-

Posts

9,394 -

Joined

-

Last visited

-

Days Won

87

Everything posted by Merle Coggins

-

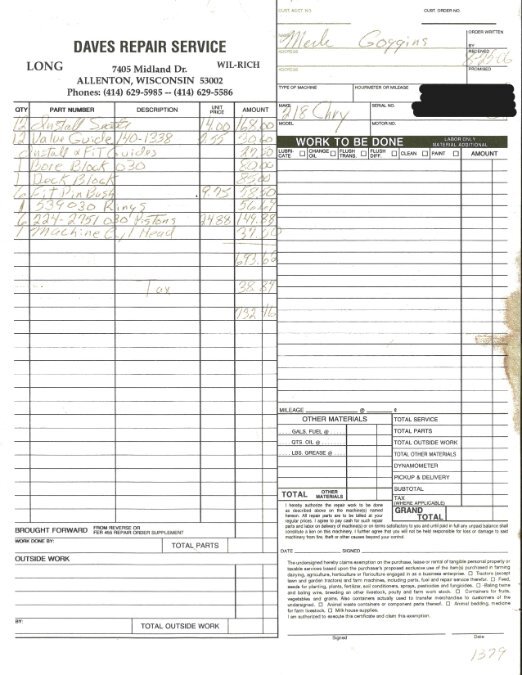

This is the receipt from the machine shop where I had my engine work done back in 2006. Included .030" over bore, decking the block, milling the head, new valve guides and seats, new pistons and rings, and new wrist pin bushings. I thought $732 was pretty reasonable at the time. Looks like my 6 new .030" over pistons were slightly cheaper than Greg's, but his rings were a little cheaper.

-

I don't believe you need to worry about that. The wheel cylinders are held in place by the 2 bolts, and nothing else.

-

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

@Bobacuda It's interesting that your FD only has 4 studs. Upon a closer look it appears that someone cut off the other 4. Someone must have installed it on a 4 hole crank at one time. The crank flange for FD should have 8 holes. I believe the 8 hole flanges are also thicker. Although, with another look I see that yours has 4 holes whereas mine only has 2... interesting... And as Bobacuda showed, the driven plate, AKA Clutch "flywheel" surface. -

Driving a Dodge town sedan with fluid drive

Merle Coggins replied to greg g's topic in P15-D24 Forum

In my FD equipped truck I’ll sometimes use the clutch in a conventional way, and sometimes I’ll leave the clutch engaged and hold the truck on the brakes. (The second is good for around town, keeping it in 3rd gear) Even when I’m using the clutch conventionally I find myself letting it engage more quickly that I might normally, since you really don’t need to use the friction zone as you would with a conventional clutch vehicle. Just let it engage and let the FD take over. -

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

That’s not correct. There is no conventional flywheel on a FD vehicle. The FD unit has 8 studs that attach directly to the crank flange. The ring gear for the starter is on the FD housing. The output of the FD is the driven plate, which acts as a flywheel surface for the clutch to mount to. Yes, the transmission gear box is a completely separate unit with it’s own oil. I would recommend just checking the level in the FD unit and adding if needed. If you do change it I would recommend ISO AW32 tractor hydraulic oil. You should be able to find that at your Tractor Supply store. It is very slow to drain, and to fill, if you decide to change the oil. The same plug is used for both. Crank the engine until the plug is at the bottom to drain. Then crank it again until the plug can be accessed through the bell housing inspection/fill hole at around the 2:00 position. This is the position for both checking and filling. -

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

Welcome to the 'family'. 1. Hopefully your locksmith can help you with your locks. If not an aftermarket ignition switch will get you going until a proper one can be tracked down 2. My first set of plug wires came from my local Farm & Fleet store. It was a generic cut-to-length set for tractors. They worked fine until I upgraded to a Pertronix ignition and I upgraded to their plug wires too. 3. Check with your local battery house, or farm store. They may have 6v batteries in stock. As mentioned earlier, measure the battery box and get the largest one that'll fit. Also, I recommend checking the condition of your battery cables and connections. Be sure to use 1 ga cables at minimum. Many of us fine 0 ga. or 00 ga. to be preferred. The 'off the shelf' cables at the big box stores tend to be 4 ga. for 12v vehicles. 4. As mentioned, most 1/2 ton trucks came with 16" wheels. But I've seen many with 15's, especially in California for some reason. Maybe the factory out there (San Leandro?) use 15's as standard vs. the 16's out of Detroit. Either way it'll depend on the width of your rims. My B2C has the original 15" X 5.5" wheels. I am running 235/75R-15's without any problems. 5. Good luck with your radiator. If you can't find a Zero pressure cap you can just cut the seal do that it won't seal, hence making it a zero pressure cap. 6. I couldn't remember the size of the crank nut, but I thing someone answered that for you. 7. Regarding the Park Brake cable. If you can get it removed, try soaking it with penetrating oil and gently pulling it one way or the other. It'll likely free up over time. That's what I had to do with mine. Once I got it freed up, and well lubed, it have been working trouble free ever since. 8. The truck should roll with the trans in neutral, even if the clutch is stuck as someone mentioned. Maybe the Park Brake is locked on? I suppose it's possible that the trans got stuck in multiple gears. I've seen it happen before. You'll just need to play around with it, or worse case... tear it apart. Looking forward to seeing your progress. -

A833 transmission for my flathead

Merle Coggins replied to Tony_Urwin's topic in Mopar Flathead Truck Forum

If you need the idle speed to be that high for good drivability then you likely have something wrong somewhere. Either your carburetor is not properly adjusted to be too lean, or to fat, or your ignition timing is off. It could also be that your points aren't providing the proper dwell time for good coil performance, which causes weak spark and sometimes maladjusted ignition timing. Another possibility is that you have a vacuum leak somewhere. This will also cause an over lean condition at idle which makes the engine not want to perform correctly at idle. -

Reminds me of...

