-

Posts

9,999 -

Joined

-

Last visited

-

Days Won

180

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

Motor mount/insulator questions for a 1947 Dodge D25C

Dodgeb4ya replied to RonJ's topic in P15-D24 Forum

Done that many times....see easy!? -

Yep....very likely a small thin piece of gasket material left on the block. I use carb/brake cleaner and spray it on the surface that I think is 100% cleaned. If any gasket material is still there it will show up as a dark almost black spot. Also use thread sealer on the three bolts....tighten firmly.

-

Motor mount/insulator questions for a 1947 Dodge D25C

Dodgeb4ya replied to RonJ's topic in P15-D24 Forum

-

Motor mount/insulator questions for a 1947 Dodge D25C

Dodgeb4ya replied to RonJ's topic in P15-D24 Forum

You can wedge the bottom of the front support mount closer to the timing cover....giving more clearance for the crank pulley and belt. I have had to do this many times on engine R&R jobs. The weight of the engine on that front mount support tends to skid the two front mounting pads towards the front of the car. Very slightly taking the weight of the engine off the support makes it easier to adjust it rearward if necessary. Of course do all this after the rear mounts are replaced properly. -

Motor mount/insulator questions for a 1947 Dodge D25C

Dodgeb4ya replied to RonJ's topic in P15-D24 Forum

Dave...is that cast damper a canadian only part? Never ever seen one of that shape and type.. -

Here's what I use for my cats... Yeah...They didn't like them the first couple times I jammed them in...

- 695 replies

-

- 1

-

-

The 52 Dodge has 2 speed electric wipers...no vacuum wipers. I'd stay with the 52 Dodge pump...this pump will also let you use the factory heat shield.

-

Was Puma wearing hearing protection at all times watching this build project? Evidently not!

- 695 replies

-

How to find Top Dead Center on Mopar flathead after a rebuild?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Correct....^^^^^ -

Motor mount/insulator questions for a 1947 Dodge D25C

Dodgeb4ya replied to RonJ's topic in P15-D24 Forum

I have never seen a front pulley like that...looks cast? Maybe Canadian thing..IDK Also that front engine support has been out...also not bolted in with the factory "U" bolts and 5/8" nuts. Generally about a 1/4"+ of belt clearance to the support plate is pretty common. Cannot even come close to answer whats the right on re-pop mounts for your Dodge... Todays after market mounts are sold as "They should fit and work" is about all your going to get these days. The hardness of the rubber is critical for vibration free operstion. Old NOS rubber can become very hard and not useable. -

That's awesome the previous owner followed thru and gave you all the paper work original to your fire truck!

-

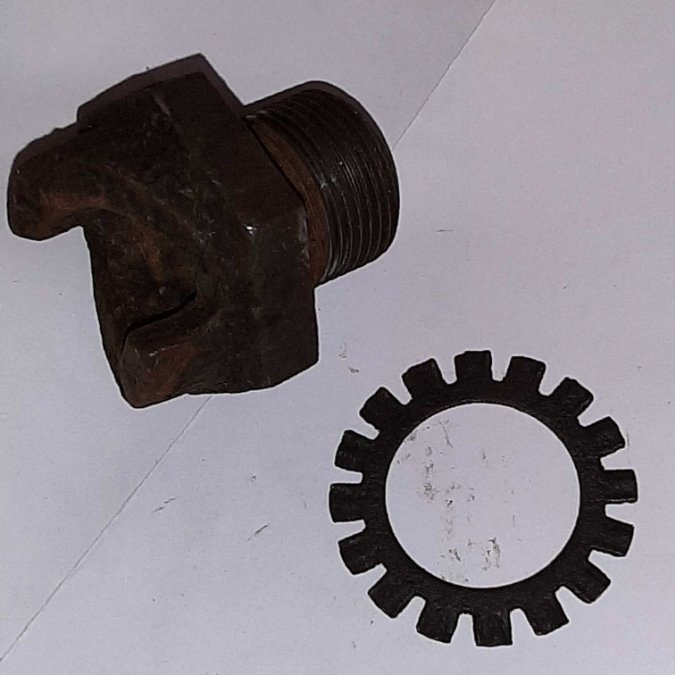

Yes the spring is out of the "R" series truck axle... one all by itself.. Spring length .810" Diameter .843 Wire diameter .180" Shoe Lever retangular hole .835" X 1.737" Shoe hole/lever cutout for spring specs in picture...

