-

Posts

4,695 -

Joined

-

Last visited

-

Days Won

35

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

I do not know what the specs are, sure you can find them in a book somewhere. I would think it would be fine, when you tighten it down it will be the pp springs compressed that distance applying the pressure. Then if you removed aprox 1/8" from the disk, it would be worn out & close to the rivets .... destroying the surface of you pp & flywheel. You have compared it to a new disk, you can see the new one would give you about the same distance. I think that a clutch disk gets a lot less wear then a brake shoe. When in use we ride the brakes safely slowing to a stop, causing wear on the shoes. Properly operated, a clutch is either engaged or disengaged. Normally you do not slip the clutch causing wear. So 1/8" wear should give you many thousands of miles. Or years? I almost question changing the throw out bearing. Only because it may be easier to physically check a bearing for condition. A bearing needs to spin freely with zero roughness or noise. ..... If your existing bearing fits this description, it may be better quality then a new one you can replace it with. Another thing to consider is your pilot shaft bushing. ..... With 26k miles on it, it may not be worn out .... something to think about though.

-

If it was my carburetor & I had to use it, I would want to give it every chance I could. They are getting harder to find. My theory is the powder is the way this type of metal rust or deteriorates. We see it all the time on aluminum heads, intakes ... wheels. It cleans up nicely with some sort of soda or bead blasting & polish.... worse cases leaves pitting behind from deterioration. Just something you do not want to see inside of your carburetor with all the small passages. Vinegar has a million uses & a excellent cleaner, it might do the trick. my grocery store stocks a gallon sized jug with a higher acidity rate that is more for cleaning then for cooking. .... I also use it as a mild flush for my cooling system to remove rust/corrosion. I was going to suggest Berrymans to soak your carb in, I soaked mine in it for 48 hours. Mine was in good shape & no powder. I paid $25 for it 2 years ago & used it with 3 different carbs and various parts since then. Today they want $62 for the same item

-

1953 dodge truck dually stake bed

Los_Control replied to Cody pierantoni's topic in Mopar Flathead Truck Forum

@ggdad1951 put you straight on this. The next step is to have your tires dismounted & wheels inspected. The wheels you have are perfectly safe if they are in good condition. ..... The only way to inspect them is to remove the tires. You need a qualified Tire person to inspect the condition of the wheel. For example if the lock ring is damaged in any way they should not install a new tire on it. It could be bent .... maybe serious rust ... often just sandblast & paint & good as new ..... your truck is 70 years old. It is important to find out the condition of your wheels. A true widow maker wheel was 30 years old in 1980 .... Thats not what you have. -

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

I like @keithb7opinion on the subject .... he really does explain well what is going on ..... I also would simply add a electric fuel pump if I had a running driving vehicle. I really am lazy, I would not drop a fuel tank and rebuild a fuel system when I could just add a electric pump ... Call it a day and move on. Since I do need to build the rear tank mount, make the lines .... I think to myself how can I make it the best job I can do .... I'm thinking that adding a return line will take another hour or two .... What if that actually fixes the problem so a booster pump is not needed? This video sold me on the idea. What I do not like in either of the video's is Keith shows the quick fix & mounts the booster pump on the firewall & proves it works .... you will be fine mounting yours near the tank. Tony he shows how to avoid the problem period. .... He claims 95% of the time. Not 100% ..... 2 totally different videos. 1 How to approach it after the problem occurs. Other to show you how to prevent the problem from happening. Neither video shows them as ascetically correct. .... I have a kit I have to put together ..... "I BELIEVE" I can create a period correct looking fuel system with a return line. -

Glad to hear it. I live on a retirement fixed income ... It can be tough to come up with extra money to buy hotrod parts. .... It is possible to spend a few $$ & have a tank cleaned & sealed .... There is a chance it will fail ... the cost is about the same as a new tank.. I would only use this if my vehicle did not have a replacement tank available. A new gas tank is not as sexy as a new set of wheels ... but it is a needed item.

-

I'm a little confused on this one. Auto parts stores are simply phasing out brake lines. Or any metal line like fuel or vacuum. I can understand this if they offered a replacement like nicop. ... But they offer nothing .... Go kick rocks they say! I have a parts + & a carquest in town..... I just can not understand why they are cutting out metal lines without a replacement. My mistake was buying 5/16" to finish the rear .... I forgot I needed 1/4" .... I bought 3 sticks of 1/4" for $1.59. I insisted the clerk made a mistake & he insisted it was correct. Once it is gone they will not replace it. .... I just wonder what the future is for metal lines that all cars use.

