-

Posts

1,927 -

Joined

-

Last visited

-

Days Won

23

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by James_Douglas

-

Like I said above, I am only considering this for the big heavy 1947 Desoto that we use as our daily driver. Do remember that we do not own a modern car. Although after 45 years, I am considering buying one... The 1949 Convertible has a basic 251 rebuild and that is just fine for a car that goes to shows and Sunday drives. Since I have documented the pressure drop in the big car over the last 15 years and have confirmed, by talking to a couple of others who experienced the same thing; doing things to slow that pressure drop is warranted in this case. I can tell you that when I had the interior out except for the front seat when I first purchased the Desoto Suburban, with its old and tired engine, there was a marked difference pulling up Waldo Grade to the Golden Gate Bridge. The interior parts added up to about 400 pounds. That was enough to effect the power to weight ratio and made a very big difference. I do not think that many on this forum understand how close these cars are to "edge" power and weight wise. Add 500 to 1000 pounds to your car and see how it goes up a hill. You would be surprised. My convertible with the same engine goes up a hill with ease, albeit at 750 to 1000 pounds lighter. So, is spending $4500 on rods and pistons too much? Perhaps, but the cost of tearing the front end apart, and the steering, to put in a V8 is a lot more costly not to mention the work involved. Food for thought. Merry Christmas all. James

-

Tony lost his access to a machine shop for small weekend work like doing rods. His day job is in a manufacturing plant. He is sourcing Carrillo Rods and forged pistons for the small flatheads. But the cost is steep like in the $4K to $5K range. He said he would do Carrillo Rods and forged pistons set for my 265 but it would take six months and about $4500. Now that IS a lot, but I REALLY want to get the bore wear down. On the big Desoto after about 50K miles went from about 140 down to about 80. In the big Desoto it is very noticeable as the pressure is goes down. Tony tells me that the Carrillo Rods and forged pistons have a weight saving is 25%. That is a LOT. Also, remember what Tom Hoover said when asked what if anything he would do different in the development of the Max Wedge and the 426 Hemi. He response was to do one thing and that is to lower the engines reciprocating weight. Since I run the engines hard to push that heavy 140 inch wheelbase Desoto around, anything that lowers the load on the wrist pins or the crankshaft is not a bad thing and the bonus would be more HP out the crankshaft. James

-

-

Has anyone ever found someone that is rebuilding the BW-OD pinion gears also know of as planet gears? These are the three little gears on a housing that was never meant to be rebuild but replaced as an assembly. Of course, I have never seen an NOS unit. I may look into, with others, in having a few sets of the pinion gears made and rebuilding the assembly. If one scrounges hard the sun gears and the ring gears show up new from time to time. I have one NOS sun gear and one NOS Ring gear and I am looking for a couple more. I really love these overdrives, I just wish that there were more new parts around for them. James

-

Rich, What was the year of the Borg Warner Catalog? My catalog is a G-1959 and shows three different counter-shaft's. James

-

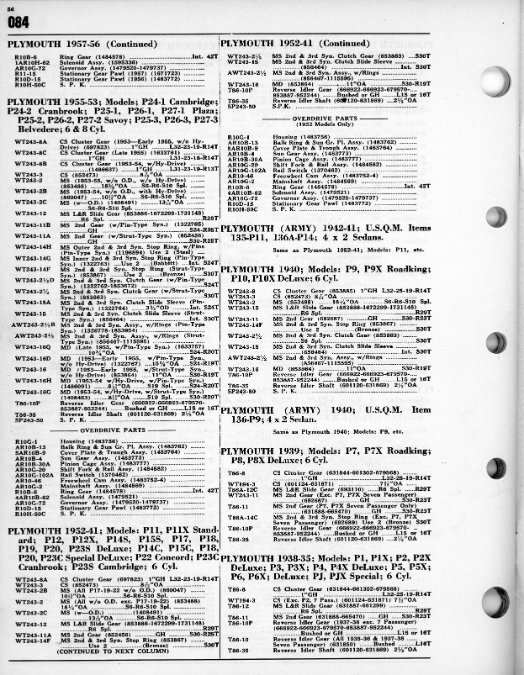

Anyone know what the differences were in the 1953 to 1955 Plymouth cluster gears? There is an early (32-23-19-R14) and late (31-23-18-R14) without hy-drive and then one for Hy-Drive (31-23-19-R13). Also, are these all different cluster gears using different mating gears? Before I spend hours in the books, I thought I would ask in the event someone else has run this down. I need a Cluster Gear for the spare trans I am rebuilding as I do not want to use the Fast Second Gear and it Mating Cluster shaft I have in my good for the Big Desoto. The other cluster gear I have has some broken teeth. Thanks, James

