-

Posts

2,561 -

Joined

-

Last visited

-

Days Won

83

Everything posted by Sam Buchanan

-

The bung on my replacement tank was NPT threads, no ferrule needed. I used a brass NPT barb fitting to transition to rubber fuel line.

-

What is overlooked many times is NPT fittings are designed to provide a seal via interference between the threads on the male and female parts of the connection. If the threads perform as designed no sealant is needed. In order for this interference fit to occur the male and female threads must be free of imperfections and torqued to the proper spec. But these fittings are mass produced and often the threads do not form the interference interface as designed and we are reluctant to apply as much torque as is needed to overcome the imperfect fit. There can also be difficulties in achieving full interference fit if a 90* fitting needs to be clocked a certain way. The main purpose of teflon tape is to serve as a lubricant so more torque can be applied to the fittings and the thread interference engaged. Use as a sealant is a secondary function of the tape and can assist in sealing without full interference torque being applied. Paste sealants work in the same manner as tape. Care must be taken with the use of tape or sealant to assure nothing is introduced into fuel or especially oil passages because the tape or sealant won't dissolve once clogging a fuel or oil passage. Proper technique will prevent this failure and keep us from having a sad day.

-

If the seal is dependent on tight threads, use sealant. If the seal is dependent on a tightly fitting flare, sealant on the threaded nut holding the flare together is not needed, the threads aren't forming the seal. A highly regarded sealant:

-

Yep, sitting on the cowl, fender or bumper is "in contact with the car". Boat and aircraft fires from using plastic cans is a reality, especially in low-humidity climates. There also has to be a reason for the federally mandated placards on gas pumps.

-

On the ground at the gas station, in contact with the car when using it for test running.

-

The static issue arises when there is a difference in the electrical potential between the tank and vehicle which can result in a spark during fueling. The plastic tank sitting in the bed of the truck, even if it is wood, would drain potential and come to equilibrium with the truck so static discharge wouldn't be a concern. The danger with filling aircraft (or boats) with a plastic can (and I've done this many times) is the aircraft immediately after flight can be holding a static potential that built up while rapidly passing through air molecules in flight. The plastic can isn't grounded to the airframe and a potential difference between airframe and can may exist resulting in a spark. The solution is to either use metal cans that are grounded to the airframe or make an effort to have contact between the plastic can and the airframe (or boat) so hopefully a potential difference is dissipated. I've used a welding rod inserted into the can and connected to the airframe with a cable and clamp to dissipate static potential. This is why the gas pumps at your local station have a placard warning us NOT to fill our plastic cans when they are in the bed of our truck. They should always be on the ground which puts them at the same potential as the grounded pump so static discharge won't occur. Now back to your regular programming.

-

-

Ditto. 8-10* BTDC works well in my P15 with 87 octane contaminated gas.

-

12-24 is #12. Zinc plated steel will be less likely to be damaged by a screwdriver than softer stainless.

-

Those are #12 which is not a common size these days. I couldn't find any locally so ordered from McMaster Carr. https://www.mcmaster.com/products/screws/thread-size~12-24/

-

Yep, Tractor Supply. I like this set because it has the 90 degree plug boots like the original wires. https://www.tractorsupply.com/tsc/product/tisco-spark-plug-wire-set-sws260 I doubt wire sets with the plug connectors already attached will fit through the loom tubes on the engine.

-

I don't think you are going to find different "brands" of plug wire sets for these cars due to how long they have been out of production. As noted above your choices are to purchase a pre-fabricated set from a vendor that caters to our community or get a generic set from your local auto parts store and cut-n-fit to your application. The subset is solid core wires (consist of an actual copper wire inside the insulation) or resistor wires (consist of a carbon core which inhibits electrical interference with a radio). Either type will allow your engine to convert gasoline into noise. I put a set of solid core cut-n-fit wires on my P15 since it has no radio and the wire set was readily available locally at a very reasonable cost. Fabrication of the wires is a simple process, just fit and replace one wire at a time.

-

As Abraham Lincoln was quoted as saying......"Don't believe everything you read on the internet".........

