-

Posts

5,063 -

Joined

-

Last visited

-

Days Won

58

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by desoto1939

-

I know in the states there are venders that specialize in hood hinge repair and rebuilding. Not sure if there are any in Australia. I would suggest that you try to do a search on automotive Hood Hinge Repair and Restoration. It might be costly but then you will at least know that the hood will stay upright and not be of any issue. If you want to have an antique car then sometimes you have to pay an expert to do the work when you do not have the proper tools and work experience or even and proper way to work on the car safely. Just my $1.00 worth of input. Rich Hartung desoto1939@aol.com

-

41 Plymouth - any tips for removing side trim clips?

desoto1939 replied to 41 Plymouth Coupe's topic in P15-D24 Forum

Suggestion: Go to a good quality automotive paint supply store. Ask to see if they have a supply of plastic molding clips. Also take along one of your stainless steel moldings and then try to find one of the clips that will fit into the back of the molding. I did this with my 1939 Desoto. Reasons: 1. The old steel clips will rust and then the water when it runs down behind the trim will eventually leave rust markings on the paint. 2. Since the new clips are plastic they will not rust. 3. When pushing the clips and the molding back into the hole it will not chip the paint and or even send crack marks in the paint. 4. If you have to remove the molding at a later time the plastic clips will just comeout very nice and clean and its easier to remove the moldings. 5. No one even sees the clips so go with the modern clips. 6. Go to the web site for Restoration Supply in Windber PA. they have a great selection of plastic clips and they are a great company to work with for supplies. It might take an hour or two of your time to find the correct size plastic clips but it will make you reinstall much simpler. Rich Hartung Desoto1939@aol.com -

Basically all oil that is being sold in todays market, AutoZone, Walmart and other oil products sold on the web are detergent oil UNLESS the label states NON-DETERGENT. If you read your owners manual for your older car most stated to use 20 weight oil in winter and 30 weight oil in Summer. These oil were dinosour oils. Todays products are better in design because of the better refining and the additives. I currently use the Castrol Classic 20/50 weight oil in my rebuilt engine and is has one of the highest amt of ZDDP, Phosphorus and Boron in the mixture according to my discussion with the Castrol representative. THe blue bottler Walmart store brand is produced and bottled at several processing plants in hte USA and this same company bottles and produces the various major other brands. So if your car has a filter, By-pass or other you are good to go. If not then I would install one on your car and start running the car with a filter. By-Pass is better then none at all. The weight of the oil also depends on the age of the engine, condition od of the engine and where you are located and currently live in the USA. As suggested aboe go to the webpage and read the article on oil and you will learn alot about the oils and how they have changed. Rich Hartung Desoto1939@aol.com

-

One very important point regarding the oil pressure guage. Mopar used a very special nut with a compression fitting and the threads are 27 pitch. Yes this is correct. When you take out the metal line from the back of the oil guage DO NOT again DO NOT lose this metal line. It is needed to fit inside the oil gage and make a complete seal. These are very hard to find. The rubber flexible rubber hose threads into the end of the metal tube. Just want to give you this FYI. Most people try to replace the special connector and they throw the metal line and the special nut in the trash. Rich hartung Desoto1939@aol.com

-

in 1934 Desoto only made the airflow model. They did not have the airstream model which was a return back to the old style square bodied cars. The Coupe is also very rare. Few of these cars are known to exist. Rich Hartung Desoto1939@aol.com

-

on my unit there is a spring clip that hold the vacuum advance arm in place but it might not be necessay to have one in place. I looked in my 39 desoto parts book and there is no listing for a spring clip to hold the lever onto the stud. Rich Hartung desoto1939@aol.com

-

in Don smiths picture for all of the people that are installing a headliner you can see the metal brackets above each door that hoods the headliner tucked up under the doorframes. Some will have some very small teeth to grasp the headliner. Use a spackle blade maybe plastic so you do not discolor the headliner. I help the painter do mine on my 39 Desoto. Rich hartung desoto1939@aol.com

-

I am looking for an Autolite Distributor shaft IGS-1081RB for my 1939 DeSoto. This shaft was used on the 6 cylinder Chrysler and Desoto engines. The shaft has a splined end when the Cam adn weight are attached to the shaft versus the next series up has threaded ends. I will attach a document showing what the proper shaft looks like. Any help would be appreciated. I currently have a NOS Distributor cam and this cam is not theaded onto the shaft it is held in place by the splines on the shaft. I had found a shaft but just missed getting it by several days. Any help is appreciated. Rich Hartung Desoto1939@aol.com Distributor shaft IGS-1081RB with spline ends 38-39 Desoto.docx

-

It all depends on if he is making the headliner from scratch, if he has a pattern to use, the material type and his labor. i got my headliner from Restoration supply in Windber Pa and it was perfect fit for my 1939 Desoto. Prices have gone up so you will have to ask around to several upholstery guys to get the price. Rich hartung Desoto1939@aol.com

