-

Posts

1,923 -

Joined

-

Last visited

-

Days Won

23

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by James_Douglas

-

I spent MONTHS with an odd vibration that I could not run down. Turned out that the left front lip of the motor mount would contact the block side mount. It would do it at idle. If you look real careful at the way the mount is designed, if the rubber gets old and compresses just a little the two side can make contact. I had to grind some clearance into the mount. You can see stress marks from the press if you have it in your hand. Also, if you have two or three of them that radius edge on the drivers side is different on all of them. Check that out real well before you do anything else. As to the Fluid Coupling. If you still have the bottom plate out, drain it. Turn it back up to the fill point. Take a screwdriver and carefully turn the inner around until you line up one of the large holes with the threaded outer plug hole. You will have to take a drill bit to gauge the inner hole size as I don't remember what it was. Then take a BOLT that is threaded to the plug hole pitch and size. Turn the end of the bolt so it will go through smooth the inner hole. Screw the bolt down. Now drive it like a stick easy around the block and see if the problem goes away (Assuming it was not the mount). If it does then you know it is the coupling. If it does not then it is not the coupling. An old timer taught me that trick years ago. He said to keep a bolt like that in the glove box on long tips. Just in case the fluid coupling seal dies or the bearing dies...you can stop, let it cool dump the oil, and screw in the bolt in place of the plug. Then drive it like a stick to get where you are going. He said he drove one like that for a year and it never caused an issue. James

-

Send you old on to: Feltz Terrill Jr. Terrill Machine 1000 CR 454, De Leon, TX 76444 PH 254-893-2610 FAX 254-893-4841 terrillmachine@yahoo.co They have rebuilt several for me.

-

Well, The simplest way is to take it to a rear-end shop and have them take the measurements and order a custom unit from Currie. Full stop, the easy and simple way to go. Just hang on to your wallet! In my case, using a >150 HP engine, I have run my 1947 Desoto in San Francisco city traffic and on the highways at 70 MPH for nearly 20 years. It has 175K miles on it. I changed the rear axle shaft wheel bearings and put in a new pinion seal and that is it. My Suburban weighs more then any of your cars. I have two pumpkins for it. A 4.11 and 3.9. The only failure I had was a ring gear bolt failed and got my attention but even that did not hurt it. I know where there are two more rearends in a yard if for some reason I needed one. (I have a spare housing and axles as well.) Just about all the parts are available if you go looking. At less than 150 HP these rearends just do not break unless something is not looked after. As to brakes, I came up with a rear disc solution. I have it on the 1949 (see thread on rear disc currently on the forum). I would either stay with the stock unit and just rebuild it or go the currie route. James