-

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

Excellent point. Yet some people seem to be plagued with it. .... My truck has never been out of the driveway so I wont know. It seems to be a topic that comes up often enough & a electric booster pump on a toggle switch is a easy peasy cure. It is not just this forum but other forums with older cars. Often enough youtube videos are made about it. I wonder what conditions are needed to actually cause a problem. We know heat causes the fuel to turn to vapor .... just physics, some engines will run hotter then others. Cylinder bores, headers, cams, radiators .... every engine is different. Then there is ambient temperature, while 95 is very warm especially with heavy humidity. We had over 100 straight days this summer over 100°F typically 108-110. But it is a dry heat ??? I wonder if altitude also plays a roll? At sea level, water boils at 212 °F. With each 500-feet increase in elevation, the boiling point of water is lowered by just under 1 °F. At 7,500 feet, for example, water boils at about 198 °F. I wonder at what temps fuel boils? I just feel I'm not smart enough to solve the problem for everyone. I do not even know if I have a future problem .... I have simply convinced myself that a proper fuel system deserves a return line. Like adding a 2 stage brake master cylinder ... it is a improvement on a older vehicle. All ya all you do you .... Like buying a fire extinguisher I sure hope you never need it. Sure is a good feeling knowing you have one. I think where @desmondmonsteris at and asking advice about his fuel line installation .... Just another option & real easy to do now ... more difficult later. -

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

Just another option that I plan to do with my fuel line. The electric booster pump is often used to fix a vapor lock condition. Modern fuel heats up & turns to vapor. When you are at a idle or driving slow, the float will close off the fuel to the carb & it sits in the line above the exhaust manifold & heats up. So while you are driving around the parking lot looking for your parking spot, you park & shut off the engine .... The already hot fuel now gets heat soak from the engine and can turn to vapor. No fuel in the system when you go to start it. .... The booster pump is a easy way to replace the fuel ... not really a "fix" though. .... You are not fixing anything. Newer vehicles started in the 1970's??? started running a return line to the fuel tank. This will allow the fuel to keep flowing & not sit & heat up. I'm using nickel/copper for fuel lines, I have a glass filter right before the carb I will add a brass T between filter & carb. Then run a line back to the tank. My new tank has a block off plate where I could easily add a fitting for the return line. ..... Key thing is to use a smaller return line to provide some resistance. So the carb will get priority fuel, the return just takes excess. I got the idea from Tony of Uncle Tonys Garage where he showed a trick adding a fuel filter with 2 outlets, 1 being a return line & how the factory did it on some vehicles. I think the engine would be happier getting cooler fuel, I feel like I'm fixing something by adding the line. Imagine being in a local home town parade going 1 mph stop & go & hit with vapor lock ..... there is a reason why car manufacturers added a return line. For me it just seems natural to add the line. When my truck gets out of paint jail & I install my tank & run the lines, I already have the line & T ... It is just 1 extra step. As far as using a booster pump to start the truck after sitting a few months, I do not plan on letting it sit that long. -

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

Just my opinion, a mechanical fuel pump is good solid old school technology. Uses a rubber diaphragm to pull the fuel from the tank. .... it still pushes the fuel to the carburetor as it leaves the pump. I think it can pull fuel further then it can push fuel. Main thing to remember, a carburetor only wants 3-5 psi fuel pressure to operate properly .... too much pressure will cause problems. A electric fuel pump is modern technology & operate differently using vibration. It simply pushes better then it pulls. .... both push & pull. The thing about a electric pump is it provides far more fuel pressure then a mechanical pump. My Dodge caravan only needs 35-40 psi fuel pressure to run .... some cars require 60-90 psi ..... A electric fuel pump can deliver these pressures. So my opinion is, you could probably mount your electric fuel pump on the roof of your truck. Run your fuel lines to it with the other end going across the hood, through the grill directly to the carburetor & it would deliver the 4 psi pressure needed to run your carbureted engine. Same time if we tried the same experiment on my neighbors fuel injected 302 that needs 60 psi fuel pressure to run .... I doubt it would work enough to even start the engine. If it did start the engine .... I imagine it could not last for long. Simply working too hard. Moral of the story, there is a proper way to install a electric fuel pump ..... our trucks just do not care. .... I would spend more money on a fuel pressure regulator & simply bypass the mechanical pump if I had 12 volt system & a electric pump. -

