-

Posts

9,387 -

Joined

-

Last visited

-

Days Won

86

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Merle Coggins

-

DCM has replacement drag links with replaceable tie rod ends. I got one for my truck so that I could adjust the length to get my steering wheel straight again after the disc brake conversion. The caliper bracket moves the steering arm inwards, which changes the steering wheel angle. The adjustable drag link allowed me to correct that, plus it tightened up a little bit of play from the old drag link ends.

-

Looks like it has a 4WD conversion and a snow plow mount.

-

Usually... I typically hold the clutch released while sitting at a red light so that when it turns green I can get rolling quickly. I've never had issues doing this. Sometimes I'll even play with the 'Friction Zone' to hold the vehicle/motorcycle in place without holding the brake. I've never burned up a clutch and I've only had 1 truck that had throw-out bearing fail. That one failed on my way to a jobsite several hundred miles away and I limped it there and home by using minimal clutch disengagements and clutchless shifts. That being said, my truck has Fluid Drive so with that I will just leave the clutch engaged and hold the brake at traffic lights now. However, I was once stuck in stop and go traffic with the truck and it started running hot. I was keeping it in 2nd gear and just easing on and off the brake as we creeped forward. I would depress the clutch and rev the engine to cool it down. Or if it seemed that we wouldn't be moving for a while I'd shift to neutral and hold the RPM up around 1500 and watch the temp come back down. That involved some tricky foot work to keep the truck from rolling while switching the left foot between the clutch and brake pedals.

-

Found a brake drum solution

Merle Coggins replied to Fowl Jeff's topic in Mopar Flathead Truck Forum

It seems that I recall someone using a trailer brake drum, with slight modifications, a couple of years ago. You may have to do some searching through the forum to find it, but it sounded intriguing. -

Then kick it into neutral if you'll be sitting for an extended period...

-

It's not uncommon for an engine to run hotter at idle speeds, especially after it's been under a higher load prior to you stopping. You have 2 factors working against you. 1 is lower air flow from the fan at lower engine speeds. The other is lower coolant flow at lower engine speeds. Try bringing up the RPM while you sit in traffic with your foot on the clutch. That'll usually bring the temp down a little bit for me.

-

That's quite a lot for not having any leaks. I couldn't find a spec for the fluid capacity. I suspect that someone drained it, at one point during some 'maintenance' to get it running, and never refilled it. It might not hurt to recheck the level again. I recall that it took a while to get mine full. It would get up to the plug level, then after a while it would settle and burp and I could add a little more. I had drained mine during the engine overhaul process and refilled it before reinstalling the engine back into the chassis.

-

How much oil did you have to add/how low was it?

-

3 speeds are synchronized. 4 speeds didn't get syncros until '51 with the B3 series.

-

I do that when I'm driving around town with 25 - 35 MPH speed zones. I'll just leave it in 3rd and use brake/gas. If I need to start out on an incline I'll drop down to 2nd, but otherwise 3rd works fine. Once I get out of town where I'll be going over 35 I'll then double clutch and shift up to 4th.

-

The transmissions used with FD have a longer input shaft and nose cone. Also, the bell housing is longer to accommodate everything. To switch to a conventional trans you’d need a bell housing and flywheel at minimum… besides the transmission, or shorter input shaft and nose cone

-

The problem with shipping these is that they have to go general freight due to the length. They can't be shipped normal UPS, FedEx, etc. Hence the elevated shipping cost.

-

Have you checked the fluid level in the Fluid Drive? It would have to be quite low to act this way, but it may be something to check. You'll need to remove the toe boards and trans cover parts of the floor boards to access it. There'll be a round cover in the bell housing at around 1:00 or 2:00 position. The cover will pop off and expose access to the level/fill plug. You'll probably need to slowly crank the engine over until you can see the plug through the access hole. Then CAREFULLY remove the plug without dropping it. A magnetic socket is helpful here, or put a paper shop towel over the plug, then press the socked over that to make a tight fit as you remove the plug. This will help hold the plug into the socket for removal. Once you have the plug removed you should be able to see fluid. The fluid level should be right up to the level of that plug hole. Official Fluid Drive Fluid is obsolete, but I am using an AW32 tractor Hydraulic oil in mine and it's working just fine. The next thought is... if the level is low, why? Is the bellows seal leaking? Or did someone drain it at some point in time and didn't refill it?

-

The in line “clicker” type pumps can be setup to draw through, and put inline with a mechanical pump. They also come rated at 5 psi max, which is perfect for our carburators. I had mine like that for a while as a primmer, or for when it started ‘vapor locking’ in the heat. I have since changed it to be plumbed in parallel. This one that you reference appears to be a rotary vane pump. You won’t be able to draw through that one, and you’ll likely need a pressure regulator to go with it.