-

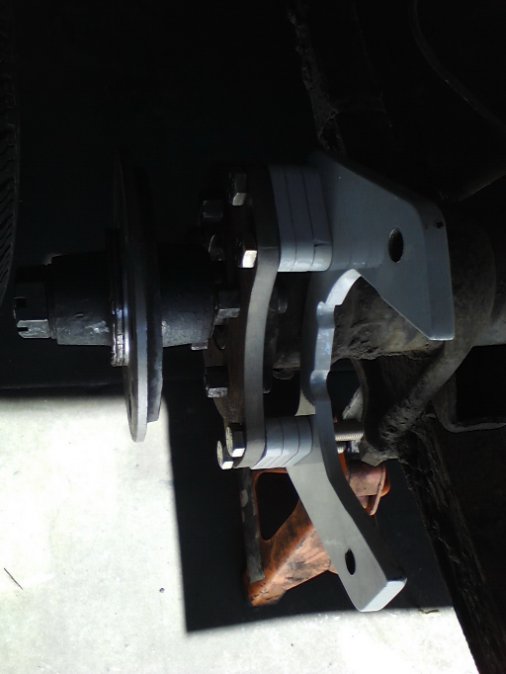

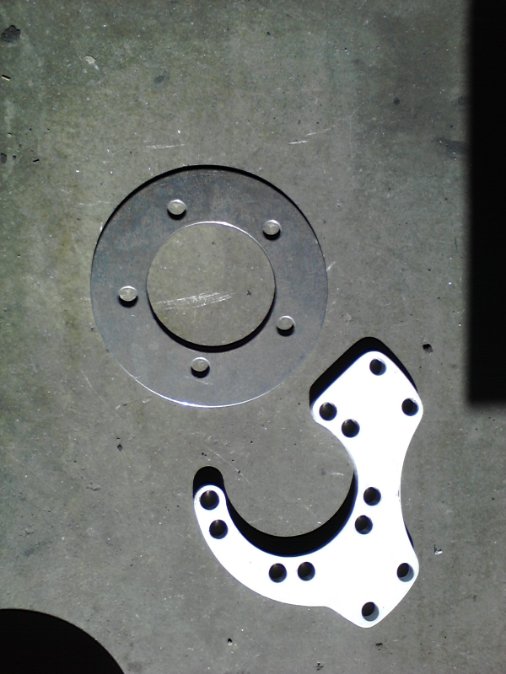

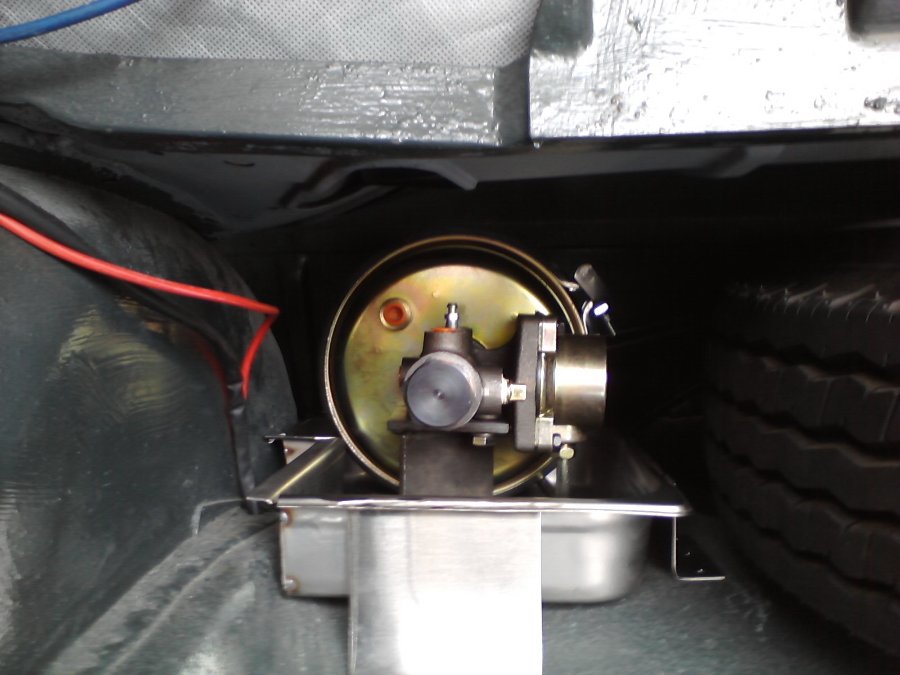

I used parts of their kit for the rears on the '49 Desoto. I also built a kit for the '47 but it is still sitting on the shelf. I had to make some changes and have some parts jet cut. I used the stock master cylinder on the '49 but what I did was to use a remote power brake booster. I put it in the trunk. The big deal was their system did not have a provision for a grease seal. I had to have the plate made. My machinist MAY still have the thing in his computer and if he does he can just cut them. I used GM c.1995 calipers that have a cable e-brake on them. The only thing is the mechanical ratio on the handle is not quite enough to lock them hard unless I press the brake before I do it. At some point I will but in a bellcrank under the floor with a lever and cut the cable into two to increase the ratio. Other then that it works fine. The power booster I mounted on the self next to the tire. I used a modified stainless oven pan to hold everything so if it ever leaks it will all end up in the pan. I also ran the brake light switch there to make it easy to change without getting under the car. One word of advise. Several of the makers of disc systems will NOT make them for the rears. Why? They had too much trouble with the discs not running true on the tapered shafts. The only way to do it correct is to take your rear hubs with the discs and the axle to a machine shop and have them true the face of the face of the hub to the axle and then mount the disc and make sure it is also true. You have to maintain a "set" of the Hub, the Axle and the pin (stamp the up with UP). You will get pulsing and problems otherwise. Send me a PM with your number if you want me to call over the weekend to talk about it. James See photos.

-

I drive the '47 Desoto all the time and all over place. With OD and 251 I run at 65-70 on the Freeway all day long. I do have the front converted to disc. The stopping power is not that much greater than the 12 inch drums. There is no fade but the real plus is directional stability when you hit the brakes hard. As to the freeway speeds. I have found that I drive in the second lane from the fast lane. If a three lane freeway, I am in the middle. In a 4 or 5 lane I am in the second from the left lane. What this does is create what I call the "teardrop effect". People come whizzing up behind me and then have to break around me to the left or right. What this does is create teardrop shape space around me with a lot of room in front for stopping distance. It has proven to be much safer than staying in the far right lane with all the people waiting for the last moment to cut over for a ramp or with dealing with people not entering at 60 MPH. My only issue with the car is the lack of power in the hills and mountains. The extra 1000 pounds makes a very large difference in these cars. My '49 Convertible with the same engine goes up the hills with throttle to spare. I would say get some front discs for directional stability in a panic stop, but in a OD to keep the revs down and be happy. I drilled some holes and added bulbs to the tail lights so could stop hearing people tell me my lower brake lights were out...

