-

Posts

2,558 -

Joined

-

Last visited

-

Days Won

83

Everything posted by Sam Buchanan

-

Well then.............

-

Are we seeing a gap at the "lower bearing" indicating the joint is not centered in the yoke? Or is that a photo artifact?

-

Welcome to the community! Remote diagnostics is fraught with peril but a couple of things come to mind when reading your post. One, try setting your timing to 10*BTDC at idle. I suspect you will have a smoother idle and our modern fuels should handle the advanced timing just fine. You may then be able to obtain a lower smooth idle speed. Second, perhaps you have an intake gasket leak that is making some cylinders run leaner than others which could also result in difficulties getting a smooth idle. Try advancing timing, setting idle speed down and adjusting the idle mixture screw to see if this helps.

-

Marc, adjust the idle speed down to where it is supposed to be, that engine should be very quiet and ticking over like a fine sewing machine when it is idling. The video sounds like it is idling about twice as fast as it should be. Brake drum looks fine to me, the problem is almost certainly in the U-joint installation.

-

Let's clear up one item up front. It is obvious that you are very pleased with the generator system on your Plymouth and that is fantastic. I'm happy for you. I am also pleased with the alternator charging system on my P15. That is also fantastic, but it seems you are not so happy for me. Yes, my alternator definitely puts out more voltage than the old generator because it was......DEAD, even after two regulators! ? The alternator under light load puts out 7.5v at idle, with all lights that drops all the way down to......7.2v at idle. In regard to the ammeter in my car, here is what it looks like when idling with lights on. I haven't verified the accuracy of the ammeter, don't really care to since I place much more value on the verified voltmeter. The highest I've seen the ammeter after a cold start is an indicated 20a for less than 30 seconds as it declines to about 10a for a few minutes then back down to what you see above. I've never calculated total load on the system, never seen the need to since everything seems happy and the battery stays hot. The wiring in my car has received considerable attention and new grounds have been established on the head and taillights. The lights are bright, don't dim at idle.....and I like them. The wiring and alternator have been perfectly reliable since I returned the car to service three years ago after extensive shop time.

-

My alternator is 60a but that is really a moot point unless pulling a huge load like AC and/or electric fans. The alternator will only output the amperage the battery will absorb to accommodate the load in the system. Even after a cold start I've never seen my ammeter go past 15a for more than a few seconds as it recharges the battery. With all lights on it seems the total load is <10a once the battery is replenished after a start.

-

That's my first impression as well. There is a little runout on the brake drum but the shaft is wobbling ~1/4" near the axis of rotation. That amount of runout would translate to at least an inch of runout on the brake drum if the shaft is bent. I don't know how much/if a healthy brake drum wobbles, never seen one rotating at engine speed. Would also be a good idea to give the output shaft bearing a good look to assure it isn't shot and has axial play....but that would be a really bad bearing.....

-

You have a serious issue with the front universal joint, either mis-assembly or defective. That must be addressed, I wouldn't want to be running the car in gear in the garage with that wobble, something may fly apart!

-

Most of us just make our own alligator clip test leads........ But if you really want to buy something: https://www.amazon.com/Multimeter-Alligator-Leads,15A-Suitable-Digital/dp/B0B66QPTYB?source=ps-sl-shoppingads-lpcontext&ref_=fplfs&psc=1&smid=AK1QMP8OV4LU7

-

Sounds like it ran out of gas.

-

How long does a rebuilt flathead engine smoke out the tailpipe?

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

text deleted -

Thanks! I had looked for those a couple years ago and didn't find them. I ordered a pair, will report back when I see how they fit.

-

It's ok if someone finds me a date, too..............

-

How long does a rebuilt flathead engine smoke out the tailpipe?

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

If the flanges are very straight and one new gasket is used the bolts don't have to be that tight....grade 5 should be fine. Sometimes stainless hardware is used to prevent corrosion and stainless is softer than carbon steel. -

I've lubed the u-joints on the driveshaft on my P15, they work fine and the shaft runs smoothly. But I've had to replace a couple of the ball and trunnion boots which have consequently split due to the sorry quality of the aftermarket boots sold by our vendors who should know better. Yes, modern u-joints would solve the boot problem but I hate to spend large $$$'s on a new driveshaft and retire a perfectly good original driveshaft. I would love to have a pair of leather boots but have been unable to source any. I recall from the past few years some modern or universal alternatives but have forgotten the details. Anyone have up-to-date info on boots that will work with our old driveshafts?

