-

Posts

4,729 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

Sometimes I wish I kept my keyboard to myself .... or had a rewind button. Honestly I appreciate the skill & effort that went into the car .... way above my skill level today. Some cars simply should not be chopped ... imho. Seriously, just my opinion. The rest of the work is not terrible .... That car needs a new roof line. Anyone been watching this dude build this 35 Dodge? .... He claims it was 35 Dodge parts anyways ... then later he bought a 35 Desoto for parts. He has done the roof maybe 3 times so far to get it where it is? I am not against chopping a roof ... I just think some style needs to go with it.

-

Hazard (4 Way) lights and Signal lights separate relays

Los_Control replied to RonJ's topic in P15-D24 Forum

-

Needle bearings into transmission input shaft help!

Los_Control replied to rrunnertexas's topic in P15-D24 Forum

Translated .... You need a BFH! -

OMG!!! first thing that pops into my mind is birth control. On a side note, I think it is great to do whatever you want .... not what others did.

-

Just got a new fuel gauge sending unit for 48 DeSoto

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

I can only imagine that different tank manufactures use different threads .... metric, SAE, course or fine ..... no screws provided makes it more universal. -

Does anyone have a pic of their shift linkage?

Los_Control replied to OUTFXD's topic in P15-D24 Forum

A very wise man once said ..... If it does not feel right, it probably isn't. Seems neutral should be middle & horizontal. At least my truck is. Every inch of pull taken away from one direction, is less one inch of push in the other direction. Seems your linkage photos do line up with others peoples photos ..... Are they the same linkages for the same car? 2 door, 4 door, wheel base, overdrive.... Your linkage does not look anything like the linkage for my truck. ..... Why should they ..... same time different model cars would be different. Maybe disconnect all linkage, then with vehicle properly supported .... verify you can get all gears working from shifting it manually under the car. It is possible someone changed the linkage rods in the past, trying to fix a problem then created another? ..... You do not have correct rod to work with your car? My truck for example, the adjusting nuts on the rod worked loose. Now the rod moves on the shift lever, damaging the threads for the shift rod making it impossible to do a proper adjustment. My goal is to remove it & then run a tap down the threads to correct the problem. Just plausible something like this happened to your car, instead of fixing what they had, they installed a used rod that does not work? -

I guess I have a bit of a problem with television today .... nothing on it is worth watching .... imho. When @keithb7 made this post, got me to searching for other videos that I like to watch. I spent so much time watching them I never shared them While I love Highway patrol, I tend to look for movies 1 hour long or more. 1930's, 40's, 50's ..... 60's things started getting weird but I do selectively watch 60's or newer. I'm just a true weirdo .... my house was built in 1948, my truck is 1949 ... daily drivers are 91 & 93 .... I'm just not ready for the 20th Century. And I'm happy This morning I was binge watching John Wayne movies from 30's-40's Ya all have to love Burn Em Up Barnes though .... here's 4 hours of your life you will never get back.

-

Head milling for compression: What is stock cam lift?

Los_Control replied to FarmerJon's topic in P15-D24 Forum

Oh my, I go to the big city once a month .... the next town over that has a Walmart. @Sniper town has 2 walmarts .... Hard to get bigger then that -

clutch & brake pedal hitting floor boards

Los_Control replied to Mark G's topic in Mopar Flathead Truck Forum

I can only laugh & suggest you enjoy the ride. I actually have a metal replacement floor pan ..... Sitting on top of the existing floor, it hits in the same place you show. I figure I will need to cut it in more precisely & weld it in. Hard to say whats going on if you have wood floors & hitting in the same place. .... Way out of my league. Yeah if the floor is sitting too high, it will cause the pedals to hit in that location. Look at your photo, if the floor was 1" lower. The legs of the pedals would ride up & over the floor .... as is they hit the floor. -

clutch & brake pedal hitting floor boards

Los_Control replied to Mark G's topic in Mopar Flathead Truck Forum

Just a guess, I'm thinking if everything lines up ... master cylinder, push rod, pedal .... you are fine. All should be in a straight line. You simply may have a mis matched toe board ...or not .... no pics yet ... Possible you may have a Ferd toe board This all can be fixed with a grinder if your pedals function correctly. -

clutch & brake pedal hitting floor boards

Los_Control replied to Mark G's topic in Mopar Flathead Truck Forum

Just thinking you can mix & match parts from different year trucks if they are the same. On the later B series, 48-50 there is a difference where the gas pedal sits. 2 balls attached to the floor. Some trucks have them on the lower toe board .... some put them on the transmission cover. Also 1950 was first year of column shift so the toe board is different for floor linkage. That also changes the shape and size of the toe board & trans cover .... Your 1947, they made that cab style many years .... very possible you have a toe board from a different year and you may need to modify it to work for you. -

