-

Posts

1,196 -

Joined

-

Last visited

-

Days Won

12

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bob Riding

-

Great info! How will they grind the adjustment screw surface on the lifters to "match" the cam?

-

After that detective work, I'm thinking you are the long lost-third brother of "Click and Clack"! I am of course going to replace all the bearings. What do you think about the tappet wear, and although I haven't checked the ring-end gaps, I was going to get new rings.

-

Both #6 and #1 have slight (I guess you'd call it pitting - can't really feel it with your fingernail) on 1/3 of each surface. None of the other rod bearings show any pitting, only a scratch here or there. #6 and #1 below:

-

I checked with the usual suspects- AB, VPW, Robert's and Kanter, and they all carry them for $14-$15 each. Are you saying they aren't very good? Chinese repros, etc?

-

-

@keithb7Here are pics of the bearings, tappets, valves and journals. I used a ridge reamer, then honed the cylinders -didn't get the cross-hatch pattern, but you can't feel any ridge now. Attached are the cylinder measurements I made with my dial bore gauge...seems in spec for taper. I lapped the valves. The tops look kind of gnarly, but underneath seem clean. You can see the different types of wear patterns on the tappets. An immediate concern is in the rough edge on the rear main bearing- I took a separate shot of both halves for detail. Have at it! Scan Sep 27, 2022 at 1.28 PM.pdf

-

I've been having fun disassembling the engine, and I'm about ready to take it into the machine shop. Thanks to @keithb7for his great videos- it makes it easier to have the courage to dive in knowing someone else has been there and back and it's been recorded. In looking over the parts, nothing jumps out at me (looking for something to cause the tapping noise that we discussed earlier) as the bearings seem good, all the wrist pins and C clips seem fine, and I can't see anything obviously wrong with the rods or pistons themselves as mentioned by @kencombs and @Sam Buchanan I was planning to have the shop shave the head, but I'm not sure if someone has already done that. I mic'd the head and got 1.8 inches, + or - I wasn't able to find any reference to stock head thickness - based on my understanding of the casting info, I have a Plymouth head made on June 24th, 1955, at 2pm. Stock compression ratio is 7.6 to 1. How much can be milled before I get into trouble? Is there a formula to determine compression ratio increase for every thousands shaved off?

-

Great thread, thanks! I agree-I don't think trying to port match is worth the effort. I will clean it up a bit and take it to the machine shop for magnafluxing and hot-tanking.

-

Very interesting. Is trimming the guides commonly done? It seems like alot of work for a non-race motor.

-

Success! Got the water distribution out in one piece, ala @keithb7 's flat bar/vicegrip technique. It took an hour or so of loosening the tube with lube and tapping the steel bar on each side. Before I take it to the machine shop for magnfluxing and hot-tanking, I want to do any work that will create debris that the machine shop cleaning will remove. To port/polish (or gasket match) or not, is the next question. I measured both the block and intake /exhaust openings and they all measure out at about the same diameter- 1.3". Does it make any sense to spend the effort to match them if they are already the same diameter, even though the gasket diameter is larger? I'm going with Langdon's split exhaust, which also measure at 1.3" dia.

-

Awesome Dodges! The '25 wagon is in excellent shape and looks to have a body made by Cantrell, who also made the same style body for the 1925 Ford Model T. I found a picture of what I believe to be the same vehicle (I colorized it to bring out the details) and although it was a very open design, it did come with side curtains to button it up against inclement weather. Great finds!

-

Good news- I think. Looks like the motor was rebuilt in 2002 with .030 over pistons, .010 over rod bearings and .020 over main bearings. The valves look pretty good and after doing the @keithb7 tests, I'm pretty happy. I will do the kerosine drip test next. If the tapping noise is coming from the bottom end, what should I look for when I remove the caps?

-

Neither one works. Time to pull it and check the bottom end.

-

Gauge doesn't work. Aftermarket gauge also no go.

-

No change. But it did start to overheat, which it hasn't done before. Time to come apart!

-

Great idea... I will do that today.

-

Great advice everyone- I appreciate learning new stuff and your willingness to help. I will keep you posted. News at 11 as they say!

