-

Posts

3,467 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

Waddya think- use #2 Permatex on new transmission gaskets?

keithb7 replied to '41 Fat Bottom Girl's topic in P15-D24 Forum

@Sam Buchanan Another perspective on the front cover differences is shown. In the past I have sprayed my tranny gaskets with Permatex Copper to help seal them up. Seems to work fine. Not hurting anything anyway. Trannies are fun!...Despite the mess. -

Doh! Never thought of that. I suppose thru trial and error I’ll find out. I have a pretty good array of technical and parts books for my ‘38. This one supplements them. I’ll cross reference things and find out.

-

My Hollander Exchange book arrived today. Wow. Lots of good info in there. Mine’s dated 1950. I’d recommend it you are a Mopar geek. Fixing your own cars.

-

My car is positive ground. My engine is currently removed, so the distributor and wire is out with it. The way I came to wire mine up like this is: I figured positive ground. When the points close it lets the 6V in the outer (primary) coil go to ground. So the positive side of coil, (primary winding) goes to ground. Ground is positive. Makes sense to me.

-

I used the original key switch and wire. I spliced-on an extra length of old cloth wire I had kicking around. Solder and heat shrink the splice . There already was a hole in the firewall. I added a rubber grommet to the hole to protect the wire from rubbing through on the sheet metal. I fed my wire to negative side of new 6V coil. Works perfectly. The old metal tube with the wire inside it, was an early anti theft device. The hot wire to the coil was encased in a shield of armor. Might take a thief 30 seconds longer to hot-wire it and drive away. I cut the metal wire shield and tossed it away. Just leaving the wire. I’m not too worried about anyone stealing my ‘38. Most don’t know what a stick shifter is. Lol. Besides it rarely leaves my line of sight. I’m not sure what size that old cloth wire is. If I were buying a piece of wire today, I’d probably go with 12 ga. No smaller. 10ga would be nice too. The 6V system sure loves fat wires. A few pics of my hack work. I’m not trying to build a show winning car. I’m trying to drive and reliably enjoy an old car that looks like it just came off the farm. So far that’s working for me!

-

I used that same Daytona valve in a carb rebuild last summer. Worked fine. I thought it was odd too. I’d never seen one before. But like you, I thought what the heck throw it in. I’ve had no problems.

-

Took my new buzz box over to a buddy's house last night. He is set up with welding gear. He got me started. We tried stick welding mainly. Various amperage and different sticks were used on some plate steel. I had fun. It works well. Now I just need to spend some time burning stick and developing a feel for welding. I will try flux core next. Then finally I'll get some inert gas and try MIG later. Sounds like MIG is the cream of sheet metal welding. I guess I'll find out. I bought an auto-darkening helmet. The lens does not seem to get dark enough. I'll take it back. Toss in another $150 and walk out with a higher quality helmet. Trade up! An electrician is booked to come on Friday morning. To tie into my 220V and install a wall socket in my garage. Then I need to fab up a welding table and get a 220V extension cord. Whew...So much cash to fork out to get set up! It'll all come together and be worth it. Its one item coming off my bucket list: "Spent lots of money to get set up so you can at least screw around with welding, and wreck stuff" - Check!

-

New guy, just want to say hello , a thank you & a couple questions. (-:

keithb7 replied to Saskwatch's topic in P15-D24 Forum

View the photo with your phone. Snap a screen shot of the same photo. Tweak the photo if needed. Crop it if needed. The screen shot will now be saved in the folder with all your other photos, however it will now be a much smaller sized file. Lower resolution. Use that photo to attach to your message and post it here. -

Decades of huffing brake clean, flathead exhaust fumes, and gear oil has got me looking this good today. Imagine what 10 years of welding fumes will do for a guy's complexion?

-

Fairly remote area. I'm tempted to go get it. 3 hrs drive from my place. Free! You just don't see many of these around. Would be a fun one to restore. Too bad so many front end body panels are gone. Maybe they are laying beside it in a scrap pile! Mount Robson is Canada's Highest Mountain. It may have been some type of service truck for the tourists back in the day? Looks like a tree fell over on the cab at some point. I already have Mopar projects on the go. Garage is full. I don't want my front yard looking like a scrap yard. I'll pass. ?

-

I watched that video recently too. I thought a rookie could learn more if there was some explanation. Why things were being done a certain way. I believe this block is getting no machining. No cylinder taper or out of round measured. What did the crank and rod bearings measure up for wear? Taking the top ridge off with a reamer makes machinists cringe. My understanding is its pretty easy to wreck your cylinders doing that. Especially a rookie. If you have a you tube channel and you need content, this works to keep views up. If you need to rebuild an engine, have reliability, and good return on your investment, this fails in my opinion. Its an experiment. Slam new parts into an old block. Roll the dice. See what happens. It’s entertainment. Not education in my opinion.

-

30 or so years ago this was a project they made me build in trade school. A guide to sharpen bits and maintain the correct angle. I’ve had this floating around and transferring to the next bigger tool, my entire adult life.

