-

Posts

2,513 -

Joined

-

Last visited

-

Days Won

78

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Sam Buchanan

-

I don't know how the kick panels were originally attached but the carpet panels in my P15 that were installed in the '80's are secured with drywall screws tapped into the substructure. I've had the panels off a few times and the screws work just fine. The heads of the screws bury into the carpet and aren't readily visible.

-

The Facet brand pumps (as opposed to cheap knockoffs) are designed for years of continuous use. They are the only pump for some British cars (ok....maybe that isn't a ringing endorsement ? ) But my experience with them has been good. They are a little noisy but some vibration isolation helps. The Carter pump in the Plymouth is the only pump, the mechanical pump is now in the extra parts box. The filter is between the tank and pump to prevent trash from fouling the pump. The pump is wired through an inertia switch on the firewall. This is a Ford part that is readily available. https://www.amazon.com/Ford-5L2Z-9341-5L2z9341a-Inertia-Safety/dp/B000NTI03C/ref=sr_1_3?crid=26DA9E3ADD5HJ&keywords=inertia+switch&qid=1674534925&sprefix=inertia+switch%2Caps%2C103&sr=8-3

-

The ECI disc kit for your truck: EC-757CK - Complete Kit $ 825.00 I don't know what kind of pedals your truck has but here are some Chrysler master cylinder conversion kits: https://www.ecihotrodbrakes.com/chrysler-master-cylinder-assemblies

-

True. What I intended to state is that the AB kit appears to consist of components sourced from ECI.

-

Maybe use the German method of torqueing? "Guttintigtt" ?

- 25 replies

-

- crankshaft

- main bearings

-

(and 1 more)

Tagged with:

-

I had a 12v Carter rotary pump on the kit car and presently run the 6v version of this pump on the P15. Both pumps have been flawless for the carbed engines with no regulator needed. My RV-6 airplane has a Facet diaphragm boost pump that has been in service for 23 years. I also had the same pump on a Chevy S-10 pickup after an engine swap. I think the Carter or Facet would work fine for you. Below is the Carter in the Plymouth mounted just forward of the fuel tank.

-

48 DeSoto engine start up after 40 year ago rebuild

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

If the ignition is in good enough condition to run the engine smoothly I doubt it would contribute to hard starting. I suspect you may not have yet found the sweet spot for choke and throttle to start the engine easily. -

I use the existing taillights as turn signals. They are obvious enough for anyone who is paying attention. Nothing will get the attention of a distracted driver.....

-

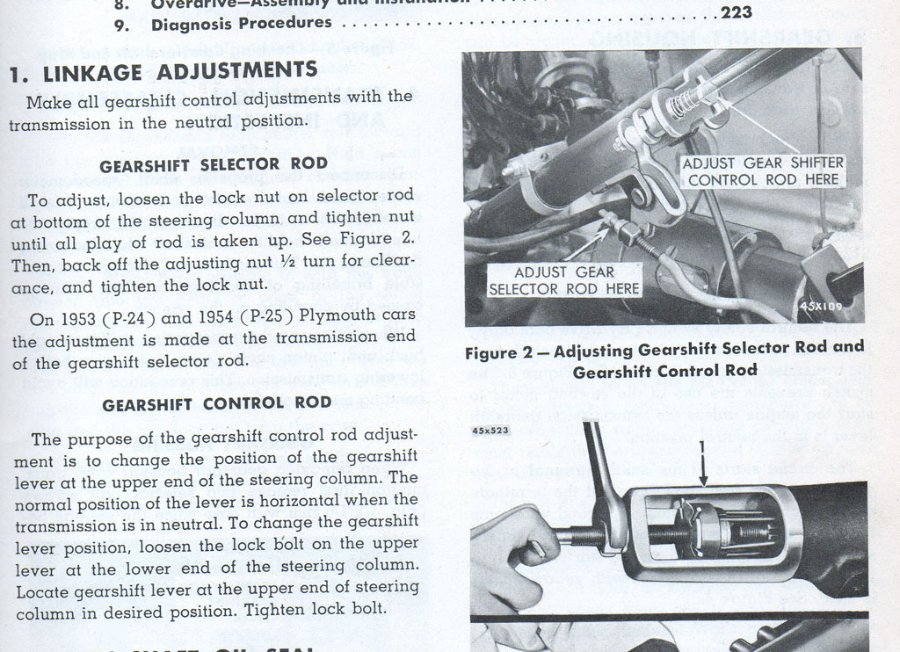

You do have a shop manual, right? In case you don't here is one source: https://www.rockauto.com/en/moreinfo.php?pk=417636&cc=1331862&pt=10335&jsn=414 The manual details how to adjust the linkage. Here is info on adjusting the linkage on my '48 Plymouth with three-speed trans: Congratulations on your new toy and wishing you many happy miles of Moparing.

