-

Posts

9,394 -

Joined

-

Last visited

-

Days Won

87

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Merle Coggins

-

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

Since the Fluid Drive is a fluid coupling, as you reference, there is no direct connection between the transmission and the engine. This is why you MUST have a working Parking Brake on FD equipped vehicles. If parked on a grade, even with the transmission in low gear, the vehicle will roll. At very low speeds there will be no power transfer through the Fluid Drive fluid coupler, which will allow the transmission to spin with very little resistance. When the engine is running the internal fins on the Impeller side of the FD will force the oil in the FD unit to transfer power to the Turbine side (output/clutch). The higher the RPM the more power will be transmitted through the FD. -

Throttle? and turn signals

Merle Coggins replied to Dodging Work's topic in Mopar Flathead Truck Forum

When starting cold I give the pedal a couple of pumps, then step on the start pedal and crank it right up. When starting HOT I have found that it starts better with the throttle slightly open. I used to use the throttle knob for that purpose, then found it easier to use the throttle pedal. After a few 2 footed starts I learned to use my toe on the starter with my heal on the throttle pedal. Quick and easy hot starts that way. -

Not seeing any paint on it yet. It left for paint a month ago... no progress yet?

- 734 replies

-

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

You should be sure all 13 fasteners have been removed. That's the best way to know you have them all, count them. Those 3 that Bobacuda and JBNeal show are easily missed as they are a bit hidden. Also those 2 longer studs that go through the exhaust manifold, shown by Bobacuda, can sometimes bond themselves to the manifold. When this happens you'll have to work a bit to break that bond without breaking the manifold. -

As I recall there's a metal sleeve inside the rubber mounts so that you can tighten the bolt and only squish the rubber so much.

-

Tight enough so that the cab won't fall off? I know that's a Smart @$$ answer, but generally when you don't have a specified torque published, just go with standard torque for that size fastener, such as this one. Torque-Tension Reference Guide.pdf

-

Unfortunately Apple doesn't seem to have a setting available to adjust photo file size. You would need a 3rd party app, like to resize them after the fact. Its a PITA. Another way would be to email them to yourself from the phone. Then it will ask you which file size you would like to send. That's another way to downsize the files from an Apple phone.

-

"48 b1b interior (dashboard)

