-

Posts

530 -

Joined

-

Last visited

-

Days Won

4

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by thebeebe5

-

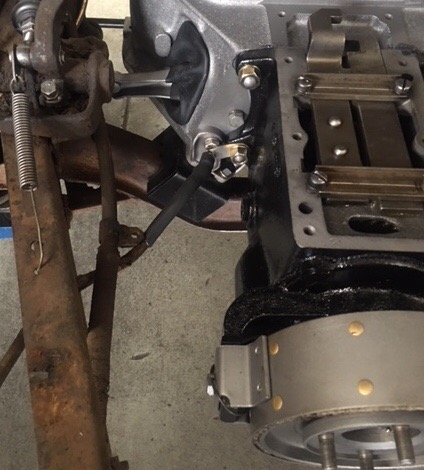

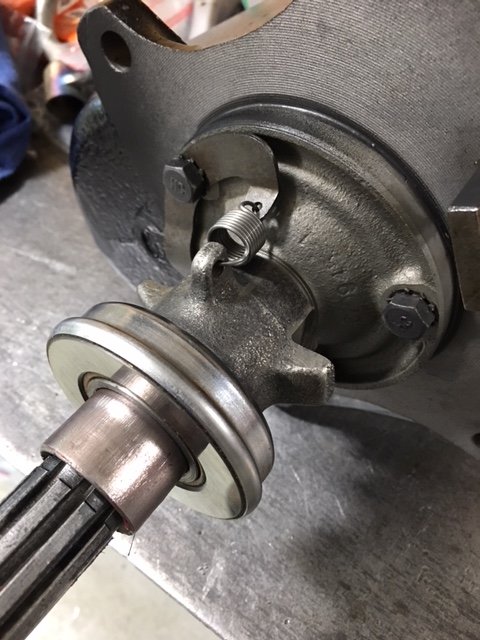

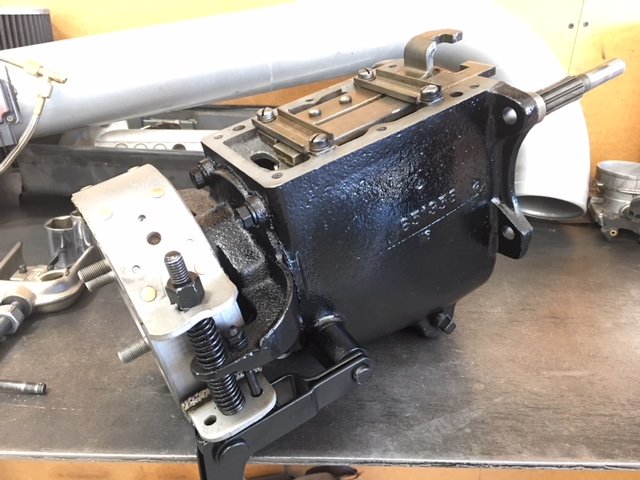

Progress was slow today, but I did get the trans installed. The throwout bearing and carrier was a challenge, but it all finally went together. Of course I had some shop tasks to attend and couldnt devote my whole day to gettting more done, but I’ll take the progress I managed and build on it next weekend. Here’s a before and after. Loads better IMO. Took the positive battery lead out and put some heat shrink on it after bead blasting the end connectors to clean them up as well. Everything was so cruddy.... nice to be reinstalling cleaned parts. Reinstalled the oil pump this evening too. After, I tried to install the distributor, but the darned thing wouldn’t seat propperly. Looking at the shaft tip it was apparent there were two wear patterns and it appeared the blade wasn’t sitting deeply enough. Head scratcher for a while.... I don't recall any trouble removing it, but it sure wouldn’t go all the way in the hole this evening.... Ultimately ended up painting the shaft and tapping the top of the (old) rotor to try to drive it home, then pulled it out to find interference contact points. Seems the slot in the pump was too tight on the distributor shaft blade, so I hit it lightly with an angle grinder and thinned it a touch. Goes in nicely now. I’ll take the drive shaft in this week and have a new one made up with modern u-joints.

