-

Posts

1,233 -

Joined

-

Last visited

-

Days Won

17

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Radarsonwheels

-

It’s always something innit? I have been testing and tuning since all the fuel system upgrades and fixes. Lately it breaks loose the tires from a stop but not in spectacular fashion. I checked out some datalogs and saw that flooring the gas was only 35% of WOT! That’s like feeding the 512 with a 280 cfm carb! Well a little investigating revealed that my cheap aftermarket throttle pedal setup had slipped it’s splines on the pedal arm. No problem- I drilled and tapped through the aluminum arm and shaft, red loctited a machine screw in there, and the shaft broke in half in a different place! Junk. I spent a day wishing I had a lathe and looking at junk you can mail order then today I made a new pedal assembly out of steel. I used a large fine thread bolt and nut for the pivot, tacked in bolts to the bracket so it can be pushed in place then installed from the engine bay side without a helper in the truck. It’s pretty crude but I think the repop harley brake pedal rubber churches it up a little bit. It’s the middle of the night and raining cats & dogs here but tomorrow I hope to try it out. I kinda can’t believe I didn’t notice the pedal slipping closer to the mat!

-

1939-40 Chrysler Aluminum Head

Radarsonwheels replied to Dozerman51's topic in Mopar Flathead Truck Forum

Wow that thing is awesome -

I used hockey pucks under my front radiator support and bought aftermarket polyurethane body mounts. They are really nice they come with a metal sleeve so you can get good torque and I haven’t had a squeak yet.

-

Nice milestone! Can’t wait to see video of it driving

- 734 replies

-

It’s the end of an era! No more Mr. Niceguy! My buddy who brought the truck up from Virginia around 03ish (?) sold it to me, got it back in a trade, and sold it to me again put in an aaoogah horn the last time he owned it. It was just a modern cheap one so it didn’t have the exaggerated wind up to it’s full scream or that low burping ah! as it quickly winds down like the old 6v ones have but it was still cool and made people smile when we’d give a friendly honk while cruising. I couldn’t find a new one that I wanted to buy, and I would love an air horn but not like there’s a locomotive coming, more like a late 70s bigrig with a flat nose and a screamin’ jimmy. Loud but still fun not totally ignorant. Maybe someday. I got a set of piaa dual tone conventional modern horn snails and threw them on the fender apron where the aooga horn used to live. They are loud but still kind of bassy as advertised. They kind of evoke a 70s caddy or lincoln maybe? But that’s just my imagination. At least my grant horn button is fresh and has a good action and electrical path, and the horn relay on the fusebox panel delivers a nice shot of current. It should be easy to give a friendly meep meep which can be tricky with some modern airbag steering wheel horns, and still be able to lay on a stereo middle finger when needed.

-

My 54 3/4 ton long bed had the wheel bolts and nubs on the drums so you could hang the stock wheels on there while getting them bolted up. I didn’t even know I had a 3/4 ton until I tried to put a 1/2 ton rusty hope disc brake kit on it and the bearings/spindles were different (bigger). But back then I didn’t know much (still dont) I ended up shaving the ‘hanger nubs’ off the drums when I went to new powdercoated ‘soft 8’ american racing wheels with chrome centercaps to replace my mismatched rims. They required you to hold them in the air while starting the first bolt. Oh and my truck was 5 on 4.5” bolt pattern...

-

This is dumb but my 230 flatty stock starter stopped working one day while out and about. I sprayed almost a whole small can of wd40 through it and it never hiccuped again for a bunch of years running 12v thru it. wd40 is mostly solvents with a little oil to leave behind so I suspect I hosed out some trash. That said mine would also spin but not crank occasionally. I would just wait for it to stop spinning then (not with murderous intent but firmly) stomp it again. It was rare that it would not catch the ring gear twice in a row. Not perfect but disn’t seem worth fixing

-

How come nobody mentioned the sediment bowl under the fuel pump? I always cracked that lil bad larry open first to see if I had gas/water layers in it or a big pile of junk goin on. It’s like a little extra thick shot glass with a loop/thumbscrew bracket- comes off in a jiff