Merle Coggins replied to Dodging Work's topic in Mopar Flathead Truck Forum

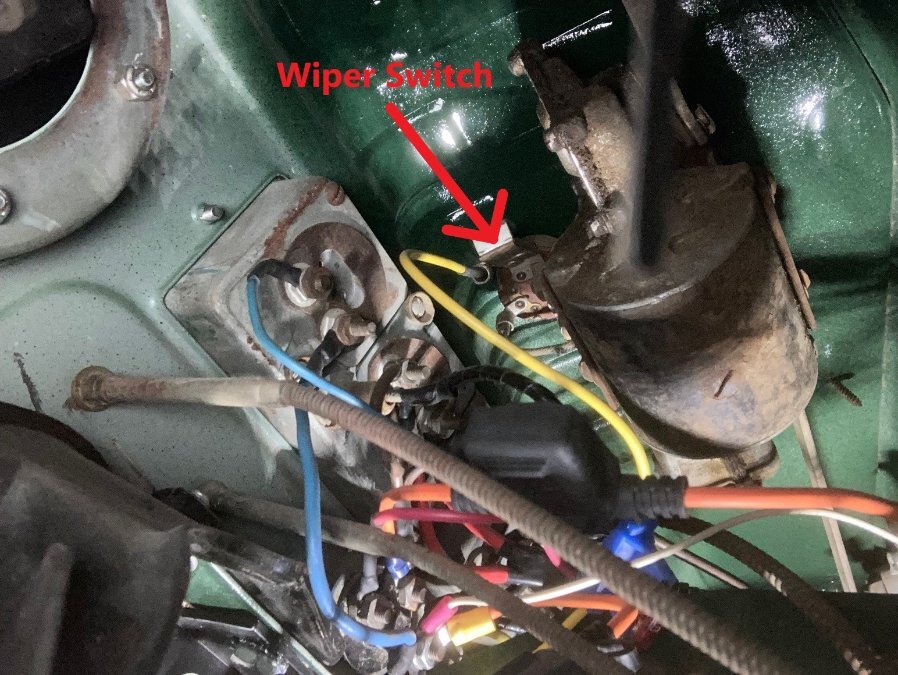

I have that same type of heater fan switch, as Los_Control posted earlier. It's essentially a rheostat to adjust the fan speed. Electric wipers was an option for the B-Series trucks, and was standard in the top cab trim package. (Deluxe or Custom... I always forget which was the top package) A parts truck that I picked up, while building mine, had the factory electric wiper motor. I pulled it, cleaned it up, and put it in my truck along with the wiper switch. The switch mounts in the same hole on top of the dash where the vacuum wiper control goes. The linkage arms and pivots are different than the vacuum wipers, so you need to switch it all to make it work. I ended up gifting my vacuum wiper setup to another forum member nearby that needed to put wipers in his truck. -

You mentioned that you have 6v on both coil terminals. This is correct when the points are open. When the points close you should loose power on the + side of the coil because that wire gets grounded by the points. As Mr. Neal stated, if the wire between the coil and distributor is compromised you could be loosing the connection through there. You could retest your voltage here, being sure that the points are closed. Or, you could also check the voltage at the + terminal at the coil, and again at the distributor terminal, to verify if you have voltage at both ends of the wire.

-

"48 b1b interior (dashboard)

Merle Coggins replied to Dodging Work's topic in Mopar Flathead Truck Forum

The wiper switch would be that chrome knob on top of the dash. On vacuum wiper models that lever would operate a valve in the wiper motor to open the vacuum port. On electric wiper systems that was an actual electrical switch to control the motor. -

Look at Chrysler, DeSoto, Dodge, and Plymouth cars from the late 40's thru early 50's. The 3.73 differential gears was an option in all of the Mopar vehicles, but those would be your best bets to find something. You'll have to do some digging to find the stamping on the top of the differential housing to know what gears are inside. I got lucky to find the 3.73 diff that I currently have in my truck. There was a forum member here, many years ago, that put up a post regarding an axle that he bought. He was looking for a 4.10 diff to use in his '53 Suburban, which he used to pull a boat, or camper trailer, and it had an OD transmission. He purchased an axle from a '50 Plymouth thinking it would have 4.10 gears. It turned out it had the 3.73 gears. At the time I happened to have an extra truck axle with 4.10 gears, so I sent him a message about doing a diff assembly swap. I offered to ship my 4.10 diff to him and it he would ship his 3.73 diff back to me. After some picture trading we decided the only difference was the drive flange, as the driveshafts are different between the cars and trucks. I pulled the drive flange off of the pinion, crated it up, and shipped it to him on my dime. It was exactly what he needed so he put his 3.73 diff back in the crate and shipped it to me. I replaced the pinion seal and reinstalled the drive flange. It was a direct replacement into my axle. I've heard that sometime in the early 50's ('52 or '53) there was a change in the spline count for the axle shafts and side gears. However, some here have reported having good luck in swapping the side gears in the differential to correct that mismatch.

-

What type of noise are you hearing when shifting gears? Grinding, clunking, squealing, etc.? Is this a 3 speed or 4 speed transmission? If it's a 4 speed, then it's likely the spur gear type without any synchronizers. This would then require developing the skill of double clutching your shifts to avoid having the gears grinding every time you shift.

-

Interesting... I hadn't heard of that brand. Obviously I'm not familiar.

-

Bad brake master cylinder lead to brake switch not working?

