-

Posts

1,196 -

Joined

-

Last visited

-

Days Won

12

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bob Riding

-

I wonder if they can add the soundtracks...?

-

I have a '54 Chrysler Town and Country wagon and would be interested in the transmission and power steering strips if and when they get put together so that they could be viewed on Youtube.

-

Good post Keith. I used 3000K bulbs in my taillights. Headlights are still incandescent halogens (sealed beams, not separate bulb and reflector), which are brighter and whiter than standard incandescent sealed beams. I would guess about 4000k.

-

I was able to retrofit LED bulbs into the taillights on my 1940 Plymouth wagon, and they work great! Definitely brighter than the stock bulbs. Last longer too. The benefits of rear LEDs : LED taillights provide higher visibility to cars at night, ensuring better safety in driving LEDs are faster to come up to brightness than Incandescent bulbs - about 0.3 seconds faster for the LEDs to hit full brightness from when the brake pedal is touched. Assume you are driving 60 mph on the highway. There are 5,280 feet in a mile. 60 mph * 5,280 ft = 316,800 feet per hourThere are 60 minutes in an hour, 316,800 feet per hour / 60 minutes = 5,280 feet per minute. There are 60 seconds in a minute. 5280/60 = 88 feet per second, 88 * 0.2 seconds = 17.6 feet So, an LED brake light could allow a person to stop 17.6 feet sooner than with Incandescent. An added advantage with our drum brakes.But there is more. I've noticed that folks react alot quicker to the instant on effect of an LED vs. the slow ramp up in brightness of an incandescent. What this equates to in reaction time is unknown to me, but it seems that LED taillights could save lives, if not sheetmetal.

-

Awesome, again. I'm taking notes! What are your plans for adapting the column shift to your AT transmission?

-

Thanks Scott. I will keep following your progress. I too was thing about adapting the column shifter to my 200R OD tranny. News at 11!

-

What I have learned from you guys so far is: The J car racks and their various derivatives are used because they are a "center" pivot style and offer the best chance of not having any steering tie rod induced bump steer. Fatman has kits that allow the mounting of R&P to 48-52 Plymouths.You need to purchase outer tie rod ends from a ‘04-‘05 Explorer- they use the same taper. NAPA # 269-3274 The tie rod pivots need to be centered exactly with the lower A-arm pivots which should completely eliminate the bump steer Steering arms can be swapped or modified to tighten the turning radius using various methods. The tie should rods follow the angles of the lower control arms. Got some shop time yesterday and started looking at the Fatman instructions. Not sure if I messed up or not... it says "Before disassembling anything, measure the height of the inner tie rod ends and record that number. Remember the new rack & pinion inner tie rod ends MUST maintain the same ride height as the stock system." I didn't measure the height and the only photo that I have shows the tie rod, but I can't tell height. I wasn't planning on installing the R&P so I didn't take many pictures of that area.? Also I'm not sure I understand #5 above. How can the tie rod assembly be parallel with the lower control arm angle? Wouldn't straight and level be the ideal?

-

Marc, My mistake- I just looked and it's a 16" record that plays at 33 1/3 RPM. PM me and we can continue the conversation. thanks Bob

-

About ten years ago, I found this on eBay. It was the unopened 1942 (P14) Plymouth Product filmstrip set, including the original dealer script dated September 24th, 1941. It's a fascinating look into Chrysler's marketing attempts pre-WWll. I assume it was the last training film series that Ross Roy did for Chrysler Corp for Plymouth automobiles until after the war. I opened it and found everything perfectly preserved. I realized I couldn't play the 16 RPM record but eventually found some folks from the Chrysler Town and Country Club in the SF Bay area that could help me. They recorded all four sections of both the mp3 audio and WMV video files. There are four sections of each, eight files in all. I tried for a while to create an online video without success. (Youtube at that time limited how much content you could upload). Obviously that's all changed and now would be a great time to try again. If someone can help meet me put them together, I would gladly take up Keith's challenge and upload them to Youtube. Because P14s are very similar to P15s, I think it would be useful to our members, and a valuable addition to our P15D24 website. Also If anyone is interested in owning this set, let me know and I'll make you a deal you can't refuse! It needs to go to a good home.

