-

Posts

784 -

Joined

-

Last visited

-

Days Won

16

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Loren

-

Two things The dampers with a rubber sandwich can be rebuilt. Don’t toss it. when you are removing something that has a keyed shaft, do not pry at 90 degrees to the key. Pry at 180 degrees or at the key otherwise it will never come off even if it is a fairly loose fit.

-

I would use sand blasting. The engine rebuilders use steel grit. You are absolutely right about Glass Beads any moisture or oil and they will be in there forever! One shop I worked at had a blaster with walnut shells that worked very well.

-

"All or Nothing" is meant to mean it either flows or it doesn't. Do you remember what the PCV valve you used came off of? I have a VPW valve (for use on another engine) and it might be of value to compare them. Thanks for sharing!

-

-

I think you're on to something! The PCV valve you are using is "All or Nothing" its purpose is to prevent intake backfires from popping seals and gaskets. The factory (or at least the one VPW sells) has a constant vacuum draw and the backfire prevention. I can't imagine there's any more benefit to the VPW item. One thing that recommends your solution is that it will clear an aluminum valve chamber cover. My 49 P17 has a large round chamber where the road draft tube goes into the block with a filter in it. I haven't been able to find that in my parts manual but I have seen them before. That type would be the ideal one to modify. I seem to recall that the retro fit items used that design back in the day.

-

Are you sure it connected right? The coil within it should only see power when the starter is running. That’s not long enough for the wire to get hot.

-

I've been trying for a very long time to discourage folks from "re-engineering" their cars and I admit it sounds harsh in retrospect. You have my apologies. I am admittedly stuck in the 1950s. I like the way they did things then all metal and no plastic. You got both barrels because folks will say "well what about this?" So I covered all the "What abouts?" What puts my teeth on edge is that someone who is not very experienced sees another guy doing a write up or a video and then they figure that is something they HAVE to do. I know it isn't and so do you. My example of the Craigslist ad sequence is being repeated all over the country. I personally GAVE away a set of rear brakes because I didn't figure I'd never need them. Plymouth parts are CHEAP everywhere but eBay and some of the specialist suppliers. I was a professional mechanic for more years than I will admit and I know it takes a professional more time to straighten out something that another guy has decided to re-engineer. That's why I mentioned the regrettable post on this forum. I'd rather not buy a car (even a nice one) if someone has re-engineered it. Like you say you can "click" on 1992 Ford Explorer to get replacement shoes. However, the next guy who owns your car may not have any idea what rear brakes are on it now. When he "clicks" on 1954 Plymouth nothing is going to fit. I may well have been harsh and I do apologize for that. Please do not be discouraged. I will read your posts with great interest and that is why we post isn't it? Like others have expressed, I'd like to know how this project turns out.