-

I’ve looked for the download section a Few times. Found some items there, but not the boot pattern. Was there a boot on the shifter to shifter base from the factory as well.? Would like to cover that up a bit. It’s always been exposed on my car (since I’ve had it...). Also, I wonder about the front of the inspection plate.... there’s a row of rivets that make me think there ought to be something installed there to help keep road dirt out from the flywheel/clutch area....

-

When I got the car it had 235/75/15 on it. They were quite wide and rubbed the inner wells in back when turning a corner. When I looked for new tires I ran across a fellow selling Coker wide whites that were essentially new and including the 16x4 rims that would have come on my car years ago. Was a huge $$ saver to buy his tires and wheels and eliminate the rub. Had I not gotten that set I would have been very careful to buy a narrower tire if I’d kept the 15s on the car rather than installing them on the floor in the garage....

-

where are the timing marks on the timing chain set?

thebeebe5 replied to Tim Van Pelt's topic in P15-D24 Forum

See if these pics help. -

Mr Insane, I had a full set of 5 rims powder coated gloss black for $180. Nothing more durable, really. NOTHING easier either. Dropped ‘em off, they blasted them, coated them and rang me back when they were ready.

-

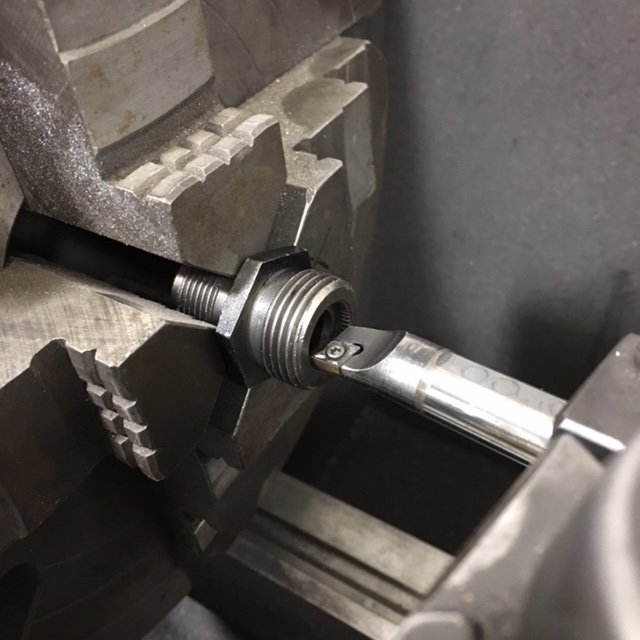

Got these great speedometer gear seals from DCM in Michigan, but they require some machining to fit. So, got out the 4 jaw chuck (which I hate by the way) this morning and got to work. Opened the hole for a slight interference fit and made it 0.030” deeper too. Fits just right now. Throw out bearing and spring installed. Now I’ll need to get the shifter assembly back together so that when the trans is in I can keep it covered. Might as well cover it with factory parts.....

-

They do great work. Felt silly asking him for such a small favor, but he was happy to oblige. http://www.uniqueaz.com/

-

Stopped by Unique Upholstery now located in Gilbert, AZ (formerly Scottsdale) and picked up my newly remade shift fork boot. My pal Scott (the owner) hooked me up!!! This was worth the Cuban cigars I swapped for sure!! Tomorrow it’ll get installed.

-

I think if you run a half to one mil clearance you’re asking for trouble. If you used the plastigauge correctly and that measurement is accurate i say run it. One to 1.5 mil is still on the tight end IMO but will be fine. I just finished my motor at 2mil clearance and im pretty happy. What’s your crank run-out (if any)?

-

Custom forged pistons can be made fairly easily these days. Talk to your machine shop about that option. They aren’t cheap though, so be prepared.

-

When I looked at using one a few months ago IIRC it appeared that some machine work would be required. Ultimately decided not to use it and went with a new style rope seal by best gasket, available through Egge.

