-

Posts

613 -

Joined

-

Last visited

-

Days Won

9

Everything posted by HotRodTractor

-

After doing some poking around it appears that phenolic carb spacers that should work on these carbs are readily available for some other brands. Most notably available for Chevy inlines. 2-15/16 stud spacing, 1.7" bore, and available at least in 1/4" and 1/2" varieties off the shelf, probably more if I look harder. I need to double check a couple of things to see if I can get away with 1/2" without a lot of fuss with the linkage - but that will have to wait until I am back home. Off to Michigan tomorrow, then to the Carolinas later in the week. It seems like this should be an easy test - I might even borrow the thermal imaging camera..... drive it around and get it good and warm under the hood. Pop the hood and take a thermal image immediately before shutting it off. Take a thermal image say every 5 minutes for 20 or 30 minutes making sure just to pop the hood long enough to image. Repeat the same test with the spacers installed.

-

Great list - with many interesting discussion topics - but I have one question. If going to all that trouble with electric fans, electric water pump, etc... why use a belt driven power steering pump with a remote canister? Electric power steering pumps are getting to be more common and could further help clean up your engine belt drive system. Simply tuck it away out of sight and route the lines as you see fit. Anyway just some food for thought.

-

I'll certainly test the coil next time it happens. I didn't really give that a thought as it seemed to me that it was fuel starvation related.

-

Correct. I haven't really found any silver bullet to the problem. At the end of the day its heat soak. Heat soak in the carbs, heat soak in the fuel line, heat soak in the fuel pump. I suspect that the slant 6 with the longer intake runners probably helps dissipate just enough heat that it isn't an issue. Pure speculation though. In any case - a little bit of cranking and it fire and cleared her throat. Maybe 4 or 5 10 second bursts. More than I would have liked, but if its the carbs themselves getting heat soaked - it shouldn't take too much air going through them to cool them off enough. The only other quicker way that would be easier on the started would be a little alternative fuel being either sprayed or dumped down the carbs. I'm not really about that.... so I'll monitor it and make a decision as I get more experience with this exact issue. It might just be what it is. Granted I have not checked the fuel pressure - but this acted a lot more like a vapor lock than a flood situation. I've always had to choke this engine to get it to fire, both before and after the electric fuel pump. In fact I ended up choking it more than I thought I should have to get it to fire when it was heat soaked. Once fired it was great. I've had the electric fuel on the car for several days at this point, yesterday was just the first time I really went out and leaned on it to make sure everything was good. In fact I've had the carb tops off twice now to make sure the electric pump wasn't overpowering the float and causing issues.

-

Yeah - I'm not surprised at hard starts when hot - I've had more than a few vintage engines that didn't care for hot restarts. I also didn't buy a turn key car. It was never advertised as such. Long road trips are totally on the list of things this car can do now. Take anything and have it sit for a while and things will deteriorate some. I'm happy with my purchase, and I hope that the seller is happy as well.

-

Man... I certainly don't need any more projects...... but a Desoto convertible would make me smile........ especially at that price. I see the guy backed out, but I would have been all over that like white on rice.

-

Fuel system is good to go. Tank seems to hold gas now,, electric pusher pump installed and operational. I do have to fix a bad clamp on the fuel filler neck, but that is minor and a rather quick fix, I just didn't have time Sunday evening after I discovered it. I found that I have a slight coolant leak - lower radiator hose seems to have a bad seal at on end. Going to get a new hose and new clamps so that can be crossed off. Its doesn't appear to be a huge leak, but I did have a slightly damp floor under the front of the car after I returned it to the shop from beating on it hard to see what shakes loose. I spent some time trying to figure out what I needed for my speedometer. The drive and driven gears to run the cable are quite a complex mess the more I dug into it. I ordered a new driven gear that should get me close IF it works. Apparently there are at least 3 different diameters of drive gears combined with different tooth counts. I figure the new driven gear has about a 25% chance of working. lol It was $6 added onto an order I was already making. If it doesn't - then I will have to pull the tailshaft housing and swap out the drive gear and combine that with a new driven gear and I will be in business. Rough calculation says the speedometer is running about 20% too high. I took the car out Sunday to run a couple of errands and put it through her paces. It performed well, although it did have a bit of a time firing back up after I stopped to pick up some last minute items at the grocery store Sunday evening. I took her up to about 80 on a secret test track in Mexico. Everything worked well. I was concerned that the electric fuel pump I installed was actually going to be borderline too small at WOT, but it appeared to keep up just fine from a SOTP perspective. I'll make sure and have a pressure gauge installed to confirm, but for right now - I'm happy.