-

The problem I have with this video is that there is some misinformation here. 1) The stock axle is weak. It is not. It's a very good design built very well. 2) The stock axle is expensive to fix. It is not. It uses Timkin Tapered Roller Bearings in standard sizes you can get anywhere. There are no proprietary bearings in this axle. If you think a supplier is ripping you off selling you cheap Chinese bearings at premium prices, then go to an industrial bearing place and buy genuine Timkin bearings and maybe save some money. 3) Only recent manufactured axles have the right ratios. Wrong. The example the video uses is 3.25 which is a pretty low numerical number for a Flathead 6. My P17 is the lightest mopar of 1949 and it came with a 3.73. I have a 3.54 ready to go in once I finish some other projects. With an Overdrive (which he does talk about) 3.25 in a 4 door is maybe too low a numerical ratio. Here's the rub, if he later installs an Overdrive, he'll be changing the axle once more. The axle he used is an integral unit. It is not easy to change ratios in those. With the stocker you simply change the 3rd member. If I am wrong about the 3.54 I can easily and quickly change back to 3.73. 4) Back to expensive to fix. Recently I saw a Craigslist ad for Mopar axles. The guy had 12 of them. He asked $100 each and got no takers. Then he asked $100 for all of them and got no takers. His last ad was FREE come and get em! My point is they don't break and if you need another one (to replace a bent axle like he had) they are CHEAP! Why enter into an engineering project if you don't have to? 5) Please refer to "Educate me about wheels and tires (and hubs and axles)" November 20th on this site. Then you'll know exactly why I do not recommend changing axles and brakes. 6) No body talks about getting your speedometer to read right. I do. The beauty of Mopar stuff is that there is continuity of design. In the cheapest Mopar of 1949 (my P17) I can use parts from bigger Chrysler Corp. cars. The speedo gears I used in my Overdrive came out of the original 3 speed. When I change to the 3.54 ratio I'll use a gear from another transmission (like a DeSoto I know about). All you need is a thin wall 1 1/16th inch socket and your life is simplified! 7) Modern brakes are better. Debatable. If you have the tools and the skills (or know someone who does) its not an issue. Friction is still friction, lining is still lining. You can still have your shoes relined with the very latest technology linings if you want. If your Lockheed brakes are done right they will perform very well and some folks prefer them. On the rear end of a light car like my P17 there is no reason to change the rear brakes. I have 12 inch Chryslers on the front and under certain conditions I can lock up the rear brakes so I see no reason to change them. Putting something bigger or more powerful on the back will make the car LESS safe. Spend your time and money wisely is all I am saying. Don't scrap the original design without thinking about it very carefully. The engineers who designed the Plymouth knew what they were doing, have confidence in them.

-

A engine rebuild theoretical discussion...Piston Sealing

Loren replied to James_Douglas's topic in P15-D24 Forum

Beautiful stuff! That is definitely a "Needs vs Wants" discussion item! Those rods are way over kill unless you're going to use a blower! lol The pistons are very modern and likely the best you can get. I definitely want it but....need it? Well maybe not. But I still want it! -

