-

Posts

10,013 -

Joined

-

Last visited

-

Days Won

182

Dodgeb4ya last won the day on March 31

Dodgeb4ya had the most liked content!

Reputation

3,754 ExcellentAbout Dodgeb4ya

- Birthday 08/11/1952

Profile Information

-

Gender

Male

-

Location

Woodieville, Wash

-

Interests

Restoring cars, trucks, heavy equipment, welding ,fabrication of many things, helping people on projects and more!

-

My Project Cars

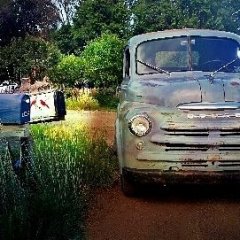

1946 NewYorker Straight "8" 3 Passenger Cpe. (Sold)..... /1952 Imperial 3 Passenger 331 Hemi Cpe/ 1948 and 1950 Chrysler Town and Country woodies/ 1950 Chrysler woodie wagon(sold)...../ Several Dodge trucks..dually 1 ton PU to 3 and 4 tonners....306/377 and 413 sixes.

Contact Methods

-

Biography

Been into the Flathead Mopars since 1968.Have 15 Mopars up to 1953.

-

Occupation

To keep all of the above running!

Converted

-

Location

Woodieville Wa. Part of the Great Northwest!

-

Interests

Old Mopar-Cars,Trucks and old AC and Massey equipment.

-

Dodgeb4ya started following Borg Warner O.D. , Are our cranks iron or forge steeL , 1952 cranbrook convertible top stopped working suddenly and 5 others

-

218 ci...Dropped forged,high carbon steel...7 counter weights 71-1/2 lbs. Rods are forged too... 230 ci. Same but crank 75-1/2 lbs.

-

1952 cranbrook convertible top stopped working suddenly

Dodgeb4ya replied to terry G's topic in P15-D24 Forum

The motor or cables are most likely the issue. Cables...good luck.- 8 replies

-

- 1952 cranbrook

- convertible

-

(and 1 more)

Tagged with:

-

Full Flow Oil Filter Part Number and Applications

Dodgeb4ya replied to Matt Wilson's topic in P15-D24 Forum

The aluminum style oil filters started in 1949 on the Chrysler cars. I have seen them on truck and industrial engines too. Boy those pictures look cold! Spring is here...the warm up is starting... -

Full Flow Oil Filter Part Number and Applications

Dodgeb4ya replied to Matt Wilson's topic in P15-D24 Forum

MoPar 1138119 is the part number for the two square profile round O-Rings. I have used typical round rings too with careful measuring to be sure of proper compression and filling the recess. Not too little and not too much. Quad rings would be a probably better choice if no factory ring seals can be located. Gasket should be fine too... I've never seen one though on the 251/265 engines though. -

Pitman Arm Attachment to the Steering Gearbox

Dodgeb4ya replied to bkahler's topic in Mopar Flathead Truck Forum

You install the arm one slot wrong...you'll figure it out pretty quick🤣 -

Pitman Arm Attachment to the Steering Gearbox

Dodgeb4ya replied to bkahler's topic in Mopar Flathead Truck Forum

It's splined .... can go on in four different positions. There are four wide machined indexing slots. -

Oh oh! It won't be $10,000..

-

Run it....it will be fine..the crack ..probably since the block was cast.

-

Resurrecting and diagnosing…

Dodgeb4ya replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

I see a lot of loose carbon by the exhaust valve on #3... Carbon could be stuck on the valve seat/face. -

Resurrecting and diagnosing…

Dodgeb4ya replied to Matfirstattempt's topic in Mopar Flathead Truck Forum

# 3 and 4 cylinder exhaust ports are rusty... As mentioned compression test required ...all cylinder readings need to be close in psi and preferably top out 90-100 lbs or even better if higher. These engines can even run smooth if all cylinders are at 70lbs! Won't have full horse power as new though. Possibly some valves not seating 100% because of rust and or burnt valve and seats. On old tired engines it's common to see top compression rings broken too. -

51 B3B build thread - after all these years

Dodgeb4ya replied to bkahler's topic in Mopar Flathead Truck Forum

A picture of that ground wire in a 1951 4 tonner..using a ring eyelet terminal as original..fastened with a phillips head screw. The hot wire and ground are located the same in two of my other trucks as from new. No J-clip being used. -

That's such a great original truck! Always ready to work too..

-

The extended lip faces the crank gear. If there is a spring in the seal that spring and open part of seal should always face the oil side of crankcase/ crank gear. Make sure the timing cover is not damaged/bent from other seal install or removals in the past. Properly support the T-cover when installing the new seal. Lube the seal lip and apply a small amount of sealer on the OD of seal before installing seal. Use the proper diameter driver to install slowly and carefully.

-

Get the car off the stands and drive it before thinking something is wrong because it won't go into OD with the handle pushed in. It's hard sometimes to get into OD on jack stands as you have to quickly rev the engine in 3rd and let off really quick to attempt a OD engagement. Might or might not go into OD. The control pawl won't engage into the sun gear easily when up on the stands. Get the car out on the road for a proper trans test.

-

I put a R10 in a 1952 panel back in the early 80's. Worked wonderful. Drove it all over Washington state. It was tedious..lots of difficult linkage fab, driveshaft, e-brake work. Trans to bell housing problems. A tough one to do but can be done. I don't remember all of it sorry to say.