Merle Coggins replied to dsapern's topic in P15-D24 Forum

You have stated that you know that the brake lights work if you send power back to them. However, you haven't specified that you have checked for voltage supply to the brake light switch. If you have no power to the switch it can't power the brake lights when it gets pressurized by the brake fluid. Try connecting the 2 wires together at the switch. Do the brake lights come on? If they do that will verify a switch issue. If not, then you need to troubleshoot the power supply. You can also verify if you are getting pressure to the switch simply by loosening the switch in the T-fitting and applying the brakes. You should get brake fluid leaking past the loose threads. Or, remove the switch and hold your finger over the hole in the T-fitting while a helper slowly depresses the brake pedal. You won't be able to hold the fluid back with your finger. This will allow you to flush out the brake line and your finger will act like a check valve, not allowing air back in when the pedal is released. Once you have verified that you have pressure at the switch, and you have voltage at the switch, only then can you condemn the switch. All that being said I will testify that I have experienced short life on brake light switches from Napa. I was replacing them every month or two when I first got my truck back on the road, some 15+ years ago. My local Napa store kept replacing them under warranty, but I got tired of replacing them. I finally gave up on Napa and purchased a Standard brand switch from Rock Auto. That one's been working fine ever since. I cut open the 2 month old Echlin switch from Napa and found the contacts to be oxidized enough to block current flow. -

It's been my understanding that the 8 hole crank flanges were made to accommodate the Fluid Drive couplings. Generally you'd find them in the 230, and larger, engines. However, the 218 in my truck does have the 8 hole crank, because my truck has a Fluid Drive, with a standard 4 speed spur gear transmission. From what I've read, over the years, the 8 hole crank flange is thicker. Probably to accommodate the heavier FD. This added thickness is accounted for in the flywheel mounting flange offset. If you attempt to interchange the 4 bolt and 8 bolt flywheels you may encounter improper starter spacing, as mentioned earlier. It may be wise to do some measuring before going too far down the 're-drill' rabbit hole.

-

This is a video that I reference regarding adjusting the steering box. Although he is working on a Packard, the steering box is very similar, and so that adjustment procedure is the same. I also recommend having someone turn the steering wheel back and forth, with the wheels on the ground, while you look for any loose joints. Even a small amount of play in the tie rod ends, drag link ends, or king pins, will be multiplied in steering wheel free play. Make sure all of these joints are tight first, then go after the steering gear adjustment as shown here. If you get it too tight you'll experience a tight spot in the steering, so be careful to only adjust to zero clearance.

-

Do you mean Rusty Hope disc brake kit? I have his kit on my truck. There are some challenges you'll need to work through, but otherwise it's been working fine for many years now. Much improved stopping power, even with the stock master cylinder.

-

If your engine is in good condition it'll easily spin up to 3500 RPM without issues. Even with 4.10 gears you should be able to run around 55MPH without issues. It certainly sounds loud, mostly due to the fan noise. That and the fact that you are used to modern engines spinning at around 2000 RPM at highway speeds. I found a 3.73 differential assembly out of a '50 Plymouth that was a direct swap into my axle. It allows me to get up to 75 MPH when needed, although I don't like pushing that hard if I don't need to. It's hard to get a clear pic while driving, but here you can see my tach at 65 MPH (indicated), running at around 3100 RPM. When I push it up to 75 (indicated) the tach will show just under 3500.

