9 foot box

Members-

Posts

660 -

Joined

-

Last visited

-

Days Won

15

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by 9 foot box

-

You could make a replacement with a coupling nut, a bolt with the head ground off and a lock nut. That’s what my P15 parts book would replicate. I don’t know what a 41 clutch rod looks like. I put the MC rod in the picture for reference to rounding off the bolt head. Rick D.

-

I recommend removing the hood and then taking the front fenders, grill, radiator off in one piece. Then you can remove the radiator and get to the five core plugs on the left side of the engine, the block drain plug and the water distribution tube. The weight of the radiator keeps the clip fairly balanced. I did use a couple 1” ratchet straps to hold up the fenders. I pulled two B model engines that way, with each truck still on my trailer. I used my forklift with a boom, but a cherry picker will work fine, with your truck on the ground. The trouble with honeycomb radiators is that when old time shops fixed them, it looked like it was hit with a shotgun. A local shop wouldn’t fix mine, but recored it with a newer style core for $500, with my top and bottom tanks. It would probably cost twice that now. You have a junk yard handy for parts anyway. Rick D.

-

There is one now for sale on eBay. I just happened to have an original, made 12/22/22. Didn’t cost a cent. Rick D.

-

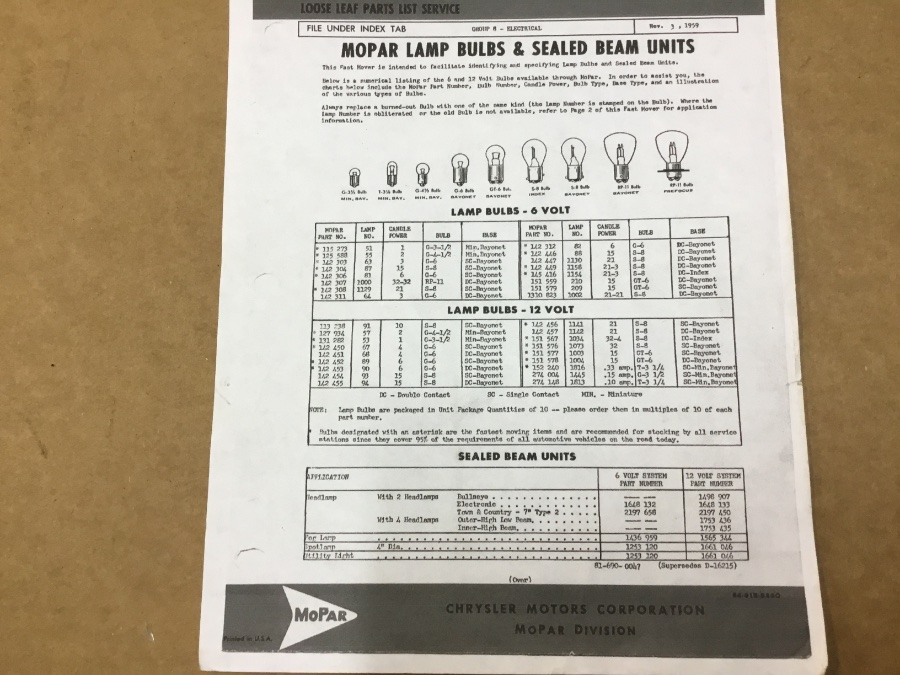

There is a bulb chart in the downloads tab. Click downloads, click the 76 items on reference information on the right and it’s the last item on page 3. It looks like this. Rick D.

