dalewalt

Members-

Posts

17 -

Joined

-

Last visited

Reputation

1 NeutralProfile Information

-

Gender

Male

-

Location

Murrysville, PA

-

Interests

motorcycles, boats

-

My Project Cars

1940 Plymouth P9 Deluxe

Contact Methods

-

Biography

Just beginning to restore 1940 Plymouth Deluxe

-

Occupation

Software QA

Converted

-

Location

Pittsburgh, PA

-

Interests

General Aviation

Recent Profile Visitors

346 profile views

-

Thanks Sniper. I put a watch on this... if I can't use one from my other engine, maybe I'll look into this one.

-

I do think the broken off piece is still in one piece (I'll have to look to see if I can find it). Kinda nervous about re-using the cap though. I don't think that I had it swapped (the oil line fitting is on one side, and points to the oil line holes in the block), but it's always possible.

-

Squirebill/Dartgame, yes, the cylinders were rusted and seized. This was a car my dad had rebuilt back in the '80's. He passed away in the early 90's, and the car sat for the next twenty five years, first in my mom's garage, then in my brother's garage. Nobody ever properly stored it. So I took it on as a project two years ago, I tried the usual... dumping stuff in the cylinders, etc. Nothing worked. I decided to completely tear it down and rebuild it. (It was hell just getting the pistons out of the cylinders). The oil was nothing but sludge. (Ah, fun times trying to clean it). Bought new camshaft, pistons, valves, guides, gears, etc. And here's where I'm at. (I haven't had a whole lot of time over the past two years, so it's a slow process). The good news... I have another engine that I had bought a few years ago. This one also is seized, but I'm thinking of popping the oil pan off and taking a look at the caps... maybe I can reuse one (I'm going to try to get to that this weekend). If so, I'll find a machine shop that can align bore the block. Dodgeb4ya, that'd be an idea, except since my dad rebuilt the car w/a 201, I'd like to keep it that way. (Sentimental reasons).

-

Should have been "the one cracked has the oil line connection". It may have cracked when I removed it... I had tapped it (all of them) with a dead blow hammer. No, the engine wasn't running; it was completely frozen. (I had tried all of the usual... hydraulic fluid, diesel, etc in the cylinders). Thanks for the info on the replacement caps

-

There wasn't any issue with identifying which caps go where... Each of them only fits in one place. And the one that cracked has three oil line connection

-

-

Dartgame, yes, it's the 201. (I verified w/the number on the side of the block)

-

I *think* it is... how would I tell for sure?

-

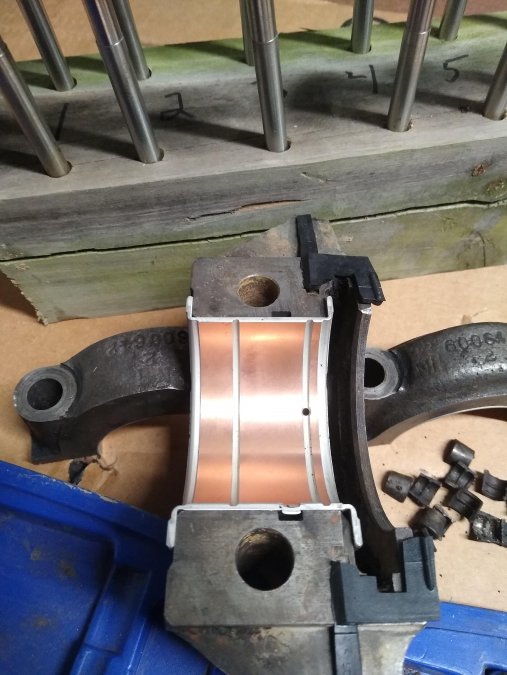

Ugh, sorry about that. It shows the base of the bearing cap with a chunk missing

-

Well, a bit more info. I checked the positioning of the caps as suggested, they're in the correct position. (Honestly, I don't think they could be out of position... I have four caps... they're all slightly different widths). So then I loosened each cap in turn and discovered that the cap with the oil tubes is the problem. When I pulled the cap off; I found a crack in the base of the cap. I put pliers on it and pulled away part of the cap: I think what was happening was that. since the base was cracked... when I torqued it, it was tightening down too much. So, I think I need a new bearing cap (this is the one w/the oil line attached). Does anybody know where I can find one? Does either Kanter or Andy Bernbaum carry them? Thank you much to everybody for all of your help (and thanks squirebill for the heads up on the checklist... that'll be very helpful)

-

Hi all, I've started rebuilding my engine for my '40 Plymouth P10. I tore the engine down (following a thread I found in this forum) and cleaned/degreased everything. I'm reusing the old crankshaft, but bought a new camshaft/pistons/rods/bearings/valves/etc. The steps I originally took was: Install old crankshaft w/new bearings (standard size) install new pistons/rods/bearings I then found I couldn't turn the crankshaft, even with a breaker bar on the end of the crank. Oops... better check bearing clearances. I disassembled everything and measured crank bearing clearance (.002, as expected). But when I reinstalled the crank and torqued to 75 ft.lbs., I find that I can only turn the crank if I put a breaker bar on the end. Is this how it should be? Or should I be able to turn just by grabbing the timing gear. (I haven't yet installed flywheel/timing/pistons/etc) Once I install the pistons, I'll check the bearing clearance on the rods. But once rods/timing/etc is installed, should I still be able to turn the crank w/a breaker? Thanks for any help/advice. Dale

-

-

H Suhling, I have the same type of seal (rubber). Along with the two seal halves, I have two h-shaped pieces (like in the first picture below). Can you tell me what they're used for/where they go? (my engine is in the second picture) Thanks

-

Question on this topic... I have an oil seal like is posted by Tom'sB2B above (2 small h-shaped gaskets and two metal retainers). How are the h-shaped gaskets installed? I've been looking through the 1940 shop manual I have for this and, for the life of me, cannot figure out how it's supposed to be installed. Are the retainers and the two h-shaped gaskets the entirety of the rear main oil seal?

-