-

Posts

9,400 -

Joined

-

Last visited

-

Days Won

87

Everything posted by Merle Coggins

-

Two batteries in Series = Add up the voltages - Amperage doesn't multiply Two batteries in Parallel = Add up the Amperage - Voltage doesn't multiply

-

Tom, I don't own that car. It's just something I saw at the car show. The story is from the current car owner.

-

How ‘bout that… I just made it in the picture. The club that hosted the car show posted this picture on their Facebook page. I just barely made it in. (Lower left corner) The afore mentioned ‘40 Dodge truck is front row to the right of center. And the Harding car shown above is in the 3rd row behind the ‘40 Dodge truck. There were more vehicles down to the left but I guess their fish-eye lens wouldn’t go that wide.

-

First Foray - Just Purchased 1953 Dodge B3B

Merle Coggins replied to Oliver's topic in Mopar Flathead Truck Forum

Yes, I believe the SEM paint is what Quiet Ride Solutions recommended. But I recall that I used a Krylon paint for plastics and it has held up well. -

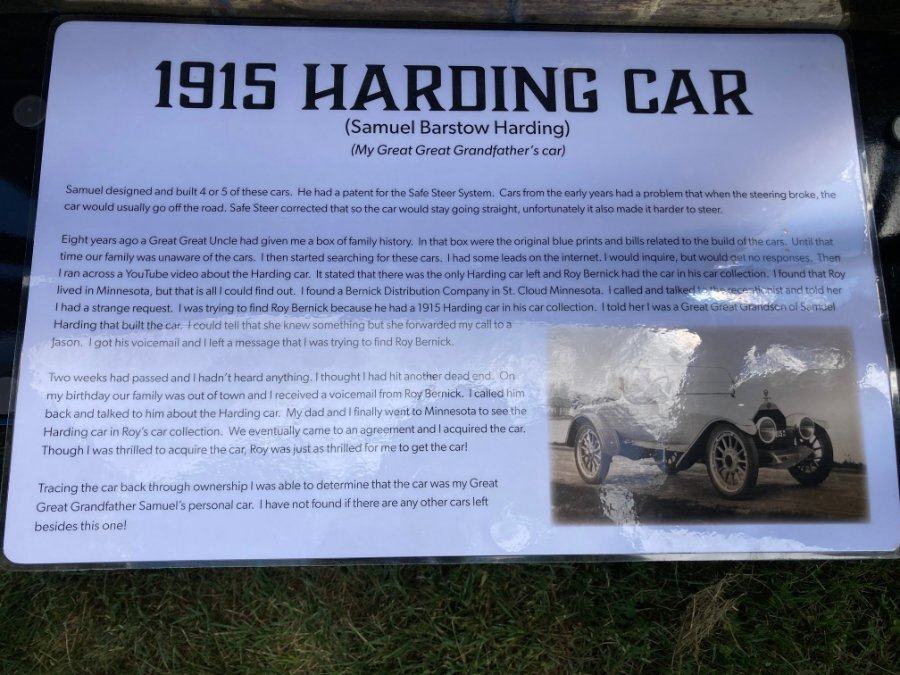

Yesterday I attended a local car show. It was a beautiful day with a couple hundred vehicles present. I had one of 2 classic Dodge trucks. The other was a very nice 1940 (didn't get a picture) Anyway, one of the most interesting vehicles there (to me anyway) was a 1915 Harding. I had never heard of it, but it had an interesting story that I thought I'd share. I took a photo of the story board but it was hard to get a good pic without sun glare. I'll transpose it here for easier reading; 1915 Harding Car (Samuel Barstow Harding) (My Great Great Grandfather's car) Samuel designed and built 4 or 5 of these cars. He had a patent for the Safe Steer System. Cars from the early years had a problem that when the steering broke, the car would usually go off the road. Safe Steer corrected that so the car would stay going straight, unfortunately it also made it harder to steer. Eight years ago a Great Great Uncle had given me a box of family history. In that box were the original blue prints and bills related to the build of the cars. Until that time our family was unaware of the cars. I then started searching for these cars. I had some leads on the internet. I would inquire, but would get no responses. Then I ran across a YouTube video about the Harding car. I found a Bernick Distribution Company in St. Cloud Minnesota. I called and talked to the receptionists and told her I had a strange request. I was trying to find Roy Bernick because he had a 1915 Harding car in his car collection. I told her I was the Great Great Grandson of Samuel Harding that built the car. I could tell that she knew something but she forwarded my call to a Jason. I got his voicemail and left a message that I was trying to find Roy Bernick. Two weeks had passed and I hadn't heard anything. I thought I had hit another dead end. On my birthday our family was out of town and I received a voicemail from Roy Bernick. I called him back and talked to him about the Harding car. My dad and I finally went to Minnesota to see the Harding car in Roy's car collection. We eventually came to an agreement and I acquired the car. Though I was thrilled to acquire the car, Roy was as thrilled for me to get the car! Tracing the car back through ownership I was able to determine that the car was my Great Great Grandfather Samuel's personal car. I have not found if there are any other cars left besides this one.

-

As 9 foot box said, the cable routes down the inside of the firewall and exits through a notch in the toe boards, then down alongside the trans to the speedo drive at the tail.

-

I saw a PIlot-House with a slant 6 several years ago. There was a guy on this forum for a short time back then. He was in northern IL, about an hour and a half drive from me, so I drove down and met him and checked out his truck. I don’t remember the details of it, but it fit. I believe the last time I talked to him he had sold the truck.

