-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Everything posted by Bryan

-

I'll see if it holds Monday, but ordering another gallon. When you pull the tape off of metal it doesn't leave much of a residue. Also brake cleaner removes it easily. Just hope it holds. On anything else like drywall or wood it's so sticky it would pull chunks off.

-

Got to feeling better and it stopped raining. Pictures. Will see if it holds. 1 gallon filled it to a little over 1/2 way up cylinders. Got to put about 3 bolts in at top where it comes into intake ports before I add more.

-

As I was saying, don't go out and put 10-30w detergent oil if you don't know what the previous person was using. If you want to use normal oil I'd recommend taking the oil pan off, cleaning it out, cleaning the screen on the sump, and behind the valve cover areas. I started mine to knocking in the early 90s by flushing with kerosene and changing the oil twice at my brother's suggestion.

-

Think it will work. Was out of town for 2 days. Wore out. Didn't do too much today. Cleaned around all the core plugs and bolt holes with brake cleaner (several times). Found that cutting the Gorilla tape is better with scissors. Also wearing disposable latex gloves is a must. It clings to everything. I tested 2 places to see how it would stick, but have not filled the block up with water or Evaporust yet. I found that pre-sticking a strip on the surfaces helps to get the last oil residue imbedded in pits. I'll try it with the lower level of core plugs first. If that works I'll tape the upper core holes over, the manifold surface bolt holes and the distribution tube area. Will do it Monday.

-

EDIT: ready!!: installing new core/ freeze plugs

Bryan replied to Go Fleiter's topic in P15-D24 Forum

-

EDIT: ready!!: installing new core/ freeze plugs

Bryan replied to Go Fleiter's topic in P15-D24 Forum

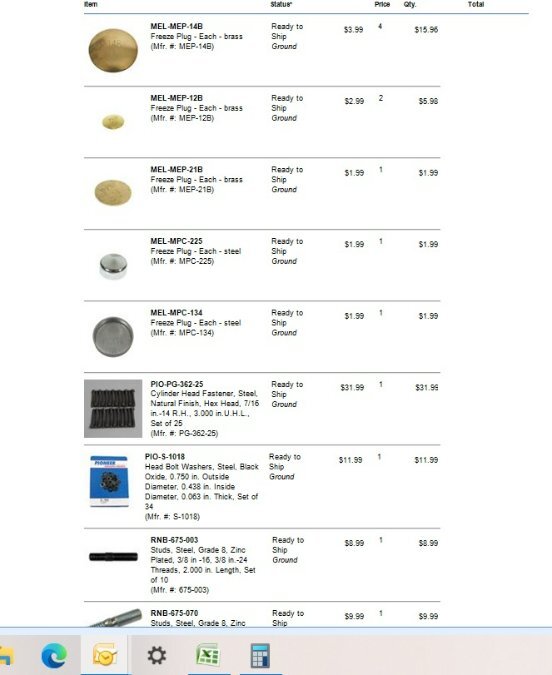

Went for the whole shebang. Even a few trial plugs for the 2nd layer on the rear oil galley. One thing..don't pry the core plug off on the head. Not sure I have the right size. -

EDIT: ready!!: installing new core/ freeze plugs

Bryan replied to Go Fleiter's topic in P15-D24 Forum

Looking at ones I need but $11 shipping for the number I'm getting. Think you mentioned at one point about doubling up on the ones in the rear. -

Read about that also. Good quality from there. Like when I was in S Korea for 3 years. Artists could take a photograph and make a full size oil painting that was almost photographic quality. Took them a couple of months. Could take any historical picture and have them substitute relative's faces. Wish I could find some better quality rings than cast iron. Don't want chrome, just something not so briittle.