-

I looked on Tod’s site but didn’t find a picture. Likely one there, but I’m just not seeing it. On this model do I want the oval decal for the side of the air cleaner like this? https://www.ebay.com/i/222972988502?chn=ps&ul_ref=https%3A%2F%2Frover.ebay.com%2Frover%2F1%2F711-117182-37290-0%2F2%3Fmpre%3Dhttps%253A%252F%252Fwww.ebay.com%252Fi%252F222972988502%253Fchn%253Dps%26itemid%3D222972988502%26targetid%3D411511147126%26device%3Dm%26adtype%3Dpla%26googleloc%3D1013462%26poi%3D%26campaignid%3D1057489367%26adgroupid%3D54502292840%26rlsatarget%3Dpla-411511147126%26abcId%3D1133856%26merchantid%3D8399494%26gclid%3DEAIaIQobChMI1O6y3sO62wIVTEwNCh26JgKXEAQYAiABEgKbP_D_BwE%26srcrot%3D711-117182-37290-0%26rvr_id%3D1553730765796%26rvr_ts%3Dcbd607d81630abc00697c708fff9253c Or the one that looks like it belongs on the top of the lid like this one? Have seen listings that claim they are all correct for a 37, but (thinking back to high school multiple choice questions....) which is most correct? https://www.ebay.com/i/362194548881?chn=ps&ul_ref=https%3A%2F%2Frover.ebay.com%2Frover%2F1%2F711-117182-37290-0%2F2%3Fmpre%3Dhttps%253A%252F%252Fwww.ebay.com%252Fi%252F362194548881%253Fchn%253Dps%26itemid%3D362194548881%26targetid%3D398677321399%26device%3Dm%26adtype%3Dpla%26googleloc%3D1013462%26poi%3D%26campaignid%3D1028253084%26adgroupid%3D54605285710%26rlsatarget%3Dpla-398677321399%26abcId%3D1130036%26merchantid%3D6310644%26gclid%3DEAIaIQobChMI1O6y3sO62wIVTEwNCh26JgKXEAQYBCABEgKJsfD_BwE%26srcrot%3D711-117182-37290-0%26rvr_id%3D1553702070342%26rvr_ts%3Dcbd79c451630ac1c55b19666fff91732

