kencombs

Members-

Posts

3,083 -

Joined

-

Last visited

-

Days Won

29

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by kencombs

-

I would suspect a brake adjustment problem also. Push rod, maybe but the direction of travel part of the problem makes me think one or both shoes are touching the drum at rest, then grab when turned. What nut are you referring to as a 'wheel nut', cam or anchor? In any case, follow the directions others have provided and that should work.

-

The only place in the code that I'm aware of that addresses light switch power source or wiring is the fairly new requirement that all switch location include a neutral. The old switch leg method did not provide for that. That is to support a lot of newer smart switches, lighted switches etc.

-

When it is misbehaving, does spark look the same on all cylinders? Could be a clue there if only 1/2 of them vs random vs all, etc. 1/2 because of the dual coil setup (internal to the coil) that I think it has where half of it fires half of the cylinders. Or if it's all then that points to sensor/control circuit. Crank position sensor came to mind first, but you've replaced that I think. Non-original parts are suspect these days though. Bad ECM ground? I'd be tempted to run a separate ground wire, ECM, Chassis, engine just to rule out.

-

That pic is misleading, IMO. They show a pulley/hub combo then just the hub, but no pulley to attach to the hub shown. Some years had separate pulleys that bolted to the hub, others has a one piece pulley/hub. So they've tried to show too much in one illustration. The ones I've seen with the separate pieces had a hub, pulley and dampener. The on the multipiece the hub goes on first, then the bolt on part, whether dampener or just a pulley. Aftermarket documentation, tends to have a lot of errors like that, as compared to factory manuals.

-

How to clean a camshaft without stripping embedded oil?

kencombs replied to ktb's topic in Mopar Flathead Truck Forum

All I'll say is that I've been working on engine internals since 1959. Cams, cranks, blocks etc. Disassembled, cleaned, reassembled and installed. Never have I concerned myself with that question. Oh, and most of them ran when I finished. -

That was common on a lot of Chrysler stuff up through at least '59 even on V8s with auto and torque converters. You'll need a special or modified wrench to deal with limited room, at least I did. Long pattern, 5/8"(I think) box end, 12 pt ground down a bit for clearance.

-

Or, go to a John Deere dealler and gut a tube of'corn head grease'. Thick and won't leak out but thins under pressure, lubing the sliding contact areas.

-

I drove my Dad's 54 as my 'date' car in high school. My old chevy wasn't nice enough for my girl friends. Assuming yours is a Powerflite, it is the same chassis and mechanically similar except his had the 241cu hemi, the 56 is probably be a 270 A series which is a great engine. There where other engine options but most were not often found in the Coronet line. edit to add: being 16 at the time and a budding hot rodder, I can attest that there are no weaknesses in the running gear. Just about unbreakable, even to a teen boy.

-

Just a word of caution with the spin-on replacements. There are a lot of filters that will physically fit the adapter. But, most are not rated for bypass duty, but for full flow. The bypass filters have a much smaller 'pass' rating, catching stuff that a full flow will let through. You can buy the bypass replacement for a small diesel to be sure. For instance the Mitsubishi Fuso 3.9L diesel I had used two filters that looked identical, except for the printed part number. One for full flow and one for bypass. I think I'll try to replicate that on my 230 just to see if I can. It's already drilled, tapped and plugged for full flow. Just have to make the lines. Then use a similar mounting base on the other side for the bypass. Maybe this year I'll finish.

-

That oil pressure relief valve mentioned should be installed behind the bigger plug at the bottom of your pic. And, probably is, or the engine would have no oil pressure. That is the key to making a bypass system work, only after the oil pressure/flow needs of the bearings is met does it open and allow oil to flow to the filter.

-

Is the OD the same as the seal on the left, but only a different ID? If so,I'd guess that it is included to make the kit fit multiple applications, maybe with different residual pressure valves. Cheaper to do that than stock two different part numbers.

-

The VIN wasn't a thing until I think late 60s. Makers had serial/model info on the body ,engine and sometimes the frame. Different states used different info on titles. In OK they used the plate on the cab/firewall that has a SN, weight etc. Other states used the engine, which can cause problems after an engine swap. My 56 has the tag on the left side of the firewall, kind of hard to see. Mine had a one digit mismatch from the title because the last digit was misread by a KS owner or official sometime in the distant past. Luckily I got to deal with the Cherokee nation tag/title office and they looked at the tag and corrected the title without a big hassle.

-

Yes, the gear is not a Chrysler (or Ford, or Studebaker etc) but made by Gemmer (I think) with common internal parts and case castings and Pitman arms to fit many.

-

IF you have an air hammer, I've found that using that around the center of the hub to help. Hammer at a right angle to the axle. I think it helps to release the tapers bond axle to hub. Can't hurt. Edit to clarify. Do this with the puller installed and tightened. Repeat tightening the puller screw afterwards. And, it is obvious I guess,but be sure the puller screw is well lubed, makes it last longer and turns more of the turning force into pulling force.

-

I don't see any thing that supplies a slip yoke function in the new parts pic?