clutch & brake pedal hitting floor boards

Los_Control replied to Mark G's topic in Mopar Flathead Truck Forum

I remember my clutch pedal rubbed on the side of the toe board before I started working on the truck. Not anywhere else. If yours are hitting the toe boards .... There are locating holes on the cab floor that the toe boards line up with and bolt into place. Mine really have no adjustment. The pedals should be centered into the cutouts. If they are not, I wonder why .... maybe they are replacements from a different truck? Might be possible to oblong or slot the holes in the toe board so you can adjust them slightly side to side. I dunno, pictures would help. -

clutch & brake pedal hitting floor boards

Los_Control replied to Mark G's topic in Mopar Flathead Truck Forum

I recently made a thread on this when I installed a bushing in mine. Thank You @Merle Cogginsfor the help I bought the bushing from DCM .... Seems it is in question if the factory ever installed a bushing .... mine never had one. First I cut the bushing for length. Then I needed to use my dremel & cut down the length of the bushing, just about the thickness of a regular cutting disk ... I used a mini disk with 3 passes. This allowed the bushing to fit tight on the shaft while decreasing the outside diameter of the bushing. Then I used a die grinder and slowly hogged out the pedal to make it round again and open it up to allow the bushing to be tapped in with a hammer. Very crude machining, the end result was very satisfactory. There is still a little side to side play, but less then the brake pedal has. .... 100% improvement. Side note, I saw Ace hardware sells generic sized bushings .... since DCM is not a direct fit & needs modified, you might be able to grab one from Ace or tractor supply. -

Weak stream on accelerator pump after rebuild on 48 DeSoto?

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

I just entered "accelerator pump " In the search box and found many examples .... is this the thread? -

1952 Dodge Coronet Steering Wheel Nut Size (Thread Pitch)?

Los_Control replied to TEX's topic in Mopar Flathead Truck Forum

So for my 1950 Dodge truck steering column, it is 5/8" x 18 thread pitch. No idea if it is the same as the 1952 Cornet, I think it would at least be a safe starting point. -

Good luck with the studs, I assume you have the correct budd wheel socket for them. Dcm may have what you need, I do not know. https://www.vintagepowerwagons.com/online-parts-catalog VPW will have most parts you need for your truck, you may want to contact them after you get your hubs off. Figure out what shoes & wheel cylinders you have. I'm sure they will have the rubber flex lines .... I think you may need to make your own hard lines .... I suspect there is too many possible combinations to have a pre-made set for sale. Brake & Equipment in Minneapolis https://brakeandequipment.com/ Another member sent in a master cylinder to be sleeved. Was a very reasonable price and a quick turn around .... just saying you have options. They also reline shoes ..... you can send your complete brakes to them to be refurbished. While they advertise custom made lines, would be a pita to ship them without getting bent. Possible you get your drums off, find out your existing brakes are not that bad.

- 8 replies

-

- 1

-

-

- drum brake adjustment

- brakes

- (and 4 more)

-

Brake flaring tools. Not for old hard steel tubing?

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

Yes the old school flare tools like this one works well for double flares. Very basic. https://www.lislecorp.com/specialty-tools/double-flaring-tool-set I bought mine from the parts+ store, sure hope I did not pay that much for it. .... $66? also good practice to make the lines a little longer then needed, that way when you forget the fitting. You have room to cut it off & redo it. I did that yesterday, I was admiring how well the flare came out ....then realized there was no fitting on it ? -

Brake flaring tools. Not for old hard steel tubing?

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

You would be flaring new modern brake lines .... not flaring lines from 80 years ago. Today my project was making up new brake lines. ..... I have a cheaper Lisle flare tool. They have some really cool hydraulic tools available .... how much do you plan on using the $400 tool? What I have learned personally myself today .... while working with both aluminum brake lines, and nicop (nickle/copper .... It is a learning curve. My issue was going animal & over torque the lines with the cheap tool. My flares were oblong & distorted, they would not seal. With some practice, I learned to feel the line & stop before distorting the line. They would turn out oblong & never seal if over tightened ... same time nicop line needs less torque then steel. .... it is a learning curve to create good flares. My point is, you can buy a professional tool for many $$ .... or learn to use a cheap tool like our Grandfathers used for decades. I did have to make a new line today, I messed up the flare ... Then I had two lines that were loose & just needed tightened. I still have rf wheel cylinder not getting fluid??? The cheap flaring tools that our Grandfathers used work fine, you just need to practice with them. -

48 DeSoto engine start up after 40 year ago rebuild

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

I agree 100% ... I'm really just trying to throw out a funny there Black lives matter ... Blue lives matter .... Non detergent oils matter ..... swing & a miss There is so many opinions on oil, mines not needed. There is a lot of truth to the sludge from non detergent oil though .... I already know my used engine will be pulled to replace seals after switching to detergent oil .... part of life. -

48 DeSoto engine start up after 40 year ago rebuild

Los_Control replied to MarcDeSoto's topic in P15-D24 Forum

Non detergent oils matter too Although they create sludge, the sludge helps to plug the oil leaks. -