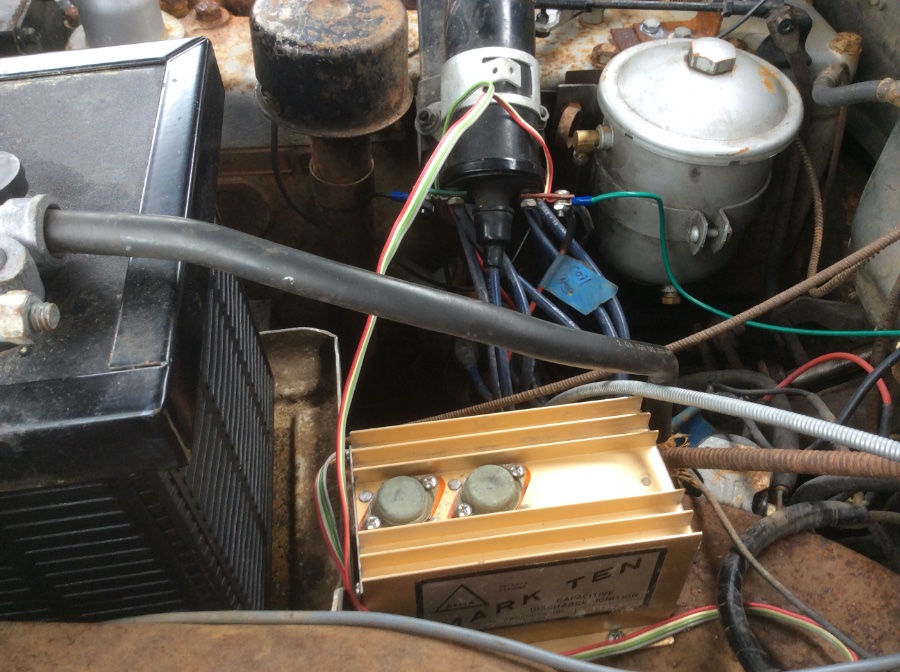

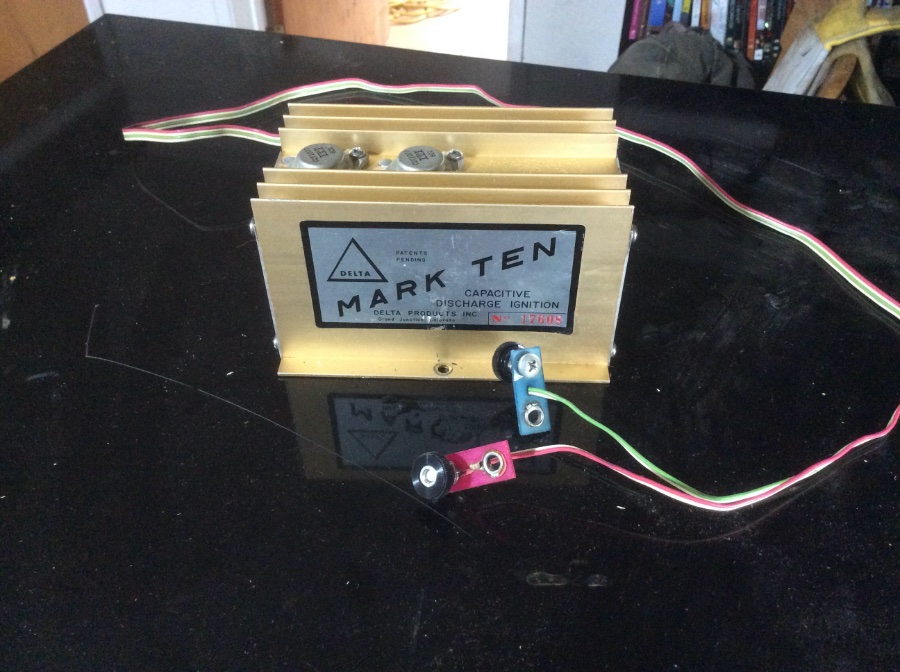

There's no question the best idea for ignitions has always come from the General. When Billy Durant bought Dayton Electric he got Charles Kettering who wasn't really an engineer, he was a scientist. Automotive ignition systems where pretty primitive in the early cars, most were vibrator coil types run on dry cell batteries in mass market cars and magnetos in expensive ones. Kettering is the genius who gave us the "battery coil" type we know as the "Point type" ignition. Durant also bought Remy which had a very poor reputation and merged them with Kettering's Delco (which had a good one) to make Delco-Remy. The gold standard for ignitions with distributors is the GM HEI, mostly because they've made so many of them and they work well. That means the aftermarket is full of innovations like Multi-spark units. We can enjoy the benefits of HEI from Langdon's StoveBolt. BUT they are 12 volt only. So what to do if you want to stay with 6 volts? Well I am glad you asked! During the 1960s there was an outfit in Grand Junction, CO called Delta Products, Inc. that made the ubiquitous Delta Mark Ten CDI. These were sold as assembled units and kits a hobbyist could build. Add to that the Delta Mark Ten B units were sold by Radio Shack (Archer & Micronta) and HeathKit. At Delta's peak they employed 500 people! So they were not a flyby night outfit by a long shot. 6 volt Mark Tens are rare and positive ground ones are rarer still. Delta never made a "B" model in 6 volt. The "B" model adds a switch to revert back to point ignition and that's all. So what's the big deal? A Capacitive Discharge Ignition fundamentally changes the way an ignition makes a spark and the type of spark. In Kettering's ignition when the points close a magnetic field builds in the coil. When they open the field collapses and a spark is delivered from the coil secondary. The points see an electrical load from the field and when they open the field still wants to draw current through the points so there's a spark at the points as well when contact is broken. In CDI the spark is produced by a capacitor discharging the current stored in it. The ignition coil is now used as a transformer to step up the voltage of that discharge. By using the points as a SIGNAL for the circuitry to charge up the capacitor instead of acting as a SWITCH to build a magnetic field in the coil, less current passes through them and they last a very long time. The Kettering Ignition produces a slow building spark that has a long duration, where as CDI (including HEI) is very quick acting and thus very intense. Imagine it this way the maximum most stock coils put out is around 40,000 volts, if you pack all those 40,000 volts in a shorter burst it is going to be intense! That long slow building spark erodes the plugs and if there's anything that would impede the spark, it does. That's why all the old 2 stroke SAAB owners loved the Delta Mark Ten. So is CDI going to make your car faster? No. However, it will make your points and plugs last longer. In the old days a tune up would last 6,000 miles and be trouble free. One of the first SAAB 99s with electronic ignition came in on the hook where I worked. The customer told me he had only changed oil for the last 80,000 miles! I did an 80,000 mile service and it ran like new. A point type car would have needed a dozen tune ups by then. Which is why Delta Products asked for and got an approval from the CARB. So how did I get to the point of trying one on my P17? Well I knew about the Mark Ten from my SAAB experience and I wanted to be able use something like it. Perlux has a 6 volt ignition which fits inside the distributor and they are inexpensive. However they are modern and easy to get. There's just not enough romance for me in that! lol In my research I found a fellow who repairs them and who had a 6 negative ground unit on his shelf. I contacted him and he said he might be able to convert it to 6 volt positive ground. He was a little busy at the time so I'd have to wait. In the mean time I went looking for 3.54 ratio rear axles on eBay (found 4 of them) and in one photo of a car I saw a Mark Ten 6 volt positive ground CDI. I bought it and sent it off to Jim to be repaired/tested. Now I have two! Jim said he'd only seen ONE on eBay in the last 10 years! The old car hobby is supposed to be FUN. I can't tell you how much satisfaction I got when the old P17 fired right up and ran so sweetly with the Delta Mark Ten tucked under the hood!

