year. Simply, this is why the label falls off.

-

The story goes: I wanted a brake tool. I did not want to pay the premium for an original. i saw some ideas on line and here. I worked with my friend who has machining equipment. He made me one. I offered a few ideas for improvements. He has some ideas. He made another one. I thought we had it dial’d in. He and I worked together to build and sell many of these brake tools. I shipped them all over the world to Moapr lovers everywhere. Unfortunately Mopar Pro bought one and reverse engineered it. He copied it 100%. I challenged him on it and his response was pretty low. He mass produced them and sells them on E-bay. I believe he also supplies them to Bernbaum. Its a free country. There’s not much I can do about it. I stopped making the tool. I figure, maybe a good way to get even is show the world how to build their own tool. Lol. Spread the word folks. Maybe we can cut his sales by 75%. ?

-

Sure sounds like a fuel supply problem. Start with some diagnostic testing. What is fuel pressure at carb inlet? Put a vacuum gauge on intake manifold port. Check vacuum as adjustments are made. Is carb responding to A/F adjustments, effecting vacuum readings. Who rebuilt the carb? How thorough of a job was done? Ultrasonic cleaning? Could be a jet problem. Could also be an acceleration pump problem. If you put some raw gasoline in the carb, not starting fluid, will it start? Suggest you do not use any starting fluid. Its hard on piston rings and cylinder walls.

-

Maradyne offers a 6V fan. I’ve considered one for my beefed up 237 engine. However the electric fan may get in the way at hiway speeds. A custom shroud is on my wish list when I get some time. I plan to build one. I think it will probably help more than a 6V fan.

-

Great point! I was bare armed and in cargo shorts. Extreme caution is required. Someone might see your white pasty hairy legs in shorts!

-

A mechanic’s stethoscope is a handy item. Safely block up all four wheels. Leave the wheels on. Get a friend in the car. Start it. Put it in gear 2nd or 3rd at idle is just fine. Your friend should be competent in the workings of an automobile. Brake, clutch park brake etc. you cannot have someone behind the wheel that might panic. You lay under the back of the car and poke the stethoscope probe at both outer wheel bearings and rear axle pinion bearings. Hear anything odd? For extra safety use solid blocks of wood to block up the vehicle under the frame. Suspension hanging. Also have the front bumper right up against a firm wall. A brick or cement wall is nice. The car is not going anywhere while you are under it. I have done this and lived to tell the story. I found a bad wheel bearing.

-

If you are in hurry under time constraints, you may want to consider shot-gunning parts. I've been know to do such a thing in in my younger years. "Don't know why or how I fixed it. I just kept dumping new parts at it 'till the problem was cured". Lol. Also known as "spray & pray". What about building a by-pass/test wire. Get a piece 12 ga or so insulated wire. 20 ft or so long. Solder alligator clips to each end. Then you can clip it to your ignition switch. It'll stay there hands-free. Then run it out the car drivers door and into the engine compartment if needed. Clip it to the coil input. You can run multiple different tests. Use it to clip to the coil out, then to the distributor input. Also clip it from hot 6V at ammeter to your input of ignition switch. You can maybe work around a possible bad wire and isolate it. Between this little jumper wire, a digital multi-meter, and a little time, you will solve this. I have thrown distributors in cars that were way-out of time. Between major and minor distributor adjustments, I can get them to fire and run pretty quickly. If I was near-by I'd surely come and help you get your Desoto running for the upcoming convention. I use the tester lead wire mentioned for a ton for projects. Quick and easy for the process of elimination when troubleshooting electrical problems. Just last week my A/C compressor on my 2006 car was not kicking on. I ran this jumper wire from the battery directly to the compressor harness. Compressor kicks in. Ok, its not the compressor, we know its good. Onto the next thing. Keith

-

Speaking of quality workmanship. I’m currently tackling this. I always thought tube benders were cheap. Apparently the person who built this brake line is cheaper.

-

Thanks Bob. I knew my little '38 P6 237 ci was pretty zippy around town! My seat of the pants calculations were right. It's like a baby 'Cuda.