-

Differential - Looking for a Warm Fuzzy

Radarsonwheels replied to Bdblazer1978's topic in Mopar Flathead Truck Forum

What diff do you have? I didn’t crack open my 1954 diff but I’ve built some newer ones. Sometimes the torque on the front pinion will involve setting a crush sleeve that determines the lash of the ring gear or said another way the engagement/depth of the pinion- you might need to mark your nut with paint or a scratch/punch to be able to put it where it was with the new seal- or maybe measure the lash of the ring and decide if it is in spec in the first place? those smartener than I will hopefully chime in but what axle are you working on? -

Haha yup exactly. I always wanted cool 1950s stuff haha careful what you wish for! The pan is awesome though lots of fun to work on. The chopper chassis is all hand made and aftermarket junk but the driveline is pure ‘52. Well it has late 50s cylinder heads and T&O 74” replacement flywheels, 2” belt drive with a diaphragm clutch, Morris impulse drive magneto, and a mild cam. The 1954 truck is all handmade junk underneath with a more original look to the outside... sorta!

-

Well non essential tasks have been shut down but outdoor activity with social distancing is fine. I can go out for food or medicine or for exercise I just don’t want to break down farther than I want to walk home. I think a cruise is just fine! I have been working on my bikes a lot lately too. Did a bunch of horse trading and bought sold wrenched and bled my way to a couple of new bikes- a clean ‘day 2’ 1986 softail with 1400 miles, and a 1952 panhead chopper that I rebuilt my way. I ride them around the neighborhood a few times a week but don’t wanna get put in the hospital by one of these terrible drivers out on the road.

-

While I was under there yesterday I swapped out the 33 tooth speedometer gear in the 727 transmission for a 31 tooth gear. The 33 was perfect for my nitto summer tires or at least real close but my speedo read way low on the highway with my new 28” dot drag radials. It’s a simple thing to swap- one bolt and the housing pulls out and the speedo gear swaps out no tools. Except it sucks to do on your back in tight quarters and it’s right above the trans crossmember. After much cramping and cursing I got the bolt started and put it all back together and of course when I road tested the new fuel pump relay there was zero action on the speedo. The housing is on an eccentric to allow different size plastic gears to mesh with the mainshaft and I must have been reading it upside down? Whatever. After four tries spinning it, having my wife spin a rear tire while I watched the trans speedo drive spin or not, having her watch the dash while I spun the speedo cable with a cordless drill, and several coffee breaks, it is finally working- put her in gear on jackstands and the speedo climbs. Just your normal average ten minute job that took all afternoon! Now I’m gonna tidy some stuff under there, wipe down the drips and mess from a recent valve cover oil leak and continued power steering leak (have a new setup just gotta install it...) and I can hopefully get back to cruising and fun

-

Hi Ken Yeah the Bosch relay definitely looks to be sealed up tighter than the Omron that came with the kit. Are you doing a sniper TBI setup too I forget if you already posted about it. Or just using mini relays in general? The sniper doesn’t do pulse width modulation on the fuel pumps- it’s on/off but the ecu triggers the relay with a ground switch. It has a short priming cycle then stays on as long as the motor is spinning, so it’s kind of a safety item so that the pumps will shut down if the motor stops. Otherwise I would have just bypassed it and done a switch in the cab by the key like a racecar.