-

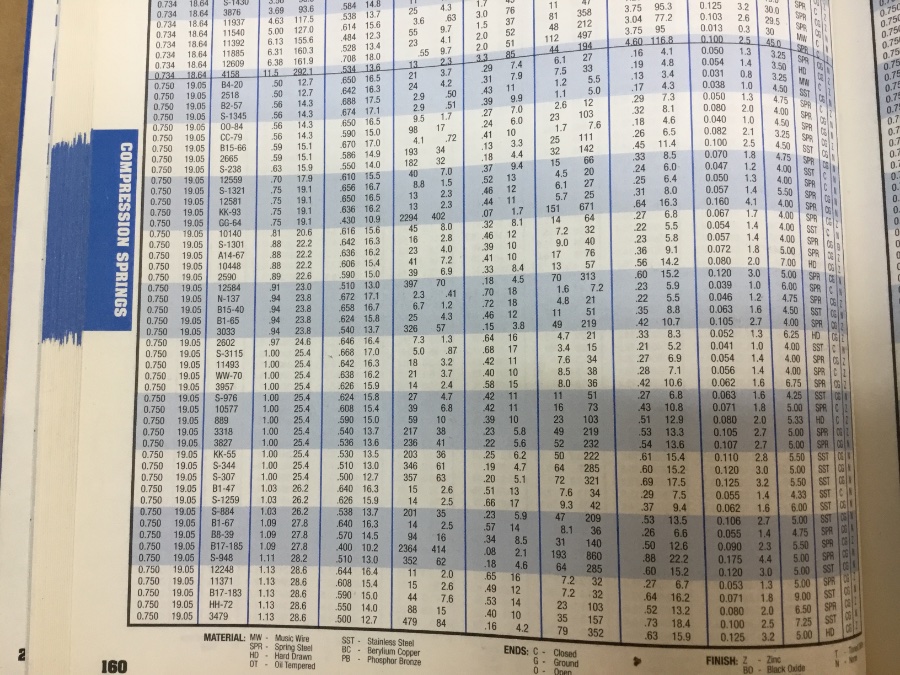

I have a Century Spring catalog. There is an online catalog also. I would think that you could find something that would work. This is a page I picked that seemed close to what was pictured. Rick D.

-

I use an auxiliary gas tank connected to the carburetor to start engines. I’ve disconnected the fuel line from the tank at the pump and connect the aux. tank there also. I place it on the cowl for gravity flow. The varnish residue in the tank can seize valves, so I would clean the gas tank before using it as a fuel source. I don’t know what that bolt is for on your water pump shaft but it could be stopping the pump from turning. The fan blades don’t look balanced, and would be my other concern. You need a Gates 42554 water pump. Use thread sealant on all the bolts. Sniper has a recent thread on a thermostat housing exchange on the car side of the forum. Your 55 block is internal bypass, so you don’t need the thermostat housing that you have. That explains why your oil pan plug is where it is. If you are going 12 volt, make all your connections neg. ground and get a new coil with a resistor mounted to it. That would be wired, hot wire to resistor, resistor to pos. coil post and neg. coil post to distributor. I don’t know why your coil burst, but it could be because it was wired pos. ground and the internal resistor won’t work that way. The extra hose in my engine bay goes to a block tank heater and block drain connection. That is what your engine could /should look like, with the newer engine, with internal bypass coolant flow. Rick D.

-

The speedometer cable on my 47 Dodge one ton goes out the floor at the slotted hole in the upper floor panel. You can get a DA-569 throttle grommet from DCM. I can get a picture of mine tomorrow, in the daylight. Rick D.