-

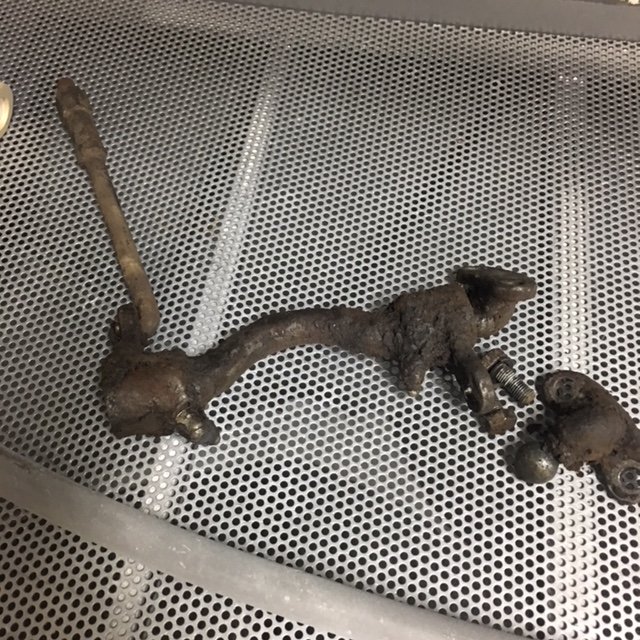

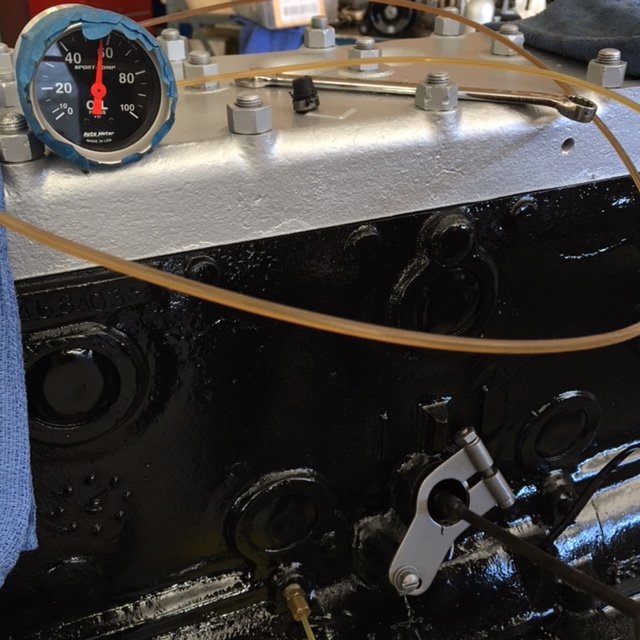

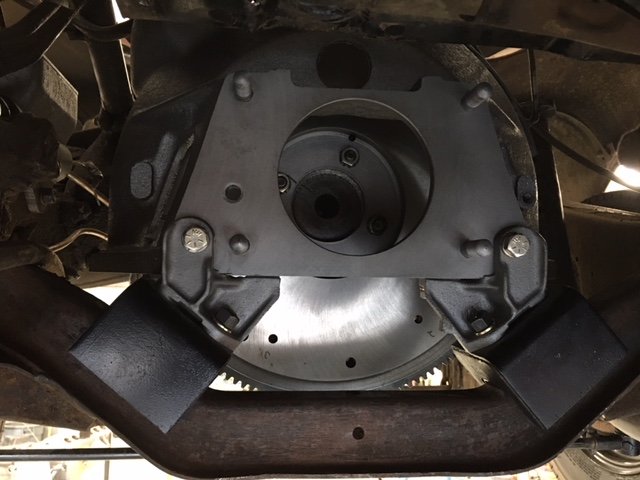

Finally got the car to the shop today. Spend the day getting the clutch linkage fixed up. Cleaned it and found the holes all wallowed out, so Brian welded them up for me. I got them ground flat today and will redrill the holes next weekend to tighten up the linkage. Also, since I’d found an extra oil galley plug and I wasn’t sure if there was a hidden one I’d forgotten (besides the one on either end of the main galley) we made a tool to run the pump with a drill. Pulled the pump back out and took the gear off, and with the drill cranking some old stock 20/50 Brian said he’d probably never use we found a cold oil pressure of 58psi. With a lighter 30wt and at temp I’m guessing it will settle in around 40-45psi. I’ll need to make (or buy) another pump to block gasket and reinstall permanently next week. Getting the engine in is a kind of a dance with this motor..... The rear mounts are attached to the trans bell housing, so I settled the motor in place and started the front mount bracket bolts but left the rear a bit low and supported it with a 2” ratchet strap. Then I cranked up the rear to a height that would allow the bell housing to be worked up behind the motor and only just started it in place. Then the flywheel has to go in because there’s not enough room rearward if the bell is tightened prior to flywheel install. Once the flywheel is started the bell housing can be tightened followed by the flywheel final torquing. Got the clutch installed too. That’s as far as I made it today, but it’s a huge step to finally running the motor and getting the old girl back on the road. Had I more time today (or had I been more efficient with my efforts) I could have gotten the trans bolted in and made measurements for a new drive shaft to be made which will utilize modern u-joints rather than the old ball and trunnion setup of yesteryear. Reading the forum it seems unanimous that modern u-joints are quieter and smoother, and it just makes sense. Rebuilding the old one would cost at least $250, so I figure I’d rather spend that coin on an unseen upgrade.

-

Okay, I’m stumped and could use some help. Ready to put the 201 back in my coupe this am and I find an extra 3/8” oil galley plug. ? Now, I’ve been over every one of the hundreds of pictures I’ve taken throughout the build, and I cannot find where another plug would go. I have both the front main galley plugged (behind the timing set plate) and rear plug just now when I hung the motor on the hoist. Where else is a square head plug used on these engines? I suppose it couldhave come off another part, but which part?