-

A engine rebuild theoretical discussion...Piston Sealing

Loren replied to James_Douglas's topic in P15-D24 Forum

I believe the purpose was to differentiate the then new Mercury from the Ford on the spec sheet. 1939 being the first Mercury which was a one year only model. The critique of the 39 Merc was that it looked like a fat Ford. The 1940 (at least to me) looked quite a bit different. By 1949 the Mercury had established its own identity (only to be lost again later). The V8 guys I knew never said anything about how the thin sleeves performed and they only talked about removing them for Mercury displacement. Think about it. You drive your car till the bores wear out and it smokes then you punch the sleeves out replace the pistons and you've got a new Mercury engine in your Ford! Another interesting thing Ford tried were steel pistons. As light as aluminum but stronger. They didn't stay in production long either. On diesel engines it is very common to see an steel ring cast into the piston for the compression ring groove. They also will cast a salt ring in them, then wash the salt out leaving a channel for the oil jets to squirt into. Ring placement has a lot to do with reliability and compression. Closer to the top of the piston increases the compression BUT....too close to the combustion chamber and the compression rings get hot and loose their tension. I've worked on cars that the compression ring was too close and they were fine unless overheated, then they had no compression. On later versions they lowered the compression rings and they never had any problems. -

In the downloads section there are instructions and drawings of the factory PCV kit. It does talk about carburetor parts that need to be changed on the B & B carburetor. One thing that caught my eye and started me thinking was the difference in air cleaners. P17s have a nice looking Oil Bath that has no "Silencing Chamber." While the Special Deluxe had a big clunky Oil Bath that did. I always remembered my P18 was much quieter than the P17 I have now. Now I know the reason or at least one of the reasons. So on my next trip to my storage I am going to dig out my collection of air cleaners and do some experimentation. If it isn't a fire breathing race car, it might as well be quiet.

-

A engine rebuild theoretical discussion...Piston Sealing

Loren replied to James_Douglas's topic in P15-D24 Forum

You'd think those thin wall steel sleeves would have been a real good thing. The hot rodders couldn't wait to push them out and install Mercury pistons. I guess cubic inches were thought to be more important than reducing internal friction and longevity. Ford didn't use them for very long as they must have been costly. -

