Leaderboard

Popular Content

Showing content with the highest reputation on 06/27/2022 in all areas

-

I finally got my 1939 Plymouth out for a decently long ride. I had a long painful time getting new window glass for my rear vent windows. Lots of problems getting the tinted glass and rubber that wasn't a horrible fit. Didn't want to take it out without the glass in except for short local drives on sunny days. I started that job last January and just finished on Friday. Yesterday I drove it to a car club meeting. All back roads in Vermont. Very hilly and lots of curves. About 2 hours each way. The temperature was in the mid-90s. The temp gauge went up and down like it's supposed to, and never went over 190 degrees even on the long uphills in third gear. The car drove like a dream. I'm a happy boy. One of the club members drove his 1931 Chrysler dual cowl phaeton. A beautiful car. Pete7 points

-

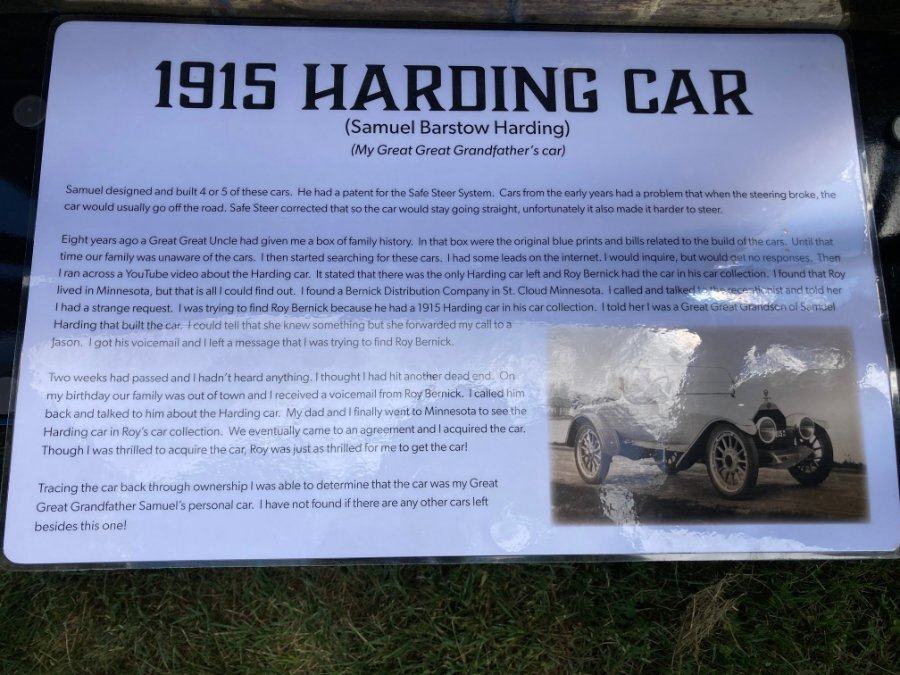

Yesterday I attended a local car show. It was a beautiful day with a couple hundred vehicles present. I had one of 2 classic Dodge trucks. The other was a very nice 1940 (didn't get a picture) Anyway, one of the most interesting vehicles there (to me anyway) was a 1915 Harding. I had never heard of it, but it had an interesting story that I thought I'd share. I took a photo of the story board but it was hard to get a good pic without sun glare. I'll transpose it here for easier reading; 1915 Harding Car (Samuel Barstow Harding) (My Great Great Grandfather's car) Samuel designed and built 4 or 5 of these cars. He had a patent for the Safe Steer System. Cars from the early years had a problem that when the steering broke, the car would usually go off the road. Safe Steer corrected that so the car would stay going straight, unfortunately it also made it harder to steer. Eight years ago a Great Great Uncle had given me a box of family history. In that box were the original blue prints and bills related to the build of the cars. Until that time our family was unaware of the cars. I then started searching for these cars. I had some leads on the internet. I would inquire, but would get no responses. Then I ran across a YouTube video about the Harding car. I found a Bernick Distribution Company in St. Cloud Minnesota. I called and talked to the receptionists and told her I had a strange request. I was trying to find Roy Bernick because he had a 1915 Harding car in his car collection. I told her I was the Great Great Grandson of Samuel Harding that built the car. I could tell that she knew something but she forwarded my call to a Jason. I got his voicemail and left a message that I was trying to find Roy Bernick. Two weeks had passed and I hadn't heard anything. I thought I had hit another dead end. On my birthday our family was out of town and I received a voicemail from Roy Bernick. I called him back and talked to him about the Harding car. My dad and I finally went to Minnesota to see the Harding car in Roy's car collection. We eventually came to an agreement and I acquired the car. Though I was thrilled to acquire the car, Roy was as thrilled for me to get the car! Tracing the car back through ownership I was able to determine that the car was my Great Great Grandfather Samuel's personal car. I have not found if there are any other cars left besides this one.2 points