-

1930 MODEL A PICKUP TRUCK

Dodgeb4ya replied to jameshanks's topic in Ebay, Craigslist and External Site Referrals

Wish it was a Plymouth truck... -

Hopefully his pricing will not be crazy $$$. If you wentbthe coil spring setup ...The retainer for the coil spring set up could be pretty easy to make...nothing much to it. The spring is fairly strong and of thivk wire. I would think not too hard to come by. That spring is a pretty tight sqeeze with big channel locks to install. I vould see the spring clip could be a better design to install....though subject to failure if over sqeezed or judt pitting and breaking.

-

The black carbon seal is hard and brittle... The bellows portion is copper and the folds can crack...

-

There are no rubber seals in the FD coupling.. There is a hard graphite seal ring and a flexible copper and steel bellows seal assembly. The bellows seal assembly steel wear ring pushes down against the graphite seal forcing it against the inner FD sealing ring surface. These parts last almost forever. But leakage can occur from... ***Cracked or pitted bellows seal ***Cracked broken or pitted graphite seal ring ***Pitted or damaged inner FD sealing ring surface... ***Worn out/loose FD front ball bearing ***Worn/ loose inner and outer input shaft bushings. Typically a worn or pitted graphite seal ring and new bellows will fix any leakage as long as the front bearing and both pilot bushings are not worn. IMO replacing the front bearing cannot be done and keep the FD coupling in balance and not cause vibration in the car. The original service tooling to remove said front bearing out the front of the coupling is long gone and now they cut the FD open to replace the bearing...then weld it up out of balance.? Also the FD inner seal ring surface can be pitted and then needs to be micro finish ground as was originally done... Not going to happen with out cutting the coupling open. Once the bellows and grahite ring are out you can examine that surface to see if it's damaged. As said usually a graphite ring and bellows will stop the leakage if the other mentioned items are good. Some pics of said FD pieces...

-

I did take apart the H300 rear brakes today off one of my 2-3/4 ton Timken axles. This shows the coil spring and some retainer plate and how it holds the shoe to the dual sided lever assembly. Could you use the same spring and retainer on your larger shoe and lever?

-

If your truck has the original 265 engine the serial number will start out TX318-xxxx You are a busy guy!

-

I would say no to welding the shoe to the lever. I wish I could see your parts and issue in person. If the square holes? the broken spring clip fits into is the same size shape as in the earlier 1952 and back B2/3 T trucks...those trucks that use the retainer and stiff short coil spring, Maybe you could use a heavy duty stiff coil spring like found in the end of a drag link and fab up the retainer.

-

Welcome aboard! Not too many here with the bigger tonnage trucks. There's a lot of knowledge here to help you if needed too. You have made quick progress so farin a short time. Do you have the 265 twin carb/exhaust engine? That was started in the 1953 2-1/2 ton "K" series trucks.

-

1942 Ford Wrecker Truck

Dodgeb4ya replied to jameshanks's topic in Ebay, Craigslist and External Site Referrals

I'm looking for a Dodge.... -

I have never seen a factory flathead oil pump with a drilled oiling hole. I just looked at a bunch of cores too...none have an oiling hole. Odd to see one...not sure to any advantage unless roundy round racing.?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

Oh oh....I see a oiling hole!?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

MoPar # 1316733 is the solenoid part #. I'd skip MoPar Mall.