-

No they haven't I thought that too, but my brother-in-law didn't think so, based on the sound. Once I pull the motor, I'll go through the valve train and check the clearances.

-

I'm just starting the removal of my 230 donor engine to replace the 218 in the wagon. After watching all of @keithb7 videos, I think I can handle the job! Thanks, Keith! It is a running engine and actually sounds pretty good, except for a slight tapping sound that increases with rpm. I disconnected the driveline yesterday and plan to remove the 3spd from the block today so I can get it out. View it here: '56 Plymouth flathead running I did some compression tests and here are the results. The engine was up to operating temp on test 1, but on re-testing the next day, it was only slightly warm on test 2. Test 3 was done immediately following 2, but with a teaspoon of engine oil added to each cylinder. Cylinder 1 2 3 4 5 6 Test 1 110 112 115 121 120 130 Test 2 115 120 118 128 128 138 Test 3 w oil 125 135 130 130 138 145 A couple of observations/questions: Would the differences between test 2 and 3 be traceable to rings, valves or possibly both? I am definitely planning to lap the valves. The service manual says the compression pressure should be 120-150 psi. How much does that change once the motor is broken in? The engine is listed as having a compression ratio of 7.6 to 1. How does that 7.6 to 1 ratio change if the cylinder pressures are lower? Does a 10% pressure drop in the cylinders equate with a 10% loss of power? The PO had some work done on the engine and the head was off - there is a new head gasket, water pump, fuel pump, gas tank, etc. How can I tell if he had the head shaved- i.e. what is the factory thickness of a 1956 Plymouth head? I couldn't find it in the service manual. My brother-in-law, who has rebuilt all kinds of engines, wonders if the tapping noise may be a rod bearing or a wrist pin, and thinks that I should do a complete teardown. Enough questions! Thanks for the help

-

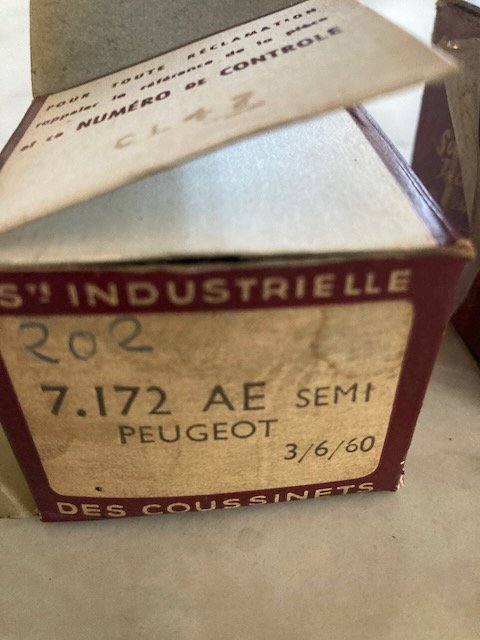

I just wanted to recognize our fellow Forum member, Go Fleiter, for the help he’s provided my friend and I in obtaining rare parts from Europe for his 1948 Peugeot woody wagon. It seems to be one of two left in the US, which makes the parts hunting quite fun! Two in the Country: 1948 Peugeot Woodie WagonWe needed to purchase three engine main bearings and as far as we could tell the only ones available anywhere were for sale from a French vendor who wouldn’t ship to the United States (or non-EU countries)I reached out to Go. He received the parts from the French company, mailed them to my friend in California and then wouldn’t take any money for the postage suggesting we donate the amount to a charity to help with the situation in Ukraine. Interesting note: the original box has a 1960 date- obviously NOS! Thanks Go! This camaraderie and willingness to help is what makes our hobby so fulfilling.

-

Awesome info- thanks Loren - I will check it out.

