-

Posts

4,717 -

Joined

-

Last visited

-

Days Won

37

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

I guess I am just funny. This is a engine my Uncle gave me, & I put it on his stand a couple years ago. Was a really nice stand, while I do not think it was gear driven, you could turn it and stop it exactly where you wanted it. He bought it back in the 70's or 80's. really was a nice stand, wish I had it today. Even then with a good stand, I did not like the weight distribution of a inline 6. I bolted it on sideways I guess I am just weird. On a quality stand sideways I could spin this thing like a top and not worry about it falling. I just never expected the modern China stand to be such junk

-

I watched a youtube vid today .... guy was chipping ice from his driveway and claimed was -5C Guy did push out his car and pull the engine. I sat indoors and waited for it to get 60F Then put on a heavy sweat shirt and went out to the garage. Was a good video also, guy really pushed a load leveler to it's limits

-

I think they would be cost effective when you have as many lights as you do. I would recommend it. Living out in the sticks, I just do not have those bulbs available to me. I would need to drive 1.5 hours one way to get them. So if a bulb burned out, would need to drive 3 hours to replace, and get back to work. Just does not make sense for me. If I own 4 light bulbs, to upgrade them to LED, the cost savings would take years to repay themselves. Honestly I am pretty happy with the traditional florescent lights. Is enough light for me.

-

I know I know ... Let me just say I was very disappointed with my purchase. But the joke is on me & I am laughing. The clerk asked me if I wanted to buy the extended warranty with it .... No mam, I am going to cut it up and weld it back together before I assemble it ... warranty would be voided. She laughed. My whole goal was to buy a welding project, I was going to make it my own, then use it. Same thing @Tooljunkie @Plymouthy Adamsdid with there used equipment. So when I get it home, I realize this is what it is .... Total junk and not a good foundation for a welding project. I simply have to search for better junk to start with. I bought the stand with a plan to buy it cheap and make it great. That one bit me in the arse. So the title of the thread ... Anyone use these stands as they are? I never planned to use it as is ... but I can get by with it.

-

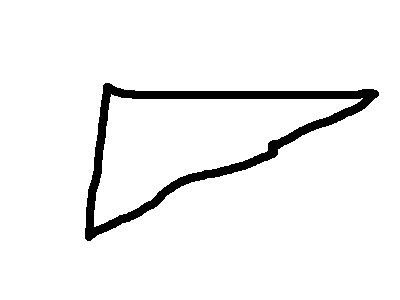

New Fuel Tank for Dodge Trucks

Los_Control replied to MMcKinney's topic in Mopar Flathead Truck Forum

silly 2 second drawing with my mouse to give you a idea of the bracket. 1 piece of angle iron, figure out how tall your frame is and how tall you will want the bracket. Cut through 1 side of the angle iron and bend it over. weld it back together. Then cut a piece of plate and weld it in to give it strength. The angle iron you have the side to drill 2 holes and mount it to the frame & 2 holes to mount it to the tank. The factory tank you have will have the spring mounted bolts on the rear cross member, you can use them to mount it to the new bracket you made. The front mount of the tank is the same, so bolt it in and you know where to mount your new rear bracket. I had a 3/4 ton 49 B1C is what I bought the tank for originally. That truck had the factory bracket on it. Factory used rivets to mount it to the frame. And my drawing is a exact copy of it Would take longer to grind the rivets off to move the bracket, then it would take to build a new one. Do not let the bracket deter you. And the filler tube on the tank mod, that is from Tanks install instructions. I have talked to others on facebook, they said it fit just fine with no mods. So maybe, maybe not. Only thing I am not sure of, how thick should the metal be for the bracket? Bigger the better ... I am thinking 3/16" For a fuel tank, overkill is good .. I wonder what others think it should be .... I still need to make mine. -

Nice scrap pile Stand looks great

-

New Fuel Tank for Dodge Trucks

Los_Control replied to MMcKinney's topic in Mopar Flathead Truck Forum

I hope so, I bought one a couple years ago but not installed yet. As far as I know the "Tanks" tank is made for the earlier1947 models and slightly shorter then the 1948 model. Or the Cross member is moved on the 48 model trucks. What this means is you need to make a triangle shaped mount, Angle iron and plate. Bolt the mount to frame and then tank to mount. The factory made this mount for 3/4 ton and larger trucks, because the longer wheel base they moved the cross member on them. So is the same thing the factory did and not considered a sketchy fix. Also something about the angle of fill tube is slightly different, you may need to square off the end to get a straighter connection to the flexible line going to filler neck on cab. These modifications seem to be so minute, not worth making a new batch of tanks specifically for 48-50 models. I have pulled mine out of the box and inspected it, I also bought the new sending unit with it ... tank has another covered opening for optional in tank electric pump, nice drain plug on the bottom ... I am satisfied with it. Still need to weld in the floor and not ready for gas tank yet. -

