-

Posts

4,686 -

Joined

-

Last visited

-

Days Won

35

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

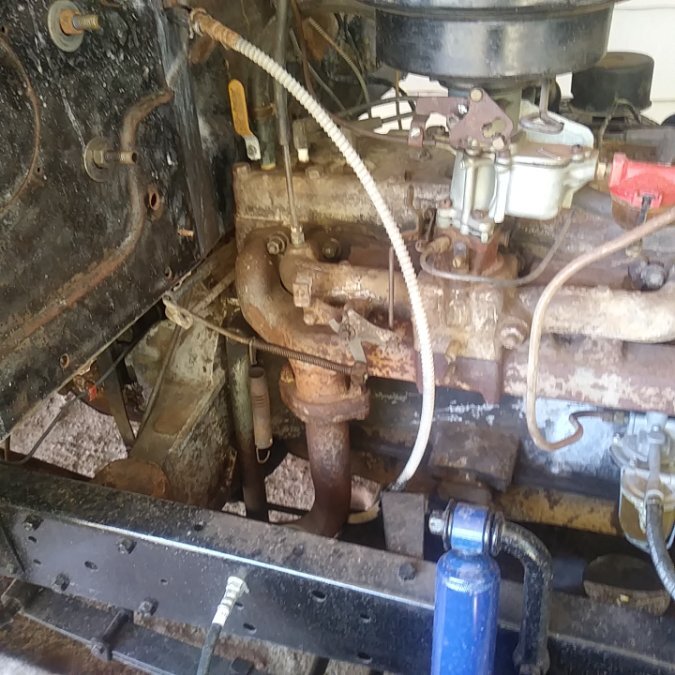

Absolutely no to all those questions. You need to time the engine with it running and distributor installed. What I am saying, is my engine is timed and runs pretty well. I have needed to work on the points a few times and I have removed the distributor at least 3 times since 2018. I need to do it again because I'm fighting a issue and not positive what the issue is. .... I'm going to change condenser and see if that helps. To change the condenser I'm pulling the distributor out and set it in my bench vise .... while there I will check everything else. Then when I set it back in, and the hard metal line aligns perfectly, I'm putting it back in exactly where I pulled it out from. I blew up my back many years ago and I simply would prefer not to bend over the fender to work on the distributor. It is a simple 7/16" wrench to disconnect vacuum then 1 hold down bolt. The photo shows a crappy 75 year old steel line that works fine. Some sort of imitation of swoopy coming out of the distributor then tall up and over the plug wires on the head. Honestly I feel the distributor has a very short turn radius, but because of the 2nd adjustment underneath you have all the adjustment you need. And a generous length hard line there is all the adjustment you need.

-

I always thought a simple visual inspection of the timing chain .... with the distributor cap off rotate engine by hand until the rotor moves. Then rotate the engine in opposite direction and monitor how far you move the crank pulley before the rotor moves. If the pulley moves 1/2" ... 3/4" is probably a very good chain, you need some slack in a chain. If you are moving that pulley 2" .... your chain is stretched and time to consider replacing it I'm sure the distributor not moving is probably some corrosion between the 2 dissimilar metals of the distributor body & cast iron block. Some sort of soft hammer and some soft tapping and lots of oil is required.

-

I say just make the line a little long, you will be able to flex it enough to do your adjustments. That is the way my original steel line is and works fine .... nicop is pretty flexible, same time any small line is including steel. One advantage though, it is pretty simple to just unbolt the distributor and work on it on the bench instead of leaning over the fender standing on your head. The rigid line does hold in place and when you drop it back in and timing should be really really close to where you took it out.

-

I actually found brake lines hard to come by .... I have 2 auto parts stores in town, one simply had no steel lines and nicop was not available at their warehouse. The 2nd store had some steel lines but not nicop .... the only steel lines available was what is on the rack in the back ... they would not be replaced when sold. I'm just suggesting my only means to get nicop was order online .... hope others have better luck.