-

I’m out in Lost Wages for a Celebration of Life party weekend for my wife’s aunt. I was out roaming and came across this route van and decided I needed to buy it… for $6…

-

tanda62's post is in regards to the bypass filter setup. ecpiano has a full flow filter converted to use an external, aftermarket, filter so it doesn't apply in this instance. Another thought on this... If the remote filter was plumbed backwards could it be blocking oil when the flow increases? I believe the block is setup that the lower port would be flow from the pump, which should go to the filter inlet, and the upper port would then feed the engine oil galley.

-

Having oil pressure at cranking RPM but none at idle RPM makes me wonder if there is a restriction in the pickup tube causing the pump to cavitate at higher RPM.

-

-

It should be pretty easy to make one with a piece of threaded rod. Remove the screw where you'll be putting the stud and take it to the hardware store to match up the threads and purchase a piece of threaded rod with matching thread size along with a few nuts. Cut the length you need and thread it into the pump. Use a nut to tighten it down against the pump body, and a couple more nuts at the top to hold the heat shield. Mine had a wing nut on top, but a regular nut would do the job too.

-

Coolant flow to heater core

Merle Coggins replied to General23cmp's topic in Mopar Flathead Truck Forum

It sounds like you'll be pulling the head soon to address the head gasket issue, so that will be a good time to clean and inspect the coolant passages in the head that seem to be plugged up and blocking flow to the heater port. -

Coolant flow to heater core

Merle Coggins replied to General23cmp's topic in Mopar Flathead Truck Forum

Yes, you should be able to blow air into the cooling system through that hose unless there is a shut-off valve, and it is closed. You should also have coolant flow out of that hose if you hold the end below the coolant level. If it doesn’t you either have a closed shut-off valve or the coolant passages in the head are plugged. The water pump wouldn’t be able to build any useable pressure at cranking RPM. It’s not a positive displacement pump so it needs RPM to create flow. -

One thing to keep in mind when dealing with brakes that pull in one direction upon application... The fault may actually be on the opposite side of the direction it pulls. The general consensus is that the brake is "grabbing" and making the vehicle pull in that direction. But sometimes the brake on the other side is being lazy and not applying as it should. This could be caused by seized components, or by a failing flexible brake line.

-

Click the 'Messages button and select "Go to Inbox" at the very bottom. From there you'll find check boxes next to each message string. As you 'check' them you'll see a popup button to delete the message string. There's even a "Select All" button at the top of the list.

-

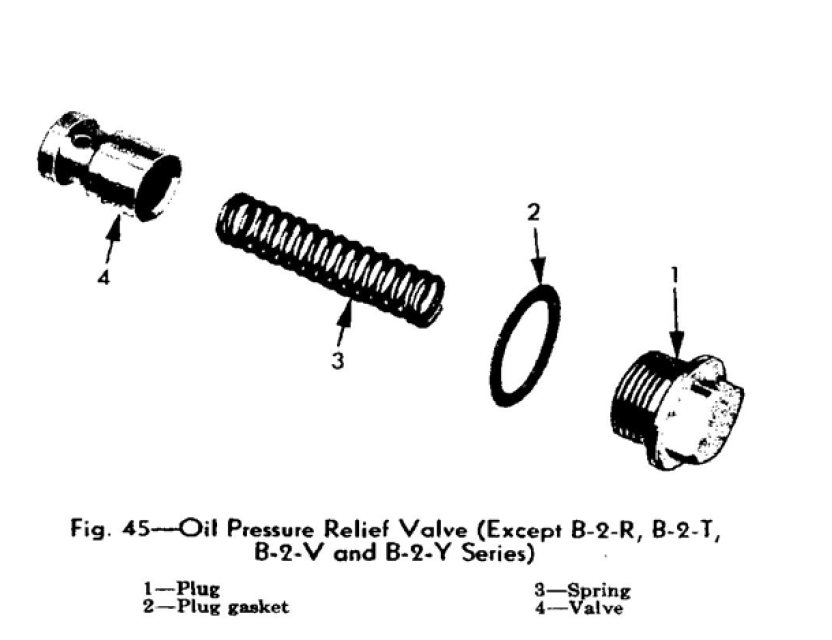

Just below where your oil filter lines connect you'll find a plug. Behind that plug is a spring and plunger for the oil pressure relief. When the valve is closed it also blocks the return flow from the filter to prioritize oil pressure to the engine. When proper pressure is achieved the valve should open to relieve the excess pressure, and at the same time open the return path for the filter so that oil can flow through it.