9 foot box

Members-

Posts

639 -

Joined

-

Last visited

-

Days Won

15

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 9 foot box

-

I have model DL arms on my 47 one ton. My arms adjust 9”to 12”. DL means direct lock and is adjustable by turning the small tab at the 4” mark left or right to loosen for adjustment. The end where the blade connects rotates also. There were at least three different DL model lengths, hopefully you have the short version. The arms and blades on my P15 cars are both 10”. The blades for a DL look like the third picture and release by pulling out the small tab on the right of the connection. I don’t know how your blade would disconnect with that newer style blade. A P15 has a 903433 right and 903434 left arm, the blade is a 830237 blade saddle hook style attachment. Rockauto has two 10” blades, a Trico 33101 and a Anco 2010, the Trico will attach to a DL or saddle hook but the Anco only to the DL. Rick D.

-

Fiddy B2C’s truck linkage and intake manifold are designed to push. Don’t turn you carb’s around. Ideally you need a dual carb linkage. Google Dual Carb linkage P15 and click the Sept. 7, 2018 thread. Mark D and Greg G have pictures of their linkage on that thread. Having a link to each carb from a traverse rod makes tuning the carbs more positive than connecting the carbs together with the Offenhauser link. Read the other links, it will help in your project. I don’t see a throttle return spring, that is a problem, because the carbs won’t return to idle on their own. Look for that thread or I’ll bring it back up for you on the car side of the forum. Or someone with better computer skills than myself, will bring it here. Rick D.

-

I believe that a 3.375” bore with a 4.250” stroke, would make your engine a 228 c.i. I would do what keithb7 did, and use new 3.4375” pistons, and make your engine a 237 c.i. What is the engine number stamped on the block, above the generator? Can you measure the stroke of the piston travel? Google t137 other engines. That has some information on Canadian and U.S. versions of engines. Rick D.

-

Pursy, you have typed some wrong numbers on your measurements. You have a 3.375” piston in a 3.795” bore?

-

I went with tweed and a marine grade, slate gray vinyl. Prestige tweed, has some options. Fabricwholesaledirect has some Ottertex vinyl that might work for you. I glued three separate 1/4” sew foam pieces to the panel, with a 3/4” margin between them, for the trim to be in contact with the panel board. I bought the staples for the lower trim from rubbertherightway.com, 19-051F. I tried to replicate the original, minus the cotton batting. Rick D.

-

The calculator chart doesn’t care what engine you use. Your car originally had 6.70x15 tires, that simply equates to a 28” tire. I run 215/75r15 Hankook tires on stock 4.50” wide wheels, with a 3.9 gear ratio. The speedometer reads correct in a school zone radar indicator. I’ve had it up to 80 mph. You initially said you had 195/65r15 tires and a 3.27 gear ratio. ? With 28” tires and 3.73 gear ratio, you could be driving 70 mph at about 3130 rpm. Rick D.

-

Could the brake hoses be replaced with hoses with a banjo fitting and bolt on the caliper? 69-88 GM calipers appears to use that style hose. I’m just using Rockauto as a reference. Rick D.

-

It sure pays off in the end, to have the right equipment. Congratulations. Now look into a bump cap, before you have to go to an ER for a tetanus shot and repair to your noggin. I googled meat cutters bump caps 8945 and ordered a couple to fit in my ball caps. I ducked under my four post lift and came up on an edge of my rolling jack, **** happens. Rick D.

-

When I replaced the gas tank in my first addition 49 Coupe, I was aware that there is a special long ferrule, that allows for the ferrule to tighten the gas line connection. After removing the fuel line, I took a pick and got it out of the outlet and put the ferrule in a safe place. The new tank required the long ferrule to complete the fuel line connection. Others have bought tanks that did not require it, mine did. It could be on the tank outlet or on the ground where you removed the old tank and moved it. Mopar-Pro wants $30 for that part.