-

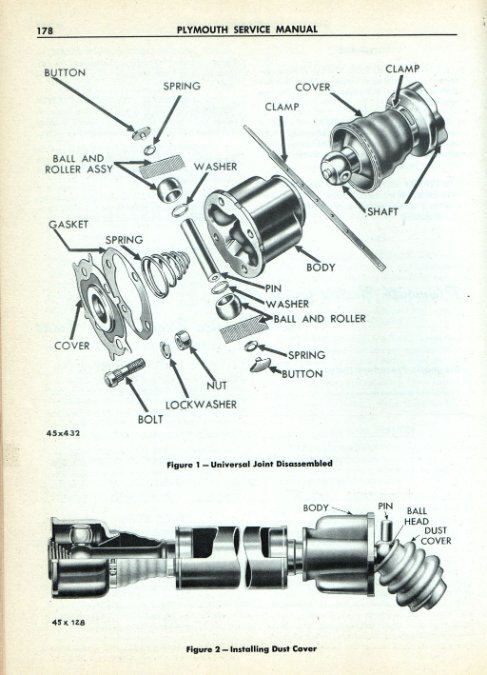

Not the case with our cars. Sniper alluded to this in a post above when commenting about driveshafts that have splined slip joints that can be pulled apart and reassembled out of phase. But that isn't the case with the trunnion driveshafts that came on old MoPars. It isn't possible to get the trunnions out of phase because the housings are welded to the shaft. This is another case where "conventional wisdom" doesn't apply to our old cars and why we need to be familiar with the unique aspects of these cars before making blanket statements. After the flywheel and clutch have been serviced/replaced the "factory" balance is long gone....and I suspect the driveshafts were balanced prior to installation on the chassis (balancing an entire drivetrain would be quite the process....LOTS of moving parts). But if someone wants to mark and index the driveshaft prior to removal that certainly won't hurt anything.....but it will only reinstall two ways (well, maybe four if swapped end-for-end...) Just for educational purposes here is the trunnion-style driveshaft which isn't remotely similar to modern driveshafts. Notice how variations in length is accommodated by the springs inside the joint instead of the modern method of splined slip joints. And also the infamous wickedly difficult to install boots! ?

-

Good to see you are pleased with your installation.

-

Why is that?