A engine rebuild theoretical discussion...Piston Sealing

Loren replied to James_Douglas's topic in P15-D24 Forum

You can't really change the material of the block without sleeving it. The closest thing would be hard chrome plating and the only way to do that is at a shop with a huge Barnes Drill Hone. Which are kind of rare these days. Grinding is out of the question as an I.D. grinder would have to be huge to swing an in line 6 block, a "wobble grinder" would be the best bet and they are super rare. There is only one outfit I know of that chrome plated automotive cylinder bores (Chevy Vega) as a regular business. Chromall in Los Angeles. I know they are still in business because a month ago I had them do the cylinder shafts from the tilt on a forklift that was vandalized. The cost might be unacceptable however. Chrysler made the 237 DeSoto, 251 and 265 Chrysler engines, keeping the same pistons but altering the crank and the rods. Each longer stroke got shorter rods. Since the bearings were all the same, you could put longer rods in to help with the rod angle then move the wrist pin up to accommodate the stroke. Longer rods with the longest stroke might not be doable because of clearance issues at the bottom of the bore. Next Item I'd look at are piston rings. New materials enable you to use fewer rings lessening friction and wear. Auto makers have tried Low Tension Rings to accomplish fuel economy goals but they have been a disaster with oil consumption (1 quart in 600 to 800 miles is not unusual!) The pistons themselves have potential for lessening cylinder wear. New engines have shorter skirts with low friction coatings on them. Cast Aluminum comes in new flavors as well. Silvolite uses a special alloy for their Keith Black pistons which bridge the gap between cast and forged. There's lots of new stuff that can be done to improve reliability and longevity. -

One of the benefits of a PCV is that it puts the crankcase under vacuum. Part of the combustion products are water vapor. When you put the crankcase under vacuum it de-hydrates the gases and by doing so it keeps the engine free of sludge. There is one thing to remember, if your engine already has lots of blow by a PCV system might not have enough vacuum to accommodate it. The hose to the air cleaner does two things, provides make up air for that which the PCV has sucked out (creating a draft) and providing an outlet for excessive blow by. My Dad tended to drive cars into the ground and when the law required a retrofit PCV in California, the blow by was such that the rear main seal started leaking like mad. So the rule is check the blow by before you install one. If it's not bad then go ahead. A PCV is the one smog device which actually has some benefits to the engine.

-

Good luck to Knuckleharley! I remember when some guys my Dad knew took a Dodge like the one thebelvedereman just got to a "Destruction Derby" at Saugus Stadium back in the early 1960s. Seems like a shame now. There was a very good looking 1940 Oldsmobile in that derby too. All the cars at that time ended up in the scrap yard on Monday morning. So it was like the racing scenes in the movie "On the Beach" literally there was no tomorrow. Being from Southern California, I also remember the Powell Bros. Pick up trucks when they were new...correction...when they were being sold. The Powell truck of course was made from 1941 Plymouths salvaged from SoCal wrecking yards in the 1950s. It is estimated that they sold as many as 2,000 or 3,000, at least that was the count from the salvage operator that supplied the Plymouths. They had to be very cheap because the 1955-56 Fords and Dodges were pretty nice trucks when new and they were much cheaper than cars at the time. When you cruised Bob's Big Boy Drive-In in Toluca Lake the car to have was a "Route 66" Corvette, a 1956 Ford Pickup with the wrap around rear window, a Chrysler 300 or a James Dean 1949 Mercury. A Powell wouldn't make it. You had to park that on the street and walk into the restaurant. lol

-

Gosh Marc I don't know about 1948 and earlier. At the bottom of the shaft on my car the sleeve that is holding the shaft in is splined. You take the nut off and it slid out. Could your's be rusted? Something small like a battery terminal puller might work. I'd line up a bunch of spares before I used a heavy hand on things. Good luck!

