-

Posts

4,686 -

Joined

-

Last visited

-

Days Won

35

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

I'm with Merle, it is 180 out assuming the plug wires are correctly installed. Simply removing the cap and see where rotor is pointing. Then lift the distributor up and rotate it 1/2 a turn and drop it back down into the slot where rotor is pointing to other side. The 4 stroke engine pistons are at TDC twice, once for compression stroke and once for exhaust. It is fairly simple to get it to TDC on the wrong stroke. You are getting fire to the cylinder when the intake is opening so it coughs out the carb instead of the exhaust. This is actually pretty promising .... it is a actual ooops moment of slight embarrassment .... I have done it a few times over the years, SBC were the same way. Is a simple 2 minute fix to lift the distributor and rotate it and do not move the plug wires. If you did everything right it will now fire on compression stroke and should run. ..... If not then you need to start over from scratch.

-

‘48 dodge deluxe. What documents should I get , need?

Los_Control replied to BayArea48Deluxe's topic in P15-D24 Forum

I could be wrong .... just suggesting all cars were parked for a reason .... being a detective and finding out why the car was parked can be fun. Very possible the engine was good and ran fine but had other issues. ...... Almost probable you will run into stuck valves and zero compression in some or all cylinders. First thing you want to check is if the engine will turn over by hand, or is it locked up? If it turns over you want to start soaking the cylinders with oil ..... when you are ready to turn the engine over with a battery, probably best to disconnect all original wiring. Then run a compression check on it ...... The older engines have cast iron piston rings, very common for the iron rings to corrode to the aluminum pistons and not seal .... then the valves are known to be sticky .... Simply the oil gets gummed up in the valve guides and the valve springs are not strong enough to pull the valves back down through the gunky oil. ..... All common issues and usually easy to fix ..... just do not get discouraged if you have a engine with low or no compression. The manuals or diagrams are not going to tell you how to revive a engine that has been sitting for 20+ years in a field. -

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

Ok spelling police ..... Lets be fair, I think I assembled the brakes fine while managing the breaks -

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

I know I should not get hung up on paint .... Honestly I do no care what color the paint is. I was so mad at myself when I installed a new water pump on the 49 Dodge .... I thought to paint it and then though that was silly .... Now it looks like rusted up crap and only a few months old. My wife .... I thought you were going to paint them pink? Me ..... I thought about it ..... pink would make your brakes wiggly, Race car red will improve your braking performance 30%. I just used the paint I had on the shelf. Been thrashing a few days on getting all installed, my body needs a break .... assemble the breaks is all thats on the agenda today. -

‘48 dodge deluxe. What documents should I get , need?

Los_Control replied to BayArea48Deluxe's topic in P15-D24 Forum

@BayArea48Deluxe very first thing is what I posted earlier ..... now tell us what condition your car is in. Does it even have a engine ..... how much rust are we looking at ..... What are your goals for it ..... What good does a manual or a wiring diagram do you if you plan to swap in a modern drive train ..... You are in the right place, I feel we have no idea how to really help you if you do not share photos and ideas of what your end goals are. Some say it came from a graveyard, what they really mean is it sat for 3 years in a barn and needs work ....... some actually get pulled out of a farmers field and need more work ..... What do you have and what are your goals? -

Exactly what failed? If the rotor button is burned off and the spark has to jump too far ..... you got some kind of aftermarket coil pushing too much volts through a stock rotor. My last rotor failure was a cheap plastic body that wore out and allow too much slop in the timing ..... How do yours fail?

-

‘48 dodge deluxe. What documents should I get , need?