-

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

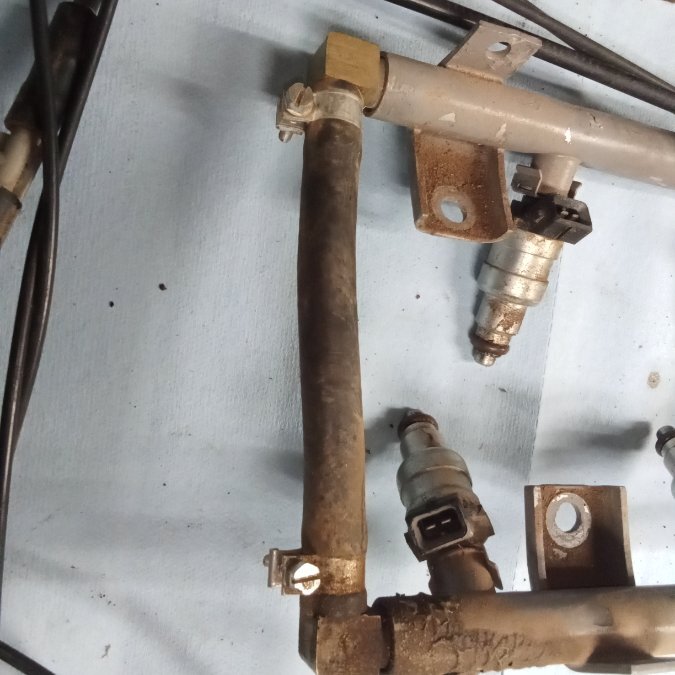

Man I have been dragging my feet on this job ..... The show must go on. Seems like I have been here before, did this exact same job and got my nose bumped .... here I am doing the exact same thing and history is telling me I'm about to get my nose bumped again. I have motor/trans sitting on mounts and just putting the big jigsaw puzzle back together. Sucks pulling a engine out the top when it is designed to come out the bottom. So many unnecessary things need to come apart. Anywho, I could use a little advice on this one. I'm just getting ready to install the fuel rail and found my repair had a leak. I'm thinking I just did not use enough Teflon tape on it and need to redo it. ..... Now I'm wondering if gas will eat Teflon tape. ..... Maybe there is something better available for threaded fittings on fuel injection lines? -

While I want to say it is not ideal .... simply is common for todays quality of parts. If you had a modern uni body car, the rockers are actually structural. The rockers provide strength to both A & B pillars, it is tied in with the roof .... There are functions built in with uni body that tie the rear frame rails and front frame rails together. .... It is imperative the metal structure is solid. With a full frame car the rockers hold the floors and doors in place. .... Simply not as important as a uni body car. I think it sucks .... my freshly installed floor pan is 20 or 22 gauge metal ..... it works but not my choice ..... the other alternative is to roll your own .... possibly you can add some bracing to beef it up ..... In the manufacturers eye it is just for looks .... possibly a uni body car they use better metal. In the end it actually does work, just not ideal ....... use it or make your own.

-

I think @Doug&Deb is correct here, it is a really small line. Measures 3/16" OD .... no idea what size fittings and threads for that line.

-

IMHO, built right they are pretty safe. The question is .... how high can you safely lift the car while while getting the stands under the tires? I actually prefer regular 6 ton jack stands that I can raise or lower while jacking up the vehicle. In this case the vehicle is not really high but comfortable to work under while on a creeper. I have all 4 wheels off the ground. In order to lower the car I have to first raise the car and bring the stands to the lowest position one side at a time .... then with the vehicle lower I can remove jack stands from one side then I can move over to the other side and remove those. I'm just saying I have to be careful and jack it up in stages. ..... If you have a forklift to raise the vehicle you can make them as tall as you want. Can anyone guess what I'm doing today?

-

I just think there may be a lot of truth here on the stomp starters Like @keithb7 has. My truck has same. Looking at my photo even though it is the wrong side ..... we can see there is no restrictions to get to it. With the 1/2 moon wrench I found I can actually remove the top bolt 1/8"-1/4" at a time ..... just not worth the effort if the starter is working fine as is. So at this stage I did purchase the wrench, I attempted it to test the wrench .... seriously not worth my time if the starter works fine. Possibly cars without a stomp starter and no linkage in the way .... they do come off easier .... us old people that stomp our feet ..... mot a pretty sight.

-

Where it actually counts is the diameter of where it sits in the recess in the head ..... That is such a common measurement that finding a replacement is just not worth the effort to talk about. In no way shape or form does a modern T-stat resemble a original .... They do work the same and do the same job ..... nobody knows in a car show what T-stat is installed. A modern T-stat is more reliable ..... maybe you want to keep & mess with the original.

-

While in a perfect world the load leveler works fine. In the real world I have to do without .... it would do me no good today. I literally have to lift the engine straight up in my wife car ...... then as a FWD car I need to set it down on blocks and reset the hoist to pull it vertically as much as is possible. I can then gain more space and remove 2 more motor mounts. .... t is designed to be removed out the bottom. While a load leveler is awesome to have ..... It is not a end all cure all issue ..... Many people have them and just as many people never needed them. I would love to have one .... I simply see no reason to spend $$ on one when it is not needed ..... It is a comfort and convenient .... just never required. Unless you do engine swaps often, you will not get full benefit from it. ..... What else you going to spend your retirement savings on? ....

-

@greg gwould you even consider doing the job without removing the toe boards and transmission cover? Just my impression the original poster does not want to ..... thats fine, I just never would consider the job without removing them.

