-

Posts

3,462 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

I’m thousands into an engine rebuild. Rear seal leaks! Lol. Of course it does. Seems to be a common issue and I’m certainly not the first to see this after a brand new seal is installed. Sealing area on crank is good. Reminds me of a Beatles song…Let it be.

-

I like 20W50 too for seasonal driving in warm weather. Not as readily available on store shelves around here.

-

The engine as it is today doesn’t need to be addressed. Unless your are personally looking for a project enjoy the car, drive it. There is typical wear going on. The variations between cylinders (from 100 down to 75) could be further diagnosed. It’s enough for me to go in for a valve lap. If you were in my town, I’d say bring it by. Lets get it done! General question for the group: Why does number 1 always seem better than the rest? First to get the coolest water from the rad and water pump?

-

I didn’t discuss the oil additive as I am skeptical about it. In some instances it might help. For example if it breaks down carbon packed in behind and around piston rings. It could assist maybe in filling a score in a cylinder wall. At least for a while. I don’t understand how it could help worn valve guides. Perhaps overhead valve engines, valve stem seals might become enlarged and help re-seal for a while. That won’t work in a flathead.

-

I didn’t discuss the oil additive as I am skeptical about it. In some instances it might help. For example if it breaks down carbon packed in behind and around piston rings. It could assist maybe in filling a score in a cylinder wall. At least for a while. I don’t understand how it could help worn valve guides. Perhaps overhead valve engines, valve stem seals might become enlarged and help re-seal for a while. That won’t work in a flathead.

-

A couple more tips on the compression test and burning oil. A few quick things to look out for. All spark plugs to be removed. Lay out each plug in order they were removed. Take a nice clear photo of all electrodes showing the porcelain color. Darker, non mocha color indicates with cylinder is burning oil. Good cylinders are a nice coffee with creme color. Take intake air filter off. Choke will manually need to be held wide open while cranking to get max air into cylinder on intake strokes. You should have a 6V charger 16a or better is preferred, on the battery while moving the compression gage to the next hole. Keep re-charging the battery between cranks. The battery will lose it's charge. Effecting cranking speed, especially at the cold temps you mentioned. Crank engine over with throttle wide open and choke wide open. Compression gauge will likely bump up 3x. Once no is longer climbing, stop cranking the engine over. Write down the reading. Repeat for all 6 cylinders. 6 measurements. These are the "dry" measurements. My recent engine rebuild netted bout 112 psi at 350M above sea level if I recall. Let's assume you get about 85-90 psi across your 6 cylinders, dry. Start back at cylinder 1. Add teaspoon of engine oil into the spark plug hole. Measure compression again. Same process as above. Record all 6 "wet" measurements. Expect some small increase in any engine when oil is introduced to the cylinder. Even a fresh nice rebuild. If you see a noticeable increase in compression, say now its 110 psi, the good news is your valves are sealing well. The bad news is you have piston ring sealing issues. Could be worn, stuck, or broken rings. Or a scrape in the cylinder wall letting oil pass up to the top of pistons. Dirt introduced, excessive carbon build up or a piece of a broken piston ring could case such a cylinder wall scrape. A full engine rebuild may not necessarily be required. But a major engine intervention will be needed for sure. If your dry compression is quite good, say 95 psi and up, and a wet test compression rest does not considerably change the compression psi, yet you are burning oil you likely have worn valve guides or valve stems. This allows for excessive valve guide to valve stem clearances. Oil mist in the crankcase gets sucked into the cylinder via the valve guide to valve clearances when the throttle is closed and your are coasting. The pistons are still making vacuum on the intake stroke, but the carb throttle is closed. Air wants to come in from somewhere. The intake valve opens. Not enough air comes in to to fill the void in the cylinder as throttle is closed. It takes the next path of least resistance, the worn valve guides. Sucking in air now that is in your crankcase. It has a heavy oil mist in it. Then you burn it. If your compression is low right from the start of your 'dry" measuring you should investigate further to ensure your valves are properly sealing before jumping to any conclusions. I'd do that by opening up the engine valve covers first. Ensure you have tappet clearance when each cylinder is at TDC of compression stroke. While in this position, have a friend introduce compressed air into the spark plug hole. Somehow seal up the entry at sparkplug hole if you can. 30 psi or so should be enough. Put your ear to the exhaust pipe, then the carb venturi. Are you hearing air hissing out? This is an indicator of leaky valves. Leaky exhaust valve is the usual culprit if tappet clearances are not maintained. Also,take the engine oil fill cap off. Put your ear to the fill tube. While your friend is inserting the compressed air, do you hear air howling in your crankcase? This is an indication of piston ring sealing issues. Repeat this 6x so you check all 6 cylinders for leakage. Go for a drive, if you can down a long hill. Gear down to 2nd, do not apply any throttle. The engine compression will be be holding your speed back. At the bottom of the hill punch the throttle and speed up in second and 3rd. Watch for puffs of blue smoke in your rearview mirror. This blue smoke that builds up in your engine while coasting with throttle closed comes from worn valve guides. Have a friend rev up the fully engine a bit while in neutral. Go back and watch the tail pipe. If blue smoke is exiting while revving up you likely have piston ring sealing issues.