-

6V Electric Fuel Pump -maybe better than Carter 4259

James_Douglas replied to Bryan's topic in P15-D24 Forum

Many years back when I talked with a tech at Carter this is what he told me according to my notes: Part Number P4259 works on 6 volt positive or negative ground. The rebuild kit (no motor) is part number 888-178. The pump has a maximum pressure of 5.75 PSI. This unit is a full time on unit and will not allow for a proper flow through if off. This unit must be installed at a level equal to the bottom of the fuel tank. This unit must be within 2 fuel line feet of the tank. This unit typically drops between 1 to 1.5 PSI at the carburetor inlet. Less loss for shorter fuel line runs (Coupes) and more loss for longer runs (sedans). The only issue when using these pumps on small HP engines is as follows. These pumps must have 5 gallons of flow every hour to keep within operating temperatures. If you are at idle for over 30 plus minutes on a hot day in traffic and your engine does not pull enough fuel through the pump could overheat. The thing to do according to Carter is to put a fuel line tee up in the engine with a 1/8 or 3/32 orifice and a return line to the gas tank. That way the pump will always have enough fuel running through to stay with is temperature range. The carter man stated that he has heard of a few people with really old low HP cars in hot areas, on hot days, stuck in long parades, have pump problems. It is rare, but if you want to make sure that it never happens, then put the return line in with the orifice. ************** Now all the above said when I tested two out of the box 6 volt carter pumps I ran into an issue. When I put a fuel pressure gauge on the "T" and checked it I got about 3-1/4 to 3-1/2 pounds. Here are my many years old notes on that: The original mechanical pumps are supposed to be between 3-1/2 and 5 pounds. I thought that is a little on the light side, but once the generator is going, I guess the voltage will come up a bit and it will probably top 3-1/2 pounds. I then did a flow test. I put a graduated pale in the engine pay and ran the pump for one minute. I got 3 Pints. This is where things get odd. The pumps according to Carter are supposed to put out between 6 to 8 PSI and up to 72 GPH. That would be 9.6 Pints a minute. I called Carter and got a lot of double talk. I hit my 1957 Carter Master book which is 5 inches thick. In the back they have both the old Carter mechanical fuel pumps and the older larger vane electric fuel pumps. In the section on the mechanical pumps they show how to test them. They show their mechanical pumps, like the MOPAR manual, as having between 3-1/2 and 5 PSI. They also show that the mechanical pumps are supposed to: "Volume: One quart of fuel in one minute or less at 500 RPM" In the section in the book on Testing, Removing, and Overhauling the older style electric Carter fuel pumps, it states: "If the fuel pressure gauge is not less than the following the pump is satisfactory: 3 Pounds for a 24 Volt Pump. 2-1/2 Pounds for a 12 Volt Pump. 1-3/4 Pounds for a 6 Volt Pump." If I use the old original Carter specifications, my newer style vane pump is just fine. When I talked with the people at the service center, they just mouth the 6 to 8 PSI and 72 GPH song. When I asked for a PSI chart via voltage they tell me they do not have one. I ask that surely the 6 volt, 12 volt, 24 volt versions have different outputs. Nope, they are all the same I am told. When I ask what the minimum volume output is they tell me they do not know. I ask them to tell me how will they determine if a pump is defective if they do not know what to measure. They don't know. I took another unit and put 18" of rubber hose on it. I took 3 feet of #12 wire and connected it. I stuck the fuel gauge on the output of the pump. I put the end of the hose in the pale with the 3 pints of gas I took from the car test. I turned it on. Guess what, 3 PSI. It is obvious to me that the published specifications are garbage. Carter to American Car and Foundry (ACF) to Federal-Mogul to now some outfit named Castle Automotive. I think over the years that the original specifications have been lost and all that is quoted is the ones for the 24 volt version. I call back later and talk to another person. I explain what is going on. I asked for them to call up the food chain and confirm the minimum and maximum design parameters for pressure and flow for the six volt pumps. I am waiting on a response. I very much doubt that 2 pumps via 2 distribution channels a year apart are both "failing" in exactly the same way output wise. *************** Basically what I am saying is take the published specifications of these 6 volt pumps with a big grain of salt. If it works it works. I think over the yeas the real data is long lost. James PS. I have a friend who is a serious Cadillac guy. He has a 1958 Cadillac Eldorado Biarritz Convertible among other things. He told that in the late 1950's Cadillac used two fuel lines with a "T" at the carb if a car was ordered with Air Conditioning. This was to deal with vapor lock. I can see that is an electric fuel pump does not have enough flow through it during a parade or the like that the motor could over heat. I have run the return line on the '49 since day one and I never noticed any issues. I run it into the filler neck. We made a little pipe with a bed in it and welded it to the filler neck so the fuel returns there and runs back down into the tank. -