-

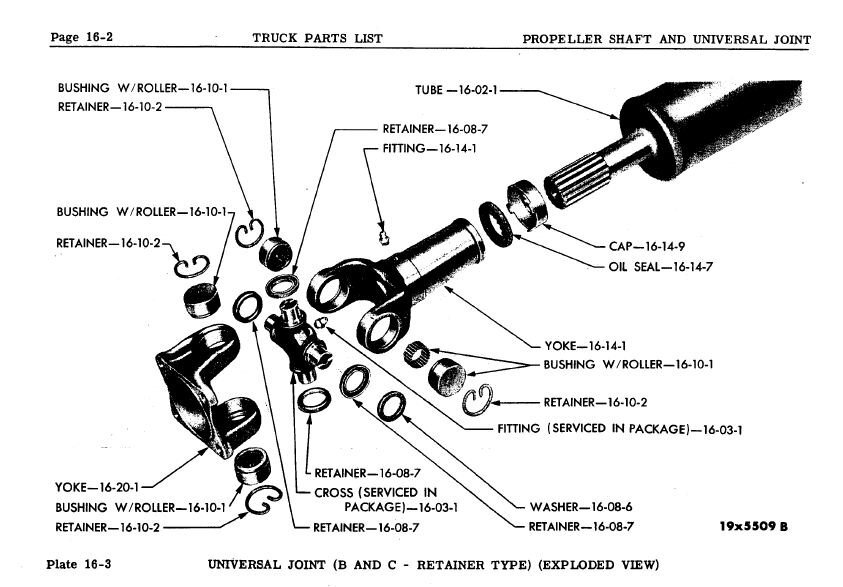

I have a 56 PU. It uses a standard spicer u-joint in rear, and a ball and trunnion in the front. I think just like yours should have. That type of drive shaft has to have the slip joint incorporated into the shaft itself as the transmission has the bolt on connection rather that more common splined shaft that accepts the front shaft's slip yoke. Mine is in good shape and everything, but unfortunately I'll have to remove the front slip parts along with the flange that bolts to the trans. I'll have to cut it off and add a new piece that fits the ujoint in the slip yoke I'm using to fit my A833OD transmission. The parts are like these: That will get replaced with this and my slip yoke/new joint. Luckily, my shaft now is way too long so I'll have plenty of tube and the rear part to use. just cut, insert yoke, weld, straighten and done. I hope. The reverse process could be done to make one that fits your truck.

-

I posted a similar answer yesterday, but it's gone! Anyway agree with Andy, except for another terminology thing. The part in the pic is an 'upright' in my neighborhood, the spindle is the part that receives the new bushings that get reamed. Very seldom does the hole in the upright (or the similar holes in a solid axle) need any work. Once in a while one will find on egg shaped a bit due to operating with bushings that where really worn, allowing the pin to get banged about.

-

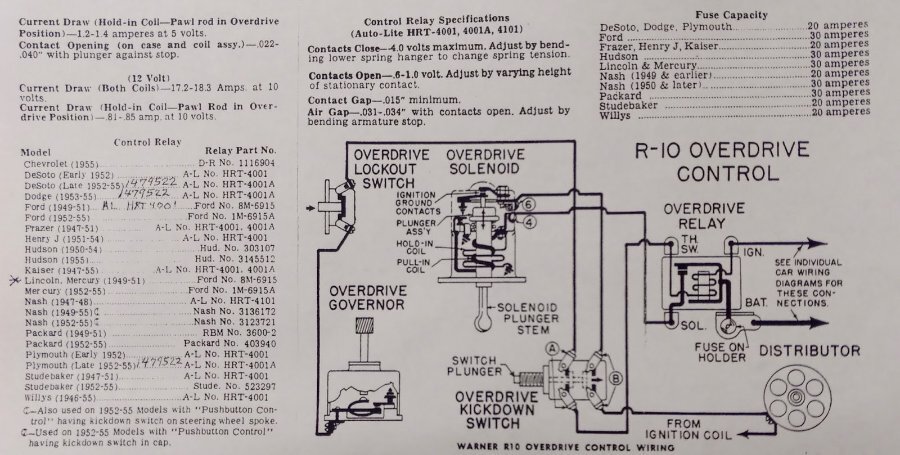

Here is the best pic I could find that shows how the kickdown, solenoid, governor and relay all work together to only interrupt the ignition only while shifting.

-

IF the oil is coming from the intake, either past stems, or in the intake air via the PCV, the back of the valve heads should show signs of that. I really can't believe that much oil enters the cylinder past the rings with the compression you have, unless the oil ring has failed. In that case I'd expect to see signs of that on the cylinder walls.

-

I am not familiar with that engine, but some of the newer, smaller, especially turbo-charged engines have issue with the PCV systems that cause similar things. GM's version especially with the intake changing from vacuum to pressure they have difficulty with reliably managing the fume and oil flow.

-

Regarding the ignition interrupter function, it is important to note that this grounds the ignition for a very short period. And probably won't be noticeable with the test you are using as it lasts for milliseconds while the solenoid plunger is moving.

-

Depression pipe? Probably on an iPhone, misspelled 'extension' and auto-correct 'fixed' it.

-

Not gonna give my opinion, because it only means something to me and me alone. But I'll recommend a visit to bobistheoilguy.com Don't go there unless you have a lot of time available to read the info though. But I will say that I use detergent oil in everything, 15w-40 in some and 0w-20 in some. Even some full synthetic.