-

Posts

613 -

Joined

-

Last visited

-

Days Won

9

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by HotRodTractor

-

I'd love to find me a 413. Add some wheels and a seat and have a hot rod. lol

-

Carter B&B: The worst carburetor ever made?! Discuss...

HotRodTractor replied to wagoneer's topic in P15-D24 Forum

I'm a firm believer that B&B carbs get a bad reputation because of the wide variation that exists in their options. There are a wide range of body and jet configurations that have great impact on how each one behaves. Add in a few decades of mixing and matching parts and I would be willing to bet that a decent percentage of them are actually mutts. When you get a Stromberg 97 - that is what it is. I'm guessing the Stromberg WW has a little more variation than that, but I would bet its no where near the variation found with the B&B carbs. I'm not saying they are the best carb, but they are definitely not a bad carb. Like anything else they need setup appropriately for the application. -

I do agree with this. At first I thought it might have been them simply evenly spacing the hemispheres and having some asymmetrical quench areas in each cylinder - but with the information about the displacements that has been located, its very likely that while the outside of the block looks similar, the insides might be drastically different. We might never know the actual truth of the matter.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

So - I found a gentleman that has a lot of records from the engine development program. He acquired them from the estate of a former member of the development team... and apparently this guy hoarded boxes of old development information. At this point, he hasn't found a lot about A-221, but here is what he does know: A-221 3.5" Bore x 4" Stroke 231cid (230.9) - This matches the description in the Chrysler Engine book as far as displacement goes. A-221 EX.6 3-19/32" Bore x 4" Stroke 244ci (243.5) A-221 EX.7 3-19/32" Bore x 4-5/16" Stroke 263ci (262.5) These are all marked as 1950 development projects... Obviously this doesn't tell us a lot about what I think most of us care about - but it is very interesting to note that the bores and strokes do not line up with existing "stock" components for any of these engines (at least not that I am aware of). It also tells us that there were at least 3 of these engines.... possibly as many as 7 different configurations that were used for testing purposes. The A-161 is the 1950 Chrysler c38 Hemi V8 project. My contact is going to keep looking and see if he finds anything of interest.

- 33 replies

-

- 1

-

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

I've never used a creeper/seat combo - but I do find creepers handy. I have one that gets used frequently. Also since I work on a lot of late model trucks - I have a top side creeper that is fantastic for working in a large engine bay without laying on the hood latch and every other uneven surface under the hood to reach what you are working on. Best seat I have in the shop for work is an old steel milk stool with a stamped sheet metal tractor seat bolted to the top of it. It seems to always be the right height for most of what I work on, and the tractor seat swivels easily with the single bolt holding it to the milk stool.

-

Ladies and Gentlemen, the End of an Era...

HotRodTractor replied to ChrisMinelli's topic in Off Topic (OT)

Also - a lot of the guys that claim "nearly free" are some of the early adopters of Tesla. They literally have free supercharging.... so as long as they recharge at a Tesla supercharger, they aren't paying for electricity. -

Ladies and Gentlemen, the End of an Era...

HotRodTractor replied to ChrisMinelli's topic in Off Topic (OT)

Doesn't answer your question directly.... but here are a couple of examples for cost of ownership comparisons. Your mileage may vary... LOL https://evannex.com/blogs/news/total-cost-of-ownership-tesla-model-3-vs-toyota-camry https://cleantechnica.com/2019/09/27/tesla-model-3-vs-toyota-camry-5-year-cost-to-own/ -

Ladies and Gentlemen, the End of an Era...

HotRodTractor replied to ChrisMinelli's topic in Off Topic (OT)

Charging stations are literally everywhere around me. Lots of restaurants are near them, hotels, even tourist attractions have them now - so you can go, and enjoy the sights or whatever while your car charges. I know several people with Teslas - the most prolific driver that I am aware of in the group has well over 100K miles on his Model 3. He drives it everywhere he doesn't need his truck and is in and out of industrial facilities constantly with it. Does the high speed quick charge while grabbing lunch, or while doing a conference calls, returning emails, etc... right from the comfort of the car. Which by the way stays pretty comfortable as the cabin maintains temperature automatically all day long if you tell it to. Works for both heating and cooling too. This does cut down on range some if its not plugged in, but for some that is a convivence worth having. -

Ladies and Gentlemen, the End of an Era...