Los_Control replied to BayArea48Deluxe's topic in P15-D24 Forum

A place to work and time to do it .... What you do not know now, you can learn if you have patience and time. .... For example I did not know how to weld .... so I bought a welder and taught myself to weld. You are in the right place to ask questions to get this done .... Just know it takes time for many of us ..... while others can do the same thing in 1 years time. I bought my project in 2018 ..... Keep in mind I'm physically disabled and been medically retired for almost 14 years .... I physically work for 25 minute then I sit down to rest my back and legs and drink a beer for 20 minute .... then get back up and work for 30 minute ..... I'm just saying even a disabled drunk can do this work. Main thing for me is knowing I have my workspace as long as it is needed, and willing to take the time to learn what I do not know. Another challenge is life gets in the way ..... This needs to be done as a project and actually enjoy what you are doing. An example is my project I tore it apart and painted it then am putting it back together, I can start it and move it around .... I need to do final body panel fitment and I have a new wiring harness to install ... I'm getting really close to driving it and want to finish it up. Oh shucks it is spring time .... I need to work on the garden and expand it as planned .... I spend several weeks working on that and garden is doing fine. Then my wife car needs a engine swap and I have put it off as long as I can .... So I have a used engine from a wrecking yard with a 90 day warranty on it and that expired 6 days ago. ...... I think I will fire it up in 1 or 2 more days, find out if it is a good one. Sometimes we just have to be adults and do adult things, then get back to our projects when we have time. In my experience a place to work and time to do it is most important. ..... Everything else you can overcome. -

Watch this video .... the guy is kinda lazy at times it seems but he made a nice tool. ..... Just looking at it you will get several ideas on how to make your own using allthread I have seen some made out of plywood to sit on spindle then allthread attached to it with a adjustable metal arm ..... so many ways to make it .... not sure I would buy one but if I did I would not buy from Moparpro.

-

No way to explain it .... you must have ghost. Obvious you must have compression in those 2 rear cylinders if the compression is blowing the rag out of the spark plug hole. Seems your new gauge is working correctly if it measures the first 4 cylinders. If by chance you had a blown head gasket between 5 & 6 it is possible that when you install the gauge on one of the cylinders, it all escapes out of the adjoining cylinder. Usually it would just show a low reading though ...... Unless the head gasket is so blown it has a Interstate opened up to allow free passage of compression. So put a plug in one hole while you check the other and see if you get a reading. Then swap plug and gauge to check other .... If you get a low reading from them both at this time .... at bare minimum you have a blown head gasket ..... you will need to pull head and investigate further.

-

Random talk about my engine, nothin special

Los_Control replied to lostviking's topic in Mopar Flathead Truck Forum

Glad to hear that, guess that helps me also. ..... If I do use the transmission and think I want to, I would be asking same question. -

Random talk about my engine, nothin special

Los_Control replied to lostviking's topic in Mopar Flathead Truck Forum

Be curious what @sniper thinks. I say that seems like a lot of play. I have a 1952 Ford 4 spd and there is very little play in it. Then I have a 1970 Dodge 3 spd. PO said it was noisy in 2nd gear, so I know it needs work. It has as much end play as yours .... I Dunno -

First Start. Rebuilt Fuel Pump Not Connetcted.

Los_Control replied to Bingster's topic in P15-D24 Forum

Would be good to have a fuel pump/fuel supply connected .... can just bottle feed it in the carb to see if it does start ..... most likely will need to bottle feed it until the fuel pump gets primed and picks up fuel anyways. So it is nice but not required to start it. Either way you do not want the old fuel tank connected to the pump in case it has some old fuel in it .... you do not want to introduce that into your carb. You can just disconnect the fuel line to the pump and then connect a new line going to a gas can there. -

I think what you can say, you had a pile of junk tires out behind the barn. What @Bingster needs to hear is it is perfectly normal for tires to lose air and go flat simply with the change in weather temps ..... we all have to adjust our tire psi at least twice a year. It is just normal on our daily drivers. Do not let others scare you out of it ..... just stand to the side and fill them to 20-30 psi ..... I know they are junk for the highway .... you know the same ..... but just to roll the car around they are fine ..... unless they will not air up .... then you need to replace. Just like jacking the rear end up we all have done it ..... same with flat tires.