I have to agree, I also got my engine on the stand today ... it is heavy. Same time the stand is performing better then I expected. Almost no lean and no wiggle unless I get crazy ... it does roll across smooth concrete with ease. ... as much as I want to talk bad about it, is really performing better then I thought possible. I honestly did not expect to be giving it a thumbs up report ... it leaves a lot to be desired, but actually performs as advertised.

-

Are you sure there is no tag on side of distributor? 6 or 12 volt does not matter at the points. I think you will need a resistor from the coil, or before the coil ... but points wont care. Excuse my ignorance for correct answer, but someone will chime in and correct me Just saying, the points are the same 6v or 12v, you would run a ballast resistor before or aft of the coil, same time if you have correct coil would not need resistor ... but has nothing to do with your points. Just depends on how your car wiring was converted. My point is, no pun intended ... points are just a switch and easy to clean replace ... condensers are what often go out. I really like the idea of using the /6 or slant 6 distributor body, and the shaft from a flat 6, You are using factory parts that are available at local parts store. If you search this site for slant 6 conversion you will find a lot of info. I hear great things about petronix, If the module goes out in the middle of no-where, you going to need a flatbed to get home. While a local parts store you may have a chance to buy parts needed to get going again. I will say many love petronix and no issues, while others who have issues. Most problems I hear, people not not follow instructions while installing the petronix.

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

I agree .... I have that piece somewhere, found it underneath the seat with a bunch of other junk I felt did not go with the truck. Going to have to dig it up and put it to use. -

Thats a very good point I did not think about. Is a very good photo, you can look down the main tube and see how thin the metal is. My first thought was to get some square tubing, & make a wider front axle for stability. That will look awesome. Now the rear axle is going to look stupid wimpy compared to the front, so replace it also. The castors look wimpy, lets make it look cool and replace those. Now the bottom is beefy, you still have the thin wall frame, add some gussets here & there .... where do you stop and say it's not worth the effort? Better off to just build a new one from scratch. Or buy a better quality stand. Thats where I am at ... I only plan to use it a few times, others have used them cautiously without catastrophic damage. I know I can use blocks and a bottle jack under the front of block to take out some of the bounce. The Ford engines have a problem with lifters rusting in place. This engine has that issue. There will be some prying and banging bad words used, while taking this engine apart. I just have to be careful. I do not believe this stand is worth putting a lot of money or time into beefing it up. I plan to have the engine on the stand today and may have other opinions about it. ?

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

And mine is a 1/2 ton 1950. No clue about the moving of the pedals, I would assume the 1-1/8" may still apply. Here is a better photo, there is about 3/4" strip on my 1/2 ton between the two holes. When the bronze bushing wears out, the clutch pedal leans to the left and scrapes that side ... the squeaking sound is obnoxious metal against metal. I would just assume, if they were to lazy to fix it right, replace the bushing. They probably only trimmed the left side to fix the problem. I would guess if you added metal back to the left side to make the opening 1-1/8" the new rubber boots and all would work. Again just a guess, you will need to measure but I may at least be close And yes they are bolted down with the standard clips and body bolts used throughout the truck. The hole around the column I only guess to be some sort of fastener for the rubber boot that fits in that hole. Mine was removed when I bought the truck so just a guess. -

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

clutch is about 1-1/8" wide and column shifter ~2" My clutch I think is original but worn and boogered ... the clutch shaft bushing wears out, instead of replacing they cut hole bigger in the floor on yours, mine they just let it rub. Also I have a column shift, so a little extra doowiggie on the column for the shifter to run through ... guessing you have a floor shift. -

I found a old post here from 2018, while there were assorted replies, I kinda thought VPW would know shipping weight ... But what do they ship with them? Does it include exhaust, oil pan carb etc? I do not know. @Dodgeb4yaVintage Power Wagon ships them....