-

I had a 1950 Lincoln Cosmopolitan that was still 6V with an electric pusher pump on it feeding the mechanical. It worked real well. Make sure you get a pump that doesn't have too much outlet pressure, otherwise you will have to have a regulator to dial the pressure back so you don't overpower the float in the carb. I also just installed a 12V electric fuel pump on my 1948 Plymouth, setup the same way as you are desiring. I've put about 50 miles on it with no issues so far.

-

Crankshaft and rods are different between the two displacements, everything else is more or less the same. I can't really help you on the C54 number, except to postulate that it is about a 1954 Chrysler. Only way to know for sure the displacement is to measure the stroke of the engine using the plug over top the #6 piston.

-

Fantastic!

-

I had a 53 Pilothouse in high school (graduated in 2000) - being a poor broke high school farm kid - I repaired the swiss cheese bottom of that tank with JB Weld circa 1997. I sold that truck in 2011 and the patch was still holding. Like most things - I've found the secret to using it being good clean metal and a bit of a scratched up surface to the epoxy to latch onto. I can't say that I will have that kind of luck with this repair - but if it lasts me until next winter, I'll be content. I simply want to drive and enjoy the car as much as possible now that better weather is upon us.

-

Who Is Actually Driving Their Vintage Mopars?

HotRodTractor replied to 55 Fargo's topic in P15-D24 Forum

It's a good thing it rains..... It currently resides on a dirt/gravel road. Lol -

Electric fuel is all hooked up and functional with a mechanical pump still on the engine. I'm using a HEP-02A 12 volt pump, which looks like its good for right about 180hp depending what online specs you find for the pump, so there isn't a whole lot extra overhead. I have a much larger Carter pump sitting in the shop if I need more, but I need to find a good place to mount it. I took the car out with the GF for quick trip and everything seemed to work just fine. I still need turn signals up front.

-

Who Is Actually Driving Their Vintage Mopars?

HotRodTractor replied to 55 Fargo's topic in P15-D24 Forum

Rinsed off the Hammond Rd dirt and mud and went to get some gas and ice cream on Sunday. Bumped into a Mopar Muscle guy at the ice cream shop - he was all excited when I popped the hood to show a dual carb'd flathead. I was going to take some pictures of the car in downtown West Liberty - but rain (and tornado warnings) chased us back home before that happened. -

Very useful! Thank you!

-

Thank you. Interesting that the D6G1 utilizes the 159 jets. I'm going to have to tear one down and document the differences and variances better.

-

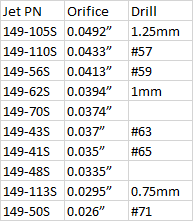

Step up Jet Chart - or best that I have been able to do so far. Just in this range of diameters it would be pretty easy to expand out to 21 different flow rates if you count in readily available metric drill bits (which it appears that Carter did). Too bad they didn't utilize some sort of smart part numbering scheme.