-

A833 transmission for my flathead

Merle Coggins replied to Tony_Urwin's topic in Mopar Flathead Truck Forum

Makes you wonder how far off speedos were back in the day. I swapped the diff in my truck with a 3.73 diff from a '50 Plymouth. Still running the stock 4 speed trans, and my speedo is only a few MPH off. Since they didn't have GPS, and cops with radar, to confirm the accuracy back then I suppose they didn't care. -

I suspect that you have something drawing on the battery that is causing it to become discharged, unless the battery is just old and won't hold a charge. If it is a power draw issue upgrading to an Optima won't fix that issue. As for securing the Optima in the stock battery box, I can't help you with that. I believe the 6v Optima is much skinnier. You will likely have to modify your hold down bracket to hold it in place.

-

You sure have done a lot of structural repairs/modifications to this frame/pan for it having been a running and driving car when you acquired it. It's scary to think what's out there on our roads when I see things like this.

-

Pulling 218 motor from 1950 b2b with Fluid drive

Merle Coggins replied to Dodge bro's topic in Mopar Flathead Truck Forum

It may be possible to remove a 3 speed trans without disturbing the cross member. On my truck with Fluid Drive and a 4 speed that is not the case. There is about 1 inch of clearance between the park brake drum and the cross member. There is no physical way to slide the trans out of the bell housing without dropping the fuel tank and removing the cross member... at least with the combination I have in my truck. -

I did see one truck with a /6, so to answer your questions, yes it's possible. However, I believe the /6 is considerably longer than your flathead so there'll be some modifications needed to make it fit. I wish I would have looked closer to that one that I saw to see what they had to do to make it fit.

-

I agree with the other statements that it's a fuel percolation issue due to the heat. I learned early on that to restart my truck, after it sat for a few minutes, that I needed to crack the throttle open a little. This allows more air in to lean out the gas that gets pooled in the intake from the percolation. I've gotten pretty good at using my heal on the gas pedal while stomping the starter with my toe. It starts right up every time that way. If I don't give it a little throttle it'll crank a long time before starting. I've lowered my float slightly, and I mostly run premium gas without ethanol, but I still use this starting procedure, mostly out of habit now, when I start the engine hot. It never fails.

-

The parking brake is on the tail shaft of the transmission to hold the driveshaft from spinning. When both wheels are on the ground then it'll hold the vehicle from rolling, unless one wheel is on ice, or something like that that allows it to slip and spin backwards. You may need to snug them up as much as possible and do final torque once it's back on it's wheels and on the ground.

-

How long are you in town?

-

Light 'er up like a Christmas tree, with a half dozen lights down each side. 😁

- 734 replies

-

- 1

-

-

I used to live near there, in Waukesha, but now I'm a little over an hour and a half north of there, in the Appleton area.

-

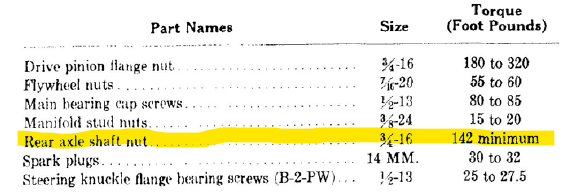

Don't back off the nut on the axle shaft. Shown below is the torque spec. @ 142 minimum. Torque it to 142ish and then a little tighter as needed to line up the cotter pin. For other bolts, there are plenty of Standard Bolt Torque charts like this floating around that can be used when there isn't a specified torque for a specific fastener.

-

That'll look good with the lights recessed/hidden into the rail. Are you going to do the same on the front corners with amber lights?

- 734 replies

-

The tires look small in the wheel opening, to my eye, but if it works for you then go for it. I run 235/75R-15's on the 15 X 5.5 original wheels on my B2C and haven't had any issues yet.

-

I figured he's go with the standard chrome lady mud flap weights.

- 734 replies

-

- 2

-

-

-

It's best to leave the 4 connecting bolts slightly loose as you mount the manifolds to the block. Then snug up the mounting nuts to ensure that the manifolds are flat to the block, then come back and tighten the connecting bolts before final torque of the nuts.

-

Just bought a Pertronix kit for the car

Merle Coggins replied to 1949plymouthdeluxe's topic in P15-D24 Forum

I put a 6v +ground Pertronix ignition system in my truck several years ago and it's worked flawlessly since. I had to make a minor modification to the points plate in my distributor so I ended up purchasing a second distributor and used that one with the Pertronix module. I also installed their coil and plug wires to be sure everything was matching. My original distributor, with points, resides under the seat just in case. I also have a 'backup' Pertronix module in my spare parts stash under the seat. I haven't needed either one... so far... -

7.2 is a good charging voltage with the engine running.