-

Posts

4,686 -

Joined

-

Last visited

-

Days Won

35

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

I removed a starter one time .... boy was it miserable. With my current truck, even with the front end stripped down to the engine sitting in the frame .... I thought about removing the starter just to clean and paint it. Even then I decided against it as long as it is working fine .... I'm leaving it alone. The 1/2 moon wrench does help .... I made a few turns on the top bolt to check it out .... still no cake walk.

-

Seems that you bought them several years ago, seems more likely they are better quality then today ..... Maybe you just got a bad one? I am not going to talk bad about the quality of fram over others .... I personally use wix filters. In another forum recently we were talking about the quality of wix filters. A guy recently ordered a batch of them and one filter he had no oil pressure when starting his truck. Turned out the crappy filter he had blocked oil flow. The way it was built it was put together wrong, he cut it open and found different quality of parts then expected. The inside of the canister had surface rust on it .... wix uses a decal sticker on outside ... this filter the canister was stamped no sticker. The only conclusion is someone in China is counterfeiting oil filters. Think they ordered them from Amazon. Imitating name brands and poor quality inside. The wix filters I bought locally 2 months ago are fine. I also think wix makes filters for Napa also, my local Napa just sells wix though. I'm going to say that fram is probably just fine ..... assuming you change your oil regularly ..... need to be careful where you buy them. A lot of people are saying the quality of wix is going down also ...... I think the quality of all is going down.

-

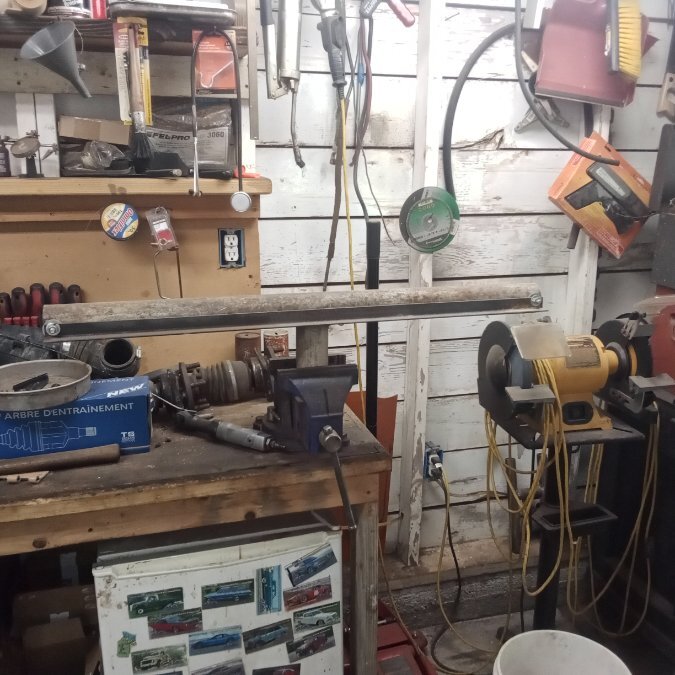

I feel if you want to start welding in patches, it is time to start learning fabrication. Really not hard for the basics. I really like this video to make a pipe anvil. While I do not know the extent of your rusted panel, the basic curves can be made at home. I will post the video below, just showing my version of it .... I do not have room in my tiny space to make the full sized version. I do have a smaller round pipe .... I can unbolt and bolt it in place .... I have some 4" pipe, to be honest I just never needed it yet. If I insert metal into it as is, then pull back on it, I can make a 90 degree bend you might find as a pinch weld on the bottom of the rocker. Then you reset it and push forward and start working a gentle curve .... sometimes a larger pipe helps make a softer gentle curve, the smaller one makes a tighter curve .... you get it .... just junk lying around the shop welded together and you use it as a tool. To be honest, the 3/16" x3' angle iron I have is too flexible for a 90, so I draw a line on the metal , insert it to the line then clamp it down .... works perfect. This photo is really sad .... just showing that I actually fixed this while newer thinner ones were available ..... I needed the practice. I think I counted 13-15 individual small pieces welded together .... that is how you take care of complicated pieces like the dog legs of the pillars welded to the rockers. Not difficult or scary, just time consuming. .... Take your time you will be fine. Every body patch in my truck came from a old school that had some 18 gauge metal shelves missing the legs ... I paid $5 for it ..... Although I do have some thicker metal for braces and such. Once you start bending and creating patches ..... it is almost addicting .... just kinda fun and you're sad once the paint is on and no more panels to create

-

Have no fear, I was just trying to be humorous and back up @keithb7 opinion on the syncro's ..... With any luck @mlozier76 suggestion with dirty linkage ... Keith has rebuilt his transmission and is familiar with who sells parts for them ..... shipping to Germany is on you though. I would not say it is hopeless though.