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

I bet it works just fine, especially for the purpose you installed it. Also would work for @desmondmonster Reminds back in the late 70's as a kid I had a 1968 chevelle with a worn out 327 .... it had a cam that the lobe for the fuel pump was worn flat and no longer work a fuel pump. I installed a electric pump right at the original mechanical location, because it was easy for a 17 year old kid with no tools to do. I was always told later why it would not work, I know it was still working over 1 year later when I gave the car to my sister. Just being used momentarily as a pusher pump to get some fuel into the system when needed .... Probably last for years no matter where you put it. -

Electric Fuel Pump Mounting Question

Los_Control replied to desmondmonster's topic in Mopar Flathead Truck Forum

To be honest, not sure you have much choice. I know I would want to keep it along with fuel line protected by the frame. I know when I removed my old tank, there were a few different areas with road rash & 1 patched hole. I would not want a fuel line that low. I would also guess that as a auxiliary pump it will be just fine, just keep it as close to the tank as you can. Electric pumps are good at pushing not so much at pulling. Either way your pickup tube still goes to the bottom of the tank And will need to be pumped up & over. I can share my neighbor has a old Ford shoebox, the original tank does not sit as low as our trucks but still pretty low. He has a later engine with fuel injection that requires a electric pump, it is mounted to the frame. Same story it needs to pull the fuel from the bottom of the tank up & out. It works with no problems ..... I imagine it will not last as long as a oem installed in the tank but works. -

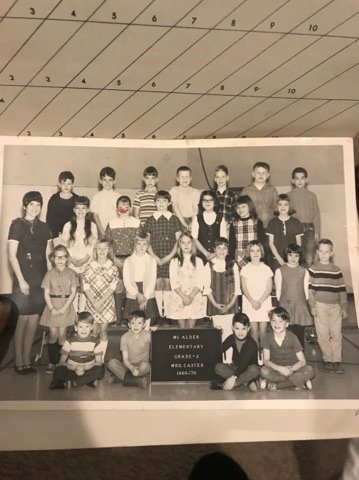

I agree 100% @keithb7I like this 2nd grade photo ..... I'm the little monkey holding the sign up for the photo. My wife I have been married to is standing above my right shoulder .... I often get asked how long I have been married? Sometimes I'm asked how long I have been married .... Fact is my whole life we have been together. Being married for 38 years, has no real truth.

-

@keithb7 The tools your wife is using, yeah the stilts are cool. The Hawk & Trowel tells me The drywall is finished, now she is adding a custom texture finish before paint. The average Drywaller will learn to finish drywall smooth. Using a Hawk & Trowel to make drywall pretty is a different art all together. ..... Something the average person who finish drywall for a living is not good at. I'm pretty good with a hawk & trowel myself, although drywall work for me rates right up there with roofing. I really love finish carpentry ... Your wife certainly appears too be performing at a high professional level. ...... I would have no problem offering her a job if I was still working. Just amusing she enjoys it as a hobby to relax after work. @keithb7 You are no different .... I do not believe you are a professional mechanic, yet you make as a hobby some very educational & professional mechanical videos. You both are extraordinary & belong together.

-

I certainly feel your pain. Simply from the other side though. I was a remodel carpenter for many years. Because you spend so much time with the client/home owner, you develop a personal relation. It may be good or bad, it is a relationship though. The best jobs are where there is no surprises & everything goes as planned. Sometimes you will open a wall & find a total mess .... The cost of the job just escalated because of past work done to a 100 year old house. One time while adding a 2nd story to a home, the multi height roof line. The staircase was a circular addition in front of the house with a cone shaped roof. Just impossible to properly tarp it & dry it in .... A freak storm came in & did a fair amount of water damage to the first floor .... Getting that call at 4:00 AM was no picnic. We had been working with that client for several years at this point. They trusted us ..... The wife sure did tell us what she thought & what we should do. She was very angry & frustrated for good reason. ..... End of the job it is THANK YOU THANK YOU WE LOVE IT! Were having a BBQ next weekend to celebrate ... Sorry mam I'm busy, maybe next time. ...... Just saying, as the worker, I want to get away also. This house we added 2" foam insulation & new stucco .... I'm just going around and installing the new lighting & exterior doo dads ..... Their pet chicken (daughters 4-H project) Would always ride around with me while trying to work. .... Funny thing is, I'm the only person it ever did this with. The wife Katie is out buying last minute hardware for the house ...... Comes home .... Katie can you put this chicken in the coop where it belongs? Sure Fred, I want a picture first so wipe that sour look off your face. Grrrr, yes mam. Working with a Contractor over a period of months in your home, there is a relationship born.