-

My latest toy showed up this morning. I have put off learning to weld for too long. I'll be 50 soon. Never too late to start I guess. I looked around at entry level Miller and Lincoln welders. 110V and 220V. I compared prices, settings, quality and read internet ratings. I began to realize that the entry level, home hobby welder market is very competitive. Top name brands utilize off-shore labor and materials too, to remain competitive. I decided to look into a made in China welder. Not ideal, for some reasons. I agree. I weighed the pros and cons. Read the reviews. I've never welded. I want to try my hand at it. This one covers MIG, TIG, Stick, accepts gas, and flue core wire too. The price is extremely low when compared to leading brand name welders. You get what you pay for. My welds will suck no matter what I buy. I'll wreck stuff no matter what I buy. The reviews on-line are promising. What the heck, I went for it. I can play around and learn without spending 4 digits on a welder. If I get half decent results and like it, I'll buy a better one some day. If I suck and just burn up everything? Well, that could very well happen. So I'll have invested less for my experiment. Next I'll tie into my 220V dryer hook up. Its in the wall right in my garage. I think I'll add a switch so either the dryer or the welder is on. I'll try some 6013 and stick weld first. Wish me luck. Much reading and experimenting to come. Anyone want to come show me the basics?....I'll take ya for a ride in my 53 Chrysler. Keith

-

Coolant Temperature Probe Ports Across The Years

keithb7 replied to keithb7's topic in P15-D24 Forum

After Richard’s comments (thanks @desoto1939) I poked around in my 265 engine compartment. Pic seen. The ‘38 temp probe in my pipe adaptor as seen in the pic above, does thread in nicely However looking again, it bottoms out. Indicating the probe is not a tapered pipe thread. Its some type of straight thread but same tpi pitch. Yet the ½” pipe adaptor tapers nicely into my head. Hmm. Richard is onto it. A special adaptor. Perhaps before I pay $40 shipping for and $30 for a special adaptor, I’ll try loading up the sensor threads with silicone tape. See if I can get it to bite in and seal. -

Spark Plugs for a 1948 Chrysler 251cu. in. L Head

keithb7 replied to Tom Skinner's topic in P15-D24 Forum

I can’t say for sure on your questions. I can offer that my 265 engine, (same bore and head, just a ¼” longer stroke) uses Autolite 295 plugs. -

Coolant Temperature Probe Ports Across The Years

keithb7 replied to keithb7's topic in P15-D24 Forum

Back from the store. ½ pipe reduced to ⅜. Bingo. The 218 head shall be used. Thanks folks. Always a pleasure doin’ business here. -

The below photo shows two cylinder heads that I own. Left is a 1949 Canadian 25” 218 ci. Right a ‘54 Canadian 25” 228 ci. The 228 engine was removed recently from my ‘38 Plymouth. Neither head has the correct size pipe threads for the original ‘38 temperature probe port for the dash gauge. (⅜ pipe I suspect) I think the 228 head Has ¼ pipe. (Seen on right). The 218 has ½” pipe. I think. I don’t have tools to check pipe threads. I'll just head down to the store and start by comparing pipe adaptors and bring some home. Option 1: Thinking I’ll drill out and tap the 226 1/4 pipe head port to fit the ‘38 temp probe. Anyone have of any concerns with me doing that? Option 2. The 218 head with ½ pipe port. I source a pipe adapter and drop it down to ⅜ pipe. One of these heads will go back on my pulled 228 engine. Then back into my ‘38 Ply. I am thinking the 218 and the 228 heads have the exact same cc sized combustion chamber. Therefore there is no compression gain to be had, if I put the 218 head on. Sadly. Would be cool if it did. Comments or concerns are welcome. Thx. Keith PS: As a side note, my 228 3 3/8” bore engine will be bored over to 3 7/16” to net me a 237 ci USA Desoto engine! That alone will net me some increased compression. (Same stroke larger bore)?

-

The gear box housing is stamped 666389. A Canadian build so that may make a difference compared to what your Hollander book states. i have noticed some differences in the parts book that I have. Different parts used depending on if Can or USA built cars. I've got some parts coming. We shall learn what transpires here soon enough. I also sourced a Hollander Interchange book for the period. Its in the mail.

-

I’ve been eyeing up a few local old Mopars for sale. People who I can tell, really aren’t dialed into the scene like so many here. Folks trying to sell and old dead car. Prices so very out of line. A local 1937 Dodge 4 door sedan is about 3x the price it need be in my opinion. Been for sale for probably, I don’t know. Six-eight months now? One thing I think I have learned over the past 4 or so years about old Mopar lovers: A large percentage of us are “do it yourself-ers”. Cheap? No. Frugal is a better word. Cheap is condescending. Yet the mopar folks are so very helpful in sharing their knowledge. A friendly, unpretentious group. I feel the need to say that as a general rule, if you inherited a rusty, non-running 1937 Mopar sedan, its unlikely you’ll be retiring early when you sell it. I’m envisioning a frozen engine. Wheel cylinders holding flakey dry contents. Rear drum puller? Just go get the oxy-acet now. That lovely 70 year layer of sludge in the crankcase. Electrical Wiring? The kind that cracks and red dust comes out of it when you bend it. All yours for only $7500. Discounted down from the original ask of $11,000.