-

I welded a nut on one end of a piece of 4130 (chrome-moly) steel tubing, a bolt on the other end, and then threaded on the original rod ends. This keeps the original ends intact in case they are ever needed again in a stock application and allows both ends to be adjusted as needed. Edit; Just thought of something else----I had to turn down the master cylinder end of the stock fitting a little on the belt sander to get it to fit properly in the Wilwood piston. There are other ways this mule could be skinned. Instead of the bolt I used, a longer, shanked bolt could be welded on a slightly longer tube than I used and the threads cut off. This loses adjustability on one end but would work fine with some careful measuring.2 points

-

1 point

-

With that mill don't waste time or money on modifying the stock axle. You are in 8.75, 8.8 Ford or 9" Ford territory, don't cut corners at the rear axle... Probably spend less $$$$ putting something better in verses trying to strengthen what's there, not to mention ample gear, carrier and other parts availability.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

This week 1953, five months after leaving White House, ex-President Harry Truman took Bess alone on 19-day roadtrip from Independence, Mo., to East Coast and back in their new Chrysler New Yorker: I really have no idea or control over the press. I can picture in my mind Truman buying a 53, then later buying a 55. Then the Journalist mixing up the story completely. I'm only saying I thought the story interesting ... If you appreciate Truman or not .... I imagine they had a new car as soon as they thought they wanted one. The fact the news reporter pointed it out as a 1953 in 1955 ...... Or is it really a 1953 ? I'm pretty sure the journalist is a idiot & the car is real?1 point

-

While I have nothing to say about the 200 Ferd 6, they were a good engine ..... Same time the Ferd 300 6 has broken records of how reliable it is. Now if you have a 200 & going with it, fine .... If you are searching & can find a 300, Thats where I would invest my time .... The 200 is not a bad engine either. The Ford 300 6 has been around for decades and a very solid motor.1 point

-

I sent my brake band to local rebuilder. Right off the top he said, "I know I don't have the proper thickness brake material. All that I can get is either too thick or too thin. It's difficult to source. I have not been able to get some for a long time. If you want it right, I will cut a thin metal spacer band. It will go behind the material and shim it to the proper thickness needed". I was grateful and indeed gave him my permission to build the shim, and make it right. He did so. It was a great fit. The brake works awesome. When I first installed it, I too set it too close to the drum. 15 minutes into a drive I could smell this odd burning odor. At a stop light I saw smoke drifting up aside my door window. I immediately pulled over. I rolled under the car, in the gravel. I cut the lock wire off and backed out the adjustment screws. All good, until I got home later and set it up properly. That was 3 years ago and its been great ever since. Good chance, based on this info, the aftermarket sellers today aren't going the extra step to shim it. I'd wager there are plenty of folks out there buying aftermarket relined driveline brake pads that perform mediocre at best. Too thick material it won't fit. Too small, it won't work all that good. I have found some aftermarket sellers to be pretty dirty. Be careful.1 point

-

1 point

-

I am sure any custom axle maker will make what you want, for a price. Back in the old days they used to cut another keyway and run two keys. All that said, it'd be cheaper to swap in a newer style axle. Cherokee and Explorer axles seems to be the favored ones and they can be had with discs as well. Not sure if they can handle a twin turbo 360 though. Might need to go 9" because even if you get a set of one piece axle shafts made up something else in the stock axle will fail, probably strip the teeth off the ring gear. Not to mention no limited slip options short of welding up the spiders as a sort of spool. But i don't know of anyone making one piece axles for our rides. I think the M37's have that aftermarket option, but I dunno how relevant it is to the pass car side.1 point