-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bryan

-

The CFM would be for the entire engine. Would the 220 CFM be shared between the 2 carbs? I would check the spark plugs for mixture, and make sure there are no leaks and the float levels are correct.

-

Even more so..I modified the drawings after thinking about it more. There may be a reason why there are gaps between certain cylinders. Might be to direct more flow around the exhaust valves. The holes to the head are also larger in those areas

-

After I cleaned my engine out and looked how the water passages are designed, I can only assume they wanted to cool the valve seats and head area. The distribution tube has holes only in the top. If installed according to the manual, it should be flared at the front to allow no water slip around the front. The water goes up to the head towards the thermostat. They didn't even have the distribution tube holes on the left side towards the valve area to make flow go up along the valve area then to the top. Directly goes to the seat area. There are no feeds at the bottom of the cylinders. Reckon there's some kind of convection current that moves flow up to follow the flow across the top of the head. You would think hey would have made holes progressively larger towards the rear of the motor. Well, when clean it works, but strange.

-

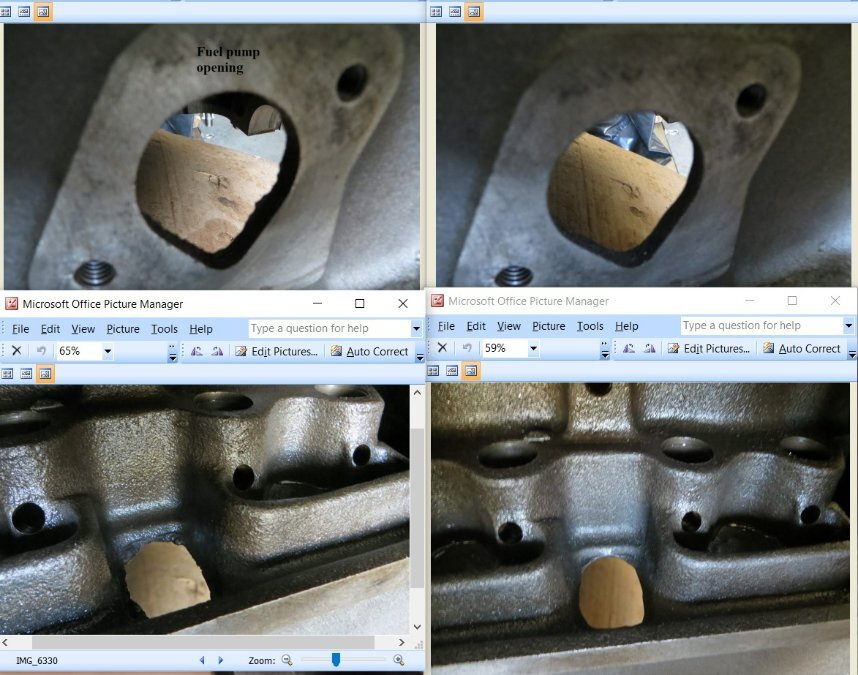

Does anybody know what THIS hole is for? Little hole in pump that goes directly to big hole in block. It's not the bypass hole I just plugged.

