-

Posts

613 -

Joined

-

Last visited

-

Days Won

9

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by HotRodTractor

-

I mean how could that not be fun? I would still rather have the A57 - it kinda fits in better around here these days. lol I mean there is a tractor, a power unit, several engines, lots of trucks, and a car all flathead mopar powered.

-

I have no idea what I would do with it... but I want one of those A57 multibank tank engines. It would make for some beautiful music on a quite summer evening echoing through the valley. Most of my neighbors still like me somehow.... lol

-

I'm a few days late - but I would send your mag to Rudy Calin - I've seen some good work out of him in recent history. I've never used him, but that is where my next mag is going. http://www.rebuiltmags.com/ Unfortunately my old mag guy doesn't do them anymore - its a shame as he was only 10 miles down the road. As for plugs - I would use some Autolite plugs they seem to work the best for these old Deeres. Its all I run. I believe the proper plug is a 3116 for the B - but I would double check that.

-

-

I know there are a couple different versions - mine has the 3/16 dies.

-

And to paraphrase Henry Ford: A tool you need and do not buy, you will find you have paid for and do not own. That flaring set has earned its keep. lol

-

I upgraded to a hand held hydraulic flaring tool a few years ago. Quality flares across the board no matter what style with very minimal fuss compared to the tool being used in this thread. I regret not upgrading earlier. Just food for thought for those that have trouble or are needing to expand their flaring capabilities. The one I purchased is made by Mastercool.

-

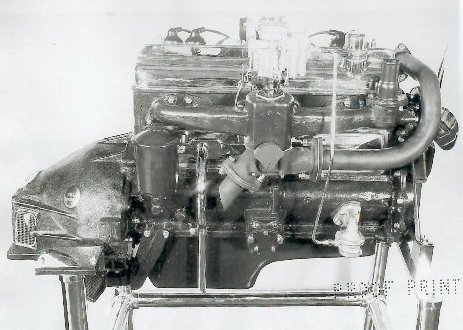

No. I'm casting a new hemi head that more or less resembles the Chrysler A161 prototype of 1947. When I get a little further down the path of a final design - i'll make a post and upload a YouTube video outlining the project, specific goals, processes, etc.... bottom line - I'm designing the head to mimic this one pretty closely with some minor updates and tweaks - then instead of taking the time and money to make molds to make the sand molds - the sand will be direct printed using additive manufacturing. Its going to take me a couple of years to pull the whole project together and stuff it into a 1928 Ford RPU on deuce rails.

-

My 265 is getting a hemi head - I don't have to worry about siamesed intake ports.

-

I know that when I go FI - I will be hiding the injectors into carb bodies. Not my picture, but I did save this as some inspiration - two injectors almost hidden into Holley 94s. I'd have to do some digging on the HAMB to remember his name, but this guy went on to hide injectors into the lifter valley in a Ford flatty - we aren't quite as lucky to have an area like that to hide the injectors. My intent is to basically do an improved version of this on a custom manifold with three throttle bodies with two injectors per. A fuel injected six pack for my I6 if you will. Jason

-

I'm not sure if you are actually talking to Tinytach or not - but I can confirm they don't care anything about vehicle voltage. I used these exact tachs on Briggs and Stratton engines 15 years ago - Its just a little self contained device with a wire that wraps around a spark plug wire and the act of firing the plug generates emf into that trigger wire and figures out rpm based on that.

-

I'd love to see some pictures of the fuel pump and hydraulic pump setup. I also have a 265 Industrial engine (block was cast in 1967). It has a chain driven cam and has a hydraulic pump mounted and driven off the front of the crank (I also have a 230 Industrial that is setup the same way...). I haven't stripped mine down yet - not sure if I will - it has good compression, runs well, and came out of a combine that only had 300 hours on the hour meter.... I kind of believe it too.... the farm that had it must of bought it in 1968, and by 1974 they were bankrupt and sold everything except for 15 acres about 9 of it was tillable ground. They did continue to make some wheat and soybeans up until 2005 on that ground - not sure when they stopped using the combine though, it was several years before that point.

-

Intake Manifold Question

HotRodTractor replied to HotRodTractor's topic in Mopar Flathead Truck Forum

I believe the mating exhaust manifold was made by the Custom Manufacturing Company as an option for this tractor. I was looking closer at that and noticed the square feet on the intake as well.- 1 reply

-

- 1

-

-

Has anyone seen an intake manifold with square mounting flanges at the block? PN 1316477-1 it looks like.

-

What would you do?? - 52 COE Project

HotRodTractor replied to 52b3b Joe's topic in Mopar Flathead Truck Forum

Not all ZTRs are like this. My ZTR has 4 wheel independent suspension - its the best riding lawn mower I have ever been around. Its also big enough that the the front wheels don't bounce - but it is also a commercial unit with a diesel engine. Its big and heavy, but floats like a cloud. -

A very quick search for some links that may help in diagnosis: http://p15-d24.com/topic/34065-fluid-drive-not-downshifting-what-to-check/ http://p15-d24.com/topic/41254-49-fluid-drive-advice-needed/ http://p15-d24.com/topic/16946-a-new-carb-question/ It seems to me there is enough information there to at least lead someone down the path of a diagnosis.