-

Thats good to know. Close as I can find the 218/230 weighs about 450 pounds. Complete engine on a pallet ready to ship. Honestly do not know for a fact, I think the older ones did have thicker steel Someday I do plan on putting the 218 from my truck on it ... I just want to run it a bit first, then get a game plan for it before pulling it. Today I have a old flathead ferd v8. I have it sitting outside under the carport. I need to get it up on a stand and in the garage and torn down. I just need to find out if it is a boat anchor, or a good engine to save. Currently spraying down with oil to keep from rusting and a pita. If it weighs 525 pounds complete, is probably 400 or less now with no flywheel, heads, intake. I figure if the stand has any issues, I can take care of while the block is off being hot tanked before putting it back on.

-

Just curious what others have done to their engine stands. I bought this cheap Harbor freight stand. My intention was to turn it into a minor welding project and beef it up. More I look at it more major it gets. By the time I bought all the metal I wanted, may as well just build a new one from scratch .... or just buy a better quality stand. The stand claims it is rated for 1/2 ton. The engine going on it is rated at 525 pounds without the trans, I do not know if that includes flywheel. I would be pulling it down to bare block and send off for hot tank. So the longer it is on the stand the lighter it gets. Real question, since this is my first engine stand, is there any do's or dont's ? I am guessing it will work fine as is. Maybe weld it together instead of just bolts, then a bigger gusset and call it a day?

-

New User & 1950 De Luxe craigslist find

Los_Control replied to Knaveofdarts's topic in P15-D24 Forum

Nice car, glad it found itself in your hands. I am same way with scrap metal, slowly building up my stash pile. I was just browsing the forum as I sit here and wait for the big brown truck to deliver my new spindle bearings. I spent some time stitching this deck back together The metal I used is from a old shovel I found out in the yard when I bought the house. I also went around the inside with some nice flat 18 gauge metal I picked up somewhere. I paid $35 for the mower at a estate sale last spring and used it all season with the deck in the condition it was in. With all the holes I had to use the air hose to blow the grass off me when finished mowing 27 year old John Deere runs & operates as it should, I only need to nurse it along for another 20 years ... what could go wrong? -

With what little I know ... points are like a switch, on or off ... should be .000 when off. If you get some sort of reading ... you know that is not correct .... it may start and run but you know is not right. It could be a bad ground or connection, or points need replaced. Could be a wire ... you will have to find what is causing it. Pretty sure you can remove the points from the distributor and check them isolated from the car. If they check out fine then you are 1 step closer to finding issue.

-

Torque spec is a 3' cheater bar and 4 grunts. Or 160 + pounds. Possibly some heat on the keyway to break the rust? ... it should just pop out in a perfect world.

-

You wont need to worry about wire size when switching to 12 volt. With 6 volt the wire is larger then a 12 volt system. What you have will be fine without changing the wiring if you convert to 12 volt. This is why we can convert to 12 volts and keep the 6 volt starter, it is built heavier then a 12 volt starter. Back in the 1970's, when these were just 20 year old beaters to drive around. People would convert to 12 volt because it was cheaper and easier then buying expensive 6 volt battery. Assuming what you have is in good condition. Usually by now your wiring is falling apart, either been replaced already or needs replaced .... or the car has been well stored and original wiring in good condition.

-

Non Political Political Content...

Los_Control replied to P15-D24's topic in Forum Announcements And Feedback

I cant say it any better .... -

Only reason why I plan to stay 6 volt is because am a cheap arse .... when I need to start replacing generator etc .... going 12 volt.

-

you can switch to 12 volt, then run a voltage reducer to certain items like radio or heater motor windshield wipers

-

I do not think so ... but why would you? 1rst issue is the starter .... you can use a 6 volt starter on a 12 volt battery charging system. I do not think you can use a 12 volt starter on a 6 volt battery. Any modern engine will have a 12 volt starter.

-

I was messing with my shifter, going to remove it from the steering column etc ... when I bolted it back together, I only had 2nd, 3rd gear. 2 leevers coming off the trans, 1 is 1rst/reverse other is 2nd/3rd I put the gear shift in neutral, then put the 2 shift levers on top of transmision in middle position & everything started working magically again. I assume this means I have excess play and need to do some adjusting, may be what you need also. Other option you can just crawl under the truck and manually shift it into reverse, then start truck with clutch pedal to the floor ... let up on clutch just to verify trans is working.