-

Posts

1,233 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Radarsonwheels

-

Intake and carb(s) decision

Radarsonwheels replied to kencombs's topic in Mopar Flathead Truck Forum

I had a repop weber 32/36 on my 230. It looked good and ran GREAT. The whole multiple carb thing is awesome for a period correct souped up deal. I dunno if anybody was hopping up their work truck though? Especially the dodges back then you would just buy the next bigger model if you needed more power. Whichever way makes you happiest is the way to go for sure. I know I do stuff the hard way sometimes because it’s more fun or there is pride or ego involved in doing or having something nobody else does. Post some pics of whatever you do- I’d love to see! -

After running the motor driving around like normal pull a couple plugs. If it’s not too rich (black) or too lean (white) you should be able to see some color on the electrode strap- the rainbow that is left from heating up steel. You want that heat mark to be centered around the 90° bend in the electrode strap. Farther down toward the threads it is getting too hot, closer to the tip and it’s too cold of a plug. There is probably a pretty wide range of plugs that will work fine without noticing much difference in performance or maintenance intervals. When you get into high compression, forced induction, nitrous, and the like you will start needing a colder plug to avoid preignition or putting too much demand on the ignition trying to spark under more difficult circumstances. You can also run a slightly hotter plug as a bandaid for a rich mixture to delay plug fouling but of course that’s not the right way to fix that. Good luck! radar

-

Checked the rocker shaft bolts under the valve covers this morning- I can hear a little tappy noise sometimes which is probably either the injectors firing or a small exhaust leak but at least now I know the valvetrain isn’t working loose like it did on first fire/break in. Everything looked great in there and all the bolts are still tight. The driver’s valve cover bolts were barely hand tight so it’s good I got them gently torqued into the squish of the cork gaskets again. Louvers are working great- much cooler after a drive almost no heat soak in the engine bay ? I have the driver’s side vent window taped shut- it swings open easily and around 50mph likes to do so by itself. I need to find or make some twist locks or some kind of tab to slip into the stock holes for the latches which are missing.

-

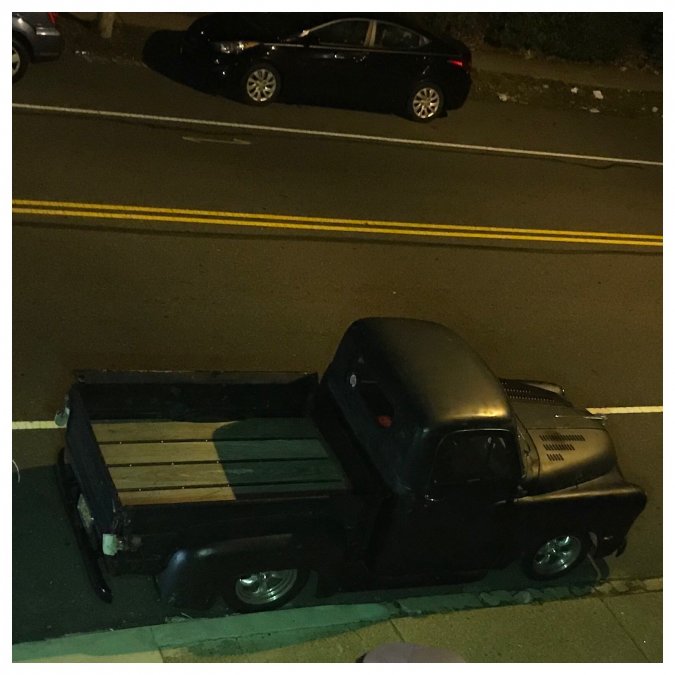

I have 500 miles or so on the truck but never took it out on the highway until tonight. The new DOT drag radial tires are a little bigger than the nitto summer tires I started with so my speedo is a little off- the iphone gps speedo app says I’m somewhere a little over 10% low. So 55ish is actually like 62. I will have to see aboit getting a new speedo cable drive gear to correct that. I took it to drop off a large speaker cabinet at band practice and it did fine. On the way home I pushed it up to 80 a couple times and it was rock solid and even seemed to like it. I was still white knuckling a little- it’s not fully proven reliable yet and it’s too cold to walk home or wait for a tow. Speaking of which I think re-coring the heater and installing a new 12v fan is next on the to-do list. Some heat would be nice and I’d like to hook up hoses to the defrost vents too. Here’s an uncommon angle to see it taken from our rehearsal space.

-

All this talk about brand loyalty and restoration vs modernization and upgraded vs ruined is fun- BUT- Got pics of your progress? I’m curious how they set it all up to fit the chassis underneath with no welding or sawsall!

-

51 B3B build thread - after all these years

Radarsonwheels replied to bkahler's topic in Mopar Flathead Truck Forum

I have had luck with the MSD blaster II coils- the red canister type. They fit right in stock mopar strap brackets -

51 B3B build thread - after all these years

Radarsonwheels replied to bkahler's topic in Mopar Flathead Truck Forum

I used a muscle car era ballast resistor for my blower fan. They are normally installed on the firewall to cut voltage to the coil. Often they have a second circuit to give full voltage for starting. I tried an ebay resistor meant for 12v conversion years ago and it didn’t work. The ballast resistors are ceramic and turn the excess power into heat so be smart about where you mount it if you go that way. I found them the best working inexpensive option- maybe somebody else knows a better choice -

Haha well said! That’s another issue too- some stuff is rare and deserves restoration and some stuff like my truck is too far gone to come out ahead doing that, so might as well have fun with it

-

But yeah if you slap a pilothouse body on an S-10 with the complete chevy drivetrain- 4cyl etc. you no longer have a cool hotrod dodge truck you have a chevy mini truck dressed as a dodge truck. Which is cool in it’s way too- drive anywhere, cheap available parts all that. I think there can be a fine line between a re-bodied chevy and a chassis swapped or front clipped or back halved type build. If it’s your truck to enjoy then who cares but if you want resale value or the approval of your peers then it gets tricky. Gotta say I am a mopar fan but anybody that likes any kind of old dodge trucks is alright with me I like them all and seeing what people do with them!