-

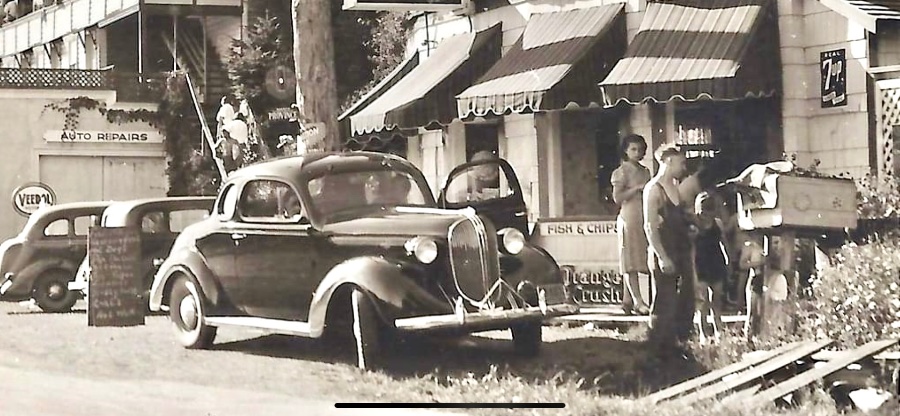

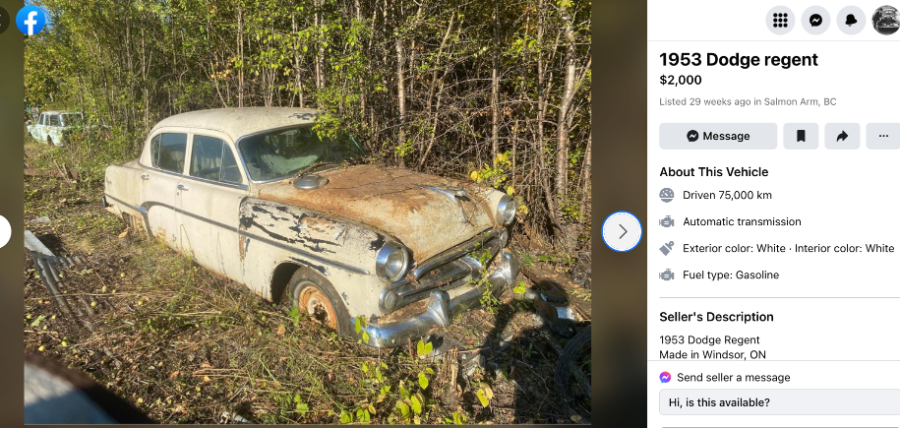

I agree. I was thinking of the power to weight ratio of the entire car weight. My ‘38 sedan with 237 ci seems pretty light to me. Much lighter than my ‘53 265 ci Chrysler. The only crumple zone is the entire car lol.

-

I just wanna drive a straight 8. Wish there was a friend around here with one. I’d love to see how it performs on the steep hill home. Perhaps the 25” 237 in my 38 Plym has a better power to weight ratio? Mine makes nice torque. Sure be interested in finding out.

-

Yup. My brakes are in good, property adjusted condition. Single master cylinder. Stock system throughout. I don’t have concerns. My cars travel at the same speeds they engineered to be driven at in 1938.

-

-

Can't get front brake shoes to go in so drum will fit on 48 DeSoto.

keithb7 replied to MarcDeSoto's topic in P15-D24 Forum

Trial and error. Just start turning your anchors and watch how the shoes move. Its easy when you have that tool. Start turning and you'll get it. There is no special steps. Just keep adjusting until you get the shoes concentric. -

Will it run after 59 years 1953 Plymouth Cranbrook

keithb7 replied to billrigsby's topic in Off Topic (OT)

I see he performed a 12V conversion! -

I like meeting people and talking about cars, when I have time. A local drive whenever I feel like it is adequate and fun. I don't particularly like parking my car for a very long day in the hot sun while I mill around, stuck in a car show. Our local big show has you tied down from 7am-4pm in August. No leaving early. I've participated a few times, asking my car not be judged. I don't want a trophy for a car that I did not restore. The local fee is pretty cheap. Its about a 10 minute drive for me. Its not about the cost, its the long day for me.I'd rather go to a show as a spectator and leave whenever I want.

-

The noise sounds excessive to me. I'll bet your intakes are the ones making the noise.

-

Stock, there's plenty of room under my car for me to move around with all 4 wheels on it, sitting on the ground. As it sits in the photo with all 4 the wheels firmly attached, if by chance something did happen, unless part of my body was actually under a front wheel, I would not be squished. Assume those two front stands collapse; the front of the car hits the pavement, on the wheels. The rear stands cannot collapse. There is no fluid drive in a '38 car. Transmission is in gear. and driveshaft brake is in top condition, adjusted and is firmly activated. My driveway is level. As the car sits, I feel I have minimized my risks. I raise the car so I have better light. Also the grease nipples and other parts are further away from my eyes, so I can actually focus on them while inspecting everything. Lol. I like your stands Sam, yet the height is not adjustable. I regularly work on multiple cars, trucks, trailers etc of various heights. I have 6 adjustable stands. Fixed height stands that you illustrate, is a challenge for me. I would require several, all of different heights.

-

I’m trying to work under my car. Gracie here won”t let up on the ball throwing game. She’ll bring the ball right under the car and nudge me if I’m distracted.

-

-

I am very surprised to see this brake line work. I cannot believe someone would go through the effort to restore a car and do this to brake lines. Hidden from sight is no excuse. These lines are off the distribution block with brake light switch. I’m very surprised.

-

-

-

I cannot speak to the ‘52 Coronet. What I can say is make it easy for yourself. Remove the hood and rad, whatever else you can out front. Lift it up and out with lots of room and great visibility. Get small bags for parts and label them for ease of reassembly. Scratch or mark lines exactly where the hood higes mount to the hood. Again for ease of reassembly. Perhaps you can leave the tranny and clutch connected to the engine? Pull it all out together. Then you can easily unbolt and split what you want from the comfort of your own living room. Take lots of photos. Better yet make a YouTube video for us to watch and be entertained! Lol.

-

Can't get front brake shoes to go in so drum will fit on 48 DeSoto.

keithb7 replied to MarcDeSoto's topic in P15-D24 Forum

Cris, did you watch the videos I made, that someone posted on your AACA post about your brakes? You need a service manual to read and grasp the concepts. Then a tool to get them set up concentric, and right. A You Tube search will all net you several brake related videos that I created and share there.