bkahler

Members-

Posts

1,951 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

I guess maybe I got lucky. There was zero body rust (other than surface rust), no rust through or anything of that sort. Same here, putting it back together Brad

-

I thought about adding fuses when I was building my new harness and couldn't get past the fact that the wiring had lasted 50 years and hadn't shorted out so to keep things simple I just decided to put back what came out. Also, I think the quality of the wire sheathing is definitely better than it was 50 years ago so I guess I have my fingers crossed Brad

-

I bought my 51 B3B in Hailey Idaho back in 1996 when I was working there for a summer. I then trailered it home to Lincoln Nebraska. That truck was the most rust free truck that I had ever seen. Brad

-

That is the same sort of hitch I've been thinking of adding to my B3B for towing light utility trailers.

-

-

Well....crap....it's the wrong color....!!

-

1956 daddy/daughter build thread

bkahler replied to sluggish01's topic in Mopar Flathead Truck Forum

Vintage Power Wagons in Iowa. -

1956 daddy/daughter build thread

bkahler replied to sluggish01's topic in Mopar Flathead Truck Forum

Great story! How about posting wedding pictures of the truck -

I can't tell for sure but it sounds like someone looking for a heater cover?

-

Rob, I used Allen's and Grey Beard's and built my wiring harness. Their information was invaluable. One of these days I need to upload my information to this site. I opted to kept the wire sizes the same as required for 6 volt even though I'm switching to a 12 volt system. My logic was if I ever have the desire to switch back to 6 volts then no changes need to be made to the wiring. Also, it doesn't hurt to oversize the wiring which is the case when you switch to 12 volts. In this case too large is better than too small Brad

-

That longer blade puller looks pretty good. i like the way you tapered it down. Now with luck you'll never need it again

-

Now that's great news That tube was definitely in pretty bad shape, at least now when you hot tank the block you only have to do it once! Which of the puller arms was the one that did the trick?

-

Glad to hear everyone is ok. Any clue who the other driver was? To be able and total another vehicle and then drive off is a pretty good feat.

-

My 51 1/2 ton uses 1/2-20 extra tall nuts and the leaves are 1-3/4" wide. When I needed u-bolts I went to my local suspension shop and they had them available and very reasonable prices. Brad

-

The puller I made about 23 years ago looked almost exactly like this. Nice job!

-

512 cid C series on Dakota chassis- build thread

bkahler replied to Radarsonwheels's topic in Mopar Flathead Truck Forum

When I was retrofitting my old 74 Argosy motorhome with a new 454 and TBI I had a brand new out of the box distributor that had issues. I had my new engine on a test stand and was doing some testing and the engine would run pretty good up to about 2000 and then there would be a distinctive hesitation and then it would run ok again above about 2400. I had my laptop connected to the PCM and had real time graphs on the screen. The 2000 to 2400 lines were pretty bad. After thinking about it I swapped out the ignition module inside the distributor and that solved the problem. I guess what I'm trying to say is don't discount the thought that it could be an electrical issue. I originally had thought it might be a fuel problem as well. Good luck! Brad -

The tool looks good and your worry about hooking the block is probably a valid concern. The tool I made had it's hooks about half as tall as yours. I'm beginning to wonder if you shouldn't go ahead and hot tank the block to see if that will help clear the crud from the coolant passages. You could then try again with your tool. You'd probably want to hot tank the block again once you got the distribution tube out but sometimes you just have to do what's necessary.

-

Passenger side kick panel - heater install B3B

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Jeff, you bring up something I totally forgot about, insulation! I'm planning on using the type of sound deadener that comes in sheets and you pressure roll into place. No matter what I probably should get the insulation in place before I do anything with the heater. Thanks for the reminder! Brad -

Passenger side kick panel - heater install B3B

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

My truck didn't have the panels or even remains of panels when I bought it so I didn't realize there are only three fasteners on the side panels. I also didn't realize they used push pins and not screws. The picture with the Model 62 heater in the red truck is just like my setup. The panel kit I have is from Roberts purchased over 20 years ago. The fasteners are in a bag but I've never opened it yet! I figure if I open the bag to soon I'll start losing bits and pieces. I guess I need to see if I can fit the panels now and then remove them for later installation. This will certainly simplify things for me at this stage of the rebuild. Thanks all! Brad -

Passenger side kick panel - heater install B3B

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Well, that pretty much confirms what I was thinking. I guess I need to decide whether to install the brown interior panels with my black seat, paint the panels and then install or buy black panels. Oh well Thanks! Brad -

