-

Posts

9,999 -

Joined

-

Last visited

-

Days Won

180

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

I had that 2bbl carb and throttle guard on my 1946 NewYorker 3 passenger coupe. My 1948 T&C does not as it's the Carter 1 bbl.

-

Domiest....you got that 2bbl carb for a great price! On the 2bbl engines there is a "throttle gaurd" vacuum chamber the attaches to that horizontal bracket on the carburetor including a vacuum supply tube. It's purpose is to prevent stalling when coming to a sudden stop. The Carter 1 bbl carb set up does not use it.

-

1946-48 Chrysler shoud be the same.

-

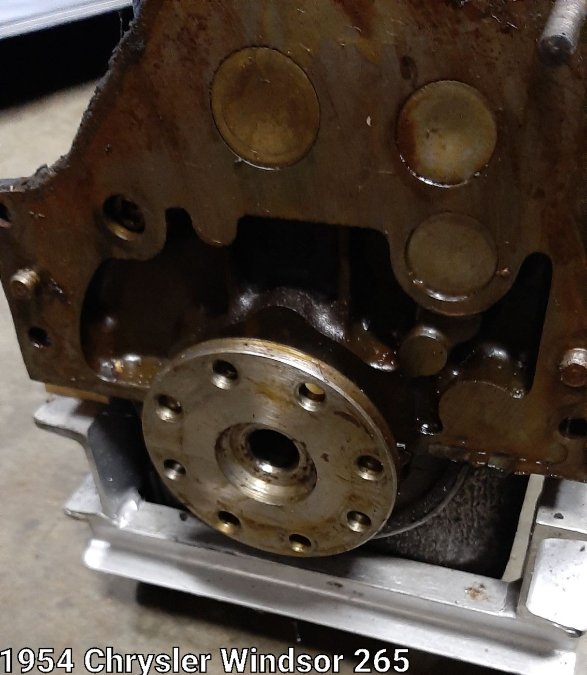

I'd put the factory Plymouth crank studs back in too....four six or eight depending on which bolt hole flywheel you use. Have to remove the pan and main cap to do so. NEVER MIND! Had to go out and look at a 265 in the shop. No ridge on the backside of the crank flange to prevent the Plymouth half moon crank bolts from spinning. This goes for all FD and torque converter crankshafts.

-

1947 Dodge 2 ton 2 speed rear end

Dodgeb4ya replied to Built in America's topic in Mopar Flathead Truck Forum

You should be able to block that speedo vacuum line off. There cannot be any vacuum leaks in the shift plumbing. The rear axle diaphram has to be good and receive full vacuum to move the axle shifting arm. The Eaton 1350 2 speed axles are a very trouble free axle. Never park the truck with the axle in high range......or you might find it has rolled away.- 20 replies

-

- 1

-

-

- shifting

- vacuum diaphragm

- (and 4 more)

-

3M strip caulk.....makes it easy to pull plastic barrier on and off later if necessary. Clean looking,fast and easy to install.

-

All of the D24's with FD did use a dashpot.

-

I learn new things here...thanks Marc!

-

What did you do to replace that broken shoe retainer clip? Good you got it all back together... Parts on these large trucks are really tough to find. But once it's all fixed right they will run and run trouble free.

-

I've only seen D24 cars with the Stromberg carb. D6H2 Carters are used on 1949-53 Pymouths....not on the larger engine DeSoto.

-

Originally a new 251 crankshaft was shipped in a very heavy duty wood box. 12" X 12" X 36".... I bought six of them years ago.

-

Looked and looked.... All I can find is this wheel cylinder Cover. OAL is 4-1/4". Bolt center to center is 2-1/8". Hole is 1-3/4" Width is 2-1/2" PM if more info wanted..

-

If you have a eight cylinder Saratoga Chrysler you have undersize drums...by one inch!? Saratoga's use 12" drums.

-

You need to learn the major adjustment procedure.... Search here...on the forum.

-

Too thick of linings is a very common occurance. The correct maximun lining thickness is listed in the factory shop manual. Brake re-liners don't seem to know the correct thickness required sometimes.

-

Pin use/length depends on piston design. Several different piston designs and heights. Use the ones that let the shoes retract enough to get the drums on. The shorter pins/pushrods are generally a safe bet unless the drums are .030" to .060" OS.?

-

The real problem with newly installed Lockheed brakes is people don't drive the vehicle enough to wear them in to conform to the drums 100%. If this is done like back in the day and a couple minor needed adjustments you ended up with high rock hard safe feeling brakes. You will never have a high hard pedal if the linings don't hit the drums 100% . The tools...the ammco 1750, Miller mt19 are the best and most accurate to center the shoes to the drums....but available to few. Other home made tooling helps. BUT....if new shoe linings when test set into the drums don't accurately fit tight to the drum surface the shoes need to be arc'ed for for fast lining wear in. This will make for faster and easy shoe adjustments on each drum using tools on a major adjustments. Get the shoes/linings arc'ed, or try to sand them to fit each drum before installing.... First make sure the brake shoe linings match/conform to the drum surface 100%.... If you don't fit check the shoes... adjust the shoes as lbest you can. Keep driving and wearing in the shoes..minor adjust the shoes up as the pedal drops. 1500 -2000 miles later....wonderul Lockheed brakes. That's the way it was back then. Today doing any brake job on most any car produces perfect powerful stopping brakes... We are so used to that now days. Ain't the way it works on old Lockheed MoPars unless you have good professional tooling and lots of experience with them. I use an awl for R&R of most typical brake springs... other wise hook tools and bendix sping tools.

-

Factory double flare is used as OE on the fuel line.

-

Is your factory floor pan heat shield intalled above the muffler?

-

Supplied with factory radio ....for noise supression. I posted a pic of a nos one a few years back and now again... 1946-48 upper line Chryslers usually always have then installed on the back of the fuel gauge.

-

Not much service to do on your M-5 "Hydraulically Operated" transmission. Just maybe drain and refill it with 10W oil. First off make sure the trans is full of 10W oil. Fill plug is half way up on the passenger side of the transmission. Not enough fluid...the trans will kick ot of the higher gear. May as well check that the fluid drive coupling is full too. You should read the shop manual on that or someone else can pipe in on that. If it's low it will not affect upshifts...it will cause engine speed flare-up and lathargic acceleration. A damaged or bare transmission circuit wire could cause this issue as well as the delicate governor silver points that get contaminated with trans oil weeping into the governor. Reading the factory shop manual is a must for working on your 47 Chrysler. The factory shop manual has it all on the 1946-48 Chrysler M-5 trans. The 1949-53 M-6 newer Chrysler transmission is different electrically. Mymopar.com has factory service films to assist on servicing the old mopars.

-

Most everything made now for the old cars is Chinese...and none of it is of very good quality. These chinese parts are mostly made to help parts venders and the importers make a very nice profit. The end user ends up with low quality parts.

-

He's still around...still selling 1941-54 Plymouth and more parts parts for nearly 50 years. He's on ebay as "seaplym"

-

Differential pinion seal replacement

Dodgeb4ya replied to Jack's 47's topic in Mopar Flathead Truck Forum

As for the 11 hole carrier gasket if you want one... All MoPar six cylinder cars except wagons and long WB cars use the same gasket. 1/2 pickup' with 11 bolt the same. If it's a 10 bolt carrier it's the same as the 1941-50 Chrysler eight cars. Either one ...Olson's Gaskets here in Port Orchard Washington will have the correct one. Count the bolt holes for the correct gasket.