-

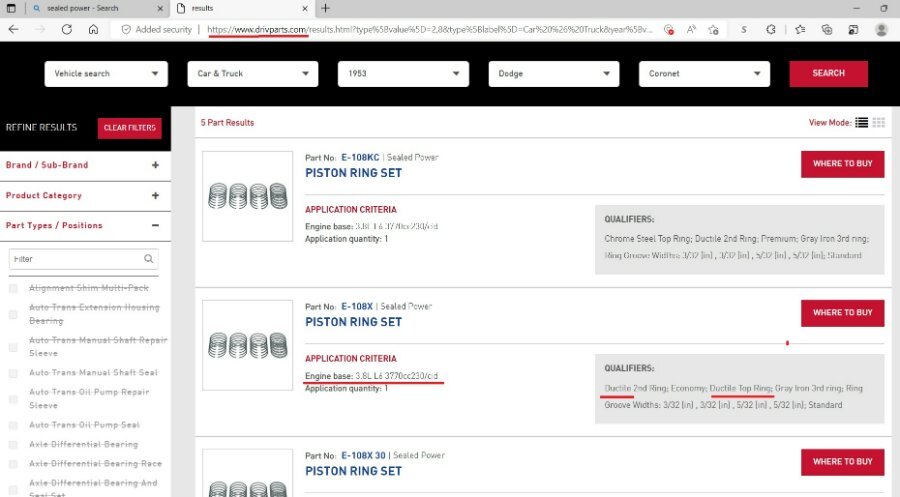

Just wrote to a company called Precision Rings..let's see what happens. -> "Was wondering about how much it would cost to make 6 top rings using a modern metal with moly coating instead of cast iron? Have a 1948 Dodge flathead 6 230 ci motor with compression ratio raised from about 6.7 to almost 8. Standard bore is 3.25". Needing .030 oversize. Sealed Power E108X 30 and Hastings 144 030 seem to be cast iron rings, even though Sealed Power shows ductile iron (I wrote to them, it isn't ductile). Thanks, Bryan"

-

EDIT: ready!!: installing new core/ freeze plugs

Bryan replied to Go Fleiter's topic in P15-D24 Forum

-

EDIT: ready!!: installing new core/ freeze plugs

Bryan replied to Go Fleiter's topic in P15-D24 Forum

If you want the car to be accurately original, then use the dish type. The cups are usually deeper, but I believe the recesses on the motor block are rather shallow. Would check this. Important are the rear and front plugs, very hard to correct if they start leaking. -

Was considering that. Had the other two tapes from work underneath the doublewide. I'll order and try it out. On Amazon it had better ratings that the Flex Seal tape.

-

I'd get it up on a lift and look underneath to see how much rust there is and the condition of the frame and pan. On my 58 Dodge pans are about $100 a piece and I had to buy about 8 including rockers & trunk. That's the parts only. If the body is okay then maybe start on other stuff. Depends how much you want to pay. If you aren't mechanically inclined and don't have shop tools then pay the $4.5K for the complete overhaul (if you want it perfect). That's driving it in the mechanics shop, them pulling the motor, them getting the parts, overhauling it, putting it back in. Complete means new everything in the motor, turning the crank, milling the heads, etc.. If it's not knocking maybe you could get by with new rings and valve guides. Don't use detergent oil in it if you don't know what was used before. Stirs up all the crud. Gas tanks run about $450-500 now. Used to be cheaper. Shop around.

-

-

Got to looking at piston rings. Noticed on Rock Auto in one place it lists Sealed Power top rings as being ductile steel. Another place grey iron (implying cast). I wrote to them and got back an answer saying they are not ductile steel. Just for info. Don't know if they are cast either.

-

Testing some tape out. Instead of dunking the entire engine block in Evaporust, or buying a bunch of rubber plugs at $12 a pair, wanted to see if I could clean and tape over the core openings and bolt holes, and fill the block up with a gallon of Evaporust. Will suspend the block over a large container in case it leaks. First test on a pipe with butyl tape (type used for trailer belly pans) failed. Then tried HVAC aluminum tape (ductwork tape, not duct tape). It seems to work. Going to let it set a while in the pipe.

-

I'm betting on the generator if nothing else was touched during the replacement.. Have you tried charging the battery fully with a separate charger overnight (terminals off), then seeing how the car starts after it gets hot?

-

Think if the belt was loose, it just wouldn't charge properly. The gauge probably wouldn't jump around. Generator, regulator, or a connection.

-

We have a lot of springs around the house. Because of that I haven't used weed killer since I've been here. Was pulling some sections up by hand but got doing so much other stuff kinda let it go.

-

It works very well with silencing. I staked 3 points on the end of the pipe to keep it from coming out, even though it is a snug fit. Only a slight decrease in performance, but that might be my imagination since it is a lot quieter. I thought I had a leak in the Y pipe/manifold pipe connection, since the truck got louder fairly quickly (within a week) a couple of months ago. Worked on the Y connection with very little change. Nope, must have been the muffler packing collapsing. I did a longer test drive, it doesn't run hotter or show any problems, just quiet like a car.

-

I have it in our yard. Hard to keep Bahai or Centipede grass growing with it around. Crowds everything out or is toxic to other plants.

-

-

Try going through this post from start to finish. He had the same type of problem.

-

Need my coffee first, just got up. There are posts about polarizing the generator by briefly shorting 2 terminals on the regulator. Just don't know which two. Since you probably had to disconnect the battery cables when you took the generator out, I would recheck the battery connections first.

-

My Hollander 46-56 book says #15 - 812 Plymouth 51-52. Have to adapt dash opening.