-

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

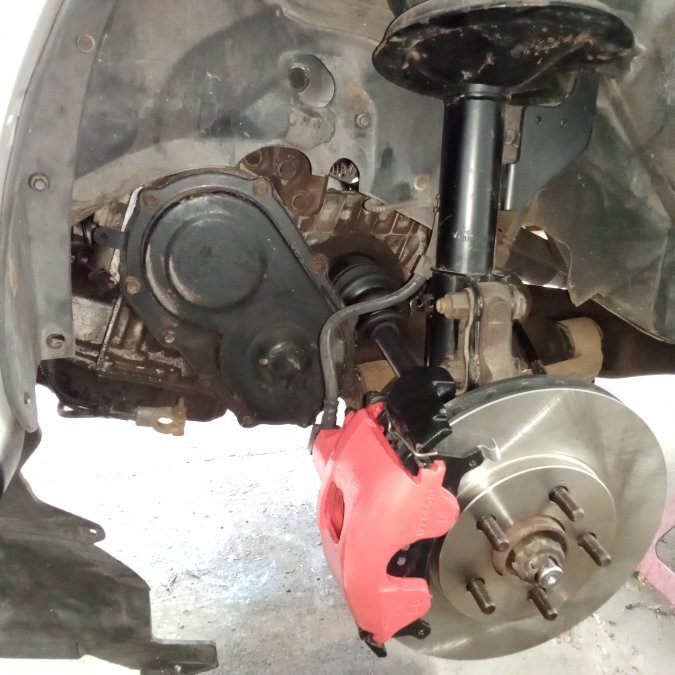

Ok been a few days, but back at it. My garage is such a mess right now with the caravan ripped into a million pieces and 2 engines torn apart to make one ..... I simply could not find my Teflon tape ..... so today I went down and bought more, this time I bought the yellow Teflon tape made for Natural gas pipe fittings. It is much stronger. I did such a crappy job applying it last time trying to use it sparingly & keep it pretty ..... Not as pretty this time but no chance they leak. So in the meantime I installed the axles .... Father inlaw put the cheapest Autozone axles on it .... The driver side never gave issues, passenger side he had to take them back for warranty 2 times ... 3rd time he paid up and bought the best lifetime guarantee axle and 20K miles is holding up fine ..... While the cheap driver side axle feels fine, the boot has a big hole in it. Instead of replacing the boot, I just bought a quality axle for it and replaced it. .... Axles are done. So I'm working on the brakes .... The rotors while possibly serviceable were worn, was obvious the FIL put new pads on but not rotors. So I bought new rotors/pads ..... pads have 50-60% on them and no complaint on brakes ..... While I'm here I just need to fix them proper. So here I am, the calipers work fine ... they look like crap .... I have proper fitting wrenches and tried everything and simply rounded the heads off trying to remove the pins. .... I just have the feeling FIL used red loctite on the threads .... I'm going to need heat to get them apart .... so I have new calipers on the way ..... I never wanted to take the brake lines loose, these things are screaming to be taken apart, cleaned up and painted. Other then a DANG! There is another $100 .... I have plenty to keep me busy running vacuum & electrical lines .... plenum, alternator, power steering pump, radiator ... 🙄 -

Let me give you my 100% expert opinion, if you happen to be a 17 year old kid pumping gas at the union 76 gas station, and some Hawt looking blonde pulls in with a flat tire she been driving on .... Can you fill up my tire? .... YES MAM, anything you want! ..... I got about 25 psi into it and a bubble appeared on the radial sidewall and was amazing how quickly it grew in a circle around the tire and blew up ..... It happened so quickly, I was able to move about 2' to the side of tire before it blew. Then she immediately blamed me for ruining her tire 🙄 The difference is, the tire was damaged and ran flat and got overheated. The tires on my Dodge truck are take offs from my daily driver .... They have good tread but deep sidewall cracks, I drove them 4 hours on the freeway to get home when I bought the truck ... In 1 or 2 weeks I had new tires on it. .... so the take offs are now the rollers for my Dodge ..... Since 2018 I have put air in them 3 times and currently needs it again .... they do go flat from sitting. .... I even took one in for a patch because got a screw in it and tired of filling it up to move it. They are old, I will not take them on the road and warm them up .... they are fine to run 20-30 psi for rollers to move around with. So long story short, if your tires are just flat from sitting and not damaged from driving ..... air them up while standing to the side of them and not directly in front of them. If they do blow, the wheel is bolted on and the force is going straight out. .... you will probably be safe if you are on the side of it. I have aired up a 100 tires on old cars that have been sitting, you want to be careful and stand out of line of fire. Sometimes they simply will not take air and you hear it coming out as fast as you put it in ..... generally they will if just flat for sitting a few years.

-

1950 Plymouth special deluxe not starting when hot

Los_Control replied to Rlopera44's topic in P15-D24 Forum

But it sure is fun 🤣 -

I think it is a fine idea to set it on jack stands for first start .... also can check the gears while at it and see if something else to add on the list of things to do.