-

Plymouth Passenger Car Parts List Model Series P15

desoto1939 replied to David T's topic in P15-D24 Forum

Here is the front page of the standard Mopa Parts reference catalog. I currently have this entire catalog scanned into my computer. Rich Hartung desto1939@aol.com -

Plymouth Passenger Car Parts List Model Series P15

desoto1939 replied to David T's topic in P15-D24 Forum

I also have the same standard parts book. I have a scanner and I also scan all of my catalogs when time permits. This way i have better access to the manual and it also saves wear and tear on my catalogs. Since I have scanned my catalogs it then provides me with the opportunity to cut out any single page and print it when someone needs that specific info or when I am looking for that part I can take it along with me to a swap meet. Rich Hartung desoto1939@aol.com -

Need help on how to use Miller Brake Gauge MT-19 tool kit.

desoto1939 replied to MarcDeSoto's topic in P15-D24 Forum

sam: Thank you for the full explanation of how you get the full diameter of the drum. I am not putting down the tool that was designed by Keith. If it works for you and everyone else that is great. Yes the tool price is a great purchase for the average day home mechanic. I originall purchased my Ammco brake tool that cam in the metal box for around $75 and then was able to get the Miller MT19 full set with the 7 sleeves for around $125 and then purchased the other brae tool the tru-brake shoe lining cutter for around $125. So I got all of the tools for a little over $300 as compared to $40-$600 at todays prices just for the Ammco tool. I do see guys on Ebay selling the AMMCO tool for $600-700. The person is buying up all of these tools when cheap and then jacking up the price and trying to make a killing on everyone he sells. As we can all see these high priced tools are still for sale by this seller. You can price yourself right out of the market. Since I do not need the new tool I was not knowledgeable of how the tool was designed to work and that is why I have asked the questions. Others might have the same question but no one ever stated how the tool was correctly used or even put and instruction sheet out into the technical section on the Forum. I have placed a long time ago how the Ammco and the Miller tools are used to let members know about the tool. Is anyone going to put out some information on how to use the newer tool? Thanks, Rich hartung desoto1939@aol.com -

Need help on how to use Miller Brake Gauge MT-19 tool kit.

desoto1939 replied to MarcDeSoto's topic in P15-D24 Forum

The correct way to use the Ammco tool is that yes you use the tool end with the dial and the other end with the rod and the flat spot fit on the inside lip of the drum. You then loosen the set screw on the dial end and rotate the dial until it does not move, Yes you have to be directly across the middle. Also remember that you now divide the reading on the dial, and lets say it is 40 which is 40 over. You then divide that in half and then set the dial at the 20 mark becasue you are only doing one shoe at a time. You then put the tool on the spindle or axle shaft shaft and then either use the half moon adjuster on the backing plate to move the top of the shoe out and according to your specs for your car the distance at the top to the rod is either 6 or 12 thousands, then do the same for the eccentric, You must know the correct spacing for the toe and heel for your car. You use a flat feeler gage to make the spacing. So again how did you determine the inside diameter of ther drum when the drum is off ther car. and to know when the shoes are set up properly. Please answer the question. I know a person that was using the tool you use and then found the Ammco tool and discovered that your tool was way off the mark and the Ammco tool gave him a proper set the first time. Rich hartung desoto1939@aol.com -

Need help on how to use Miller Brake Gauge MT-19 tool kit.

desoto1939 replied to MarcDeSoto's topic in P15-D24 Forum

Bacelaw: I have a question for you since you use the modern brake tool. i have both the Ammco Brake gage and he Miller MT19 brake gage and also the Miller Truebrake tool that uses the sleeves and then you can cut down the linings to fit the arc of the drums. My question that the Ammco and the Miller mT 19 both measure the diameter of the drum so that you can get the shoes properly set and so that you have the proper spacing at the toe and heel of each shoe. With the newer tool the drum is removed from the spindle and or the rear axle. So how do you measure the drum with your new and improved tool? I am still trying to fingure this out by looking at the tool. Can you explain how this tool is better than the Ammco or the factory Miller tool? Rich Hartung Desoto1939@aol.com -

go to the MOnroe shock webpage and do some searching on their site. I do know do a search around the 1946 years. All of the shocks that they say fit were good from approx 1939 up to in the 50's. Since you have put on 17 inch tires do sure if this will affect the length of travel that you will need on the shocks. Also you can get these shocks at good prices if you know the Monroe shock number. There is someone selling rear shocks a pair for over $300 on ebay that is highwasy robbery. I got fonts for the 39 Desoto and they were MOnroes froma Napa store for arounf $37-40 each. So I spent $75 and save $200 plus dollars and also shipping. So do your homework. Also how much play to you have in the steeringbox? This might also need to be rebuilt. Also rebuilding the upper and lower control arm bushing will also improve the handeling along with the alignment. Rich hartung Desoto1939@aol.com