-

Agree with above. Need to learn if it is piston sealing or valve guides letting oil in. Proper compression test can help narrow down the culprit.

-

@BingsterI'm glad to hear my videos have taught you some things. That was my primary reason for making them, to help other old Mopar owners. I've aborted the tool & die making business. Lol. I'm trying to refrain from calling out the dirtbag with no morals. ?

-

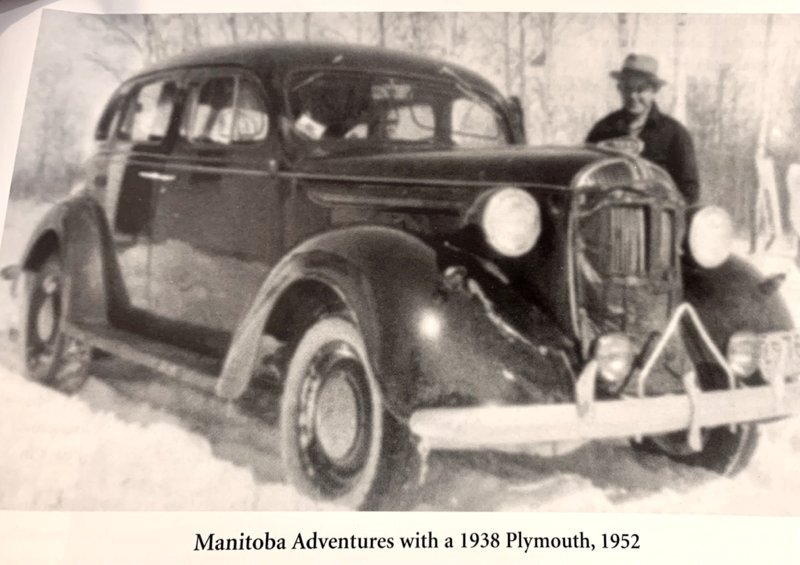

Speaking about my own experience, I love my 1938 Mopar cars. Some things I like better about them than 21st century cars. I drive my old Mopars quite a bit each spring, summer and fall. Any excuse to drive an old car I'll take it. To the bank, store, post office, doctor, whatever. A '38 Mopar could almost be considered my daily driver for 7 months of the year up here in Canada. Yet I do not drive a '38 to work every day. Nor do I want to drive one in icy cold winter weather for several months. I do like some modern conveniences. A/C being the biggest one in the summer. The 12V quick spinning starter and a very efficient heater during the bitter winter in my modern car, wins. Sure I could convert my '38 to 12V and install A/C. Add a alternator and electric wipers. I'm not interested in doing that. I really can't imagine today, trying to have an old flathead-era Mopar as your only car. It can be done, but I'd need to be quite prepared. All wearing parts, I'd want spares bought and stored here at home. No excessive down time waiting for parts, then getting the wrong parts and waiting again. I'd prefer a hydraulic lift. I'd be under there a lot lubing and adjusting everything. It would get good seat belts. A better audio system than the stock AM radio. Upgraded cooling system. I'd stay off the interstate type hi-ways. Brighter head & brake lights. I can live with the stock engine power, transmission, brakes, suspension & steering. The winter up here would be brutal. Likely the most challenging part to overcome. An upgraded heater system somehow would be needed. Then, what's really left in this old 1938 car? Its now a concoction of new updated parts and systems that still needs a lot of tinkering and maintenance. I love my '38 cars for exactly what they are. Beautiful, interesting, fun cars to take out and drive in fine weather. I image this scenario seen below here in my '38 Plymouth. I did recently acquire the rectangle window heater filament system seen here. It suction cups on the inside of the windshield. Sure, it might be fun once for a gag. Everyday for a couple winter months? Sure they had to back in the day, but I'm soft I guess. No need to punish myself and prove I could daily drive my '38 Plymouth all winter in 2024. To win a bet? Might be fun then. Lol.

