-

Posts

1,197 -

Joined

-

Last visited

-

Days Won

12

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bob Riding

-

I love the upholstery. I may try to duplicate it when I do my '52 Suburban!

-

Me too.Thanks!

-

65 and rebuilding...I guess I'm late

-

Manual Rack and Pinion install on 1940 coupe

Bob Riding replied to 40desoto's topic in P15-D24 Forum

Just sent you a PM. -

Took advantage of the warm temps here in central California (no, I don't say "Cali") to paint my '56 230 that I'm rebuilding. My grandson was very interested and so I had him be the masking tape remover. Smart kid!

-

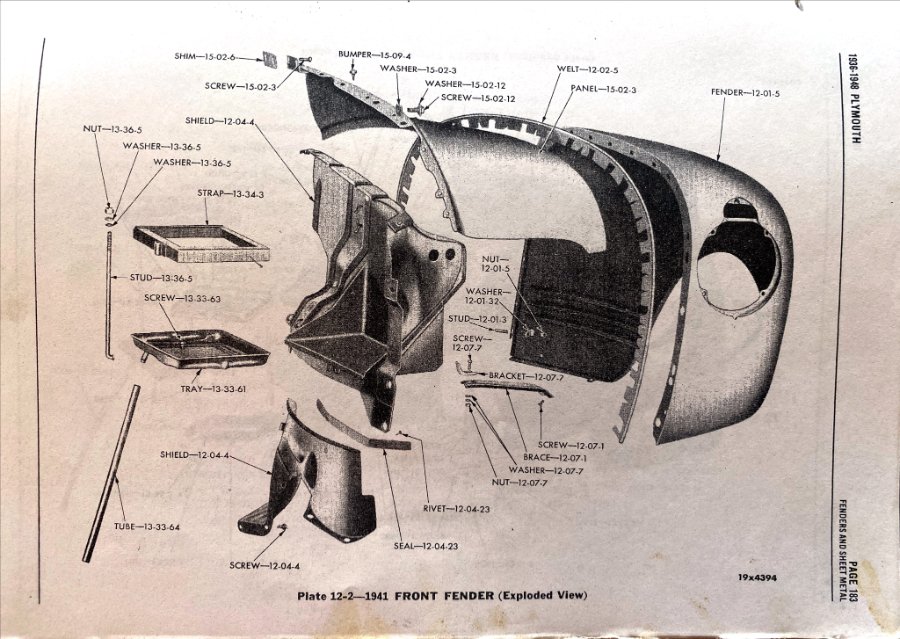

Does anyone have an "exploded view of 1941 Plymouth Front Sheet Metal?

Bob Riding replied to andyd's topic in P15-D24 Forum

If I rember correctly they are actually a bit different. The '41 having the alligator hood vs the butterfly hood for the '40. Here is what I have for the P15s... -

Does anyone have an "exploded view of 1941 Plymouth Front Sheet Metal?

Bob Riding replied to andyd's topic in P15-D24 Forum

-

Wilcap (Transmission Adapters) Still in Business?

Bob Riding replied to Bob Riding's topic in P15-D24 Forum

Thanks DJ. Yes- I got the same result. All the web pages say Wilcap, (and all of the Mopar-related pages say sold out) but the contact info is for the new company and the old phone number in Pismo Beach CA doesn't work. I'd drive over to the coast to check out what used to be the brick and mortar store, but all that's listed now is a P.O. box. Maybe somebody passed away?- 6 replies

-

- transmission

- wilcap

-

(and 1 more)

Tagged with:

-

I need to buy a flexplate and hub to attach my Mopar-GM Wilcap adapter plate (on my 265) to a GM 2004R trans. The Wilcap aluminum adapter plate came free with a 218 motor I bought a few years ago. According to the phone message, the company is now called Transmission Adapters but they are still using the Wilcap web pages. They are based in Wisconsin, and when I call day or night, I get "We are experiencing high call volume and sales orders. Leave a message and send an email and we'll get back to you" I've not received a call back or email response in a month of trying. Anyone have recent experience with these guys? Also is anyone else making an auto trans adapter for our flatties? If I didn't already own the GM 2004R, I'd just try to find a TorqueFlite and be done with it!