-

When I got the car I thought the shifter was kind of stiff but it only had 37,000 miles. So I didn't think much about it. Over the time I've had it the shifter has gotten stiffer until I had to do something about it. I knew it wasn't the transmission because I had changed it to an Overdrive and it worked the same. I read the shop manual and that helped to familiarize me with the various parts but in the end that did not point to the problem. Finally I isolated the stiffness to the support bearing just under the shift lever. To remove it you take the shift lever off and at the end of the shaft (in the engine compartment) there's a 9/16 ths nut that holds the other parts together. If you're careful they all stay in place (held in by the coil spring) and the shaft will slip out. In order to get it past the steering wheel you need to remove the two screws from the column support under the dash and the two screws from the support bearing, then you can slide it out with the bearing. There was plenty of rust and dirt on the shaft so I wire brushed it before trying to remove the bearing. Once I had it out I dropped it in a can of diesel fuel and put that in my ultrasonic cleaner surrounded with water. That freed it up a little but it was still too stiff to use. While moving it back and forth I discovered it moved further counter clockwise than clockwise...indicating it was threaded. So I unscrewed it till the center came out. Inside the support bearing I found what looked like a Leather sleeve the center part was screwed into. That part went back into the ultrasonic cleaner while I wire brushed the center part. After drying the part off I liberally coated the threads with Vaseline inside and out and screwed it back together. Now it felt very nice indeed. I am thinking the leather is there to dampen any vibration with the threads offering some resistance. When the leather drys out it really resists being turned! Now it shifts nice and easy. A modern car would have a design that has plastic parts that you'll never find replacements for unless they break a lot.

-

I was working on a Model T and I needed to know the center to center distance between the crankshaft and the camshaft. So I went to the Model T Ford Club website for that data. What I found was that some member had measured a dozen blocks and came up with a range of numbers carried out to 5 decimal points! Since Model Ts have poured babbitt main bearings I found that crazy. Poured babbitt bearings are reamed with a line boring bar that registers off the cam bearing bores in the block. It uses a "false cam" and an arm front and rear to align the crank with the cam. If you know what the desired measurement is you can figure a tolerance + or -. An average of the range of 12 blocks gave a number that did not make sense. No engineer picks a size that requires 5 decimal points to express especially when the measuring equipment of the day could not measure better than 3 decimal points. I went to my decimal/fraction chart on the wall and found exactly what I was looking for. The Model T measurements were in fractions not decimals because that was the best measuring equipment they had then (the period of around 1906 to 1908). The closest fraction size gave me what I needed to know plus I could guess a tolerance. The decimal guess of the Model T club member was a little off to one end of the range. If I had made it the average the cam gears would be noisy or they would bind. There are a lot of odd ball stuff in automotive engineering. Check out the oil tube between one side of the Plymouth block to the other. That is an unusual size for which you can't buy fittings for.

-

If one has to have Bendix style brakes it would not take much to adapt the Bendix backing plate to the stock rear end then you could have your choice of 10x2, 11x2 or 12x2 inch Mopar drums. It would take a really sharp eye to notice the difference. One might even take a look at when Chrysler switched over to the Bendix style and you might find out they will bolt right on. I am not saying they do but I doubt Chrysler changed enough that they couldn't be made to work. Common ratios available for the stock axle are 3.54, 3.73, 3.9, 4.1, if you find you need something outside of that range, then you might want to change the rear axle. However, my choice would always remain with the separate Differential Carrier type such as the 1957< Chrysler 8.75 or Ford 9 inch. I am getting too old to wrestle with complete rear axles or setting up ring & pinions under the car. I have the tools for Dana 44s and have done many. I just don't care to do one under the car or truck anymore. The stock axle was/is really well designed for its day. The 1957< Chrysler 8.75 is the logical evolution of that design sized up for more power and torque. That would be my first choice, but because they have such a good reputation they command a hefty price. You can sure afford a lot of stock axle parts for those prices. As i said before, I'd be spending my time and money on other things with a greater return on investment. But then your mileage may vary and it is of course your car and your choice. I used to get in arguments with my Dad about "Needs" vs "Wants." He hated it when I told him "You don't need that to go faster, spend your money elsewhere." He always got what he wanted but when it came time to race (the Dry Lakes) he always drove cars I built, because his stuff was never ready. I learned my lesson years ago that engineering projects rarely work right the first time. Better to use proven stuff than re-invent the wheel. If it bolts right on then it may work well first try. On rear axles: when you see a car crabbing down the road, the cause is usually the rear axle is out of alignment. If you never take it out, you'll never generate such a problem. Just sayn'