-

How long does a rebuilt flathead engine smoke out the tailpipe?

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

It may just need an "Italian Tuneup"........ -

Here is some info I pulled together in 2019: https://p15-d24.com/topic/50484-servicing-u-joints/?tab=comments#comment-535812

-

I would skip the Mickey Mouse approach and install a 6v alternator. When/if you decide to move to 12v you can sell the 6v alternator to someone on the forum who has gotten disgusted with trying to get their generator/regulator to work.

-

Static timing rotor at 6:30 not 7:00 on 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Don't set the radiator cap on top of the radiator while the engine is running! When it falls off into the fan, damages a couple of fan blades, the fan disintegrates due to imbalance and distributes shrapnel around the shop......you will have a memorable day. Engine sounds good--might be due to the video audio but sounds like it is idling kinda fast. -

new 1947 plymouth owner! where to get parts

Sam Buchanan replied to blochworx's topic in P15-D24 Forum

Rock Auto offers manuals and parts books in either hard copy or CD: https://www.rockauto.com/en/moreinfo.php?pk=10593924&cc=1486874&pt=10335&jsn=377 https://www.rockauto.com/en/moreinfo.php?pk=14711425&cc=1486874&pt=10335&jsn=381 -

No problem at all with using both gauges at the same time. The voltmeter just needs one wire connected to the car's battery voltage and one wire for ground. It doesn't care if an ammeter is being used. I connected mine to the switched terminal of the ignition switch. In your diagram it could be either red wire at the ignition switch.

-

Potential problems could be solved by getting rid of the ammeter. Leave it in the panel if wanted for aesthetics but don't connect it. Add a voltmeter, much, much safer and useful. Here is the one in my P15 located under the dash, semi-hidden by the steering column. I installed it while trouble-shooting the generator and regulator before I got fed up with them and tossed them for the one-wire alternator. The voltmeter is so useful I just left it in place. I still have the ammeter because it works but won't hesitate to retire it if it gives any problems....would only require putting both wires on the same post. This is showing the battery being charged at 7.2v at idle (verified with digital multimeter) with the headlights on. Alternators rock.

-

I hope you have better luck with a local shop than I did. A local shop could cut the glass but it was going to cost much more than the vendor I used and linked above. I added pencil grind to the laminated glass which the local shop didn't offer. Maybe your shops will have better service. Total cost with shipping from Sanders was $76 for the driver door glass.

-

Running lean....leaking vacuum advance??

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

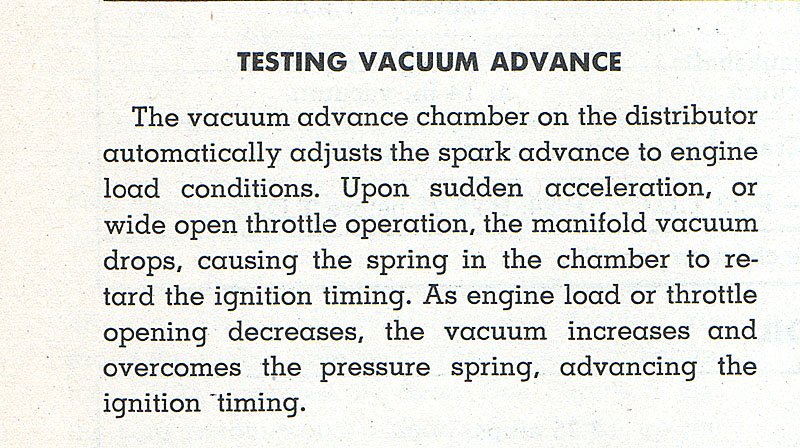

Ken, it is totally stock per the Mopar engineers. Here is a scan from the service manual. But regardless of how it works....mine is busted. ?