1952 Dodge Coronet Steering Wheel Nut Size (Thread Pitch)?

Los_Control replied to TEX's topic in Mopar Flathead Truck Forum

I might be able to tell you the size for the truck .... tomorrow. I would guess they are the same as the cars. While I have the nut in my hand, My tap & die set only goes to 3/8" and it is larger then that. So I do not know what it is. Tomorrow I'm going into town for shopping for the month, also stopping at tractor supply to buy bolts for the bed of my truck. If nobody comes up with a answer today, I will bring the nut to town with me tomorrow and see if I can match it up. Looks like a common thread though. -

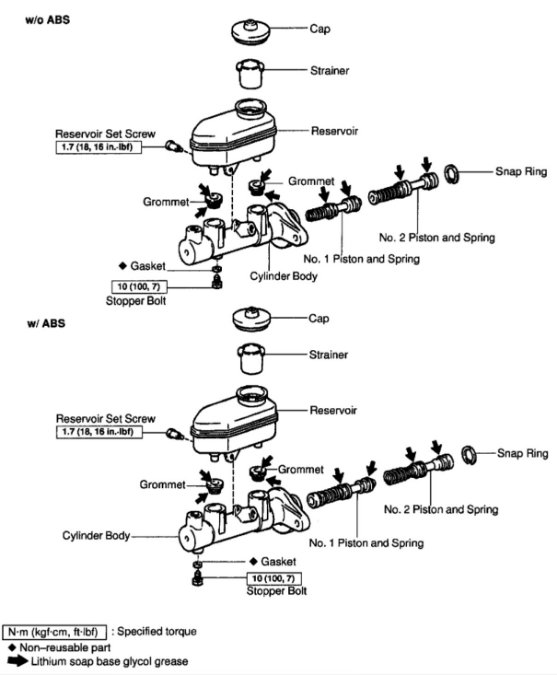

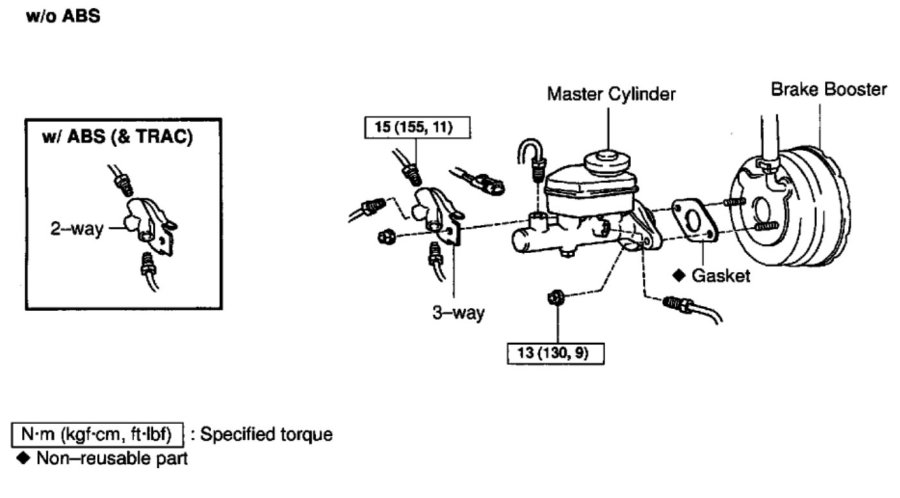

Thanks Ken, gives me a direction to look. What I have found from Toyotanation.com, rebuild instructions for a 1991-1994 Camry master cylinder ...... The images show a 2 bolt mounting .... they are 3 bolt though. Top image without ABS is what I would use. Here is a rebuild kit. Nowhere does it say residual valve .... thinking they may be built in .... comparing to our original master cylinder. One other thing, they talk about is the distribution block .... 3 way W/O ABS .... 2 way with ABS. Really throws a monkey wrench in the works .... without it you have 2 lines front/rear .... easy peasy. Seems to be part of the brake lines, would this be the proportioning valve for the disk brakes and not needed?

-

That is the way mine is, Top to bottom Arm, Fld, Bat ... Not sure what brand it is though

-

I found with my chebby truck, the larger rear reservoir feeds the front disk brakes ..... guessing the calipers require more fluid then the rear wheel cylinders. Where I'm lost at is .... I know nothing about the proportioning valves or how to choose correct one for my application .... Drums front & rear. I see what @lostvikingdid, and it looks great .... I think they were using disk brakes up front. Then another reported that after talking to scarebird this was not needed, using their disk brake swap .... the master cylinder would take care of it? The Toyota master is setup for disk/drums for the 1991 Camry .... So this is where I'm lost .... what happens if I just install the master cylinder without any mods or aftermarket proportioning valve? For my Drum brakes. Just trying to understand the system so can order correct parts.

-

Hello Matt, curious if you have found any answers to your questions? I just ran across your post while searching for a answer to the residual pressure valves. I also plan to use drum brakes. And am wondering what to do about the built in valves on the Toyota master cylinder? If nothing else bring your question back to the top for more views.