-

Excellent work! Did you plan to do the front shock relocation ala Rusty Hope's kit?

-

Andydodge and Scott -Thanks for the updates. I have a donor 56 Plymouth Suburban that I wonder about it's steering arms. More to investigate...

-

Brilliant! However on my '52 front end, there are only 2 holes...can I swap out older steering arms without screwing up the geometry?

-

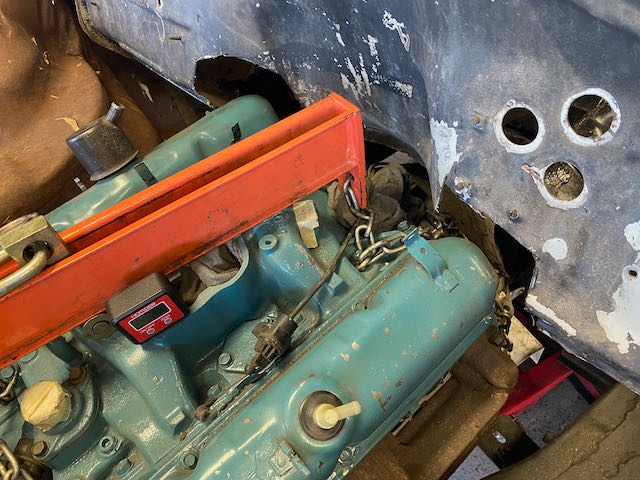

Me too! Great photos. I am at the engine mockup stage and need to make sure I leave enough room for the rack. My frame is different than yours- a '52 is probably narrower where the rack will sit. Once I figure out where the 360 will be, I'll concentrate on the rack positioning. What is your thinking on having matching Cavalier rods- aesthetics or function?

-

-

Wow- I just assumed the PO hadn't replaced them! I will remove and replace with steel washers. Thanks!!!

-

Hi Dan. yes they are rubber. I got them from Andy Bernbaum Auto Parts

-

No problem. Good luck!

-

I just finished mounting my '52 wagon body to the frame and had some extras that I just measured. Both top and bottom donuts are 2" in diameter, 1/2" thick, raised center is is 1" diameter. Both pieces have a 5/8" hole. I used 3.5" grade 8 fine thread bolts. Torque to 35 ftlbs. Large (1.75") flat washers above and below.

-

I ordered the wrong outer tie rod ends from a ‘04-‘05 Explorer, but they are 1/2" internal threads (female end) and the junkyard arms are almost 3/4". Which ones did you buy?

-

Dropped the body back on the frame...perfect alignment- i was expecting to at least have to fiddle with it a bit. Now on to engine mockup.

-

It's a deal. I have a kid (late 20s now) from my old Boy Scout troop who is a professional welder. He did my floors on the '52 and I'm sure will be able to make the R&P work. News at 11...

-

-

Me too, too! My kit came last week- I'm waiting for the Detroit Axle R&P unit to arrive. Detroit Axle Remanufactured R&P I have the other bits that I will need from my junkyard rack. I will send the junkyard rack back to Detroit as a core, which will get me some kind of extra special warranty (I believe). I guess Scott and I are in a race! Actually, I'm not in a hurry, but will document my progress as I go.

-

Undercoating. Was it ever done at the factory?

Bob Riding replied to MarcDeSoto's topic in P15-D24 Forum

Good idea! I just ordered the Herculiner Truck bed coating. I will report out on my results. -

Undercoating. Was it ever done at the factory?

Bob Riding replied to MarcDeSoto's topic in P15-D24 Forum

Love those 40's advertising terms - "Bonderizing", "Sand-Mortex", "Hi-test safety glass", "Super hydraulic brakes", "Automatic overtake", "silent -ribbed tires", and of course "Deluxe" everything!. Although this is from Nash, mother Mopar was no stranger to creating marketing jargon that sounded impressive, rocket-age, but was probably not that much different form other automakers products.