-

Posts

471 -

Joined

-

Last visited

-

Days Won

5

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by sidevalvepete

-

Good advice here. Thanks for posting. Helpful to anyone and encouraging for those dipping their toes into a job like this for the first time. ?

-

No washers needed in my 38 D9 Dodge which is the same as the Plymouth chassis. However, if yours fits better with added washers then I would do it. Stops sideways movement...

-

Some pics of the numbers you have quoted would be helpful. Especially the block number. Stamped on the boss at top of block above where generator is mounted. Your "serial number" is foreign to me...

-

I'm sorry Steve, memory isn't that good to remember difference that your examples show. I don't have photos of mine either. Will check with a couple of others with late 30s mopars to see if any information there. Perhaps others can help here, even just check the numbers on the case of their 3 speed transmissions.

-

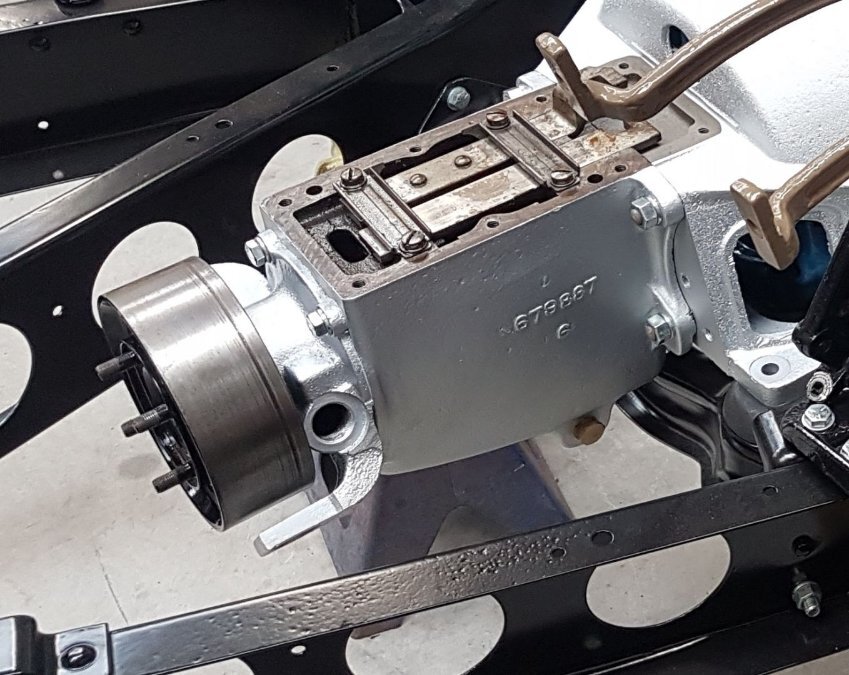

This is a pic of my transmission. Is from a 1938 D9 Dodge. Detroit made but the D9 was based on the Plymouth 201cu of that year. Numbers on the case very similar to yours. Am not sure of the significance of that, maybe all basic 3 speeds were the same around this time. Mine is original to the car.

-

Well Jim, your rotisserie and mig I see are courtesy of having generous, like minded mates and from reading your thread you have years of learnt skills from fellow enthusiasts and night school. Getting this big old girl back to former glory takes commitment, time and all of your learnt skills. I commend you and think your posts will be a great help to others contemplating or doing their own rebuilds. Look forward to seeing more...?

-

Nice to see the progress Jim. It's a big job but when you get past this part with the main body you will have a real solid, rust free base to fit up all the doors, guards etc to. It is a big car the seven passenger model, well worth preserving.

-

Know a lot less than a fair chunk of you guys but would hazard an educated guess here...my '38 Dodge was built in the US. This is confirmed by the 1938 Shop Manual version that covers the Export models that has the chassis numbers listed. There are probably Export versions of the Shop Manuals that correspond to this vehicle that would contain said chassis numbers. Agree with Andy that it is an Export model but not sure whether the US or Canadian version. Those engine and chassis numbers will tell the story in an Export Shop Manual, as well as the block length - 23" for US, 25" for Canada. Look for the right manual, they are invaluable.

-

This may or may not work for you Keith... https://www.ebay.com/itm/115212617682?hash=item1ad33507d2:g:wgQAAOSwig1h61i2

-

Glad to see you back on the road after this project. Your attention to detail should give you an enduring result although in this game there's always another curly one around the corner. Have found much of the pleasure is in doing the project and overcoming the problems on the way through...as long as it gets to success at the end of course! Well done ??