-

If you research old threads you will find a write on these by me...

-

For moving blocks off of the back of a truck, I sometimes use my pump tables. A couple of guys can slide engines off if you have cardboard under them. I then mount the head of the engine stand on the block, level the pump table to the stand and slide it in. I then just lower the stand away. Speaking of stand, I had my shop jet cut a 1/2 thick steel plate to match the rear of the block. I will weld it to the head. Then I can use six bolts to hold the block. Even with the little pipe arms, I cannot get things like the core plugs in when attached. I do that work before or after it is on the stand. I should have it done in a couple more weeks. I will post photos. James

-

Help with Welch plug removal while engine is in car.

James_Douglas replied to White Spyder's topic in P15-D24 Forum

I use a 90 degree drill and drill a hole in the disc. I then use the puller you can get for $10 at any auto parts store. The real bitch is pounding a new one flat in the engine bay. No place to swing the hammer! I am looking into milling out the holes on my new engine for the '47 so that I can use a cup style rather then a disc style plug for that engine. James -

I have had issue with Classic Cars for years and insurance. In my case here in San Francisco since I have only 2 garage spaces (on street is not an option) for my cars I do not own a "modern Car". The companies usually will not write a classic car insurance policy unless one owns a modern car on regular insurance. I convinced them that our "regular car" was in fact the San Francisco Municipal Railway. We take a bus or trolley for 75% of our trips or just walk. My wife and I have driven a combined total of about 3000 miles a year and have for 30 years... It took years for me to find a company that would give me classic car insurance. The deal I had to make was to keep the 1947 Desoto on a State Farm policy and now the 1949 Convertible is on Classic Car Insurance. If I every have a big claim on the 1947 DeSoto, I know I will be in for a fight as they use market value not replacement value. James

-

No. These are SAE and used in most modern cars. PVC is what you see at the auto parts store. It has lower heat ratings on the insulation and is deadly toxic like all burning PVC insulation.

-

Others have asked the important question. What is the usage of this car going to be? If it is occasional then go find a good used drum. One thing to keep in mind is that often the "drums" can be the same front and read while the axle flanges were different. I have run front drums, with the rivets drilled out to remove them on the rears and bolted them together. I have also done this on the fronts in the past without any issues. On the subject of cast iron drums, I do not agree with one comment on them being less strong than steel. The 1963 to 1970 C body Chrysler cars had bimetallic drums as standard. However the Police and Heavy Duty drums were all cast iron. I used a 1968 set on the front of my 1964 Chrysler 300-K and did a number of hard stops from over 100 MPH without any problem. Now that said, those drums were made in the USA and with our product liability laws you can bet that they watched the Q & A. In Asia, for get it. On my Desoto's that is one of the reasons I went to discs so I did not have to hunt down drums. I know someone who needed new drums for his 1958 Cadillac Eldorado Biarritz Convertible. He got a new manufacture set. They had to turn them to get them both round and to get them to the same ID. So far so good. I see used ones on ebay all the time. They never post what the ID size is so you could buy a pig in a poke. ********** Caution ********************* What I am going to say next is to be taken with a grain of salt and may or may not be accurate. In the late 1980's I was introduced to a man who was an Engineer at Chrysler from the 1940's until the mid-1970's. We talked brakes and drums in particular. He told me that when they designed drums that they came up with the maximum oversize. Then then cut that in half mostly at the insistence of the risk managers. He said that for a car driven occasionally he would feel fine going past the recommended 60 thousands oversize up to 100 thousands or so. He did say if the car is going to be driven daily and or in the mountains down big hills he would only go to 80. For hot rodding he said stick to 60. I asked about drilling and venting. He said that the feedback from racing in the early 1960's was starting to filter into their testing of new designs. In particular the drilling of drums for out-gassing. Also, placing little screen with forward facing vents to push air into the brake cavity. He said those things work when pushing drums hard. He then said that all that work stopped as it became apparent that Discs were going to be the future as they provided so much more benefit. It was and interesting set of conversations and I learned a lot about drum brakes. His one big issues was to get and learn to use a drum shoe arc machine. He said 90% of the drum brakes out there were not properly set up or adjusted. That was the largest reason to go to discs --- to get rid of the human factor. ************* Caution on the above ******************** James

-

I purchased a trans complete from a 1954 Chrysler that has the Powerflite on a Flathead six. It has the all important adapter plate that Chrysler used for that. I may or I may not use it...time will tell. They are out there. I think I would get the Wilcap adapter and get a trans that did not require switching the car over to 12 volt. You could have any good shop or car buddies that are close help you with the change. James PS. I have been told that the Chrysler adapter plate may well work with a cast iron Torqueflite, but I have not been able to confirm this. I have wondered about having my plate scanned by a company here in SF that does 3D scans that my machine shop can upload into their jet cutter and make as many as one would want...