- 6 replies

-

- transmission

- wilcap

-

(and 1 more)

Tagged with:

-

Sorry, I meant the housing...

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

I'm assuming I can drill my pumps- the shafts aren't hardened beyond easy drilling?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

Interesting. Do you have a picture of your pump?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

Can't find this broken spring on the column

Bob Riding replied to mvpcustoms's topic in P15-D24 Forum

What Sniper said... -

I just checked and none of them have the oiling hole. Thoughts on drilling them? 2 of the 3 were already working, apparently just fine.

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

So don't remove it!

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

Can't find this broken spring on the column

Bob Riding replied to mvpcustoms's topic in P15-D24 Forum

Very cool! What brand of a/c compressor did you buy? -

Thanks. I wonder why they would plug up the hole?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

After reading recent threads re oil pump failures @Marcel Backsand reconditioning procedures @JBNeal -thanks guys!, I've been getting into my oil pumps to see what's what. I have 3 pumps. Here's what I found: (P28 Running) M37 (Melling) from a P28 running motor with decent oil pressure (P28 Not Running) Chrysler branded pump from a P28 (not running)- stamped 1314611-99 (C54 New 2003) NOS M37 from a 25" Chrysler 265 - installed in 2003, never run. All pumps looked OK. The M37 Melling pumps had some staining and the rotors were a bronze color and both had the upper shaft oiling hole The Chrysler pump, no oiling hole, but instead what looks like a brass plug The teeth on the drive gears had slight wear marks, but no missing teeth All measurements, that I could do, were within The Freewheeling Tony Smith's tolerances. I used 320 and 400 grit sandpaper on a sheet of window glass to clean up the end covers and housings, then filled the up the cavities with Lubriplate #105 Motor Assembly Grease. Thanks @keithb7 They all operate smoothly, and I assume, will give me minimal trouble. A couple of questions: FW Tony Smith cc'd the older Sealed Power (cloverleaf style) vs. the newer M37 (cross-style) and found that the NOS pump with the cloverleaf style rotors is a high volume pump, moving about 10% greater volume per rotation than the newer style pumps. I planned to use #3 pump in my 265, but if it pumps slightly less that the other 2 used pumps, is that a good idea since it is a slightly larger motor than the P28 230cid motors? How do I remove the brass plug from the Chrysler pump? Grind down and drift punch it or drill it out?

- 18 replies

-

- sealed power

- oil pump

-

(and 1 more)

Tagged with:

-

Can't find this broken spring on the column

Bob Riding replied to mvpcustoms's topic in P15-D24 Forum

Unfortunately, he wants $16.99 for shipping an item that is less than 1 ounce. Put in a USPS envelope is $0.60. Maybe an alternate $1.00 spring from Tru-Value Hardware or Home Depot would work? -

I suppose you could hook up a 1 gal backpack sprayer to get a similar result?

-

In a recent thread @keithb7 suggested packing the oil pump with #105 motor assembly grease in lieu of dunking it in engine oil. Thoughts?

-

The '54 Chrysler hemi-equipped cars had the same setup- it must have been a BIG deal - look at the horn button! (my '54 4dr)

-

I know it came out of a '54 Chrysler 4dr. I'll ask the PO if he know, but what @Dodgeb4ya said makes sense. When I first saw the oil fill pipe, I thought it had been crushed! I'm used to the Plymouth/Dodge sixes!

-

@Los_Controlmakes excellent points. If it is indeed a P15 motor, the service manual states that a compression ratio of 6.8 to 1 should yield 105 lbs per cylinder with no more than a 10lb variance. That is true up to the P24 in 1954. In '55 and '56, the P26 and P28s C/R increased to 7.4/ 7.6 to 1, respectively, and 120-150 lbs per cylinder.