-

My Motors Manual tells me 1935-39 Plymouths used the same Gemmer gearbox. My Hollander Exchange book says otherwise. Gemmer part number 640505 upto SN 2446145. After sn 2446145 Gemmer part number 645332. Not very helpful when I do a google search. That old info seems long gone. I do know that the 1935 to 1942 Fords also used Gemmer steering gear boxes. The vintage Ford parts market is infinitely larger than the Mopar market. Try these guys here. https://www.millworkshotrod.com/products/january-v92-x14 and here: https://www.earlyfordstore.com/products/1935-1948-steering-sector-seal Ask them for the seal internal diameter. Keep digging up Ford steering parts. You'll find one. This is how I bought all the parts I needed to rebuild my 1938 Plymouth steering gearbox. I got them all from the Early Ford Store and they fit great.

-

When I start thinking about knee pain, lack of motivation, or getting older, I come here and am reminded to keep my 53 year old mouth shut! Lol. On the side side topic: It is -18F,/-29C here at my place this morning. Its 35F/2C in the garage right now. Is there anything that I need to do outside or in the shop today? Nope. The living room with the fireplace is likely where you'll find me, on P15-D24.

-

What a great car. Thanks for sharing the photos. The hood appears considerably longer than my 6 cyl ‘38 Plymouth. I really notice the extra length in the front fenders. Beautiful dash and gauges. My ‘38 Chrysler has the optional overdrive. Does your Imperial have OD? I think I see an OD activation knob in a photo. I have the same clock and AM radio package.

-

I think I may speak for many by saying, we’d love to see some photos. I’m a bit of ‘38 man myself. I’m quite interested in your ‘38 Imperial.

-

Welcome. I’ve found this site to be the best anywhere, for flathead era Mopars.

-

I was just eyeing up my garage now. Thinking about maximizing efficiency. Storage space etc. Wondering, how can I fit a 3rd car in here? I could fit it, yet working on anything would be painful. Shuffling cars around constantly. I quickly forget about it and move on. Yet a Model T coupe is pretty small. Right? See…Attention span of a gnat.

-

Merry Christmas to all. Who here might try and sneak a few hours in the garage this afternoon? I likely will. Family arrives later!

-

If I recall there is a steel ball with a spring behind it that acts as a relief for the hydraulic oil pressure. Maybe the ball's spring is weak, broken? Maybe there is dirt/oil build up in the ball's seat, causing it to intermittently not seal properly? Just a guess. The ball is located beneath the plunger pin of the 6V solenoid. Best practice would be to measure and record the transmission hydraulic pressure. It should be 38-40 psi at about 8 mph. You jack up the rear wheels to get them turning as the pump only makes pressure when the driveshaft/rear wheels are turning. You can actually do a simple visual test. Remove floor access cover to transmission. Remove the electrical interrupter switch. It threads into the piston cylinder. With the rear wheels jacked up, put the transmission in low range. Throttle up to about 8 mph. Watch the piston through the interrupter switch port in the transmission housing. The oil pressure made by the hydraulic pump (38-40 psi) should force the piston piston forward. If the piston does not move forward, piston is stuck, or the hydraulic pump pressure is low. There are 2 springs inside the cylinder. When the oil pressure is dropped behind the piston, the piston return spring in the cylinder pushes the piston back. There is also an engagement spring for the shift fork rod. As the piston moves forward the shift fork spring is also compressed. When you let off the engine throttle, the shift fork spring enlarges, while mating gears synchronize, then it completes the shift, sliding the clutch gear forward. Its quite a system.

-

Personally I would not run synthetic oil in these old engines. If you do I suspect the engine will burn and leak a lot more oil than it does today. For my clean, rebuilt engine, detergent dino oil is just fine. No zinc added.

-

The oil weight is a factor that can lead to shifting problems.

-

I did upload a few videos on the M6. I tore down a spare one that I had. I wanted to learn more about it and how it worked.

-

My understanding is when cold, a slight exhaust valve tick is fine. When exhaust valves heat up they expand and the valve lash tightens. Then the tick goes away. A little wider lash means better exhaust cooling. Especially important at longer distance hi-way speed trips. If lash it too tight, when the valves heat up, some may not be closing completely, leading to an engine miss. Most noticeable at idle . Eventually leading to a burnt valve and a dead cylinder. The valve lash very well could have been your initial problem. It sounds like you have found a decent mechanic who understands these old flatheads. Not an easy thing to find!

-

My concern is mainly around Coker selling brand new tires that are dated 2006. I like to think I reset the date to 0 when I installed them. Aging typically begins at install date for me. If Coker told me “Hey we are having Black Friday sale on NOS tires. They are brand new, but manufactured in 2006. Price is 20% off”. I’d likely pass. Now, if they were 60% off that might be a risk I’d take! Lol.

-

That date makes me a little nervous. If Coker disclosed the tire age, good. If that info was withheld, I might make an inquiry with Coker. A quick online search revealed: