-

Posts

9,369 -

Joined

-

Last visited

-

Days Won

86

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Merle Coggins

-

If your fuel bowl was full the pump is not the problem. However, you may have an accelerator pump issue if it didn't squirt fuel when you moved the throttle linkage. As for 'cutting out' at 20-30 MPH, it could be that the points are not installed properly. Some have a spring that runs parallel to the points arm. If it doesn't get hooked in place properly there is very little spring tension and the points will start to bounce, or float, at higher RPM's.

-

51 B3B build thread - after all these years

Merle Coggins replied to bkahler's topic in Mopar Flathead Truck Forum

They are welsh plugs. Install them the same way you would do on an engine for coolant welsh plugs, aka 'freeze plugs'. Set them in and dimple them flat with a hammer, or large drift punch. No sealant is needed if the surfaces are clean. -

The outer groove may be for attaching the stainless trim.

-

Are you sure it's the pilot bushing making the noise and not the throw-out bearing?

-

Yikes... I don't have much advice on a field fix to get you going, but that is probably why it wouldn't idle. I had a hard starting, rough idle, issue many years back when my cheap points rub block wore down rapidly and my points would barely open. I'd guess that with the points plate floating around that your points weren't functioning properly. Plus the timing would likely float around too. Could you possibly use machine screw with a locking nut for a temporary fix? It would depend on space above and below for the head and nut.

-

Good news that no serious damage was done with the green paint. Bummer on the motorcycle tank repaint... I had a can of spray paint spontaneously start to leak while on the shelf in my laundry room. It had probably been there for several years and I believe the can seam rusted, but one day I could smell paint fumes in the house but couldn't identify where it would be coming from. As I walked past the laundry room I heard a hissing noise. I opened the door and noticed the mist. Fortunately all the paint pigments were settled at the bottom and the leak happened about half way up. It was only clear paint solvents, but it was still a mess to clean up. Once I realized what it was I grabbed the can to toss it in the garbage, stirring up the pigments in the process. It started spraying color into the garbage can. I got it outside to remove the fumes and commenced to cleaning up the mess.

-

You could probably option the Standard cab with vent windows for a nominal fee.

-

The "Pilot-House" moniker was given to the B-Series trucks due to their "All-around" visibility like in the Pilot House of a boat. However, as stated, only the Deluxe and Custom cabs got the corner glass. The Standard cab did not. Also, the Standard cab did not get the wing/vent windows in the doors. They only had a single roll up window. To add to the confusion, as I understand it, the Canadian built trucks never got the corner glass on any models, but they still seem to get the Pilot-House nickname.

-

As I read this post it shows that you posted it 2 hours ago. 2 hours ago was 4:50 AM where I live. I was still in bed. Alarm goes off at 5:00 AM and I begin my day... I guess none of the other Ausie's and Kiwi's were on with you either.

-

Send a message to Mark, a.k.a. ggdad1951. He has rebuilt some throttle and choke cables with new inner wire.

- 25 replies

-

- 1

-

-

- throttle cable

- choke cable

-

(and 2 more)

Tagged with:

-

I have a DTG1 on my truck and it doesn't have a fast idle cam. I don't recall where I got my rebuild kit, but it did come with a dash pot plunger. However, I pretty much have it disabled by screwing in the screw above it so that it has no stroke. It is supposed to help the engine to not stall around when coming to a stop against the Fluid Drive, but I have never had an issue with that, even with it disabled. I didn't like how it would hang up the idle when I wanted it to come down.

-

Oil filters were an option, or dealer installed item, back then. My truck didn't have one when I got it. I found one and added it. Regarding the 2 ports above the pressure relief that you see... The one directly above the relief valve is the connection port for the filter return. The one just ahead of that, with no threads, is a dip stick port that isn't being used. It has a cup plug pressed into it. Slightly above these ports you will see a ridge running along the side of the block with 3 or 4 port in it. One of them will be feeding your oil pressure gauge. This is the oil pressure gallery. Use one of these ports to feed pressure to your filter (likely the one seen in the same picture), if and when you get one.

-

Is there an open parking lot nearby, or in a nearby town, that you could use to try repeating the situation without worries of blocking traffic? If so you could try different scenarios to see if it is a tire binding issue, brake issue, or other issue. Once you figure out how to repeat the situation it will help you hone in on where to look further.

-

I saw that spec in my B2 shop manual too, but I also recall a Serial Number break during the B2 series when I was getting my king pins. The later B2's and B3/B4's have a slightly different size king pin. But I wasn't able to find the spec. yet.

-

Locktite and Permetex both have an Anaerobic Gasket Maker that will harden to a plastic like material when sandwiched between two metal flanges. It is great stuff for sealing up things like differential mounting surfaces, or axle flanges. As for your search for a drift to remove the bearings... I have used a hammer handle at times when I didn't have a drift handy. Anything fairly solid, and long enough to reach through the hub will work.

-

Different tension springs are not unusual. They are used to change the advance curve throughout the RPM range.

-

Adding to what Mr. Neal said above on the escutcheons, I have found that a skinny needle nose pliers are helpful here. You may need a little screwdriver to get the escutcheon pushed back slightly, then slip in the needle nose pliers with one jaw on either side of the handle. this will push the escutcheon back on both sides to expose the pin. Usually a pick, or small Phillips screwdriver is all that’s needed to push out the pin. The number you have exposed on the differential is the casting number, or part number, of the housing. The ratio will be stamped into a flat pad. Some are on the top, some are near the fill plug as Mr Neal stated.

-

Frame restoration questions

Merle Coggins replied to fireguyfire's topic in Mopar Flathead Truck Forum

I painted my whole chassis black. I suspect that the springs may not have been painted when new, but at least the rest of it would have been. I only stripped mine down to a rolling chassis, so it all got painted black. -

I have a fire extinguisher mounted horizontally next to the seat in my truck. I take it out at least once a year and shake it around to keep it loose.

-

supply line/return for heavy duty oil filter

Merle Coggins replied to rlcokc@aol.com's topic in Mopar Flathead Truck Forum

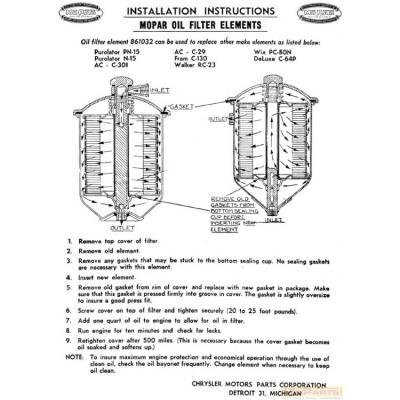

This topic was discussed a few months ago, and Bob (Dodgeb4ya) posted this image that shows that the Purolator and AC filters work from outside-in, whereas the Wix and Deluxe units filter from inside-out. -

I have also added an electric pump to prime my carburetor when it's been sitting for an extended period. I used to have it plumbed in series with the mechanical pump and found that sometimes it could push fuel through the mechanical pump and sometimes it wouldn't. I suspect that it had to do with the position of the diaphragm. Maybe it restricts flow through in certain positions? Sometimes I'd just have to give the engine a quick crank to get the fuel flowing again. The electric pump was also helpful when things got hot and the pump on the engine struggled to pump fuel. I could switch on the electric pump to help push fuel through the system. I have since re-plumbed my fuel lines and put the electric pump in parallel with the mechanical pump. This allows for easy priming, and it can still assist the system if needed.

-

Looks like it’s had the MIdas touch... ?

-

supply line/return for heavy duty oil filter

Merle Coggins replied to rlcokc@aol.com's topic in Mopar Flathead Truck Forum

There were a few different filter suppliers back in the day. What you have there appears correct for that type. That upper port is clearly marked “INLET”, and as you stated earlier it is connected to the pressure gallery. I believe I can read Purolator on the label and it clearly uses a different element than the sock type that Deluxe uses. -

supply line/return for heavy duty oil filter

Merle Coggins replied to rlcokc@aol.com's topic in Mopar Flathead Truck Forum

OK, stew on this... On the sock type with a perforated dome under the lid, as you referenced, the pressure enters the center post, through a couple holes in the side of the post, and migrates through the filter media. It then collects above the perforated dome where it can drain back to the sump. I’m sure the filter media could be just as efficient in reverse, but the flow of oil may not be as efficient in reverse. That, and the cover gasket would be under constant pressure vs. being on the low pressure return side. -

supply line/return for heavy duty oil filter

Merle Coggins replied to rlcokc@aol.com's topic in Mopar Flathead Truck Forum

The Deluxe Filter that I have is stamped "IN" and "OUT" next to the ports, and it is plumbed with the pressure feed into the bottom (IN) and the return to sump (OUT) at the upper side. Some other types of filters, primarily the pleated filter cartridge type (from what I've seen), have an outside-in filtering process. In these types the pressure inlet is at the upper side of the canister and the return to sump is at the bottom.