-

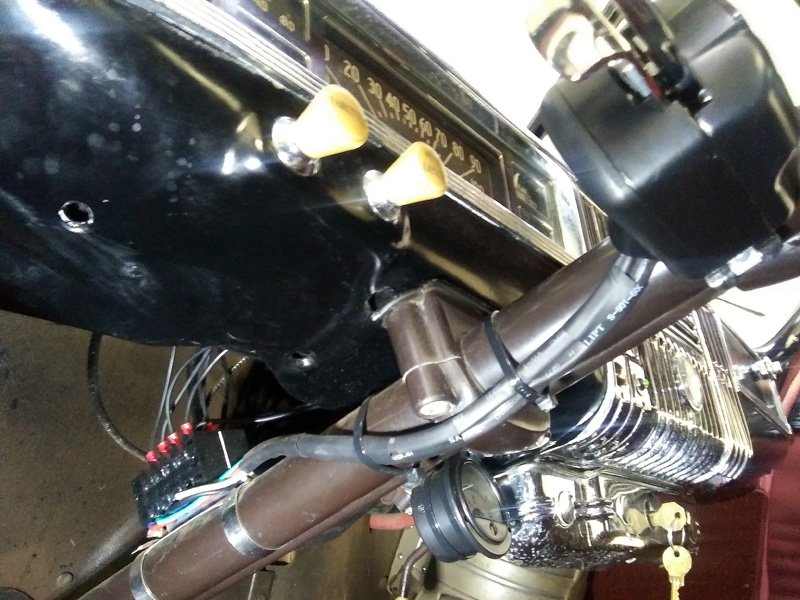

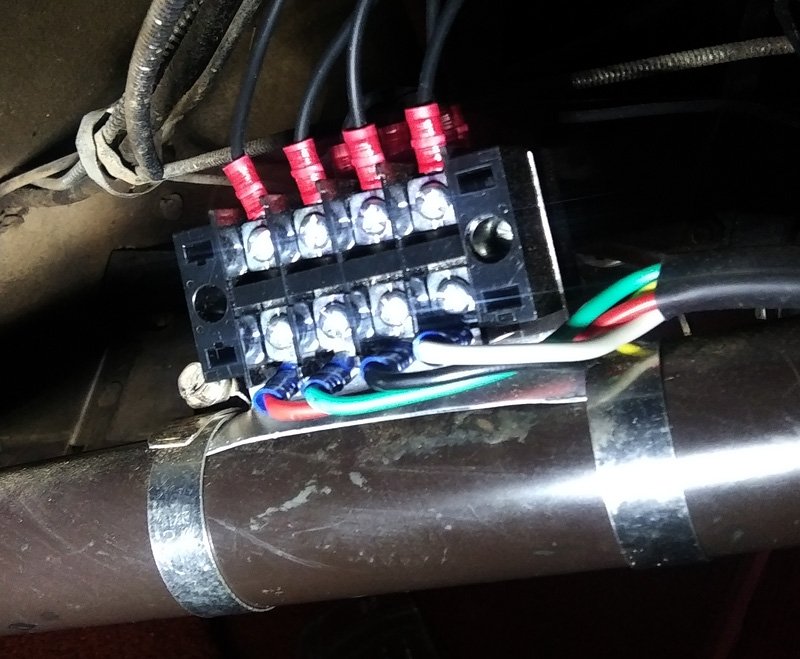

It is actually a quite simple installation. The key to getting full functionality is to adapt the stock light fixtures to dual filament bulbs. This is easily done with these pigtail adapters: https://www.ebay.com/itm/283429109868?hash=item41fdb1006c:g:7CkAAOSwV0NbCIOL&amdata=enc%3AAQAIAAAA0HgtlcEDd03CCb35P8AcfPD0l75EIPot8TBuNzMpFZetvJohSU5wqrVKG2SNannijZA%2BXyByfxNiyYRG1AhIlWO3Q%2FoLB2ftHanrlsx4TCx1pw8J%2F0wfvdFzaZF7lxGylqSMykPrETYG3L0LY9PCTW%2BYWN%2BKLoneIao5DUXRInIfqNjAZgWDId%2Bbpu7L6CNRkzGKpyqt0Iu6iPwreUsB%2F2jbcvmyAW5xDfvWyQIQgeQlnaoEasTuqasLiNcwRT3k0urLFgrUHfCrQVQdEzo3wxA%3D|tkp%3ABk9SR5T-9MDLYg Here is the Signal Stat switch that includes ALL wiring needed except for the flasher unit: https://www.ebay.com/itm/Universal-7-Wire-Turn-Signal-Switch-Signal-Stat-900/143096919345?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m2749.l2649 Just connect wire A to wire B.......no relays or additional switches needed....very simple. This gives you the same functionality as modern cars using the stock light fixtures.

-

Way back in the previous century when I was just a youngster my first car was a 1963 Beetle. A stop sign on a rural road was partially obscured by foliage (that is my excuse...) which resulted in me reducing the very high velocity of the poor bug to stationary status in as short a space as possible. Just before all the speed was bled off the brake pedal went to the floor and I rolled out into the intersection. Fortunately the mom in the big Buick had seen me in time and was able to stop sufficiently that only the driver door on the Bug was caved in. A very close call. A steel brake line had ruptured which meant the single chamber master cylinder lost all pressure. Many decades later I still remember that near catastrophe......my P15 has a WilWood dual chamber master cylinder....and ALL new brake lines and hoses.

-

If you have any doubts about brake system integrity........don't drive the car, fix the brakes.

-

I like the way my P15 runs with timing set at 8-10* BTDC (strobe at idle, vacuum advance connected). Did you file the points before or after you set timing? Timing needs to be set after gapping points because changing point gap changes timing. Are you referring to cold or hot hard starts?

-

If you can get metric fittings to thread properly into old Mopar master and wheel cylinders you're golden........

-

If you don't want to flare tubing nicop lines with installed fittings are available in various lengths at your local auto parts store. I replumbed the brake and fuel systems on my P15 without having to make a single flare, just connected the appropriate lengths of tubing. Just make sure you get tubing with the proper fittings, lots of metric fittings out there.

-

The aftermarket tank in my car just has a metal tube extending from the tank fitting to the bottom of the tank, no filter or sock. Probably a good idea for those of us with these tanks to drain (flush?) it every year or so to remove any particulate that might accumulate.