-

Sure you do not want 18 gauge? 20 will work I guess ..... the rockers do offer some structural support .... A & B pillars connected to the floor ..... just a patch 20 will be fine. 20 is a real pita to weld because it is so thin. Modern cars use 20 gauge ..... the replacement floor pan in my 49 Dodge truck is 20 gauge. I have welded 20 gauge several times in the past and feel comfortable welding it .... I just kinda cringe when I think about a upcoming job using 20. I dreaded just thinking about welding in my floor pan ... just have to be extra careful and adjust your welder properly and take your time. What welder do you have? Just if it was 18 gauge I simply would not give it a 2nd thought. and if I had a choice I would choose it.

-

Worn syncro's will cause them to pop out of gear when you let off the throttle or remove torque. Back in the old days the circle track racers often had a wire hook on the dash to catch the shifter and hold it in 2nd gear. The short tracks they typically put it in 2nd gear and left it. Go roaring up the straight and just when you might want 3rd your into the corner and backing off. Really tough on syncros and not unusual to pop out of gear ..... just when your going into the corner and need both hands to maneuver the controlled slide on the dirt track. Sooo, could just strap it down in 3rd gear and pretend your a race car?

-

For me I think it is personality with knowledge that makes a good content creator. That keeps me interested. A few years ago I watched a lot of videos when I wanted to teach myself to weld. .... I stumbled across DD speedshop channel. He just keeps me interested to comeback and watch more. He works at home in the garage much like I would. ..... He is a mechanic in a shop for a day job. He rarely talks about that. Then comes home from work and works in the garage sometimes until 12:00 midnight. And video tapes it. .... then all day and night on the weekends. He usually works on 55-57 chebbies, has rebuilt a Mopar Cuda ..... Latest project was a 1967 Camaro that had been sitting for 20 years and used as a parts car. Within 3 months he totally stripped the car down in his garage .... replaced every spec of rust in it .... Inside rockers, outside rockers, floor pans, trunk pan, rear subframe & all connectors .... front sub rails, .... everytime he went to fix 1 thing he found 3 more things rusted ..... it's a chebby. He replaced the rear quarter panels, doors,front clip with all new parts and the only original part of the car is the roof. My only point is, he makes it interesting and does it quickly .... 3 months he had that car completely rebuilt and painted, a dyno tested 436hp sbc with a rebuilt T10 4spd and a rebuilt posi 12 bolt rear end. .... 80% rewired and was working on the interior and found out he does not fit in the car. Sitting on the floor, head hitting the roof, knee's knocking the doors and steering wheel in his tummy .... His last video on the car couple days ago was him stripping it down and selling it as a roller that needs a drive train. My only point is this guy made thousands of dollars from youtube making those video's on the camaro. He is currently paying storage on over 20 cars he has built on youtube over the last 6 years. ..... He did buy his neighbors house so he can have 2 garages to work out of .... He rents the house out to pay the mortgage he uses the garage. Which allows him to make more youtube content. ..... While waiting for parts on the vehicle in one garage he is working on the other car in the next garage. Making more $$. Now he is currently liquidating all of his cars and keeping a few of his favorites ..... his goal is to buy a commercial shop in town and build cars there ..... I suspect he will quit his day job and become a professional youtuber. Just like years ago, young men & women flocking to Hollywood to become a famous movie actor ..... Today they are running to youtube ..... some girls are going to only fans .... If the girls are good, they are making $10K a month sitting at home in front of a camera .... While the husband is at work ...... Same thing with the dudes ..... if you are good at what you do, you will make $$ at it while working at home. .... I'm not saying the guy is a genius he does make it interesting to watch and getting prepared to make it a full time job. I'm only suggesting that it is the newest thing to get rich quick and everybody and their sisters want to try it. .... You never know what clowns you will run into.