-

I want to say it does look original. Here is a photo of my 1950 218 engine T-stat .... looks the same to me. Same time I just use it as wall art, would never put it back in service. .... Same time it is just such a common size that it could fit both a 318 & a 350. .... Just really is a non issue. If it is important to the owner, they might be able to find a NOS replacement on ebay .... just personally something I would not bother with.

-

Thanks @Sam Buchanan I was going through a bit of a crisis and tossed out a quick short reply without searching for the answer. In the middle of a engine swap on wife car and need to get new/used engine off the stand to install transmission .... then my jack on the engine crane pooped the bed. So while trying to fix it, I made a short post ..... Now the replacement part is ordered and be here next week ..... All dressed up and no place to go ... I got time to look it up now

-

I hate to say keep searching the forums, seems like it was so easy I found the direct replacement and I never wrote down the number for it. I wish I did. It is something common like a 350 chebby T-stat you get from any auto parts store and the gasket also. When it is time to replace mine, I will just have to get the number off of it and go get another ...... A wise man once said, never remember anything that you can just write down and retrieve later .... I might be a wise man if I wrote it down. There are many threads on modern replacement T-stats.

-

Fair enough, the photos in your post do not show the base ..... To me the base is far superior to other bases.

-

It is, but here is the one he is considering on buying .... total different animal. And $200 which is not terrible.

-

I have the 1000 pound stand and it works ok. First thing I did is make a longer handle for it, just 1/2" Galvanized pipe 3' long. I needed a jack handle for my crane, I started with a 3' pipe sitting in the corner and was going to cut it to length .... just works perfect as is, also doubles as a handle for the engine stand. The longer handle gives more leverage and control when turning the engine over. My original intentions were to weld in a angle brace from post to base to add more stability .... Then I have some scrap square tubing, I was going to make a wider front base. This would give more stability to prevent tipping over. Simple things to do and still may do it sometime. I think so far the heaviest engine I've had on it is my flathead V8 .... It works fine as is. I also have seen others with same stands and have 426 Hemi's ... 440 big blocks complete and turn them over on the stands and not drop them or tip over. I have also seen where A guy rolling one in a garage and get a wheel caught in a dip for a drain and tip it over ..... so they can tip over if not careful. With all that said, the 2000 pound you list is tits! Very stable, foldable for storage .... very professional looking and would be difficult to ever tip over impossible to go wrong with it. .... You will be the talk of the town with that stand Or be normal and use the other stand.

-

Way off topic 1993 caravan transmission

Los_Control replied to Los_Control's topic in Off Topic (OT)

So I got it out of the car yesterday .... Dang spring weather gets in the way and had to spend a month in the garden getting it ready & planted. .... Finally got serious working on it ..... got the engine on the ground yesterday, I need to swap the transmission and order a couple parts .... I'm out of locktite. ...... June 11 the warranty will expire 🙄 -

Last custom tool I made was to remove the plug on the rear end. When I needed it a 2nd time I could not find it ... I looked everywhere and ended up making a new one. This time I thought I was going to be smart .... I'm going to put this wrench in the right hand corner of this drawer so I can find it next time. In my best Gomer Pile voice SURPRISE SURPRISE! I found the first one I made sitting there.

-

Seriously there is so much work you can do from the top, makes everything so much smoother for us old folks .... I would not even consider doing the job without first pulling the floor pans. Do everything I can from the top then crawl under and get the rest. My truck needed a new floor pan installed, so I had the toe boards out, transmission cover out, then I rough cut the floor pan out .... It was so nice having all that access to everything underneath .... I hated to actually weld in the new floor and lose the access.

-

As far as I know The trick to grinding the rivets off is now you can remove the drums without using a special puller. If you have bolts, sounds like to me ..... someone replaced the rivets with bolts. I dunno, maybe someone will come along and correct me. I'm not saying it is a bad thing to have bolts ..... usually what I have read they remove the rivets and do not replace them with anything. This will allow you to remove the drum like a modern car & not need a puller to get them off. So I understand someone removing the rivets .... I just have no clue why they would replace them with bolts .... ... Give it a day and maybe the smart people who go to bed early will answer tomorrow ..... pretty sure never were bolts involved there.

-

Just hard to say if the wheel is sitting 100% absolutely flat against the drum I'm going out on a limb and say ..... NO! this will not work. You can grind the rivets down on the drums and remove them ..... assuring your new wheels fit flat. This is sometimes done to call it a improvement ..... putting new wheels against them can only lead to disaster if not sitting flat. You will need to mount a machinist gauge then check the run out while turning the wheels ..... If not flat they will eventually fail and warble out the bolt holes. Ruining your new wheels. At the very least they will cause vibration and wobble til they do fail.

-

I think that would be ideal keith ..... My experience with a non ratcheting starter wrench, they work but still only getting 1/4"-3/4" turns at a time .... working but going to take some time. Ratcheting wrench would speed it up.