Hamilton

Members-

Posts

102 -

Joined

-

Last visited

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Hamilton

-

Oh, I think you'd have figured it out. Well, you might not have figured out the actual issue, but you'd have eventually solved it by changing out the cap and rotor which, even if you didn't realize it at the time, you'd pretty much narrowed it down to.

-

This exactly the unit I use. After the one I'd had for about 35 years took a dump, I found this one at a garage sale for fifty cents. Being a cheapskate at heart I offered a quarter, which they readily accepted.

-

Absolutely true - particularly given that you've yet to install the rods and pistons. As it sits, your crank should spin quite freely. _

-

I was in Oregon visiting my folks and hadn't ridden the old Canby Ferry for a long time, so I went to the SMS warehouse. If they still offer fabric creation, and if you're seeking originality and don't mid spending a little extra top get it, there's no need to settle for "a close match".

-

Ten years ago anyway, the owner of SMS Auto Fabrics (Canby, Oregon) also owned a textile mill in the Carolinas. At the time SMS was, and might still be, the largest repository of OEM auto interior fabrics anywhere in the world. They didn't have the correct broadcloth wool for my `49 Plymouth but did have a sample book, the swatch from which was a perfect match to the piece I brought with me to their shop (pulled it from under where the front seats folds forward, so it was effectively still like new). I left them a deposit and was told it would take about three months. It ultimately took six but they absolutely nailed it: the weave, the color, the pattern, all spot on! At $90/yard they didn't give it away, but all in all, I thought it was fair, given that they literally had to create the fabric from start to finish. Your car probably came with mohair but if they can reproduce the broadcloth wool I suspect they can handle mohair. If you're looking for originality, I doubt others can match what they can (or at least used to) offer.

-

^^^ This. Tighten slowly and if you're paying attention you can feel the "give" when it crushes. Tighten the plug only ever so slightly after feeling the washer crush. Too much and you lose the seal. This is also why re-using is not recommended. _

-

Yup. Started pumping gas as a high school freshman - back when hustle was the name of the game. Checked and sold oil, mounted tires, washed windshields etc. As a junior I took a ration of shit from people when gas prices spiked (to about $0.37/gallon if I recall) as a result of the Arab oil embargo. Like a high school kid had anything to do with it ...

-

Glad it turned out to be so simple. _

-

As someone mentioned, we're kind of flying blind here, but I suspect (coincidences happen, after all) that you have more than a single issue to identify/address. I was trying to think of whether there was any way possible for an accelerator pump to act up so badly that it would inject fuel briefly at start up (causing the brief spike in RPMs you mentioned) but then not deliver it upon acceleration (causing the backfires). However, given that you said both carburetors worked before, but neither does now, other than a possible leak at the mounting point, we might safely assume that component isn't an issue, which is why I think you're dealing with more than one. The inability to idle without constantly working the throttle and the 2K idle when holding the choke closed both speak to your air/fuel mixture - the likely culprit, as mentioned in earlier responses, being a vacuum leak. The good news is that the number of locations for a vacuum leak to occur is pretty limited on these old flatheads. Still, you need to diligently and carefully check them all. You're probably also looking for an electrical and/or timing issue. Worn or sticking distributor components can cause backfires, as can something as simple as a hairline crack in a distributor cap. It's just a matter of testing and eliminating one potential culprit at a time. On the subject of backfires: it shouldn't be too difficult to identify the source. Obviously, the direction from which the sound came is a major clue. If you're uncertain of that, think back in your mind's ear to how they sounded. A carb backfire is more of a popping sound (sometime pretty loud, to be sure). On the other hand, tailpipe backfires are typically more of the BANG! variety and can even sound like gunfire, an attribute I wouldn't associate with one emanating from a carburetor. Good luck! Let us know what you find.