-

Bringing up baby was a good one, Katherine Hepburn with Cary Grant. https://rumble.com/v46302b-bringing-up-baby.html Check out pilothouse classic films channel for more of your classic movie itches. Or pilothouse classic westerns https://rumble.com/c/c-5536437 If you prefer the more rough & tumble John Wayne adventures in a movie. What a co-inky dink Los_Control owns both those pilothouse movie channels .... is it possible he would do a shameless plug here? 🤣🤣🤣 Just something I do in spare time. I enjoy all the old classics when the movies still were entertaining ..... Late 50's they were really getting weird. 1960 is my cut off date. Same time I do have some later movies posted there .... But they are good entertaining movies to watch .... Like John Wayne, I have a ton of his older stuff when he was a kid, but 3 or 4 of his newer then 1960 films. .... Same with Randolph Scott, Gary Cooper, Cary Grant ..... But 90% is all pre mid 50's.

-

Well anyone can have a youtube channel .... does not mean they should use it ..... such is life. About the Left handed wheel bolts ..... not every car manufacturer was as brilliant as Mopar engineers. They actually did things the old fashioned way with studs and right handed threads. ...... Seems even today they still have not caught up with our Mopar brilliance. 🤣🤣🤣 Then Mopars are really the unwanted red head stepchild in the automotive world ..... not really a common vehicle that people drop off at a restoration shop to be restored. Think I was 50 years old the first time I worked on one ..... I had a Uncle beating it into my head, remember the driver side is left handed ...... Not everyone had the same advantages as me though 🤣 The guy may be a total idiot I have no idea who it is or to watch them either ..... I just wouldn't beat up on them too badly for that mistake.

-

Thats why you get paid the big $$ ..... excellent idea. At least find out what you are working with. Probably depends on what year they sprayed the foam in ..... todays market most would not be flammable. If it was done in the 70's-80's .... good chance it is. In construction we used a typical cheap brand called great stuff .... It really was great stuff to have around. To pass fire code, every protrusion where holes were drilled in the framing for pipes or wires, the holes were then foamed so a future fire could not get air or the fire could not spread to the next cavity through the hole. .... It's job is to prevent fires, along with insulation in cracks,windows & door frames etc.... So it would be difficult to buy flammable foam. In the early days when it was just used for insulation, all bets are off.

-

Not sure I understand your question ..... original rockers were all steel. ..... Offers a fair amount of support for the A pillar and floors ...... should be welded imho, not riveted. Not sure I understand the po used foam for a internal filler on the rockers? I'm afraid if you try welding to the rockers with foam as a backing .... the foam will catch fire and burn very hot .... unless it is a a fire retardant foam of some sorts .... I doubt it. Again let me say I do not understand your question ..... If the PO sprayed in some sort of foam to protect the rockers ..... I would be worried about it being flammable ... rivets might be the better choice here ..... although welding in patches would be superior.

-

OK BTTT ....... I have not been working on my truck lately reported earlier was working on the wife car but spring happened ..... If you going to have a garden planting season is important. So I abandoned the wife car and been working on the garden .... Actually widened it & made it longer .... spread about 60 cubic ft of mulch .... (30 bags of mulch) Someday I will actually work on the yard itself, but garden is off to a good start. Seems my Dodge truck wont run now ..... I'm pretty sure right now it is out of gas. Was always easy in the past running off a 2 gallon gas can. Now with the tank installed, I did add 4 or 5 gallons of fuel in it about 3 months ago .... gas gauge not connected .... It starts and dies ..... I'm thinking it probably maybe has gas in it ..... it should start ..... I have 5 gallons of gas to add to it .... I need to move it so I can mow the grass under it. No time to work on it right now ..... am getting excited to finish the engine swap on the wife car now. Very possible if it goes well, I may be fiddling with it for the rest of the summer putting everything in shape after sitting 2 years ..... AC was borderline at the time. Then my daily driver chebby is needing some serious attention .... is due for a good tune up and have issues with the doors .... hinge pins always needed to be replaced on the drivers door .... now the wind caught the passenger door and it needs a lot of love. I really want to get back to working on my old Dodge .... After painting it last fall, it is on the stages to final assembly, wiring, lights, tune and work the bugs out of it ... Sucks but I really just have to play adult and work on other projects first .....

-

The steering box and column are 1 piece ..... basically you disconnect the front tie rods to the box, then the column supports and then the steering box from the frame .... it all comes out in one piece. This also makes it a pita to rebuild since you basically need to cut the shaft, replace the steering gears then weld the shaft back on ..... you can do what you want, it all comes out in 1 piece or you make it separate pieces. Removing the steering wheel then lifting the cab high enough to clear the column is a luxury most do not have .... You may have that with a fork lift or high ceilings ... many do not. Again I'm disqualified because my box is in great shape ..... I have no desire to mess with it.