-

Optima battery suddenly too weak to crank on 48 DeSoto!

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Driving this car now is going to be kinda breezy!! ? -

48 DeSoto engine start up after 40 year ago rebuild

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

That sounds pretty good! The stumble may very well have been due to not giving the engine time to come up to temperature. Fine tuning the choke should make it run smoother when cold. The new rings are going to need some time to seat, the tailpipe smoke doesn't alarm me on first starts with fresh rings. Did you replace the valve guides? Idle that thing down to about 450 rpm and let us hear it tick over. Congratulations on turning gasoline into noise! -

Optima battery suddenly too weak to crank on 48 DeSoto!

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Tell us about the engine overhaul. You've stated it was rebuilt 30+ years ago.....what did this overhaul involve? Did you do the work or was it farmed out? How has the engine been stored for the past thirty years? Also, throttle tip-in stumble could also be due to the distributor advance not working properly. -

Looks like that is an ECI kit. https://www.ecihotrodbrakes.com/dodge_plymouth_discbrake_conversions

-

Appears to be the same kits referenced in the first post of this thread.

-

I'm running the stock 15" wheels with Scarebird on my '48 P15.

-

I'm pleased with the installation and performance of the Scarebird kit with hubs on my P15. https://p15-d24.com/topic/58096-scarebird-disc-brake-conversion-p15/#comment-625750 Update: I just checked the Scarebird website and it appears the kit for my car is no longer available. I don't know if this is a temp supply chain issue or long-term.

-

Possibly. The tricky part is how the rubber transitions from being on the inside of the glass to the outside where the glass is hinged. The front vent rubber is a very complex design.

-

That's my concern, the Steele rubber for the front vent windows didn't fit particularly well even though they were high-$$$$$.

-

The rear quarter gaskets on my P15 are pretty crusty and need to be refreshed. Anyone have a current source for new rubber that actually fits? Yep, that may be a tall ask....

-

This is what cured the second gear crunchies in my P15: The oil? A little pricey. Smooth shifts in all temps? Priceless. https://www.amazon.com/Red-Line-Transmission-Transaxle-Lubricant/dp/B000CPCBEG/ref=sr_1_3?crid=3PQJZ01RRLZRH&keywords=redline+mtl&qid=1673645781&sprefix=redline+mtl%2Caps%2C174&sr=8-3 Modern oils are too slippery for our old trannys, keeps the synchros from working as they should. GL-1 might work OK in your transmission but the RedLine is probably your ultimate fix.

-

Fuel pump operation was one of the first things we suggested should be checked way back when...... I'm trying to be diplomatic.... ?

-

New master cylinder from Rock Auto? - Sleeved instead

Sam Buchanan replied to motoMark's topic in P15-D24 Forum

My personal database includes a near-catastrophe decades ago in my 1964 VW Beetle. A brake line gave way near the conclusion of a vigorous stop and we rolled out into an intersection with no brake pedal pressure. Fortunately the mom in the big American iron saw me in time to nearly get stopped before the bumper caved in my door. If she wasn't so attentive it's likely I wouldn't be in this discussion today. The master cylinder isn't the problem....it's all the lines, connections, and wheel cylinders. If just one of them fails you have zero brakes. A dual-chamber cylinder will leave you with some measure of brakes in the other circuit. In the olden days it was just single chamber and those brakes usually worked fine. But we have better/safer options today. It's a personal choice. -

Problem connecting wire to Sisson choke on 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

If the threads are just wallowed out you might find a metric screw that is close enough in size to cut new threads as you force it in the hole. Soldering or JB'ing should be your last resort. -

Optima battery suddenly too weak to crank on 48 DeSoto!

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

I doubt there is enough meat on the old Mopar bone for suppliers to spend the $$$’s on quality …….. -

Optima battery suddenly too weak to crank on 48 DeSoto!

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

If your wires are solid copper conductors just strip 1/2" of the insulation, bend the conductor over the insulation, insert into the coil....and start the engine.