-

Hi All, I am working up my materials list for the conversion of the 1947 DeSoto to 12 volt. {Too many changes I will make requires it}. One thing I am looking into is what insulation I will use. I will use Cross-linked Polyethyene. The question is for the under dash work, which of the three insulation thicknesses should I use. SXL is way to thick for under dash work, it is great for #10 wire in the engine bay for main feeds. So it is up to GXL medium, or TXL which is very thin. I like the idea of using the thin wall as it is flexible, but I wonder if I am going to have problems down the line if I do. I have used some of all three wire types, but in limited ways. If anyone has had any extensive experience with the thin TXL I would like to hear about it. Thanks, James

-

Standard moved all its production to Mexico and closed the NJ plant. The last couple of SMP ignition parts I purchased, and I got like 6 sets were junk and I returned them. James

-

Most likely the Schrader Valve for wheel cover causing and issue. After that it could be that the tube is leaking and the tire seal on the rim is not consistent or a rivet is weeping under motion. The tube needs to come out and be checked in a water tank. I suspect you will find and issue with it. James

-

One a side note... Some years ago I ran across a MOPAR or Other technical note that stated that the axle bearing end play on these pre-1955 rear ends should be upped. I cannot remember the extract numbers but it was from something like 8 thou to 15 thou. I can look through my paperwork to see if I can find the note. The reason listed was that with the all new "freeways" speeds were going up and the axles were growing with the heat generated by the higher speeds. This caused bearing binding issues. I know when I rebuilt both the '47 and the '49 rear ends, I added more play and I have not noticed any problems in doing so. So when one pulls out the axles to clean and repack the bearings...something to think about. James

-

Another newbie M5 trans. question: falling out of gear

James_Douglas replied to Sean Jackson's topic in P15-D24 Forum

The way this thing works is that once the load of off the trans AND the piston is pushed back by the spring due to the fluid dumping OR a lack of fluid it will drop out of gear. make sure it is filed up and NEVER drive a M5/M6 without full fluid. Go over to the Imperial Club and read over all the service booklets on the trans... -

New carpet recommendation Plymouth PJ

James_Douglas replied to rrunnertexas's topic in P15-D24 Forum

I like to use a carpet that works great and is very quiet. But, you need to have an experienced upholsterer use it and it is not cheap. The stuff is from Bill Hirsh and it is a wool hogs hair carpet. James -

I used Paul Little at Harnesses Unlimited for my 1949 Desoto which is stock. It was a very nice harness and looks great. For my 1947 Rebuild, I will be using Coach Controls for the main panel and using cross-linked Polyethylene for all the wiring. Not PVC which is what 90% of the kit suppliers use. I am doing so many modifications to the 1947 Suburban, with electric power assist, electric water pump, electric fans, AC and the like... James.

-

Sorry to resurrect a thread... Can anyone confirm that the bare 1946 to 1950 case 1139155 can be used in place of the 1950 to 1960 case 1635577 ? Thanks, James

-

On cars with Fluid Coupling the bell housing is longer. The standard three speed will not work unless it was one that came on a car that had a fluid coupling. They used longer input shafts. On a car that had a fluid coupling, you can use the semi-auto (M5-M6) or a proper three speed with the long input shaft. The 1949, second series or true 1949 models, used a slightly different M6 that had a different set of wiring and controls. If using a three speed with a fluid coupling of course this is not an issue. James

-

I will be doing a dual conversion on the '48 Desoto later in the year. I will use the modified version of the ECI kit as used by Don Coatney and James Curl. You should look up their old threads. What I am going to do is a variation of what I did on my '49. I will use the dual MC under the floor with a firewall mounted remote fill and I am going to use the SSB Dual power remote booster which will fit under the car near the MC. Basically like Chrysler used in 1951.

-

I would have to go look at my '47 Desoto, but, I thought one went up and one went down on these?

.jpg.7f0f918a609f27549042d79cfe79c1c1.jpg)