-

I'm not totally familiar with your setup, but I don't believe the issue you are experiencing is with the Fluid Drive. The fluid drive is is just a viscous coupling between the engine and the clutch. The shifting mechanism you speak of sounds like you might have a "Presto Matic" transmission. This type of transmission operates off of electric solenoids and if the previous owner was swapping between 6V and 12V.... I would say you should start your investigation with your electrics. Going from memory there is at least 2 solenoid cans on the transmission and there is an input on the carb. Under certain conditions (speed, RPM) the solenoids shift a gear, essentially turning a 2 speed transmission into a 4 speed transmission. I am sure that if you search on here, you'll find discussions of converting this setup to 12V, find a wiring diagram, and even finding "modern interpretations" of how this system works and how to make it work using just toggle switches to eliminate some of the system for troubleshooting purposes. There was also about half a dozen different names this transmission setup had through the different Mopar branches, so keep in mind it might be listed under one of several different names.

-

Yes there were some factory grill guards available and different styles depending on the year. I have always been partial to this one with the "D" in the middle of it. Only pic I could find quickly, sorry its not the entire thing - I could go out and snap a picture later, but I think you get the idea.

-

I haven't started looking into it, but I want to do similar with my 1-1/2T. I'm wondering if I can somehow adapt something like a ZF5 or NV4500 to it. Not really designed for that heavy of a truck, but used in modern pickups for the type of loads that would be used on a vintage truck like these. Probably not easy, but doable. Another issue that always needs to be brought up... parking brake..... and axle swap is the best way to solve that, but might not be ideal for a heavy truck.

-

Yesterday I picked up an addition to the farm - an 1948ish (still somewhat unsure on exact year) Ward Tractor sold through the Montgomery Ward mail order catalog. These tractors were built by the Custom Manufacturing Corporation and marketed under a long list of names, but were more or less all identical. These tractors were build using mostly military surplus parts and depending on the exact options and manufacturing location, they were more or less Dodge trucks with big rear tires. The Ward tractor now under my care has a little less in common with the typical Dodge truck as the rear axle is very different. It utilizes a Timken rear axle with outboard planetaries - there were some versions that did use actual truck axles with a 2:1? gearbox between the transmission and the rear axle. This particular tractor has a 230ci 6A engine, with a fluid drive clutch assembly, a 5 speed New Process transmission. On the right side of the transmission is an auxilary PTO assembly that runs a 540 PTO shaft to the back of the tractor to power implements as well as the belt pulley on the side. There is also a PTO hookup to run a PTO shaft forward if desired (not sure if it was ever used like that). It has the before mentioned Timken rear axle with planetaries and utilized hydraulic drum brakes for the rear wheels. The dual exhaust was a factory option from Custom and this tractor is basically stock when it comes to the exhaust. This tractor is also converted to LP at some point in its life. I have a large LP tank and misc parts that were originally on the tractor, but now it currently runs off a 20lb LP tank stuffed up under the hood to reduce the weight and make it into an antique pulling tractor. (also notice all the extra weights and it has wheelie bars on the back). These tractors were governed pretty low from the factory (2100rpmish I think) - and consequently they were pretty low on power because of that. I think this tractor is about a 48hp unit as it was shipped from the factory. My plans are to restore the tractor to like new condition - eventually - for right now, I'm just going to clean it up and make it presentable. It needs a good bath, a wax, some wiring cleaned up, some paint on the pulling parts, a little TLC to the LP setup, and it should be good to go. I should note - it sounds damn good under a little load - and I think its going to fly in road gear based on the very little bit I have drive the tractor. I've been hesitant to take it out and open it up as I don't think there is much propane in that little cylinder and I know how much my LP Deere drinks under load.... that grill cylinder isn't going to get me far. Anyway - I hope everyone enjoys something a little different, but mostly on topic. If anyone has any experience on these engines running on LP - I'd like to pick their brains on vaporizers and LP carbs.

-

- 8

-

-

They just want you to post a wanted ad in the classifieds to keep the clutter out of the forum.

-

You know me well! I do want to add a Silver King or a Plymouth to my collection. First - though I want to add an actual Chrysler powered tractor to my collection. I have one I am going to look at on Saturday actually..... I was already planning on taking a lot of pictures because I am sure many people have never seen a WWII surplus Chrysler powered tractor before - this one has a 230ci engine, fluid drive, 5 speed??? truck trans (what I have been told), a 2:1 gearbox that was tank surplus, and a truck rear axle with planetary gearboxes on the ends.

-

My reference book says it was a $3 option in 1955.

-

Very nice to see this back and progressing. I love the proportions - I always twitch when guys chop these trucks and chop the rear window(s) instead of doing what you did. This approach just makes more sense to me and it looks right in practice.