-

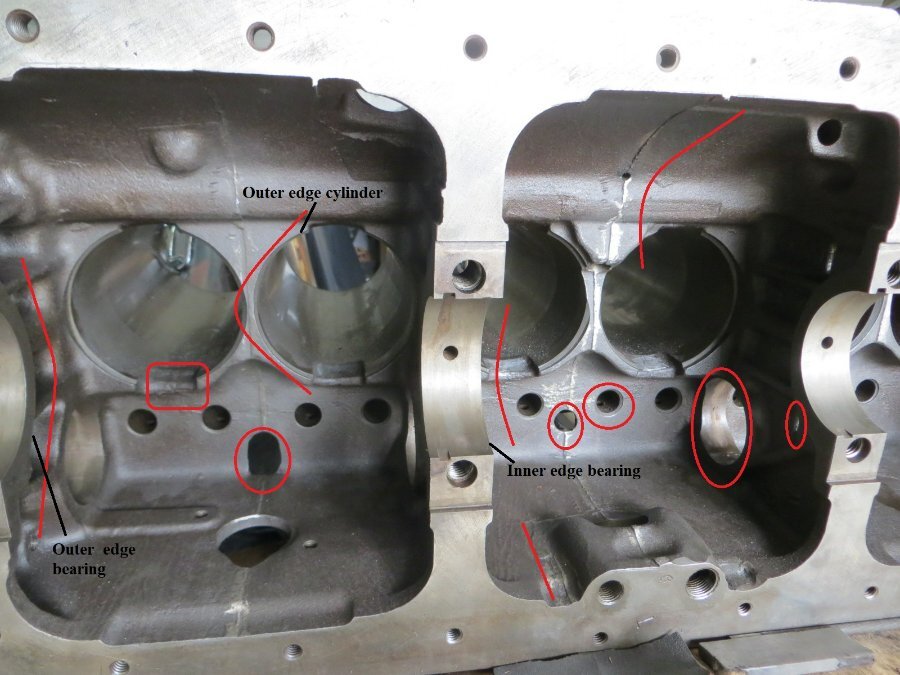

On the inside I used a dremel grinder on the casting ribs. On the rest I just did enough to barely remove the roughness of casting, not even a bevel edge. On tappet holes I used 150 grit sandpaper and my finger tip. On the outside/inside edge of the main bearings I used the end of an Arkansas stone. Also on the inside edge of the oil pan. Again, just enough to smooth it, not create a beveled edge.

-

Haven't heard of that but I'll look it up. Just doing the basics. Don't get me started. ?. After working near the oil pour tube I was wondering what the entire engine outside would look like ground smooth and painted. Wish I had the money for some Ross custom pistons, but naw. I'll probably drive it on Sunday, the wife to the library, some local car meets. Just didn't want any loose casting edges coming off, I did find that the inner main oil passage to the galley are exactly the same size as my fine rat tail file.

-

Deburred the block today. Cleaned off ridges on the driver's side of the block. Also inside the block. Plenty of sharp edges. Also use a wire brush on a drill to clean the outside a little more.

-

Only thing I could find is the guy that did mine before. rfurtado1 on eBay

-

-

Too late, I done did the wild thing with the brushes. Yep, I use the CRC also..have about 12 cans of it. Works good but now and then I get a can that runs out of propellant with the can about 1/4 left.

-

More deburring work and port cleaning today. A lonnng day. Deburred around the oil holes in the tappet galley, the fuel pump opening, around the tops of the tappet holes (tappet hole edges with 150 sandpaper and my finger), little bumps next to the side of the tappets in some places. Cleaned up the ports and somewhat matched them to the gaskets after comparing the gaskets with the intake and exhaust manifolds. I chickened out and didn't want to remove a lot of metal, didn't know how the ports internally are connected to the face. I know there is a LOT of water jacket open space around the valves and intake/exhaust ports. I removed just enough metal to make the edges even with the port surfaces further in. Worked on the valve areas too, but just a minimal toe remove sharp edges. The valve seats are sitting on a narrow ledge of metal in some places, didn't want to undermine that by grinding.

-

More carbon buildup in #1 + #8 cylinders than the rest....Why?

Bryan replied to 48 New Yorker's topic in P15-D24 Forum

How does heat range on a plug affect how much carbon builds up on the piston? The plug burns hotter or colder based on the range, but that only affects the plug. It doesn't affect the mixture. I shouldn't even say burns hotter. It retains more heat and has less deposits. The spark is the same. -

More carbon buildup in #1 + #8 cylinders than the rest....Why?

Bryan replied to 48 New Yorker's topic in P15-D24 Forum

The only thing separate are spark plugs, each wire, valves and rings. Whatever timing or mixture all should have in common. One thing I noticed on mine (6 cylinder) are the water passage holes are different near the cylinders, and the further spaced cylinders (from each other) have a water passage space between them in the block. The closer ones are joined. -

Thanks. I have the bottom to do and then I'll deburr the block and clean the ports up. One thing with the gun brushes, it leaves tiny brass bristles. I'll have to pressure wash it again at one point, but would have to anyway after the grinding. I looked at the water jacket areas. They are all around the ports and the valve areas. Can't take too much off in the ports, just gasket matching and cleaning off edges.

-

From what you're typing it sounds like it already is right hand drive. Are you trying to change it to left side steering like in the USA? Confusing.