6V Electric Fuel Pump -maybe better than Carter 4259

James_Douglas replied to Bryan's topic in P15-D24 Forum

Let me go find my notes on this... One of my complaints about the board is the inability to do a serious SQL search on the database. It would be nice, for a price, if one could buy a read only copy of the P15-D24 database and do a SQL search with it to look things up. I paid a guy some years back for a copy of a MOPAR parts database and it has been great to run SQL to look up part numbers... James -

Looking for soft rubber upper rear motor mounts.

James_Douglas replied to MarcDeSoto's topic in P15-D24 Forum

Steele -

Wiper options after 12V negative ground conversion.

James_Douglas replied to Racer-X-'s topic in P15-D24 Forum

Sorry I misspoke, but on purpose as most people have no idea what a buck converter is. They understand the idea of stepping down one voltage to another....hence my use of the term. Sometimes a descriptive term is worth more than the technical correct term to convey an idea. I have extensive experience with such things. I had to design and spec a set of transformers to convert the 220V Delta Power (110V-110v) on our fleet of ships to 120V (0V-120V) power for all the computers, GPS and the like. Also, the 110V APC power supplies do NOT have fuses on both mains so in a ship delta power environment we had them catching on fire if there was an equipment issue. Which on the bridge of a $100M freighter with $800M in cargo was not a good thing. James -

Funny, The POS he sold me did not have his name stamped on it. James

-

6V Electric Fuel Pump -maybe better than Carter 4259

James_Douglas replied to Bryan's topic in P15-D24 Forum

Yes, but how many times have you been stuck for an hour in 5 MPH stop and go traffic. How many 1 MPH parades. If you do, it will fail sooner or later, The Carter engineer was quite clear. There is a minimum flow requirement for the motor to not burn up. The problem is that the flathead six does not use enough fuel at idle or close to it to hit that flow target. He says about a dozen times a year they get people calling and complaining that the units burn up. James -

Wiper options after 12V negative ground conversion.

James_Douglas replied to Racer-X-'s topic in P15-D24 Forum

The 1946 to 1948 Desoto wiper unit is a motor and gear box in one unit. Nobody is making a 12 volt version that I have found. Hunt down a good regulated step down transformer that is rated at 100% more than the draw on the motor. It will last forever if you do. James -

Old bushings rubber versus TP material of replacements

James_Douglas replied to '41 Fat Bottom Girl's topic in P15-D24 Forum

Plymouth and Dodge used rubber control arm bushings? Chrysler and Desoto did not. James -

Has anyone installed a new ring gear on their Fluid Drive?

James_Douglas replied to MarcDeSoto's topic in P15-D24 Forum

NO, NO, NO ! You can check it by placing in crankshaft size down on a steel plate and just measure it. (https://www.harborfreight.com/6-piece-telescoping-gauge-set-5649.html) The tool plus a dial indicator will tell you. Do NOT under any circumstances allow anyone to spin a fluid coupling without a transmission attached to it. The input shaft "holds" all the guts inline and if you spin it without a transmission or the VERY specialized tools the factory supplier used, you will damage it. The machinist has no idea what he is doing and thinks it is just another torque converter. I have cut the welds and moved a ring, some of the Chrysler 8's had a coupling that had the gear a little bit deeper and need to be moved to use in a six. As an aside, Chrysler made two coupling with different stall speeds. No way to tell by looking at it which one you have! James -

6V Electric Fuel Pump -maybe better than Carter 4259

James_Douglas replied to Bryan's topic in P15-D24 Forum

If you go looking in my old thread you will find some stuff on these pumps. One thing is VERY important. They do not like to be run without fuel flowing through them. There is a specific amount of flow per hour that has to be maintained so the will not overheat. The best thing to do is to put a "T" at the carburetor and a return line to the tank. Weld the "T" on the return side and drill a small hole, the size is in my old posts, which will allow for the proper flow so the pump never gets hot. Also, this help a lot with any hot day problems as in stop and go traffic the fuel is always cool at the carb input. James -