-

ggdad1951 truck project montage: FEF!

Los_Control replied to ggdad1951's topic in Mopar Flathead Truck Forum

Love the photos .... for some reason arrest me red wont leave my mind ? -

-

-

I wonder if you fill the fuel tank if it leaks or you smell gas fumes? ..... Think we all agree the tank is rusty. What is possible is to drop the fuel tank down & really inspect it good .... you will need to do this anyways to search for a replacement .... not a waste of time. Then if you feel comfortable with the condition of the tank, You can possibly use muriatic acid in it and clean it. Flush it clean it several times ...use some JB weld to plug the pin holes in it ... flush it some more ...... You may get 6-9 months from it before you have more issues. .... Or it could be a complete flop. Big scaly rust will plug a fuel line. At this stage of deterioration, the small fine rust particles will pass right through your filter plugging your carburetor. Your needle or seat on the float may not work smoothly anymore because of the fine powder rust ... It can only get worse from here. I personally would want a new fuel tank ..... I'm blessed enough to have one sitting on a shelf waiting to be installed. Next best option for a workaround, I might look for a fuel cell you could install in the trunk to get you by while looking for the proper tank. I would rather use a metal boat fuel tank strapped down with straps .... then run a rusty gas tank. A rusty fuel tank is like ********** Fill in the blank. ..... Nothing you can do will make it better. You pull that tank, toss it to the curb .... You find a new way to supply fuel to your engine.

-

Sometimes I think we get a little carried away (with perfect) I feel if the pp has been sitting for a long time, you have it out in front of you .... You can disassemble clean & inspect it, grease it properly where it is needed. I'm only suggesting that maybe Drag Racers took the time to measure pp spring pressure. .... The farmers or kids never bothered with it & worked just fine for them. What exactly would you do if your spring pressure was at 145..... instead of 155 .... would you replace your 70 year old springs for new ones? We are talking about 70 year old equipment & a 90 hp engine. ..... what exactly would 155 spring pressure tell you?

-

I wonder what our mopar pressure plates look like .... I've never seen mine yet. I do have a 1951 Ford I have worked on .... I assume the technology & construction is similar? What I learned from my experience might help you? How I took mine apart without a press ...... I took mine apart, the spring height is important. The idea that they are all the same height and not collapsed or giving a uneven spring pressure. Seems the springs are color coded. My red ones are considered to be a "Dump truck clutch" This is a 11" clutch from a 1/2 ton truck. I can buy some softer springs that might be blue then I think there is yellow .... you get my point, they are color coded for the stiffness of them. Again this is Ford but assume all pressure plates have same options. No good photo of the fingers, but I was able to properly grease the pins that hold them in place. Inspect the holes the pin rode in was not wollered out from wear. The fingers where they meet the throw out bearing is important to equally meet the bearing surface of the bearing. .... Mine are adjustable for fine tuning. I'm only suggesting that the average Joe can go through a pressure plate & freshen it up, inspect it for wear, replace the springs if needed. IMHO this pressure plate is ready for service, I just spent a afternoon on it before putting it on a shelf. .... Just a motor/trans I saved from the scrap yard that I may never use. A modern pressure plate is a throw away or maybe a core .... older pressure plates were made to be serviceable. I'm a little torn on the disk myself ..... something tells me to replace it .... something tells me to scuff it up with some sandpaper & run it.

-

Really is a beautiful truck ..... Just looking at it you know it has been taken care of. I do not know anything about the history of the truck. Just guessing whoever owned it before you may have done major brake work to it. ... I would fix the brakes before I painted it. I would think the front brakes over all condition may be a indication of what the rear brakes "might" look like. Sadly the drum puller tool is almost a requirement. Will cost you the price of the tool to look & see. .... I wonder if you have a tool rental place near you? It is possible you simply need to change the wheel cylinders & be back in business daily driving that truck. While you prepare to install the 8.8 at a later date. The adjustment tool you can make. Here is one version. I have seen photos where the guy welded the all thread to a extra castle nut. I have seen another made from pvc pipe. Was talk about using a spare brake drum & cutting slots in it .... you can get around the brake adjusting tool. Myself I just got mine set up where there is a slight drag on the drums without a tool. When I finish painting the frame then will finish running the new lines. Then when I drive the vehicle, I will get up to 20-30 mph & do a panic stop slam on the brakes .... really get the shoes set into their position. Then I would use the tool to properly adjust the shoes. The idea of the tool is to get full shoe to drum contact ... it is fine tuning, you will get brakes without it though.