HotRodTractor replied to ChrisMinelli's topic in Off Topic (OT)

I actually like the concept of electric vehicles. While I think it might be a while before I take the leap myself for various reasons - I have had my eye on Rivian. I firmly believe they have positioned themselves to give Tesla a run for their money in the truck market. Not that it would take much.... the Cybertruck looks hideous to go along with how useless it would be to most people that need a truck. I know I have a couple coins earmarked to use if Rivian ever does an IPO.... -

Interesting.... the T137 website lists a T112 engine as a 23" engine.... T137 T Engine list HERE

-

I never said anything about testing by the general public. One or two company owned cars for early testing wouldn't be out of the realm of possibility. I don't disagree about making assumptions. I am looking for evidence. Posting, commenting, discussing, all gets eyeballs on a subject and you just never know what you might find. If evidence is found - that will help confirm or deny - as well as start a whole new wave of discussion. Since resurrecting this thread I have 2 new leads. I have no idea if they will actually bear fruit, but its 2 leads I didn't have. I'm not all the concerned about the missing head bolts. For a flathead - those would be absolutely necessary - for a hemi head - those extra bolts do little to nothing to contain combustion. Enjoy your coffee and pie.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

That could be easily mitigated by having the intake on the left and the exhaust on the right. Not to discount the idea of simply running the exhaust down and crossing under the oil pan to travel down the right side of the vehicle to miss all of that troublesome stuff found on the left in a left drive car. I suspect that some of the stuff that you see in the pictures above was done specifically for road testing. I have seen blurbs that state that inline 6 engines equipped with a hemi heads were used in road tests in cars (maybe trucks too). To me the above candidate seems like a likely choice for such a test. Its a bolt in for a test car - it has manifold heat, exhaust that could hook up with existing exhaust, gas line hookups in the same place, wiring connections all in the same basic locations, etc... While not perfect for overall performance potential, pretty solid for a road test to show significant improvements over existing offerings. This is all pure speculation on my part without evidence to back it up. I'd like to find that evidence. Its certainly understandable that they would want to do real world road tests to prove out a new direction for their engine development teams.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

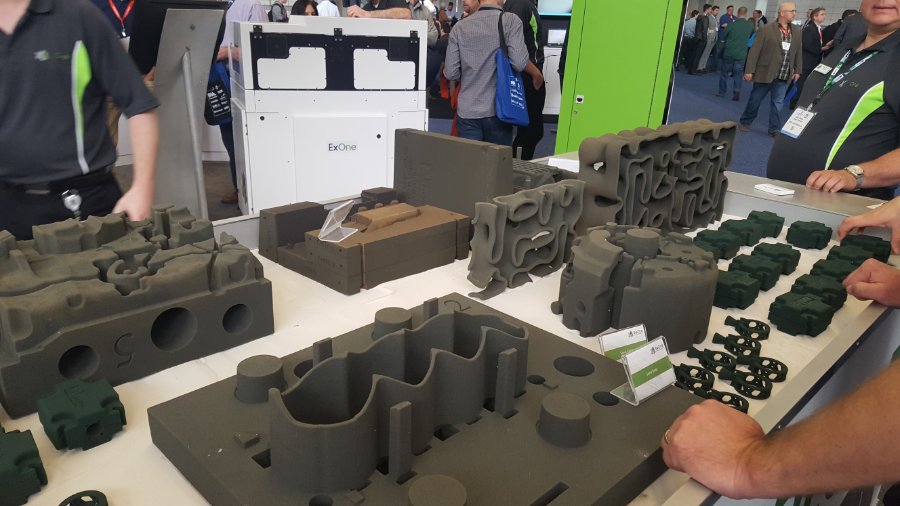

I love the post and the search for good data. Its fantastic. However - you no longer need to make actual castings to test out ideas and designs on the flow bench. Additive manufacturing can cut huge costs and chunks of time out of that development cycle. Design it, print it, test it. Modify. Rinse and repeat. Then make your foundry tooling and only have to worry about tweaks and changes that might need to take place to cast good parts. On Edit: Its also very possible and cost effective to direct print 3D sand molds today to also help cut costs until its time to make production tooling.