-

Thank you - may I inquire as to who sells jets that I can buy a sampling of? I appreciate the idealistic approach to just using real gasoline, unfortunately that is simply not a realistic approach if someone wants to take nice long road trips and be able to get gas at readily available and convenient locations. Yes - I know there is something like 100 different gasoline formulations available in the US based on region, time of year, elevation, etc... will the state of tune be 100% perfect all the time everywhere - of course not, but it will be usable and good enough. I knew that Grose had passed on, but I have seen his jets for other carbs reproduced and was hoping there also an equivalent readily available for our Carters. I'm not surprised that there isn't. I'd love to get a copy of the D6G1 sheets if available. I have many others, but I lack that one and since that is what I have a pair of on the car, it would be nice to know what the stock factory parts are exactly. Also thanks for the center section information. I have not looked that closely at the carbs yet. I didn't think the jets were the same, but though my limited observations I found lots of 159 series info, little 224 series info. Yes I agree - carb bores ultimately control what the carb is capable of. That is the airflow control, the jets simply meter gas into the flow - and hopefully at the desired air/fuel ratios. You setup the airflow, then you adjust your jetting to get to a target. Ironically you state that I am factually incorrect, but then turn around and make my exact argument. Ball and Ball carbs are not as well supported in the aftermarket either for stock tune up parts or aftermarket vintage race tuning components simply because of the wonderful number of variations that are present. The built each carb to the intended application back in the day and it made it hard to simply take just any Ball & Ball carb and do x, y, and z to it and get the desired results like you could with say the ever popular Stromberg 97. Its variety in a way lead to its downfall in long term aftermarket support. There are at least 2 (maybe more) manufacturers making brand new 97 carbs today, I highly doubt anyone is considering tooling up to make a run of brand new Ball & Ball carbs. I'm not saying variety is a bad thing - I like variety as it gives a ton of options - but that also leads to lots of complications. Case in point - jetting - which this thread is about. I have yet to find a jet chart that lists all the part numbers, flow rates (and the info on the test conditions. ie gas at Xpsi over the course of a minute or whatever), and orifice sizes. A quick Google search and there is piles of documentation and PDF documents on tuning 97s. Yes - while my interest in documenting carb components is somewhat self serving (tuning my own carbs) - its documentation that I intended on sharing with the community as a whole. This thread simply started as a way of compiling jet information, and granted I asked about the cut sheets for carbs I own and lack the information on. The whole mixing and matching of carb parts to try and build something else came in later. Perhaps my car is tuned to the nth degree and its perfect. Perhaps not. In any case I still plan on compiling information to aid myself and assist others that want to make their cars the best they can be for themselves. No offense taken - I can only ask for help gathering jet information and attempt to keep the thread steered in that exact path. Mixing and matching carb body components is a whole different level and thread topic. And as far as being an expert - if you would like to discuss the multistate physics of atomizing an incompressible fluid into an compressible fluid - I'm game - its literally my job. Quite frankly for what I am after, writing a custom OpenFOAM script just seems like a waste of time when I just need to go a hole size or two bigger or smaller to achieve what I want. Perhaps I came off a bit harsh - but I really wanted to keep this thread simple and about the jetting. Enjoy your occasional, if unenjoyable, visit to this site. I'm sure that if this was a conversation in person it wouldn't go this way and it could be perfectly civil and rewarding for both over a beer.

-

I get the whole smaller bore, less CFM thing. I engineer air atomized lube spray equipment for a living. I'm currently less interested in making a "frankencarb" than I am in having a list of jet sizes for both the main and step up jets just to use as a baseline for tuning any particular carb a little richer or a little leaner regardless of cfm rating. If there is a chart that says you have a -13S jet with 0.XXX" diameter through hole and you need to lean it up a couple of steps to a -12S with 0.XXX" diameter hole, you would then have a part number as well as a diameter that you could shoot for. Consider this all information gathering for when I go to tune my dual carbs this summer.

-

It came from your friend Michael Warshaw. It looks like a good piece and should fit a stock car quite nicely.

-

Here is the crux of the issue. The new "1948 P15 tank" is just a couple of inches longer than the tank that is in the car. In fact the tank is 33" wide. There is only 31-1/2" between the dual exhaust - plus it appears that the tank should mount slightly more to the driver's side to get the filler neck where it needs to go (also notice the filler neck locations between the two tanks). My epoxy repair looks pretty decent and appears to be bonded quite well. I'm going to let it sit for another day and make sure it is good and cured, and then go over it looking for any thin spot or holes I might have missed and address them before putting the tank back into the car. Still not sure if this will be the long term solution, but its the today solution so I can finish the gas supply and start driving the old girl and enjoying her a bit in this nice weather. The last thing that I HAVE to do before driving it too much is get the turn signals up front. Everything else is a want and not a need.

-

I remember reading that a while ago. Thanks for the reminder. If I recall correctly you did exactly what I am planning on doing in the future. I'm just simply asking questions trying to understand it better now, so I am prepped when I get into the meat and potatoes of it. The solder is a good idea too - simple, quick, and effective.

-

Engine serial number: T112915511164 C That seems like a lot of digits - but assuming the engineering code is "T112" - that means its a 23" motor, either a 201ci or a 218ci built between 1941 and 1947 used in a WC and some WC-15 vehicles. I know that doesn't tell you much, but its what I have. Good luck.

-

I don't doubt that. In fact I just found a thread this morning where you weren't happy with the previous owner's positioning of clamps on the fuel filler neck. lol This is a thing that happens with modified vehicles. No big deal. Just a fork in the road.

-

I believe the tank I bought is correct for the car, but the tank that was in the car was not. The new tank is "flatter" and "wider" with a welded elbow on the fuel filler neck. Even the filler neck is in the "wrong" location (either location can work, but originally it looks like the filler neck should be at the back of the tank and not the front). The tank is wide enough that it doesn't fit between the dual exhaust - and in reality the driver's side exhaust is what is really in the way. I'll snap some pictures of the tanks side by side and it will be obvious. I never even gave it a thought that the tank in the car might not have been an original tank. My bad. I shouldn't have assumed. I'll get it figured out though.