-

Nice car. Interior looks fine IMO.

-

I get it. Got a new replacement front motor mount that is most certainly made overseas. It’s too wide by almost 1/4”.... tomorrow I’ll cut it in half and weld the top and bottom plates to the proper width. I’d send it back, but I got it 9 months ago thinking my rebuild would go faster. What a HOOT. I should know by now I should just double my completion estimates for both time and money....

-

I like it. ?

-

Very close to wrapping this project up, or so I tell myself.... i know I have a long way to go. Last weekend got the motor painted to my satisfaction. Finally. Three tries to get a fairly smooth coat of paint. It’s not perfect, but it will do. Today got the oil lines fitted for the full flow oil filter. Recall I’d started out with AN-6 fittings in mind. Ended up going with a -8 fitting that matched the ID of the pressure side oil galley so as not to restrict oil flow. But the larger fittings would have interfered with each other unless I went with a different style fitting, such as a 45° angled nipple to keep the two fittings more separated. As it turned out there was a lot of meat on the nut side that screwed the 3/8” NPT threads into the block and I simply chucked each up in the lathe and turned opposite ends to make room. Now they’ll fit right in there without issue. Got the water pump mated up. Fuel pump on. Need to get some 1” heater hose for the bypass so I can permanantly install the water neck. It’s just perched up there after last weekend’s paint.

-

So, looking at that cork gasket.... if it gets compressed when the distributor hold down is tightened it’s going to cover up the oul return hole in the block bore for the distributor. I think.... Has anyone else seen a metal washer like I took off? It fits the hole and distributor shaft like it belongs.... maybe a rubber backing on it at one point...? We have a large assortment of o-rings here I could use, and that was discussed at the shop. Just wondering f there’s a proper way....

-

Don’t recall anything other than the metal cup washer (pictured) sealing the distributor when I disassembled the motor. Looking through my gasket kit and wondering if any of the few round and similar sized gaskets like the cork or paper ones pictured are required when reinstalling the distributor. The service manual doesn’t show even the metal cup washer in the schematic. Thoughts?

-

Just a PSA... A few years ago I had a heckuva time finding these. Someone here at the forum confirmed they were in short supply and offered a few sets of older, dried up (and they cautioned likely shrunk) stock for templates to make my own. Well, last week I went searching again and lo and behold they popped up in stock at Autozone with free shipping over $25. Ordered three sets at $8.99/ea and they showed up today. New stock, nice looking Fel Pro cork side cover gaskets. Autozone order number is #072260 and the website said mail order only. Hopefully stock will remain for those of us that need them.

-

- 2

-

-

Last weekend and this weekend my time was spent painting the trans and installing the brake, and painting, repainting and RE-repainting the motor. First try was Duplicolor gloss black. It went on like oatmeal..... sanded it down the next day and tried a different batch of Duplicolor and got more oatmeal. Dammit. Sanded it again yesterday and used a different paint; the Seymour Hi Tech paint the shop uses for just about everything. What a difference! It actually shines, and went on wet and leveled fairly well for a rattle can. Could have been better with a proper spray gun and some good automotive paint, but I didn’t go that route. Maybe my next engine... This one is now waiting in the back row of the engine room to get back into its car. Also, still stripping and painting various small parts in preparation for reinstallation. Also got the original air cleaner stripped. It will be gloss black again.

-

All kinds of places. Ebay is a good source. Andy Bernbaum another. Others may chome in with additional options.

-

The lines on my '37 were all 1/4". I bought a 50' roll and separate fittings at my local NAPA. Ended up with a bit left over. The price on that Amazon listing is really good especially if it's 1/4". I paid a bit under $1/foot for the line only.

-

I'm jealous of that cabinet too, @Cpt.Fred. Brian says that's the best purchase he made for the shop all those years ago. LOVE the flip top lid, and the capacity is enormous. I regularly soda blast vintage V12 heads in there and there's more than enough room. Routinely stand big V8 heads on end, too.