-

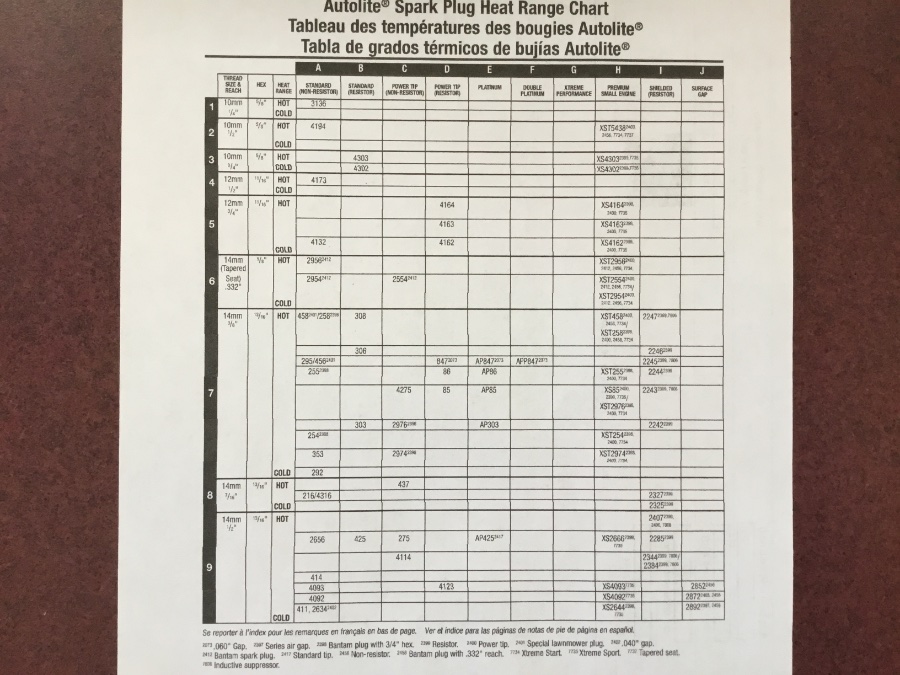

Firing order is 153624, points .020”, resistor plug gap .035”, non-resistor 45’s .028”. Plugs should have the crush washer. If the generator still has a red tag, it would say 6 volt. It might not be a 12 volt conversion. Disconnect the battery wire at the voltage regulator, it will save you the cost of a new one if it isn’t converted to 12 volts. The extra voltage can ruin the field winding in a 6 volt regulator. What is the serial number on the side of the block above the generator? You can determine what the engine is by googling T137 other engines. Take some distilled water to add if needed in the radiator. I’ll leave it at that. There is too much to add. Rick D.

-

To back off the cam adjusters at 9 and 3 o’clock position on the backing plate-put your wrench on the hex head and push the wrench up. Looking at the backing plate, the right bolt head would be turning ccw and the left bolt head would be turning clock wise. Back them off till they stop turning. That backs off the minor adjustment as much as possible. If you have a portable air tank, I would blow the dirt out of the spark plug wells, pull the plugs and squirt some lubricant in each cylinder before I start moving the truck around with only the clutch and transmission in gear to stop. The emergency brake might work or could be part of the problem. It makes it easier to follow a persons build thread if you just keep it all on this one. I think you can change the heading to Buck’s B2D build, for instance. Anyway good luck. Rick D.

-

-

Transmission interchange from 1940 to a 1947 Special Deluxe

9 foot box replied to RonJ's topic in P15-D24 Forum

If your bell housing is longer than 8” between the engine and transmission, it has a fluid drive coupling. If it’s fluid drive, get ready to amaze yourself and riders when you learn more of it’s operation. Rick D. -

I’ve been using an 8 volt battery in my 47 WD21 with a 49 Spitfire engine since I got it 14 years ago. I was able to adjust my voltage regulator to 9.2 volts and the regulator quit clicking and the gauge was steady. I haven’t had any bulb or coil failure. So, yes, it works for me. Rick D.

-

Transmission interchange from 1940 to a 1947 Special Deluxe

9 foot box replied to RonJ's topic in P15-D24 Forum

My Hollander book states that a 40-47 Plymouth transmission will interchange, if your Dodge isn’t fluid drive. If it is, you have to put the longer input pinion shaft in the Plymouth transmission. And probably use your Dodge levers on the Plymouth transmission for the linkage to adjust correctly. Rick D. -

Rodney, I found a Gates pdf file at assets.gates.com. It has a 20923 molded hose on row 260 that I think might work for you, with the two different size hose ends. Rick D.

-

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

I had mentioned about detailing, well I did a little bit on the trim today. It’s paint on gray primer and needs multiple coats of stripper. The old paint is tough. The trim moulding seems to be nickel alloy maybe. It’s not as magnetic as the fender flare. I did a little more today. Rick D. -

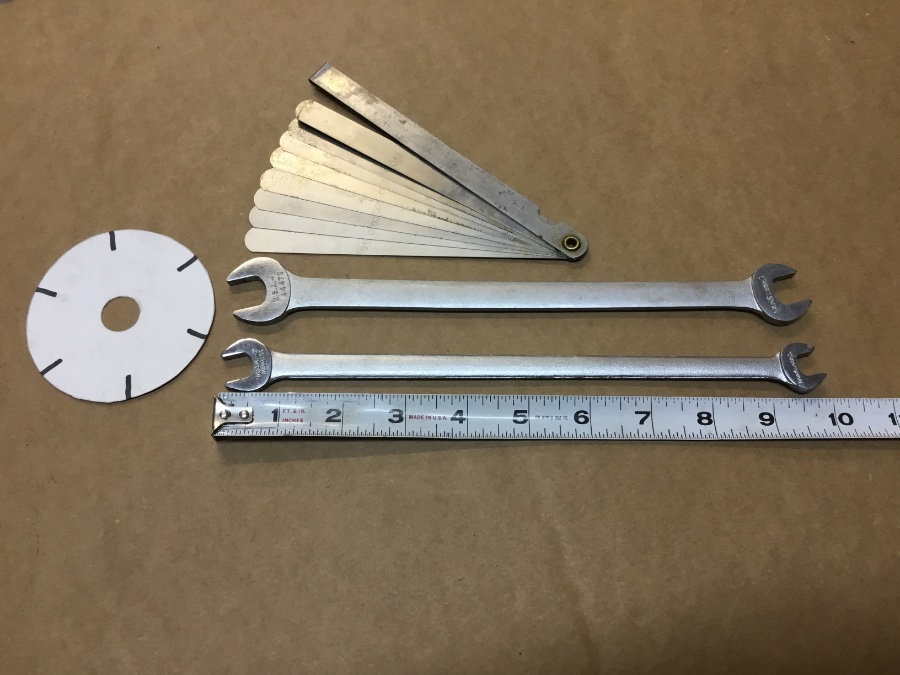

What feeler stock do I need to set the tappets hot?