-

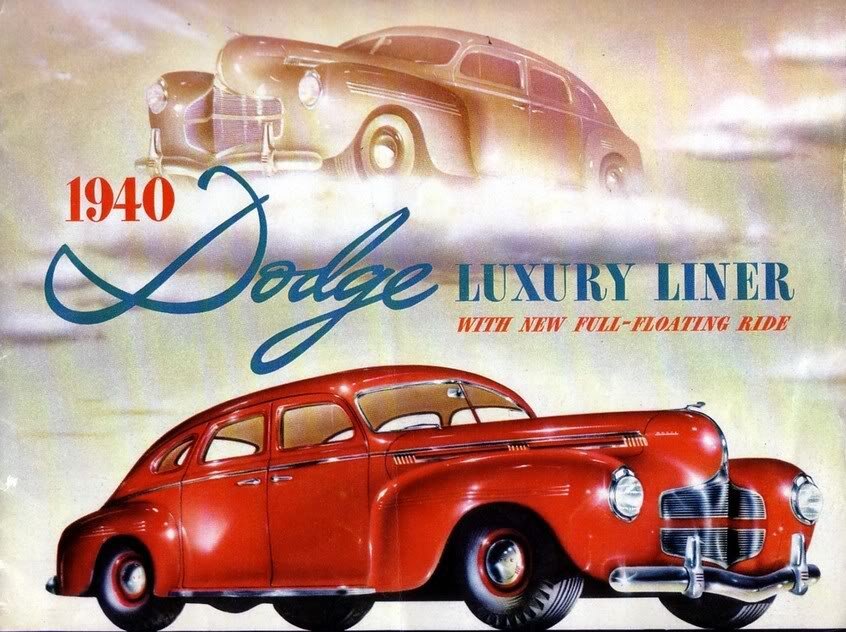

I'm looking at enhancements for my '40 wagon, and since it will be getting a heart transplant soon (230 engine and power pack setup) from a '56 Plymouth, I started wondering what other more modern technologies would be transferrable to the old girl. The '56 has power brakes - I don't think the original is in good enough shape to use, but I wonder if there are aftermarket vendors who sell "universal" power brake kits to boost the old drum brakes?

-

I am doing an engine swap between my '56 with the Power Pack option (230cu in with 2bbl carb, 132hp) and my current powerplant in the wagon, a 218 with 2-1bbls and split exhaust. The 230 is running and still in the car. I want to do a valve adjust before I pull it. Keith's videos show him doing the adjust while the engine is running. Flat Head Chrysler Valve Clearance Check The Tech Tips suggest bringing it up to operating temp and then shut it off and do it hot. Others say cold with different tolerances. Thoughts?

-

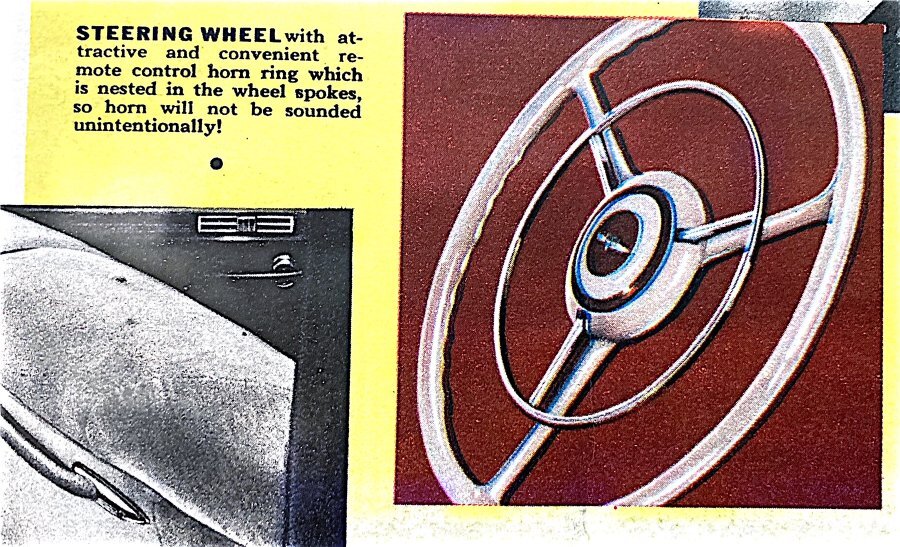

Accent Color Identification for Steering Wheel Centre on D-14

Bob Riding replied to Marcel Backs's topic in P15-D24 Forum

Hershey's Chocolate! -

Accent Color Identification for Steering Wheel Centre on D-14

Bob Riding replied to Marcel Backs's topic in P15-D24 Forum

.jpeg.28b7d36ff14eeb827515321b74ed677e.jpeg)