-

That is probably the best way if you know what you are doing. Personally I just did not have the space to blow my truck apart. I did the front first ..... then finished it .... When I got that back together I then took the bed apart and finished it .... Just depends on what level of restoration you are going for. I simply do not have the room for a full blown frame off restoration ..... my end goal is a daily driver. I never did take my cab off the frame, I just do not have space for all the parts. It would have been nice to at least change the rubber cab mounts .... While mine look ok visually, I'm sure they are shot. I'm just saying for my purpose a daily driver I did not remove the cab ..... for a restoration and if you have the room removing the steering box & cab is required.

-

Just the crate should have some info on it, address too and from .... Something to back up the sellers story. Lets just pretend that the seller wants $5K for it ..... It is still packaged in it's shipping crate so you believe it is rebuilt ..... What are you willing to pay for it? They might want $5K for it ..... Are you willing to pay that for a George Asche transmission? ....... This could be considered like buying a artist painting ..... what are you willing to pay for the pleasure of owning it? ...... No price is right or wrong ..... If you get 20 years service out of it and it works for 20 years .... is $5K too much? TBF I'm just trying to open the conversation up .... bring it back to the top to get others to chime in on price that that have purchased these transmissions. Just a tough one to tell someone else what they should pay for a art piece that is no longer available. Personally myself I would swap to a T-5 or a 318/727 for less $$ and roll with it .....

-

While I think that has a lot of weight to it ..... more importantly does it have any paperwork to prove anyone did go through it? Next is what do you know about the seller? ..... If there is no paperwork for proof? Like a old Ford flathead V8 8BA a very desirable engine and has some value .... It has to have some documentation from a machine shop for magnaflux testing or assembled on a engine run stand running to be of any value. ..... Otherwise it is basically worth scrap value and you are taking a chance on it ..... I have seen these engines bought from a estate sale and look perfect but once you start them & warm them up, they have internal cracks and leak coolant out the exhaust. Basically a junk non repairable engine. .... This is fine as long as you do not have a fortune tied up in it. I'm only suggesting to be careful here because obviously you can not test it before buying it ..... same time if no documentation that anyone went through & rebuilt it ..... you only have the sellers word to rely on. ....... How well do you know the seller? I agree with you ..... I think a rebuildable transmission core is less then $500 ..... A R10 over drive will be worth a little more. What does a rebuild transmission cost for your BMW? ..... My wife 1993 Dodge Caravan was $2k 8 years ago. It is a rare item and getting rarer all the time .... be nice to know what they want for it ..... You can buy it now or possibly never get a opportunity to buy another one ready to be put in service. I would like to see you get it for less then $2k ..... I have no idea what they sell for .... I figure it must be at least worth the value of a Caravan transmission. With today's inflation. Same time if the seller does not list a price ..... offer them $500 ..... you should not be the seller & buyer in the transaction. Just my worthless random thought on it ..... Whats it worth to you? You have other options.

-

I guess I'm just not familiar with the actual machinist process. ..... Good possibility I'm just lazy .... Lot of information on the cap .... I assume they have a stamp machine set up and all they really need to do is change the bearing size. I did something similar when retreading truck tires, every Monday I needed to stamp out 200 aluminum date tags for DOT .... The stamp was all setup, just needed to change the week number. Insert blank tag and pull handle .... repeat 200 times. I just assume they have a stamp machine like that for bearing shells ..... I also think if they were going to turn the crank they would do all journals the same. It really would suck if each journal was a different size and required a different bearing size ..... So in my mind, I just think it would be easier to stamp the crank once then to stamp each cap ..... but what do I know

-

I usually have a name for my vehicles ..... The wife caravan was passed down to us when Mother passed away .... Father named it the *******. We changed it to Lady Belle and have taken better care of it then he did .... except I keep blowing up the engine in it 🙄 My daily driver truck is chebby ..... Since it is a step side it looks like it has a big butt ..... So chebby is a mix between chubby & Chevrolet. My Dodge is the Hound dog hauler ..... some day I would like to letter the doors with a pic of 2 dogs and Hound dog ranch Like a business sign. For short I just call it Hound dog. Any car I drive for some time gets a name.

-

Mightyvac MV8000 ..... Is one I would not recommend. ..... I bought mine about 4 years ago and was never really satisfied with it ..... I probably attempted to use it 6 times. It is still stored in its original packaging and looks like new ..... The back of the plastic gauge has cracked .... looks like a freeze crack from cold winter weather. Just saying I bought it, was never happy with it .... now it is junk ..... Only $50 on Amazon ..... this is not the one for you.