I used SealAll on a gas tank and it certainly did the job and it didn't leak as long as I had the vehicle.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Personally I like the drum parking brake on the transmission if for no other reason than the cool factor I really wasn't impressed with the e-brakes that were on the Cherokee axle. They looked really flimsy. Granted they are only meant to keep the vehicle from rolling but still.... -

Quick question. Can the cardboard kick panel still be installed in the passenger footwell if the heater is installed? I'm not quite ready to install the kick panels but would like to proceed with the heater installation. That's what got me too thinking about the kick panels. Last thing I want is to have to pull the heater just to install the kick panel! Thanks! Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Hi Bob, I thought about it for maybe 2 seconds and opted to stick with my freshly rebuilt transmission drum parking brake. I spent a lot of effort and time refurbishing and installing the original system. Plus, after looking at the drum brakes that were on the jeep axle I decided they were pretty much junk. To me they sorta looked like a cheap afterthought. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

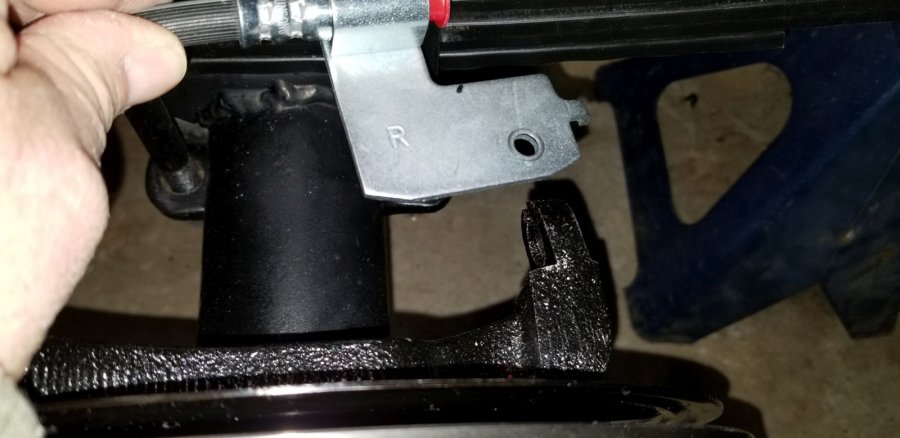

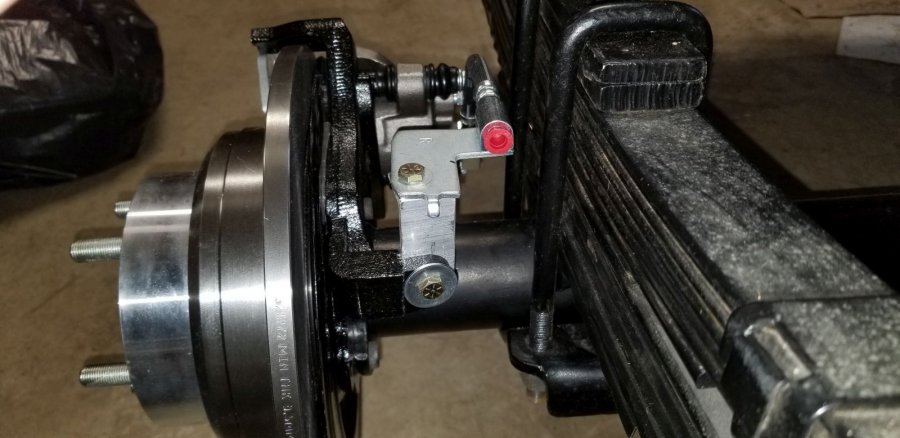

My return to work lasted two days and then we were all told to work from home. That old Chinese curse which says "May he live in interesting times" sure has new meaning in this day and age. I haven't had time to work on the king pins yet but I did take care of one small job last night. I needed to figure out something for the new rear brake hoses and how to fasten them so they didn't just flop in the breeze. The Cherokee axle has a casting flange on each side that is used for the parking brake cable. Since I'm using the original transmission drum brake these two flanges were now available for use as mounting points for the brake hoses. This was actually a pretty simple mod and didn't take all that much time and effort to complete. The right and left side hose mounting were mirror images of each other. I'll route the brake tubing down below the leaf spring and along side the axle housing over to the brake hose Tee. Brad

.jpg.9cd3efa1e55fc82d997f0f37bfdf7fa9.jpg)