-

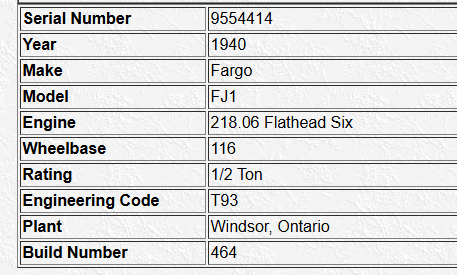

1940 Fargo identification update

Merle Coggins replied to harmony's topic in Mopar Flathead Truck Forum

-

New B-3-B owner with some basic questions

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

If it's been sitting for 20+ years many things can happen. Moisture can get into the cylinders and rust the rings to the cylinder walls. And if it gets bad enough there'll be a layer of rust scale build up on cylinder walls that would need to be sanded down before anything will be able to move. Also, the valve stems can get rusted to the guides making it so that the cam can't rotate. Worse case scenario both of these have happened. When I acquired my truck someone had already removed the head, likely in an attempt to 'unstick' the engine. The cylinders were filled with a mixture of who-knows-what. I pulled the engine and laid it on it's side. From there I could remove the oil pan and all of the bearing caps. Then I could pull the crank out the bottom. I could then use a block of wood and a BFH (Big F---ing Hammer) to drive the pistons down slightly. That gave room to get a flapper wheel sanding drum in there to remove the majority of the rust scale. Then another block of wood and said BFH from the bottom to drive the pistons out. After that I focused on the cam. I was able to grip the cam sprocket with a large Channel Lock pliers and rotate it back and forth a little at a time, while spraying penetrating oil on the valve stems. Eventually I got them all pushed up enough to remove the cam and tappets. Then I could drive the valves closed with a hammer and remove the springs. With the springs removed I used a long punch to drive the valves up and out. My local machine shop was able to bore the cylinders, replace the valve guides and seats, and other misc. machine work, and now the engine runs great again. Hopefully yours isn't that extreme. -

Aftermarket radiator options ('51 B3B)

Merle Coggins replied to ktb's topic in Mopar Flathead Truck Forum

That first radiator that you reference shows the fill neck closer to the center. I'd be concerned that it would end up under the center hood section making it difficult to check/fill. I also feel that the straight upper hose connection would be much better than the 90 degree one. If anything it should be a 45 rather than a 90. -

‘51 Dodge pickup stomp starter

Merle Coggins replied to Bobacuda's topic in Mopar Flathead Truck Forum

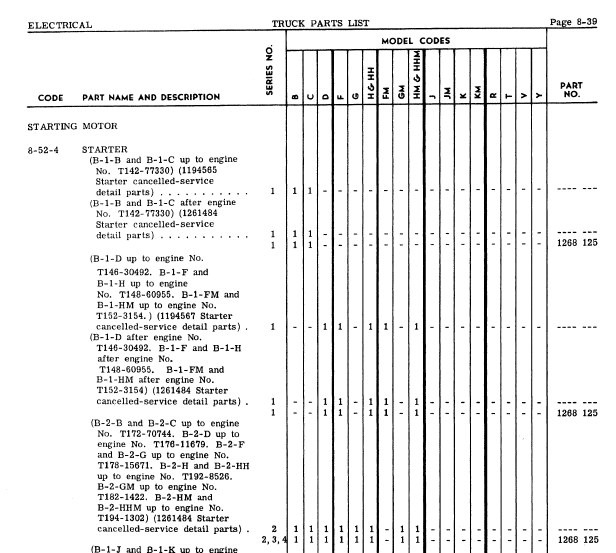

I suspected the --- --- referenced a previous P/N that was superseded to the 'current' P/N, but I don't have an earlier version of the parts manual to reference the older numbers. -

‘51 Dodge pickup stomp starter

Merle Coggins replied to Bobacuda's topic in Mopar Flathead Truck Forum

I took a look in my parts manual and it appears that the same starter P/N is used for all trucks through the H series. I haven't been able to figure out what the --- --- is referencing, but even though they break things down by serial number breaks, and what-not, they all end up showing the same part number. So, it shouldn't matter which year you get one from, ('48-'53) it should work for you. I know you are asking for '51 specific starters, but based on this Parts Manual data, I'll share a few pics I have of the starter in my '50 B2C. These photos weren't specifically targeting the starter when I took them, but I believe they'll show you how the starter yolk/arm on my truck looks, compared to what you may have. I couldn't find any pics in my photo library of the starter after installing the cab, to show the alignment of the starter to the stomp rod. If you want/need that I can go out to the garage this evening and get some for you. -

I can hear it in my mind. Detroit Diesels have such a unique sound.

-

I'm with Dave on this. Cut the bolt by any means available. You won't want to reuse it at this point anyway. If you want to pull the trans out with the driveshaft connected, as others have said, it may give you options to get things in a better angle to work. Either way you'll need to get that bolt cut off to remove the driveshaft flange, because it's covering the nut that retains the drum to the output shaft. That nut will need to be removed to pull the park brake drum to properly replace that bolt. If the hole is worn then a new knurled bolt still won't hold, and it'll need to be welded in place.