-

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

The PO must have hit a deer, because the tie rod, oil pan, gas tank and drive shaft were all hit. The drive shaft is out .012” in the middle. I got the pan and tie rod straightened. There was an 1/8” of lead sludge on the bottom of the pan, not to bad. There was about the same amount of sludge at the bottom of the filter canister. I took the Floato oil strainer off to clean, and it felt heavy. There was a solder patch and hole in the top of the strainer, it was full of oil making it a Sinko oil strainer. Got four 16” lock ring wheels sand blasted last Friday. I got four 17.5 wheels with the truck that could be mounted tubeless, but tires would be an expense I don’t want to deal with yet. And I have some good 16” tires. The rear end is geared 4.78, so a tall tire is preferred, but it’s a tapered axle with a 5 on 4.500” pattern with a bolt on adapter to 6 on 7.250” pattern. Not a full floating axle that I would expect on a one ton. The adapter came off so I can use my hub puller. My W series trucks and wheels use 9/16” studs, B models and later, went to 5/8”. I got a K-Series service manual and there are some discrepancies with a Dekalb and Dodge chassis. I called gas tank renu in Spokane, but they don’t seem to be in business anymore. Or Northwest Radiator gave up on the franchise. I’ll pull the gas tank tomorrow, I have a gas tank on a 53 Dodge chassis that I have, that might work. I could probably use the rear axle too. It would have a higher gear ratio and I could take out a few leaf’s in the rear spring’s. I won’t be loading it with any weight. I imagine 100 gallons of milk in glass bottles, in metal crates, would add up. That’s where this project is presently. Rick D. -

At the top of this page, under search, is a technical tab. Click that, then brakes. It will explain the procedure. Rick D.

-

Rebuilding My 218? 230? 1940 Desoto Flathead Suggestions

9 foot box replied to 40desoto's topic in P15-D24 Forum

Cleggengine.com and oldpartssource.com have rebuild kits, once you know bore, bearing sizes and which rear main seal that you have. eokd mop218 is a parts number. -

-

I would suspect the armature wire continuity then. Could be a faulty crimp connection.

-

I’ve been thinking of adding some springs to the seat of my 49 P15, the 46 is comfortable. The outboard edges are weak in the 49. I found some 6,8 and 10” coil springs at Albrightssupply.com. I’m hoping that I can add some coils from the bottom of the seat and hog ring them into position, to firm things up. For now I have a sheepskin pad for myself and my wife sits closer to the center. You can probably find coil springs at other automotive upholstery supply businesses. Rockford is another that I can think of. Rick D.

-

I used a hold down that I had in my parts. It is for a Ford truck or Bronco. I found one for $20 free shipping on eBay. 110982 made by United Pacific. From seller goodspeedusa. I enlarged the holes to fit my original bolts. My battery is a group 2 NAPA. I have a 110983 style on another car and had to raise the bolt on the inner fender 1/2” to get a nut on. Rick D.