-

How to connect fuel pump to carburetor on 48 DeSoto?

Merle Coggins replied to MarcDeSoto's topic in P15-D24 Forum

A tubing cutter will give you a cleaner, straighter, cut without debris. -

Camshaft Bearing clearances? More than manual?

Merle Coggins replied to Bryan's topic in P15-D24 Forum

How did you measure the clearance? If you measured the journals with a mic, and the same with the insides if the bearings, keep in mind that the bearings will compress slightly once installed. It would be more accurate to mic the bearings after installation, then calculate your clearance. -

The compression in the cylinders is what gives you engine breaking when you lift off the throttle pedal. You also get some engine breaking with a FD unit. It’s all spinning at relatively the same speed when you are motoring down the road. When you let off the throttle, to coast, the momentum from the car now drives the clutch through the transmission. This now makes the turbine impeller force oil against the input impeller which tries to spin the engine. So you still get similar engine breaking as you would in a conventional clutch/trans. vehicle. At lower speeds, and engine RPM, this effect is much lower. Another factor that comes in to play with FD equipped vehicles is that the FD unit itself makes for a much heavier flywheel on the engine than a conventional flywheel/clutch setup. This makes the engine RPM’s drop more slowly when you let off the throttle.

-

If you have a hose connected between the heater connection at the back of the head and the return connection at the water pump then you have created a radiator bypass as well. Coolant can now circulate from the head back into the water pump to circulate through the engine again without being cooled by the radiator. This can cause your engine to run hotter than it should. It’s best to block off the connections of not using a heater.

-

As they showed above, and as you already surmised, the Fluid Drive attaches to the crankshaft and rotates with the engine. Inside there are a pair of impellers. One is connected to the FD housing and spins with the crankshaft. The other, the turbine, is connected to the output, which is the clutch plate. This acts like a flywheel on a conventional engine and the clutch attaches to it. As the rotating speed increases the input impeller drives more oil against the turbine impeller to increase the output torque to the clutch plate. The clutch will then drive the input shaft of the transmission which will in turn supply the power through the selected set of gears to the transmission output shaft to drive the driveshaft, supplying power to the differential.

-

Letter designations on headlight switch?

Merle Coggins replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

According to the wire diagram for my B-Series truck, B is the Battery connection, which is where the circuit breaker connects. H goes to the Headlights. A goes to the front parking lights. R goes to the tail light(Rear?). And D goes to the instruments (Dash) lights. -

I believe he was referring to the grill bars.

-

Ok....I blame this one on 48Dodger

Merle Coggins replied to bkahler's topic in Mopar Flathead Truck Forum

By B2C has the extra hole in the clevis for the spring, along with a hole in the cross member for the other end of the spring. Maybe the later models put an extra hole into the arm for the spring instead of making that asymmetric clevis. Someone with a B3 or B4 model may be able to offer a picture of their setup for confirmation. Not the greatest pictures, but you can see how I improvised the spring connections for a spring I had available. It works fine. -

52 doors and hood disassembly

Merle Coggins replied to BulldogTom's topic in Mopar Flathead Truck Forum

Half the battle is knowing where to find the information you need. I stress this to my Tech's all the time when I'm doing training. -

New Member - 1948 Dodge B1B

Merle Coggins replied to Bob Mawyer's topic in Mopar Flathead Truck Forum

I happen to agree with Tim on this one... ? -

52 doors and hood disassembly

Merle Coggins replied to BulldogTom's topic in Mopar Flathead Truck Forum

Sometimes the information is in a different chapter than you'd think. For example, the fuel gauge information is in the Fuel System chapter, even though it is an electric component that you may think would be in the Electrical System chapter. -

Nice find... I don't know why they used different model designations for the Canadian built Dodge trucks, but your DG1 is comparable to the US built B3B except that it would have the longer 25" engine vs the 23" engines we got down here. Don't write off that engine yet. It may be salvageable. It may be seized up now, but unless the internals are total rust, or the block is cracked, it's possible to revive it.

-

52 doors and hood disassembly

Merle Coggins replied to BulldogTom's topic in Mopar Flathead Truck Forum

Hi Brad, I have a factory B2 Shop Manual (pictured below). I also have a digital (PDF) copy of a similar manual, maybe even the same version. I don't recall where I got the digital version. The image quality isn't very good but I can access it from my work computer so I can look up things when I'm surfing the forum during free moments at work. If you'd like a PDF copy of what I have I have uploaded it to WeTransfer to share. You can download it from this link. https://we.tl/t-ijcKHuMEZ9 The link will be valid for 7 days only. -

I suspect the "112" should be "T12" if the "T" stamp wasn't held straight and the top didn't stamp correctly.

-

First Foray - Just Purchased 1953 Dodge B3B

Merle Coggins replied to Oliver's topic in Mopar Flathead Truck Forum

Often times during extended parking the wheel cylinder cup seals will relax and begin to seep fluid. You can usually spot trails on the insides of the tires where it drips and runs down. You may be able to fill up the master cylinder and bleed the brakes and all will be good again, for a while. It's best to do a thorough inspection of the brake system for signs of leakage. -

Oil passages to main bearings - different diameters

Merle Coggins replied to Bryan's topic in P15-D24 Forum

Why do you want to drill it out? Did it not do a satisfactory job of oiling? Was there evidence of lack of lubrication? I'm sure they had a reason for using the bore sizes that they used. Don't try to reinvent the wheel here.