-

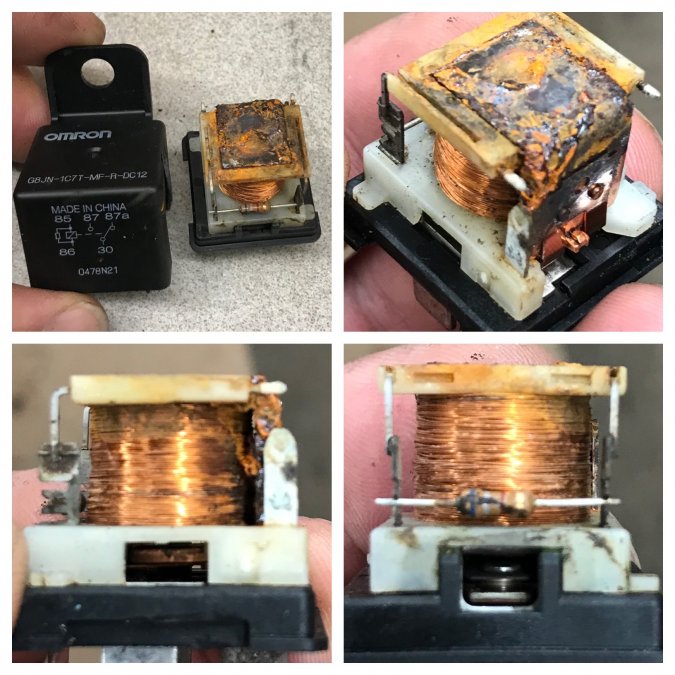

I’ve been shy to drive too much with this stay home order in PA. Didn’t want to break down farther from home than I’d want to walk. My neighborhood had a rolling parade/carshow on easter organized on facebook. Really cool and made the news. I did the first half of it. Right around when the cab started getting toasty the fuel pressure started dropping and the pumps started sounding bad. It turns out the fuel pump relay had un-tucked itself and was hanging down about 3” above the exhaust pipe in the trans tunnel. I swapped it out for a genuine bosch relay- Holley uses a chinese unit- and opened up the old one to see what it looked like. looks fine right?

-

Pilothouse Grounding - How'd Dodge Do It?

Radarsonwheels replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

I’ve also done relays for the headlights and stuff like that which work but I decided they are not worth the extra spaghetti. -

Pilothouse Grounding - How'd Dodge Do It?

Radarsonwheels replied to Jocko_51_B3B's topic in Mopar Flathead Truck Forum

Yep on my build I welded stainless studs to the frame in the back by the battery, in front of the firewall, and up by the radiator. They are all connected to the battery with heavy cable and a heavy cable is also ran to a starter mounting bolt to ground the block. Maybe overkill but my first remote battery installation- in the rear passenger trunk of a ‘72 dodge demon street machine- really cranked better with a heavy welding cable ground straight to the starter/engine block from the battery. With the ground just bolted to clean metal on the trunk floor/rear unibody frame stub it was harder to crank the worked stroker smallblock, especially when it was hot -

Mine currently has a modern fuse box on the driver’s kick panel but when I still had the flathead I used two 20 amp breakers like you’d find on a harley. They are great because when they trip you can turn off the power and they reset after a few seconds. I’ve been far from home at night looking for a gas station that had tube fuses (blade fuses too at different times) and I’d much rather just tape up a short to get home

-

Got bored yesterday and decided to see what the ipe bed would look like if I did another round of penofin without power washing the gray off it first. The ironwood/ipe apparently is so resinous it doesn’t really absorb much finish to speak of and grayed out after a year or less outside. Apparently if you like the gray/silver you can do nothing and it will be pretty stable outside for 50+ years so there’s no pressing need to nourish or protect it. Also any coating like polyurethane will just peel off in sheets after some sun damage so that’s out. I liked the way it looked wet after a rain the other day so I left it black/silver and soaked in a coat of the penofin I used when I built it. This is a fresh pic. It mellowed some after a few days and now shows the grain a little more. I dig it.

-

Well the truck seems to like the new high volume/pressure fuel pump. I re-flashed the last solid tune to the ECU and it probably has some learning to do before I can lock down the learn table and limit closed loop fuel adjustment based on the O2 sensor. It was also another crappy rainy day so that affects traction and visibility. Hopefully more joyrides soon. But things are looking up.

-

Thanks Brad I gotta solve the fuel pressure issue first which is purely mechanical. Hopefully then it’ll be ok. Drove great yesterday before the pump started failing again. The pumps are on a relay controlled by the ECU but it is not pulse width modulated just on/off. It has a prime cycle when you switch it on, then constant on once the motor is running. If the pump swap doesn’t cure it I will go back over the harness for sure.