-

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

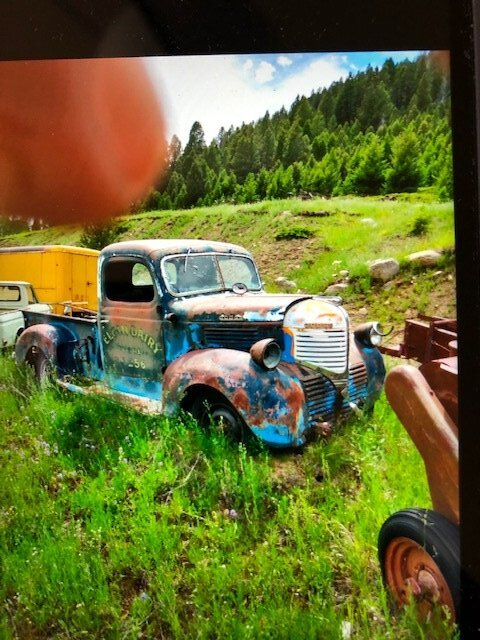

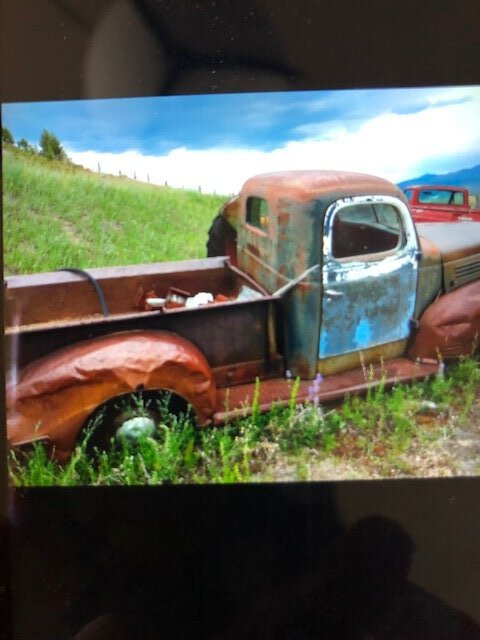

The mostly blue truck is a 39, the beat up one is a 40. The 40 has a hose connected to the tailpipe and a pile of sand in the bed. The owner used to put the hose in a gopher burrow and fill any exhaust holes with sand. The husband of the owner trailered it to a car lot for an ugly truck show, in the past, and drove it into position. I have to see them again and check out a bone yard of more parts that might be around. That odd ball fender might have come off of a decent donor. Parts is parts for any W series truck owner. I saw the radiator from the 39, the top tank was getting eaten away from the PH of the acids on the brass. As an aside, a rancher a few miles away has a Plymouth truck box and tailgate sitting on the ground, loaded with cast iron to recycle, I’ve talked to them a couple times and I guess it will just rot into the ground. I’ll try one more time. Iron prices are better. -

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

Here are three more project trucks. I have some more talking to do. The daughter said she learned how to drive in the 39, which is a bad reason to let them deteriorate anymore. I found a 50 cent Disneyland parking stub with a note to her dad on the back and a pair of pliers in what was left of the glove box. I'm going to give them to the woman as keepsakes. -

A couple months ago, I went searching for a milk truck in an area that had a few dairies forty or more years ago. Well I found a couple and a 39TC and a 40VC. The 39 could be a good project, the 40 has some badly dented rear fenders and a newer year left front fender. So the headlights mount different on each fender. The 50 Dodge is missing the front and rear axle and engine parts. The hood was laying on the right side, so I put it back on. It would take too much rigging to load on my 20’ 12,000 gvw trailer. A local man with a roll-back said he would charge $300 to deliver it to my place and I would unload with fork extensions on my forklift and set on some square timber’s. Upon opening the hood on the 57, I thought that I could get that running. I called a week later, and the husband of the owner said that the grand kids were coming and he’d let me know. He called about a month ago and bumped up my offer, that I agreed to. On a Friday I went to the ranch and filled the tires and squirted some ATF in the cylinders, oiled the door hinges, added brake fluid and pulled it into a position for an easy load. I went to get the truck the next day and emptied what was in the back and hosed it out when I got home. Sunday I rolled it off the trailer and parked it in a convenient spot to work on. It was still light out, so I did a compression test and got 105 psi in all six cylinders. I had disconnected the lines to and from the fuel pump but the pump was spitting old gas so I plumbed the line into a jug and capped the fuel line from the tank. I took the screws from the carburetor top out and sucked the old gas out of the float bowl. I hooked up portable gas tank. It started up, had good oil pressure and idled fine. Since then I have replaced all the coolant hoses and detailed it a bit by painting the headlight surround’s, air cleaner, oil filler cap. The engine doesn’t have a serial number but the frame has a number that I will use for registration. I have it on a 4 post lift now, to do an oil change, fuel tank removal and scraping of the crud that accumulated over the years and the mandatory brake and seal work. The last license plates were 1982. The left front fender needs more work than the right front. The 1” horizontal and vertical trim at the rear corners and wheel wells are aluminum, and I look forward to getting the paint off of them, they will add a nice accent to the body. I had other pictures, but these worked, I think.

-

'46 WC exterior door handle assembly

9 foot box replied to Solga's topic in Mopar Flathead Truck Forum

Aaa There should be two holes in the escutcheon on the handle. Two 10-32 countersunk oval head screws hold the handle to the door. The handle has to be turned down to the opening position to install the screws. This is assuming you have the correct handles. -

The Cooling System...Pushing It's Limitations

9 foot box replied to keithb7's topic in P15-D24 Forum

It’s possible that when the car was in storage, before you bought it, mice had moved into your muffler. You tried everything else. -