-

Finally, except for the bottom, got all the threads cleaned and chased, water holes on top of block cleaned, core plug openings cleaned, and knocked around with a small round file in the water passages between cylinders. Also cleaned the tappet bores and oil holes with shotgun bore brush. At one point I'm going to dip it in vinegar. Takes too much evaporust. Keeps knocking the pics out of order when you post.

-

The valves and spark plug are way on the other side and totally away from the piston. Easy to forget on these engines. Done it a few times. The piston can only meet the flat part of the head.

-

Got my REMY remanufactured starter on Friday. Got to check today if it is the same fit as old. Plus somehow check it. Don't have a 6V battery or charger at the moment. Spent enough this month.

-

Was looking at it again, waiting for the temps to warm up outside. On higher performance engines with thermal expansion and RPM stretch could lessen gap by as much as .02. Minimum Quench / piston to head clearance ? | Hot Rod Forum (hotrodders.com) Given people on this forum were stating compressed gasket thicknesses of ABOUT .040 don't think I'd ever want my pistons more than flush. Not building a hot rod but don't want to lose any HP.

-

Bought this from a welding shop that makes trailers. Cheaper than Tractor Supply sold them. Ended up using it a lot to clear out my father's barn.

-

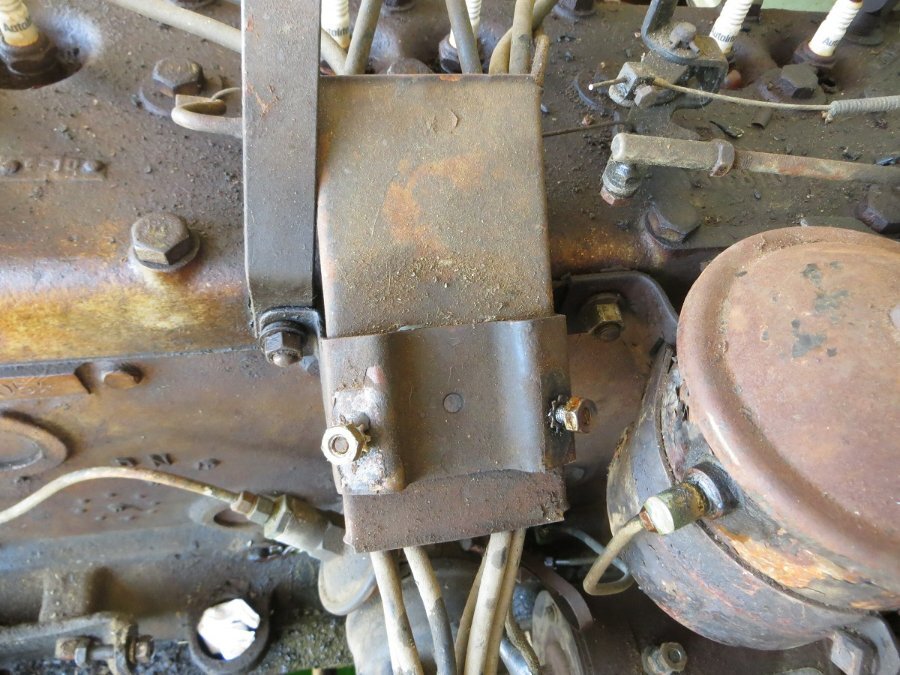

Got all the threaded bolt holes in the motor front chased, plus the ones for the intake/exhaust manifold and tappet covers. Got too cold and windy, even in the garage. Was looking into the water passages. Did a little cleaning work with a round file from the top and sides of the block. Was very careful not to drop the file in the motor. Also careful not to mistake cylinder head bolt holes for the water jacket holes in the top of the block.

-

I'd just be happy to find a vacuum advance for my 1953 IAT distributor that didn't cost $65-75.

-

Cold and windy outside. Cleaning main oil galley and side galley with shotgun/rifle cleaning brushes. 12 gauge wouldn't fit in main, had to use a 20. At some point I'll have to pressure wash again. Brass brushes are leaving small bristles. Also chasing all threads. Got the front done. Stopped to get warm and eat. First oil galley pic is before cleaning. Passage is still rough.