-

when you do the next waxing of the car. Get some clay bar and then clean off all of the road containments. Use a micro fiber towel. I use a detailers spray as th eliquid to make the claybar remove the material. Then when applying the was do not go in circuar motions apply the was ina linear fashion like would do when sanding a board. go with the the grain or how you would look at the hood from sitting in the car. So front to back of the hood. Also take off the wax in the same manner. Do this same thing with all body parts of the car. Also remove the tag on the micro fiber cloth. Never use a dish detergent to clean the car, it removes the grease and or wax. Rich Hartung Desoto1939@aol.com

-

Loren: I had an issue where I could not get my carb and my 39 desoto to idle properly. I took my original carb and a couple of replacements and a NOS replacement carb to a Carb rebuilder. Put the old carb on his engine and it imediatle flooded his engine. Then put on the NOS one and it ran perfectly with a little adjustment. When I had the old carb off the maniflod i had noticed that there was raw fuel in the intake maniflod of approc 1/8-1/4 inch of fuel. This was an idication that the carb was flooding and after running the car in the summer it was alwasy so hard to restart a hot engine. Thought it was the ethanol gas issue. When I toke the old carb apart and rebuilding it I picked up the float and shook it and noticed a clunking feeling in the float. There was gas in the float. So this was making the level in the bowel seem to be alwasys wanting more gas and was flooding the carb and this did not permit the fuel to vaporize to get the car started whn hot. Problem has been solved for my 39 Desoto. Rich hartung desoto1939@aol.com

-

with the coil in the firewall and the armored cable that connects to the back of the coil it sort of was an early theft prevention setup since would would have to cut the armored cable to jump the ignition wires. They did find that this made it harder to start because of the extra length of wiring going to the dizzy. They then did move the coil down onto the bracket mounted on the side of the head. Rich Hartung desoto1939@aol.com

-

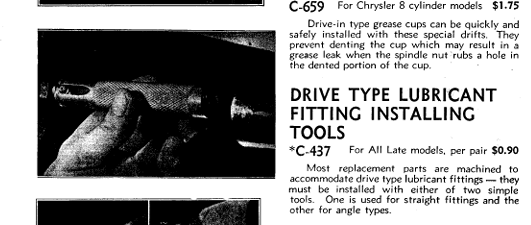

Here is a page from my 34-41 Miller tool catalog; I does show that they did have drive in style zerk fitting both for straight and angled fitting. tool number d-437 Rich Hartung desoto1939@aol.com