-

Well speaking for myself I get much more disappointed seeing brand X power in a mopar than brand X chassis. I like chevy and ford but build mostly mopar stuff and in my mind the mopar legacy is all about the motor engineering. Chassis stuff is just more generic- it is pretty acceptable to just throw mustang II IFS in anything, and a ford 9” based rear has so much aftermarket support it’s the go-to unless you are a mopar dana 60 guy or a 4wd truck guy. Having said that I did look for a dakota donor for mine both because it was dodge and because the track width is really nice. A lot of trucks swapped onto S-10 chassis end up looking like funnycars with the front tires tucked a mile into the fenders. Plus back to the mopar engineering history the dak was really ahead of its time with rack and pinion steering. What the S-10 has going for it in spades is they made a ton of them for a long time. Parts are probably super easy to find on the shelf and swapping v8s in is super common too so it probably also enjoys good aftermarket support for fancy brakes and suspension.

-

Buick is a shame but who cares that thing looks great

-

Throw it under there. Brakes are much easier to work on and all the stuff said above checks out. I had an ‘89 dak axle under my big block truck but thought better of it after I got carried away hopping up the power. Fit fine under the tubs. dunno which one you have but probably an 8.25 chrysler corporate axle? Is it sure grip? And what ratio? The 8.25 is cheap so you might come out ahead making sure you use the right one- don’t waste time on a 2.94 ratio one legger with a lot of endplay in the pinion! Also watch out for those trailer perches they are just meant for locating an axle that only holds up weight not resisting the torque of a driven axle. I have a set on the shelf that looked too flimsy to use and that was when I was putting a jeep zj axle behind the 225 flathead! By the way a jeep zj 90s grand Cherokee axle is almost the same thing- possinly narrower? but with disc brakes stock and I think came with 3.21 or 3.73 gears- and often sure grip! The discs off it went on my 9.25 axle with a very little work so stealing discs for your 8.25 at the junkyard is another cheap easy project to think about. good luck!

-

Finally actually finished the hood louvering project- the hood reinforcement struts have been sandblasted clean and welded back in and the hood and scissor hinges are bolted back on. The epoxy primered areas don’t really clash with all the patina that’s around them- I like the look too. Hopefully the end of my heatsoak problems- if that even was the cause of my brake switch failure. don’t mind all the dust in the pic from blowing off the engine- sanding off 6 layers made a lot of it!

-

51 B3B build thread - after all these years

Radarsonwheels replied to bkahler's topic in Mopar Flathead Truck Forum

Hi Brad! Hey nice work man. I have a piece of trivia to share- a jeep ZJ rear axle takes the stock driveshaft U-joint like it was made for it and provides modern disc brakes with a cable parking brake. It does need billet wheel spacers though- they are a little narrow for our track width. My truck’s OG 4.10 rear was still working like new but the brakes were always a problem and I never found parts for the stock parking brake- 2 birds one stone. I did have to make a bracket for the parking cable splitter and weld on new skinny perches for the original leafs, along with relocating the axle shock brackets but it was a great swap. Fingers crossed that your engine decides to free up and there isn’t any significant rust damage on sealing surfaces. I’m enjoying your build thread- lots of great pics! -

The frame is looking great! Is that all elbow grease and scotchbrite pads soaked in gasoline or are you getting in there with the twisted wire cup on a 4” angle grinder or something? Doing suspension work and motor work on a bare frame is a treat. I wish I had a 2 post lift to pull the cab or bed any time I want. Enjoy the access and get it all as done as you can while she’s bare! How’s the sheetmetal? Is that just some orange that’ll DA off in a few minutes or is there a lot of swiss cheese?

-

And now I went and put a thumb print in it. Oh well I left the patina on the edges and just sealed it up in black so no harm no foul. The epoxy has a little orange peel but not too bad and in a couple days I’ll stick the hood back together. It’s crappy and raining today and tomorrow anyway shoot it already is tomorrow! Happy Halloween y’all

-

Ha! I picked the hood up at the shop today, deburred, sanded, and degreased it. I decided to do a better job than usual since this will be the worst part to sand in the future. I got some black eastwood epoxy primer and it lays on pretty nicely. That’ll do for now to match the black truck and protect the raw sliced metal. I still have to clean up, paint, and weld the rear hood structure/ supports back in. The hood is pretty stiff with the work hardened sections from punching but I like the scissoring hold-up bars. This pic is the first coat of primer. 1/2 hour coat intervals and it’ll need a scuff before topcoating if I ever get around to making this pic a little nicer.

-

I did the rustoleum rusty metal primer followed by oil based enamel, brushed on, for under my bed firewall and some frame. I am confident it will last a few seasons or longer

-

Weber 32/36 DVG on Chrysler 265

Radarsonwheels replied to bvilletrack's topic in Mopar Flathead Truck Forum

This was on a 230 flatty but should be the same -

Weber 32/36 DVG on Chrysler 265

Radarsonwheels replied to bvilletrack's topic in Mopar Flathead Truck Forum

I got a repop off the stovebolt website with 12v electric choke. Lokar knockoff throttle pedal/cable to replace my rusty broken linkages too off amazon. man you will love it I never changed a jet just set the idle and it started and ran like fuel injection -

Awesome! I use an iphone app called diptic it lets you do photo layouts or just single pics but when you are done and hit save if you select the smallest resolution it saves at a perfect size for here. More pics!! And good luck on that $$$ sheetmetal gamble