-

Speaking of only the three axles mentioned in the video, all are integral housing types. That is, if you want to change ratios you either pull the entire axle or you do the work on a lift. If you have a lift and the skills required that's fine. If you don't have one or the other you'll want to pull the entire axle. Of the three the Dana 44 is the most desirable. However, its design for some folks is a step backwards from the stock Plymouth axle. Your Plymouth has a removable Differential Carrier (most likely a 3.73 ratio confirmable by looking at the area under the fill plug where the ratio is stamped) which means if you want to change ratios or you need to change a bearing, you do not have to remove the entire axle, you simply remove the Differential Carrier. This design is why the Ford 9 inch and the Chrysler 8.75 axles are favored over the Dana 44. The stock Plymouth uses all standard Timkin Tapered Roller Bearings so if you need a bearing you can go to any bearing supply or your favorite Mopar parts supplier. Plymouth did not use the dreaded C-clips in the stock axle. The axles are retained by the out board bearing and they rumble a lot before they fail. I've had Dana 44 axles leave the vehicle with the wheel attached. Ford 9 inch and Dana 44 use a double row ball bearing and when they fail the wheel takes off. Those outer bearings on those axles are a pain to replace, where as the stock Plymouth is much easier. The only draw back to the stock axle are the keyed tapered hubs. If you have access to a good heavy puller, they are not problem at all. The cost of a good puller is less than replacing the rear axle. For my money there's not much of a case for changing the stock Plymouth axle. They wear out like everything else, but they rarely break (I've never seen only break). So for the money vs benefit of changing an axle I'd rather put my money somewhere else, like an Overdrive transmission. Just sayn'

-

Old time mechanics always had black marks on edges of their shirts. Before they installed a set of points they would rub them on the cloth to make sure there was nothing on them. Any oil from manufacturing or preservative would burn on the points and cause a "come back." If you have a dusty road and one of those GM "Window" distributor caps, the dust gets burned into glass and the points won't close.

-

Want to start engine on my 48 DeSoto with body off

Loren replied to MarcDeSoto's topic in P15-D24 Forum

I wouldn't start it with out the body on. The body will get jealous and will let you know its been offended by developing a rattle that you'll never find! JK You might strap a box to the frame and go for a ride. I would. Just think of how easy it would be to double check stuff. -

I've heard it said that the Americans and the British are two people separated only by a common language. As I recall that quote came from the film "Patton" from 1969.

-

My most recent pet peeve with disc brakes has nothing at all to do with their design. Cars have gotten so reliable and so long lived that dealer mechanics have lost their expertise. A foreign brand has wear sensors in the brake pads that trigger a dash light when a little more than 1/8" pad is left. Yet the mechanics try to sell you brakes when fully half the pads are left! 4 years ago they handed me an estimate for $650. I asked if that included turning the rotors or replacing them? "Oh we don't turn the rotors we just replace the pads." A quick glance at the estimate indicated that they charge $450 labor to change the pads! I never went back and 10,000 miles later the pads were still only worn 1/2 way. My daughter got the same treatment recently from another dealer only her estimate was $3,500! (front & rear) So I've concluded that the mechanics have so little to do they have to cheat in order to make a living. I went to a Toyota dealer for differential parts for an early FJ Cruiser (they have a particularly weak rear axle). I was told they don't stock parts for them because no mechanic employed there can rebuild them, but the do stock complete assemblies! The mechanic's trade has really deteriorated to the point I don't believe it will recover. On the modern cars with front or 4 wheel drive, the wheel bearings are double row ball bearings. That's not a bad thing but there's no adjustment like Timkin Tapered Roller bearings. So it's a good idea to check for wear. Usually they make noise when worn but sometimes they don't. If there's any slop in them the brake pads will wear faster. With worn bearings every time you turn, you load the bearing and that puts pressure on the brake discs. Then there's the dreaded "Snake Tracking" you have to be on the look out for! lol