-

Here's my contraption. A factory steel cap, drilled and threaded. I figured I might as well use an old valve left over from some long-ago vehicle. This, combined with a vacuum bleeder and a lift makes short work of brake bleeding. edit: the rubber line in the background is part of the lift, not the bleeding system,

-

Yes, bias ply tires are less expensive. I bought a set of Cokers last fall, shipped to my home for just over $700 shipped to my door, including tax. Understand though, I don't drive the long distances you mention. If I did, I'd have spent the other few hundred dollars on radials. _

-

^^^ I have to connect the power and ground leads to my battery charger, as my timing light won't function on six volts. _

-

Given the low cost I went with one of their coils. _

-

Definitely call versus trusting their online catalog. Here's the one that worked for my 6V positive ground '49 (same part no. PLODGE referenced above): https://www.amazon.com/gp/product/B001CMX3QS/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 Works perfectly and installation is a simple affair. _

-

<iframe width="560" height="315" src="https://www.youtube.com/embed/rLNeA2yp80k" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe> One of my friends did something like this when resto-modding his '57 Nomad. Simple enough and fairly inexpensive, particularly given that he recouped much of the cost by selling the hoists after completion. https://www.youtube.com/watch?v=rLNeA2yp80k

-

Okay, I'll go first and admit that from just that one image I probably wouldn't have even identified it as a jack, much less identify a particular model/use/nomenclature. _

-

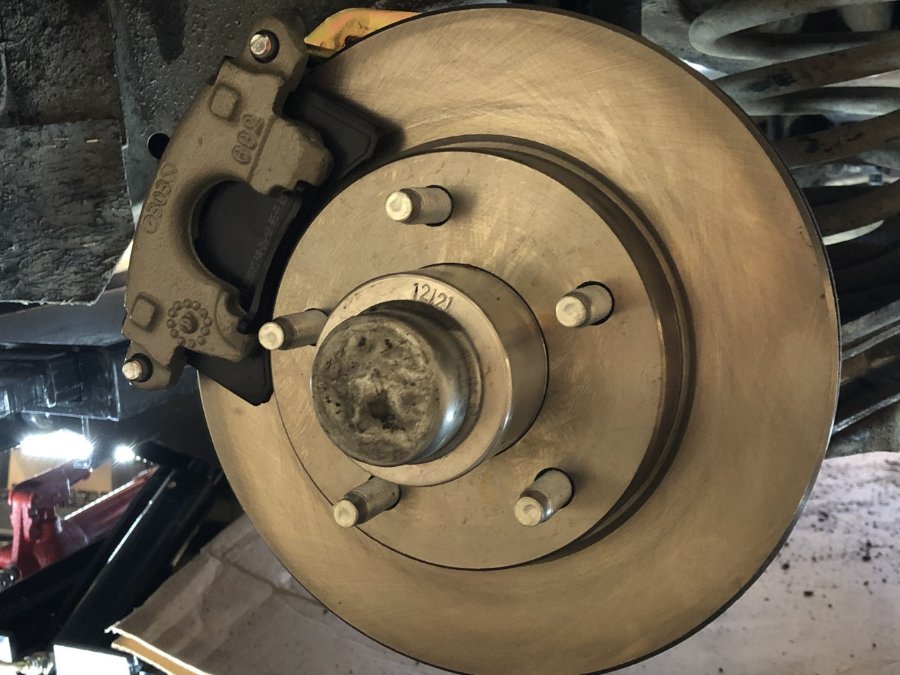

Will these front discs fit my 52 suburban? :)

Hamilton replied to Bigscooter's topic in P15-D24 Forum

If it's a Scarebird their name will be stamped on the adapter plate that's bolted to the hub. _ -

Is automotive paint all water based now in California?