-

Car/truck safety precautions when working alone in your garage

keithb7 replied to desoto1939's topic in P15-D24 Forum

A baby monitor may work for some people. I don't think it'll work for me. As mentioned, the cutting, grinding, hammering, tool clanking, cussing, the propane heater blasting. I believe the best advice is to just take your time and do things right. There are many ways to safely prevent a car from being able to pin you down. Before you get under there, take an extra 10-15 seconds to analyze the situation. What could happen? Then mitigate any risks. I can see how people are injured every year in their shops. A couple of years ago I came home to find my neighbor performing a brake job. Not sure where he got the 1" diameter screw jack that he had under an axle. No safety stand. The jack precariously positioned. Wheel off. They were banging on things with a hammer. Prying with pliers to remove brake hardware. I was appalled at the stupidity. I sternly asked them to stop and get their legs out from under the car. I went and got my 3T hydraulic roller jack and 2 jack stands. I put them in place and prevented the imminent disaster. This is merely 1 example of why every year so many people continue to get hurt around their cars. Stop. Think. -

Jump In. Join Me For A New Year's Day Drive....My 1938 Plymouth

keithb7 replied to keithb7's topic in P15-D24 Forum

Yes @Worden18 Video Pad editor. Easy to use. I enjoy it. -

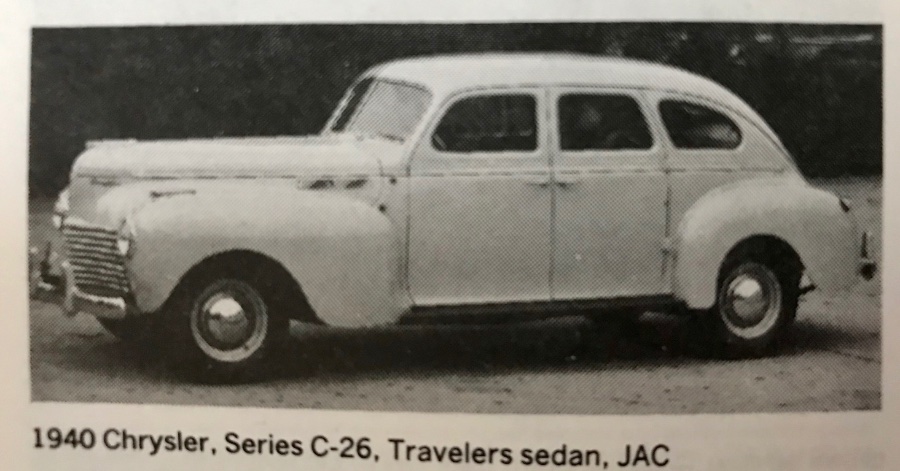

According to a book I have here, the C26 Traveller 8 cylinder shares its 128 ½" wheel base with the New Yorker, New Yorker Highlander, and the Saratoga. The Traveller was the most stripped down base model of the 26 series. Basic interior and available with a manual transmission only. All were available in: 2 dr coupe 3 passenger 711 qty 2 dr coupe 6 passenger 1,117 qty 2 dr Vic. Sedan 6 passenger 275 qty 4 dr sedan 6 passenger 14,603 qty Total production of the 4 different models of the 26 series is documented and shown. The numbers reflect the total production of the C26 series for each body & seating style. For example. 4 dr 6P sedan. The Traveller, the NY'r, and the Saratoga total combined production 14,603. I cannot tell you how many 4 dr 6P sedans were only Travellers.

-

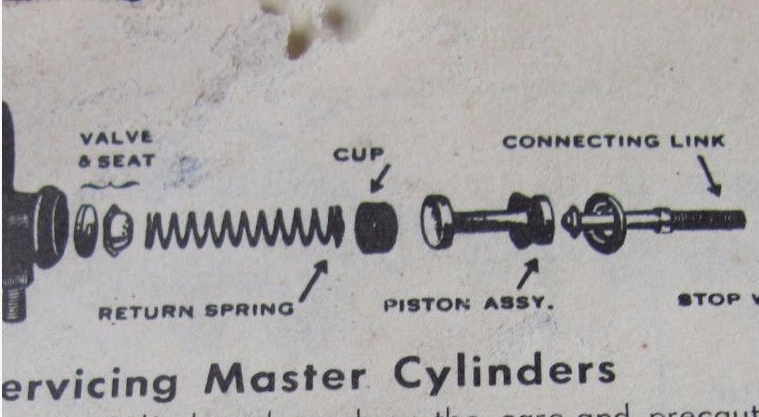

I found this image helpful. A little later year cylinder shown. However similar assembly. Your item D is in the very far left of my image below.

-

The best part about the snow...You really feel rejuvenated when it finally melts. The sun warms up your face again. You hit the tools with renewed energy. A little more spring in your step, as you roll the old Mopar out of the driveway for the first time of the new cruising season. The seasonal changes do bring structure to your life. In some areas, more extreme than others. I am grateful I don't live further north than here. Folks up there got it a lot worse!