-

Take the belt you have to a good parts shop or probably even an engineering supplier and they can measure/compare your belt and give you the next size or two down.

-

Keith.... maybe, as the mopar tech suggests, is your temp gauge reading correctly?

-

Looks like a really good project to do. Seems a well preserved car to start with. Look forward to seeing your progress. I always enjoy learning about the story of these projects too. It has been looked after for a long time to stay in that condition up until now. Do you know much of it's history?

-

What goes on the left side of the block?

sidevalvepete replied to MarcDeSoto's topic in P15-D24 Forum

Ditto......always.... -

Dodge DR Convertible Coupe comes out of winter hiberation....

sidevalvepete replied to Semmerling's topic in P15-D24 Forum

Thanks. Is awesome to see these family vehicles stay part of the family story.... -

Dodge DR Convertible Coupe comes out of winter hiberation....

sidevalvepete replied to Semmerling's topic in P15-D24 Forum

Yes, it is a beautiful vehicle. Keen to know a bit of it's story.....a lot of care goes into what we see, whether over it's whole life or in a dedicated salvage restoration. Thanks for the pics and welcome to the forum from New Zealand ? -

No, Detroit built for the NZ market. Yes to the D9 being based on the smaller Plymouth wheelbase and body size. Chrysler Corp did lots of things like this to be a global supplier that enabled them to do business into overseas markets and meet the different conditions in those countries. The design of the whole range of WCP vehicles from an early stage allowed this export business to service all the peculiarities of different markets. Some were government tariffs around size of vehicles, encouragement of local assembly industries or bodybuilding, righthand drive traffic systems etc. You will all see some of this engineering in your rides from the sharing of body, engine and chassis parts; symmetrical stamping of the cowl panel and dash design that can accommodate adaptation to right hand drive. They had smart people that quickly turned Chrysler Corp into a giant global player. A great US success story really.......now the world needs this type of creativity and scale to fix what we have inadvertently brought upon ourselves....very quick solutions to our human induced climate problems.....here's hoping.....

-

A bit more progress. Still been slow going but feel like am on the home stretch now. Seatbelts added. Am limited with room so no option with retractables. In NZ to be legal we have to pass compliance certification for modified vehicles. Adding seatbelts is one of these modifications. So it can't be a simple addition of old belts from the scrapyard. Therefore what you see is new belts and approved mountings that meet the cert requirements. Bracing plates in the B pillar, the same added strengthening for the rear mounting points above the rear quarter windows, altering the seat base to allow the front seat clasps to fit in the optimum position to the floor and lastly adding fixing plates for the four floor mounts. A relatively simple safety measure being a bit of an engineering project to get a pass mark... Hood side panel louvres finished and installed. Panels ready for fitting after a few tune ups in engine bay. Battery box cover painted and installed...battery getting a trickle charge in pic. Have wired in this facility to happen when parked up for a while in my garage. Waiting on a grille guard to come back from plater which should be this week. Fit that, then wire up some front indicators which I have chosen to fit in some fog lights. Then back to upholsterer to refit the headliner that was detached to rebuild the dodgey vacuum wipers and seatbelts, fit carpet and trunk lining etc. Then I will be able to take up Keith on his invitation to join his Great 38 Thread of 2022......looking forward to that!!!

-

Have finished the vent louvre task. Reinstalled in the side panels. Ready for final placement when a few final tuning jobs done.

-

Always like your detailed input Loren.?

-

Recommendations solicited: fire extinguisher

sidevalvepete replied to JonathanC's topic in P15-D24 Forum

Important to consider what sort of extinguisher to get and how they perform. For example, dry powder fire extinguishers function by smothering the fire and starving it of oxygen. They work fine but if the powder gets quickly blown away then the fire can rapidly reignite. They work well indoors and with electrical fires, not so well if your fire has oil or petroleum involved. Wet foam fire extinguishers do a better job on clinging to the fire source and keep it out but a bit more messy. Have seen a few examples when the retardant gets sucked into the engine and can quickly start corrosion if not pulled down before that can happen. Still a better bet than having the whole car burnt to a crisp though..... -

Always good to stop and look at any old vehicles. Glad you are on the outside of this one though.....not lying down inside ?

-

More ticked off. Well done. Is obviously satisfying for you as it's your project but also good for me an others in keeping us inspired to plod on with our own.......thanks for the update and pics.....