-

I think what you say is very true. If the bearings are good, you do not want or need to replace them. While I bet the majority of people would replace bearings just because they tore the engine apart ....Not because they were needed. This would be real obvious on a modern day race car where the engine was torn down in the pits between races .... They may replace the piston, not going to replace the bearings if they are still good. They will disassemble the engine searching for a issue & fix it. Then reassemble the engine & run it. The average person does not disassemble a engine between races. ..... So it is just naturally assumed new rings & bearings are required to put the engine back together. That is correct. They would be replaced as needed, not just because. There are a few youtube channels .... where they work with old steam engines & pour new babbit bearings. .... They do it because is needed.

-

@Solga what gear ratio is your new Explorer rear end? ..... Something very important but not yet brought up. I owned a 1996 Ford Explorer "sport" Just a 2 door AWD version with 4:10 gears ... was sporty & quick off the line.. I think there was at least 6 different gear ratio available for the Explorer. ..... Which one do you have? Our old trucks like a gear ratio between 4:10 & 3:55 while 3:73 seems to be the sweet spot for a 90 hp flathead 6 with a 3spd trans. My daily driver chebby has 3:08 gears. .... Just imagine putting the 3:08 rear end in my Dodge truck. It would be a ******* to drive around town .... eventually on the highway it would get up to highway speeds ..... then on a slight incline on the road I would need to downshift from 3rd to 2nd to get enough torque to climb the hill .... You put too tall of a rear end in the truck, may be the worst driving experience you ever felt. You want a Ford explorer 8.8 with drum brakes, 3:73 gears. .... Or a Jeep Cherokee with same specs. ..... 4:10 ... 3:73 .... 3:55 Anything taller like a 3:08 .... would suck. I'm all for swapping the rear end myself. just I would be looking for specific requirements before doing the work.

-

What I mean is .... I love this build thread, the guy has so much energy and powered right through it and built a great truck. While my project is much more milder ... & slower ???. I have different expectations. My goal is to put it back to functioning original as much as possible. It will be the most simple way possible & the cheapest just to fix what I have. My biggest goal right now is putting paint on places that has not seen paint in many years. Getting grease & lube to all the places needed ... rewire it & drive it. 90% of my driving is in town between 25mph - 35mph .... Once or twice a month I will drive 25 miles to the next town. I'm happy with a truck that will drive 45-50 mph. This is my build. Point is @Radarsonwheels builds a great truck. .... Myself I will build my truck, I will love driving it at 35mph around town to do my business. What does @Solgawant? .... what condition is your original truck in? Daydreaming is good ... most prominent builders will sit in a chair for hours staring at their vehicle deciding what they want to do. These are only questions you can answer.

-

It's really easy to say you have just about the easiest rear end to install in your truck, just slap some new spring perches on & go. There is some thinking involved installing the perches .... but a simple process. Another bigger issue is the U-joints. My truck has what is called Cleveland u-joints. ..... I would guess your truck does also... maybe not. I do not think you can mount the Cleveland u-joint to the Explorer yoke. .... Most likely end up having the yoke on the driveline changed to fit your standard u-joint rear end. That would not be a bad thing. Several years ago the Cleveland joints were almost impossible to find new. Then a few years ago I heard a source opened up but they were like $80 each .... No idea if they are still available today ..... I would also have the driveline shop change my front yoke on the trans to something standard and eliminate them. But if you are going to install a different engine/transmission, you will end up with a different driveline anyways. The next thing on the rear disk brake rear end, is making the brakes work safely. No car manufacturer ever put disk on the back with drums up front. I think Braking is approximately 60/40 with the front being 60% .... now you are looking at a front disk brake conversion. ...... This is called "project creep" Because now you are looking at a new master cylinder. You want the 440? you are now talking more creep. I think a person really needs to think what they want their end outcome to be. At this stage you may be better off doing the Dodge Dakota frame swap.