Hamilton replied to MarcDeSoto's topic in P15-D24 Forum

If you get busted for exceeding the one quart per day/eight gallons per year threshold just claim than any excess is actually a peaceful protest. If they don't believe you, keep breaking things and lighting fires until they do. _ -

It seems strange that they wouldn't address this. Heck, rather than shipping the incorrect caps they'd be better off shipping no caps at all and advising people to adapt their stock ones. Even stranger is that the rest of the kit appears to be well thought out, well manufactured and of high quality. _

-

Resurrecting an old thread, as I just received a Scarebird kit for my `49 Club Coupe, a kit which still includes dust caps that don't work in this application. As noted by Doug&Deb above, the original caps can be made to fit just fine with a bit of work. Not sure how D&D went about it, but here's what I did. Several of my larger sockets are slightly tapered at the end where they connect to the ratchet, (somewhat) gradually flaring out to their full diameter. For me, the 36mm socket was just the ticket. Using the socket as a swadge, situate the cap over its tapered end, apply heat until the metal becomes pliable (an orangish/red glow is a pretty good indicator) and tighten the vice. Takes about five minutes per cap.

-

Your point on the parts all being Mopar is fair. But your follow-up post above, listing all the parts one would need to source belies your earlier one, wherein you referred to it as "an easier solution", as, in IMHO anyway, a quality disc brake conversion is a far simpler, and likely more effective solution. Remove the tire, dust cover, drum, springs and backing plate to expose the spindle. Bolt on the adapter plate, slide the hub assembly into place, slip the rotor over the lug studs, use two bolts to secure the caliper and pads, install the new, longer brake line and dust cap and re-mount the tire. Rinse and repeat for the other side. Remove the residual pressure valve from the M/C, bleed your new brakes and take `er out for a test drive. All Mopar? Nope, but it's also not so many parts that a note in the glove box (or in a receipts notebook or spreadsheet) won't suffice. And while the guy down the street is still cleaning and/or refurbishing those 70+ year old Chrysler parts (never mind installing them then fighting, unless he happens to have the special tools, for proper adjustment) you're wheeling your old friend down the road - probably for a good spell before the other guy is even close to being ready. Believe it or not I'm a fan of originality. But when it comes to installing safety items on a car that is driven regularly (seat belts, turn signals and, yes, disc brakes) I'm one who will look the other way. _

-

Yes, just a few bolts. _

-

No need to pull the engine. Remove the drive shaft, disconnect the various linkages and the speedometer cable, remove the four bolts securing the gearbox and pull it out. What you refer to as the lower bell housing is, if it's anything like my '49 Plymouth, really just an inspection cover, easily removed by unscrewing a few bolts. With the gearbox out of the way and the inspection cover removed, you can now access the pressure plate bolts. Best to break one or two loose without actually removing them, rotate the engine (tugging on the flywheel should do the trick) to reveal the next couple of bolts, loosen these, then repeat until you've made your way all the way around. Now make another rotation to remove the bolts you broke loose on the first go-round. Carefully lower the pressure plate to access the clutch disc. Done ... well, sort of done. You still have to re-install. edit: before removing the clutch, do some investigation into proper adjustment procedures. Otherwise you might go through all the trouble to pull everything apart only to find you're facing the same issues after putting it all back together. Lots of info here on clutch adjustment.

-

Of the 84 vehicles I've owned, six have been Mopars (eight if you count an original-style Caravan and a new Ram P/U). They were/are, in order: 1) 1949 Plymouth Suburban 2) 1964 Plymouth Fury 383 4spd 3) 1971 Plymouth Duster 340 Wedge 4spd 4) 1977 Dodge Mirada 5) 1949 Plymouth Special Deluxe Club Coupe 6) 1949 Dodge Meadowbrook Of these, I still have only the Club Coupe, having purchased it from the original owner in 1989 and presenting it to my father as a gift. We had a 49 Plymouth four door when I was a kid (imagine cramming two parents and six kids into one in the middle of summer and driving from Portland to Los Angeles and back). Even after that bit of folly, the old man had a soft spot for the `49 Plymouth. One day as I was driving home from work I spotted this one for sale on the side of the road. I pulled over and gave the owner a deposit on the spot, then gave it to my dad. It had 32K miles on it then, and sits at just over 39K today. Unfortunately, it became mine again after my dad passed in 2012. So, although owning 84 cars and trucks is pretty solid evidence that I have a tendency to not keep them, this one never leaves the family, at least not while I'm alive ...