MOPAR used the brass washers only on the two far ends of the exhaust/intake studs. I know some people with Chrysler Eights that have had manifolds crack when someone left off the brass washers on the far ends and replaced them with steel ones. In fact the manifolds themselves are a three part interference fit that is wedge shaped and is supposed to move. Ones that rust and don't move crack. So in general I agree with you on the thermal expansions thing when it comes to thick heavy cast iron that is subject to extreme cycling from exhaust heat I think we will disagree on this one... James

-

Thanks for the info on the Yoke washers. My sense is that the washers will have to be "wing" shaped to deal with the Edmond intake and the Cast Exhaust. I also noted that the two sides may well need to be different due to casting irregularities. Some slight core shift I suspect. James

-

I would like to take a look at the sun, planet and ring gears to see if they can be made to work in an R10. I know that in some of the later 1960's transmissions that those versions of the planet assemblies had 3 or 4 gears and could be directly swapped. I just have no idea about the R10 and R11. James

-

I am working on my prototype block now on the engine stand and I also noted that the flange was different. I to am making up a set of stepped washers for the attachment. My only thought is do I make them out of steel or bronze to allow them to move with the heat-cool cycles like the factory did on the outer studs? I am going to use my Edmund's manifold so it will move a fair amount. For the exhaust, I plane on wrapping the first 2 or 3 feet of the pipes with header wrap. James

-

Did the Plymouth Trucks use the passenger car rear end or the Big Chrysler 8 rear end or the Dodge truck rear end? Does the existing ring gear use 10 bolts to bolt it to the cage or 12 bolts to the cage. (Not to the housing). James

-

I am the one having OD problems. I think one of the planet gears is failing. Although almost every part in this transmission was replaced with NOS, the planet gear unit, the sun gear and the ring gear all were used. I got about 60K miles on this unit before it started to fail. I suspected that it may fail at some point. Since the rest of the unit sold to me as rebuild had in fact (well documented) many parts that were worn beyond specification. I always suspected that given the crap parts sold to me that the OD parts that I could not replace may at some point fail. So now I need to pull and open up a perfectly working transmission to deal with one or all three of these parts. What I am considering doing is to rebuild a bad trans and spare OD unit I have. Then swap it the one in the car and then open up the existing unit and see what is up. I did just score a NOS Sun Gear for the OD. If I could score a planet unit and a ring gear I would be happy. When I rebuilt this unit I paid Frank Mitchell like $400 for a NOS balking ring and gear. No doubt that is why this unit shifted so nice. Since that was the only NOS set I could find and it is SO IMPORTANT to the proper shifting of these units I am looking into seeing if they can be plated up to specification and perhaps a little more to make up for a worn ring. The Borg Warner books go into detail about how the ring MUST have a certain foot pound pull of resistance to shift properly. I really like these overdrives here in San Francisco Traffic. Especially with the fluid coupling. I just wish there was some NOS parts available.

-

Sounds like a residual valve - linkage issues is not allowing the master cylinder to back flow like it should... In my 1949 I am using a stock MC in the stock location with a remote power brake booster and 4 wheel disks. The only problem I have is it stops too good...

-

48 Chrysler axle shims and end play not making sense ???

James_Douglas replied to harmony's topic in P15-D24 Forum

I am not a big fan of replacing the old leather seals with modern seals in a lot of these applications. Here is why: The leather seals can take a LOT more punishment than the modern seals. The modern seals are designed with THE ASSUMPTION of much more stable shafts and much more consistent surface hardness and surface roughness. These old designs have nowhere near the close tolerances that the more modern cars have. A story. An late old friend of mine, a guru in Jaguar XKE circles, used to club race his early XKE Coupe. He found that when racing it or when coming back down Highway 50 from Lake Tahoe in a spirited drive, that his independent rear suspension would start to leak oil from the shaft seals from the intense heat of the inboard disc brakes. When they cooled down they would drip a bit but he could live with it until he got around to replacing them. When he tried a set of modern seals they would fail and the car had to be towed home as once they failed they were junk and did not hold any oil at all. This concept also applies to the rear main seals. You can see my old posts. I have a Victor rear main seal that is the two part type. The seal area is 10x wider than the currently available seals from fel-pro or Best Gasket. This seal also has a vulcanized material over the actual seal. More contact patch and more robust material. Sometimes playing mix and match with different engineering era's does not work as expected. James -

I am working on a manifold adapter to my edmunds dual 1BBL manifold to take a Holley Sniper 2BBL. Given what we know about the physical fuel distribution issues that have been discussed at length here on the forum.... ...I am thinking the the dual 1BBL physical layout with a Holley Sniper feeding it may yield the improvement that the Dodge Engineers figured out then they went to a dual 1BBL Carters and dual exhaust set up that ended up with 136 HP on a 265 engine. James