-

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

Thanks sniper ..... it is hard to say at this point. I just remember buying it at Napa and requesting high pressure fuel injection line ..... It cost $8 per foot. I bought a few feet of it because I also used it for my transmission cooler lines .... FWD car they are only about 10"-12" long from the radiator. ..... Then I ordered online a set or assortment of high pressure clamps to have spares on the shelf. The only thing I can read on the hose today is. Made in the USA 07/08/21 04 36 ....... There is some additional writing up by my thumb but simply can not read it. I only assume Napa sold me the right stuff, they certainly charged me for it .... It is reinforced under the exterior rubber coating and not simple to cut ..... I'm just comfortable thinking I have the right stuff .... I have often been wrong in the past. -

Sheesh I do not see any problem going forward. ..... My first project came from a farmer, it was a 3/4 ton B1C factory flatbed with the bed missing. While it was a 3/4 ton it had a 1/2 ton front axle under it ..... meaning bolt pattern for wheels was different between front & rear. While it was a 1949, it had a 1938 engine installed. Every brake drum and brake shoe on all 4 corners were ran 100K miles past their useful life. The shift handle was from a ancient hose bib. Would take hours to go through all the farmer fixes on that truck while he kept it operating and useful. I think your truck looks pretty good with the mistakes you have found so far .... simple fixes. .... Good find.

-

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

Thanks for the reply JB, I agree it looks bad in photo. I just wanted to snap a photo before I cleaned it up to show the leaky fitting. The repair I did last time when I installed the used engine, I only got less then 50 miles on it before bearing spun. I feel the hose is like new, vehicle was just parked for 2 years til I got over being mad at it. So it had dirt and dust on it and wiped clean easily. I appreciate your input on Teflon, I was thinking same also, just not sure though. I have had problems with Teflon in the past .... I guess I use it sparingly on plumbing fixtures to keep a nice clean job for customers .... when I slather on pipe dope it is messy, but never have a leak. I suppose I just repeated past problems trying to keep it looking neat. Only thing I can think of that might be a better fix, use steel braided lines and AN fittings. I honestly know nothing about them and do not know if actually better .... other then it looks better. IIRC, the caravan carries 35-40 psi in fuel rail .... not incredibly high. -

Sam I believe you are also the one that pointed out my newly purchased alternator required a external voltage regulator .... I love and respect you and appreciate your advice. I purchased my items for a 1972 chebby truck thinking I would get 1 wire internally regulated alternator ... coil same way ..... You set me straight. I made my bed and have to sleep in it .... I kinda like the mopar way with running ballast resistor on the coils. I have seen them fail before and cause no start issue.

-

We really getting off topic here and stealing @Davidcc thread about vacuum lines. @Sam Buchanan It depends on which coil you buy. Not all coils are created equal and some require a external resistor and others do not.

-

Actually not .... the problem I have is self inflicted but I saw no other way .... I'm just doing the 12 volt conversion and installed new ballast resistor, coil, wiring, points, condenser .... I changed too many items all at once. .... It could be a faulty new item on any of them .... I'm just picking on the condenser first because it is somewhat shady installed. .... just as easy could be the new ballast resistor or new coil .... Still in the middle of the engine swap on wife car and just no time to look at it.

-

I get what you are saying @Ivan_B I just want to say that bending 1/4" steel lines is easy. .... I'm not claiming this is the best job ever. I bent 1/4" steel lines for my rear brakes and feel it looks presentable. I do have a decent tube bender .... this was all done by hand and not worth bringing the bender out. There is a 90 degree bend going into the wheel cylinders and think I used the bender for those .... sure I could have gotten by without it. nicop is even easier to work with. As far as the condenser goes, I know it can be done on the side of the road if needed. I just prefer to pull it. In fact if you scroll up and look at my first photo .... you see a custom made condenser and that is connected to the coil to replace the condenser in the distributor. I was told by the creator .... I dunnno I never ran one that far away from the points .... they are designed to bolt to distributor body. Near the points. Others have told me yeah! that will work fine. ..... I say it starts and runs fine .... let it sit and idle for about 45 minute and it just gets a weak spark and dies .... let it cool down and will run fine again. I thought I was smart and I just disconnected my known good oem condenser and left it installed .... all I need to do is connect the wire for the condenser and disconnect the aftermarket condenser ..... Thats how simple of a job I need to do ... Yeah I'm pulling the distributor to connect that wire. ..... I do not need to, it is such a simple job I will and that allows me to inspect the condition on everything else.