-

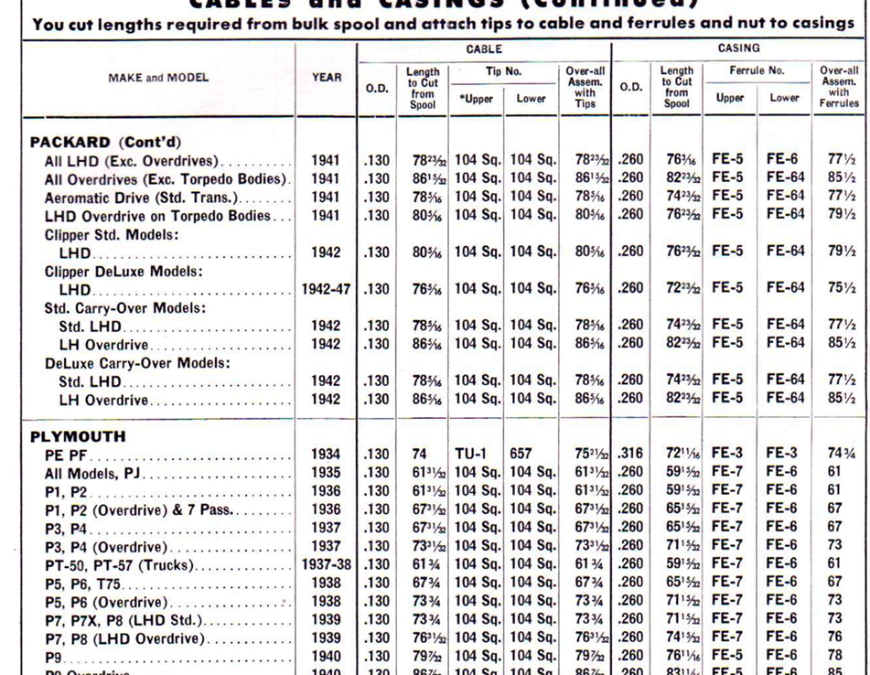

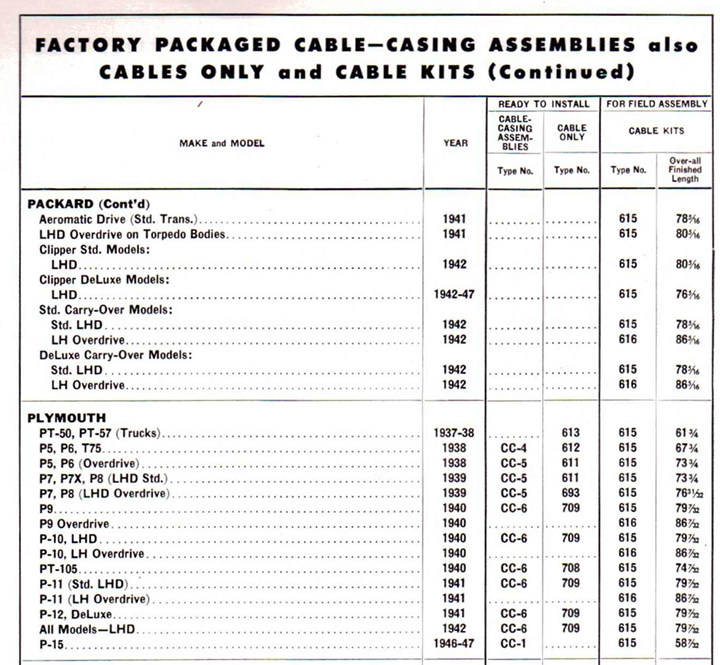

Here is some info taken from my speedometer cable catalog. This was taken from my AC speedometer catalog. Hope it helps. Rich Hartung desoto1939@aol.com

-

when you register for the Hershey event they remind you that everyone should have a PA sales tax number and that you should write your PA sale Tax id number on the registration form. I have know that the PA revenue has been at Hershey but I think over the years they go after the real big venders that make their living off of selling parts such as Cocker tires and other big venders. If you do not have a visible license they then can shut you down or ask that you file a report on what you sold. I know most small time venders do not charge PA 6% sales tax. Rich Hartung

-

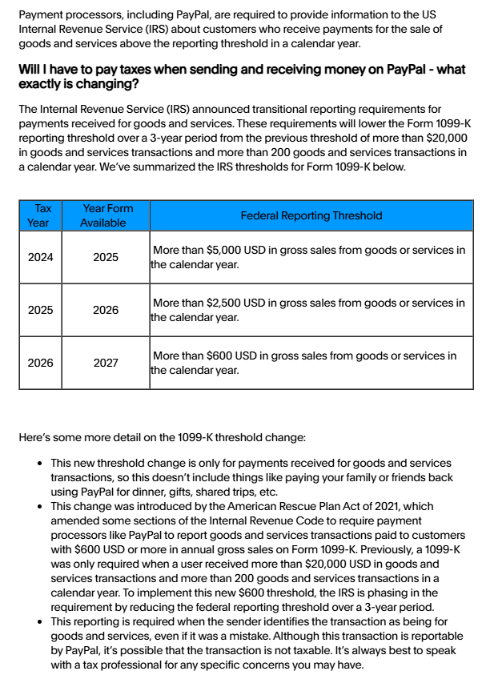

I know this is not a regulat topic but will also affect every member of the club and anyone that sells items via a webpage provider. Please go to the article and read the information that I posted. I am not a tax preparer but jus posting the information. Please do not take this posting down it is for informational purposes for the members. Thanks, Rich Hartung desoto1939@aol.com

-

I have attached an information sheet that I received from Pay Pal regarding the dollar amount of sales that will be reported to the IRS for 2025, 2026 and 2027. So of the biggest sellers might get hit with a 1099-k form. SO make sure you track your sales, the cost of each item that initially it cost you, travel cost and any other expenses to purchase the item along with postage to ship the item food and also lodging cost. Like traveling to Hershey, the cost of a vendor site, etc. The Fed Gov't needs money so they are going after every $$$$$$$$ than they can get their hands on. So starting in 2025 I would suggest that you only deal in cash, money orders or personal check or a bank check. Do you own research on this information Rich hartung.

-

I agree with Tom, Since you do not know when you are going to use the engine, and maybe never, Definately use penetrating oil in the engine. If it was me I would try to get the engine into your heated basement to also help eliminate any moisture and also the heated area of the basement will help with preventing any rust. Then every several months then go down and had turn over the engine to keep the cylinder walls lubricated. Maybe put in some used sparkplugs or plugs the holes. If the holes are pluged then remove the plugs before you try to turnover the engine while in storage. Could also put in a use head gasket without any gasket sealer and thne tighen the head but to to full spec's just to seal the head and also lessen any rust issues. If the head is tight you can always remove the head to check on the wals of the cylinders every so often. But good plans or mice and men go astray. Also I would not wrap the engine in plastic because that kind of traps moisture, maybe a breathable cover like a blanket. Rich Desoto1939@aol.com