9 foot box replied to MarcDeSoto's topic in P15-D24 Forum

I bought a couple Craftsman tappet wrenches, 44472 and 44475. I had the .002”-.012” feeler gauges in my set. I put the indexing disc under the rotor with cyl. No.1 at TDC held in place and turned engine over to No.5, mark pulley, hold disc, turn engine to No.3 and mark pulley. No.6 cyl. will be at TDC, No.2 will be at mark on pulley and line on disc, same as No.4 cyl. I set my tappets not running on an up to temperature engine, with the right front wheel and inner fender panel removed. The indexing disc and/or marks on the front pulley is handy for a leak down test also. -

Your getting really close to what this forum is not about. It is what it is, you aren’t going to change it by ranting. No matter what font you use. Rick D.

-

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

I also think the wheels should be painted that way, of course. But I thank you for a post, rather than a trophy or heart. Rick D. -

57 Dodge 300 DeKalb milk truck

9 foot box replied to 9 foot box's topic in Mopar Flathead Truck Forum

I thought I might bring my 57 Dekalb up to date. I think I saved the gas tank, by my cleaning process and dent removal. The wheels and tires are on another tire woe thread. Rick D. -

Since you determined that the tank fitting is 1/8” npt, you could use an inverted flare fitting to pipe size. You will still have to muscle your fuel line around to get the threads aligned but not as much as putting on a filter.

-

I had four lock ring wheels sand blasted. I washed any residue off and brush primed and painted them satin black. I like to use 7.50R16LT tires, they are taller than 215/85R16’s. I use tubes with a TR150 valve stem that you bend after putting the tires on. I like to keep the wheel dry so I wipe the bead and wheel with rubber lubricant. I got four 8.5x17.5” wheels that could be assembled tubeless, but I would need to buy tires and they would still be a shorter height. I’m going to wipe the tubes with corn starch when I assemble them. I had a flat this summer on another truck and the tire dismounted easily and the wheel was still clean. There was a short piece of cellophane type tape inside the tire that rubbed a pinhole in the tube, another reason to use corn starch or talc. Rick D.

-

I have model DL arms on my 47 one ton. My arms adjust 9”to 12”. DL means direct lock and is adjustable by turning the small tab at the 4” mark left or right to loosen for adjustment. The end where the blade connects rotates also. There were at least three different DL model lengths, hopefully you have the short version. The arms and blades on my P15 cars are both 10”. The blades for a DL look like the third picture and release by pulling out the small tab on the right of the connection. I don’t know how your blade would disconnect with that newer style blade. A P15 has a 903433 right and 903434 left arm, the blade is a 830237 blade saddle hook style attachment. Rockauto has two 10” blades, a Trico 33101 and a Anco 2010, the Trico will attach to a DL or saddle hook but the Anco only to the DL. Rick D.

-

Fiddy B2C’s truck linkage and intake manifold are designed to push. Don’t turn you carb’s around. Ideally you need a dual carb linkage. Google Dual Carb linkage P15 and click the Sept. 7, 2018 thread. Mark D and Greg G have pictures of their linkage on that thread. Having a link to each carb from a traverse rod makes tuning the carbs more positive than connecting the carbs together with the Offenhauser link. Read the other links, it will help in your project. I don’t see a throttle return spring, that is a problem, because the carbs won’t return to idle on their own. Look for that thread or I’ll bring it back up for you on the car side of the forum. Or someone with better computer skills than myself, will bring it here. Rick D.

-

I believe that a 3.375” bore with a 4.250” stroke, would make your engine a 228 c.i. I would do what keithb7 did, and use new 3.4375” pistons, and make your engine a 237 c.i. What is the engine number stamped on the block, above the generator? Can you measure the stroke of the piston travel? Google t137 other engines. That has some information on Canadian and U.S. versions of engines. Rick D.

-

Pursy, you have typed some wrong numbers on your measurements. You have a 3.375” piston in a 3.795” bore?