-

Roof also made 16v conversion heads for 4 cylinder Dodge engines as well. Others made more Dodge OHV conversions as well. Morton and Brett comes to mind. Probably others.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

I think this has multiple reasons why it didn't take off, even if it was successful. The push was for V8 due to packaging size - ie shorter in length. The head above is significantly more complicated, but not more complicated than the V8 production heads that eventually came out.... but the block is also more complicated - it adds at least one more "hold" in a machining operation to angle the lifters - and that tooling is rather long and deep to get into that location in the block. Not unachievable, but not ideal for a production environment. These angled lifters also add complication in the cores used for casting. Its the difference between a prototype for testing, and actual implementation in production - lots of successful prototypes fail in that transition. Successful for a test engine might not be longevity. It could simply be efficiency, power curve, peak power, or any number of other test criteria. We don't know exactly why it was built, but we do know that it was built. You could be right - it might never have ran - but I swear I saw a picture of this engine on the dyno, but I haven't been able to locate that photo again. The search continues.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

Fair enough. I'll do my best to make some exhaust noises in the future. lol

- 33 replies

-

- 1

-

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

Yes - that book is how I verified the development number to A-221. I'm aware that it was an experimental engine - one of several that ultimately lead to the first hemi V8s being introduced. Adding a hemi head to a flathead does work very well... its just not cheap. That is one reason why the Ardun conversions for Ford flatheads are so coveted. Or more recent and more on topic - the Edgy F-head for the stock engines the vehicles that have brought us all together. There are plenty of other examples in the early days of hot rodding of converting a flathead into an OHV or an F-head configuration - particularly on early 4 cylinders.... there is a lot of interesting and cool parts to be found. Several examples for the Ford flathead V8 can be viewed HERE I'm going to disagree with you on that. I can't say for certain how this engine ran, but I do believe it did run. I've studied the photos hard - and have the start of the solid models as a proof of concept before I came to the conclusion that its not only possible, but its very doable. Experimental overhead cam on the left. Experimental push rod hemi on the right - granted - this image shows the lifters tilted to correct some geometry - but its not out of the realm of reality to make that happen.

- 33 replies

-

- 1

-

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

Correction: This is the A221 experimental engine. Built in 1948 I now have a kind of crappy picture of the dual overhead cam inline 6 cylinder engine coded A173 - it is significantly different in construction than the engine pictured above. The carb and intake are on the driver's side of the engine with the distributor being in the back on top? of the head maybe.

- 33 replies

-

- performance

- conversion

-

(and 6 more)

Tagged with:

-

I'm lost. I thought the engine and the potential power it produces was the discussion.....

-

Eh - I just ignore them - there is still a TON of good information on there, and new info gets posted all the time. Its the internet.... can't let the masses ruin it for you.

-

I know there was a pretty lengthy thread on Inliners International a LONG time ago about doing the same thing. I believe it was the user "Hudson" and he was discussing doing it on his Custom pulling tractor with a Dodge flatty. I know he posts on the HAMB, but I don't recall what his screen name is there. If you happen to know of the thread on the HAMB - I would love a link. I did some searching and came up rather empty.

-

I'd love to come - but this year isn't it. The GF is up to her eyeballs in Covid testing and vaccinations (she works for the local health department and helps run the drive through clinics). Current work travel restrictions for myself, which could change at any time, would also be problematic. I hope you have a fantastic and safe turnout!

-

I would measure to verify - but I seem to recall the factory aluminum head I once had used the same plugs as the cast iron head. I never installed it, so I could be wrong.

-

Now Milton is a guy I understand. I actually started with the company I am with 15 years ago with my desk in "Storage Area B" lol Business was booming and engineering was the bottle neck, so people were hired and shoved everywhere they could.

-

The answer is: It varies. Some people just run 2 of the same carb that was originally equipped on the engine (Make sure they match!!) - this is what is in my 48 Plymouth. Some people search out for carbs used in the factory dual carb setups - not an easy task - and some parts are quite hard to find now. - I have a set of these, but have not ran them yet. That vehicle is still under construction. Some people use brand new Daytona UN2 carbs - they are basically manufactured as vintage 1 barrel carb replacements. These are the carbs that were on the car that did the Peking to Paris race not that long ago.... until then I wouldn't have considered them as an option, but it running a road race across 2 continents makes me want to take a closer look at them.