-

I agree, crap in the fuel entering the carburetor can plug up the jets and cause a lean running condition .... and a back fire simply because it needs more fuel. Good call on your mechanic, keep his phone number handy. I also am experiencing a similar condition ..... also I changed some wiring and need to troubleshoot which is causing the issue .... sadly I will not touch it for a couple months at this point.

-

I'm with you brother .... Pretty dirty what they did to you ..... same time it has been going on since the industrial revolution a 100 years ago. .... Legally. Not saying I agree with it ..... I simply will not deal with them either. Spare parts are great to have, and it takes time or years to collect them as they become available. Then you still need to store them. I bought a home made utility trailer for parts .... I assume I may have a decent rear end or spare drums, I have spare original wheels .... the sheet metal, tailgate is much better than what my truck has ..... So far I have taken the fill plug off of it and replaced it with my crappy one. Just not easy to have a parts car or a 1/2 a truck trailer around ..... at least my trailer doubles as a bin for scrap metal and call up a scrapper from time to time to empty it. Not everyone wants this stuff lying around or a HOA will not allow it.

-

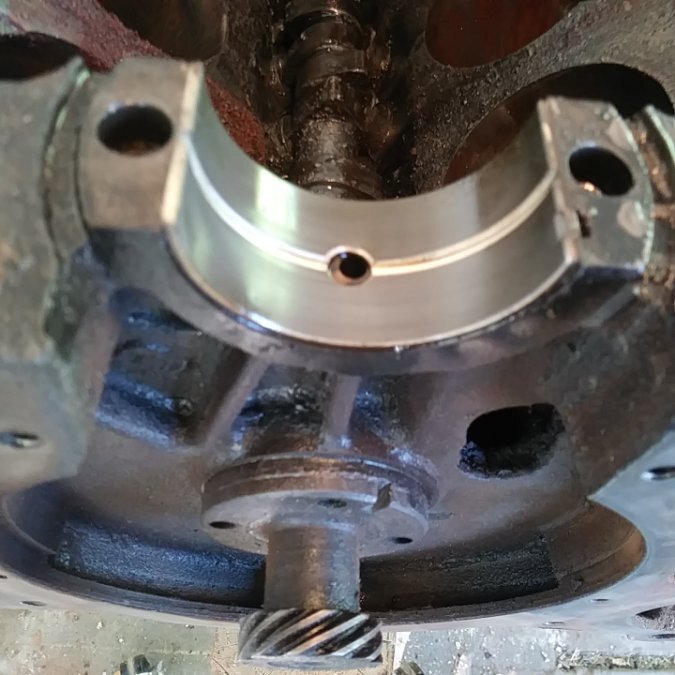

Ok so now 2 people has seen the crank stamped. ..... In my mind it would be much simpler to just stamp the crank then to stamp individual bearing caps? I know nothing about the history of my motor, other than it was the kids Grandfather truck and was parked in the barn for decades. The fuel pump was missing. Tear down & inspection, I just assume it has been rebuilt at some point because the bearings show zero wear and crank is stamped. To be honest the stock cylinder bores match the bearings ..... Grandpa the owner was a farmer, maybe as his personal rig he rarely drove it .... except to church on Sundays?

-

My engine does not have a tag riveted to it .... It is a 1951 Ford flathead .... makes no difference for this discussion. On tear down the pistons were not stamped, so I assume they are stock bore. Some valves had a makers mark on the face of them while some did not .... I assume some were replaced. The crank right on the front heavy weight, was stamped 10/10 .... In some fashion. I think it was 0.10 or something more technical .... But I knew it was telling me it had been turned on both mains & rods..... It was stamped up on the flat part of the weight. You can see the flat spot of the weight in the photo, I was taking the photo to look at the journals. I'm a bit concerned with the dark line in the center. The journals are totally smooth, you can not catch or feel anything with a fingernail. .... just discolored. Perfectly understandable the way the main bearings are made ... I expect it. Just do not understand it on the rod bearings. Either way I think the engine can be cleaned up and put back together, except for the poor cam .... It is pretty dirty and hard to clean .... afraid it may need a new jr 400 race cam and adjustable lifters to match the new headers when put back together

-

I'm going to agree with this, I have a 1951 engine the crank is stamped 10/10 .... the bearings have no markings though.

-

I'm curious to see what others have to say ..... Mine were like a twisted nail that held them in place. To be honest I do not think I can install them a 2nd time in the same hole and expect them to hold as well as the first time they were installed. For originality I suppose you could install them .... I suspect some sort of adhesive here would work better. Good looking truck.